Low bed pressure-reducing circulated fluid bed boiler combustion process

A technology of circulating fluidized bed and process method, which is applied in the field of circulating fluidized bed boiler combustion technology and equipment, which can solve the problems of high power consumption, wear and combustion efficiency of the water wall in the combustion chamber, etc., achieve enhanced combustion and reduce power consumption of auxiliary machines , the effect of improving combustion efficiency

Active Publication Date: 2008-03-26

北京杰创华睿科技有限公司

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

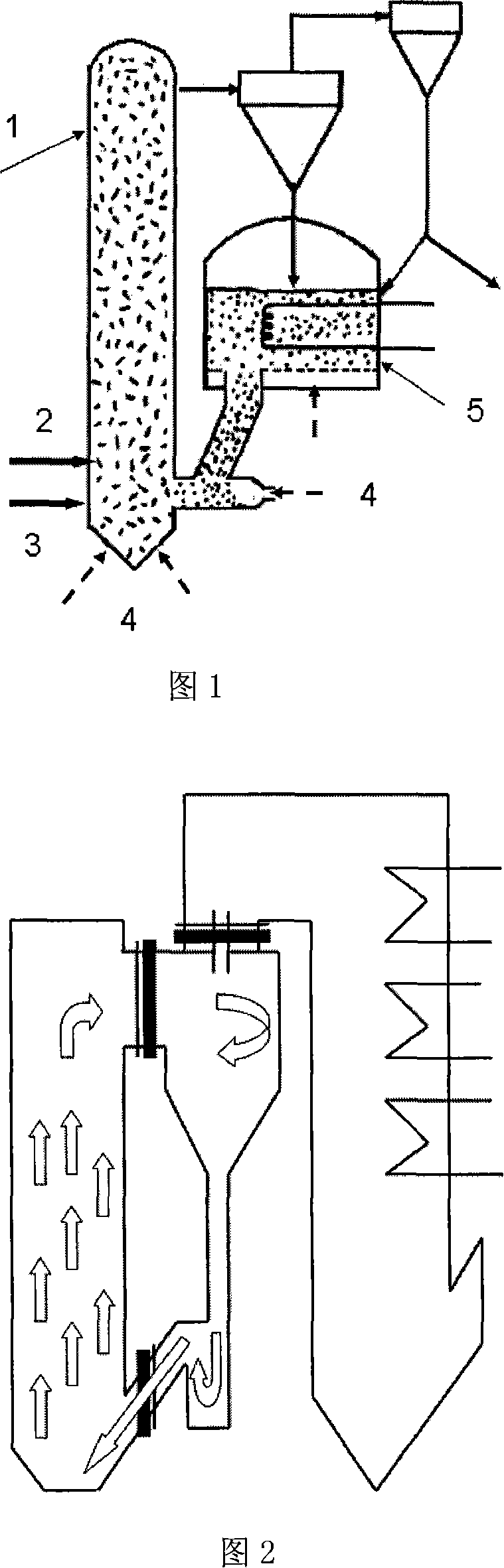

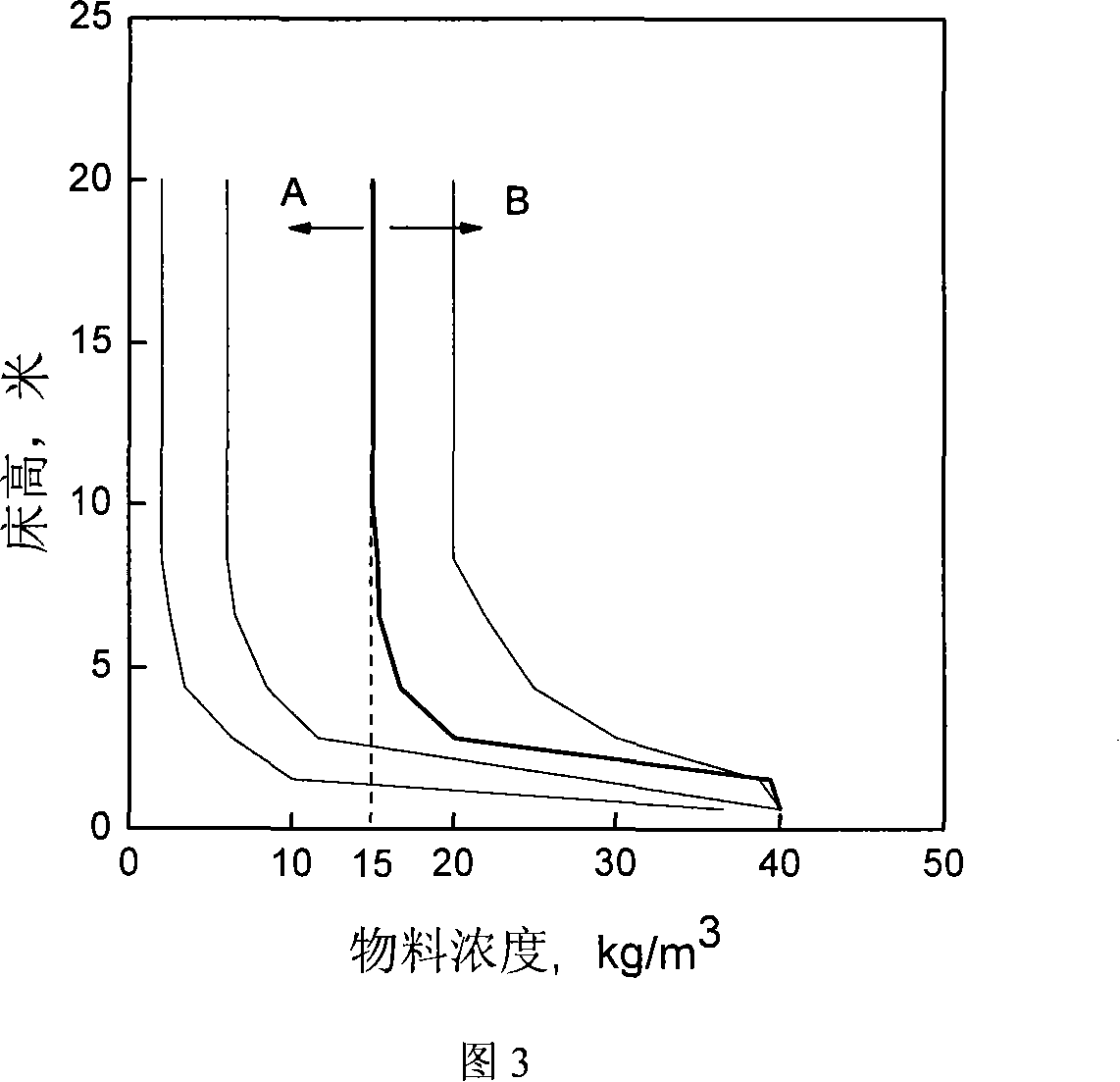

[0012] Aiming at the deficiencies and defects of the prior art, the purpose of the present invention is to provide a low-bed pressure-drop circulating fluidized bed boiler combustion process method, which is under the precondition of maintaining a fast bed state in the circulating fluidized bed combustion chamber , by reducing the material stock per unit area to reduce the material space concentration in the upper part of the combustion chamber, so as to solve the problems of high power consumption caused by high fan pressure head, serious wear of the water wall in the combustion chamber and low combustion efficiency in the existing circulating fluidized bed boiler shortcoming

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0035] For example, the combustion chamber height of a circulating fluidized bed boiler burning anthracite is 30m. 3 . The combustion temperature is controlled between 850-930 degrees according to the fuel burnout and desulfurization effects, the fuel particle size is selected to be 0-8mm, and the bed pressure drop can be obtained between 3.6kPa and 7.1kPa according to the calculation formula provided by the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

This invention is a low bed pressure drop circulating fluidized bed boiler combustion technical method, which relates to rapid circulating fluidized bed boiler combustion technique. It makes sure the circulating fluidized bed rapid bed fluid state. The inner bed temperature is controlled within 850-930 degree. The fluidizing wind speed is 4-6.2m / s. The average particle size of circulating materials is smaller than 300mum. The material concentration of the space above combustion chamber second air port is kept 1-15Kg / m3 rapid bed state. This invention can greatly reduce the pressure head of first and second wind machines. Thus, it effectively reduces the power dissipation of assisting engines. In addition, as the space material concentration decreased, gas mixture improved, combustion intensified, the combustion efficiency of boiler is further increased. This invention can also reduce the attrition rate of combustion chamber water-cooled wall heating surface.

Description

technical field [0001] The invention relates to a circulating fluidized bed boiler combustion technology and equipment, in particular to a low bed pressure drop circulating fluidized bed boiler combustion process method. Background technique [0002] Circulating fluidized bed boiler is a device that uses the principle of fluidization to achieve high-intensity combustion, and controls the combustion temperature in the optimum desulfurization temperature zone of limestone. At the same time, due to the small amount of NO generated by coal combustion in this temperature zone, bottom pollution emissions can be realized. The gas-solid two-phase flow in the upper part of the combustion chamber of most circulating fluidized bed boilers belongs to the fast bed flow state. Fast bed refers to a kind of particle generation formed when the material concentration (referring to the weight of solid particles contained in the unit volume space in the combustion chamber) of a certain particle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23C10/00

CPCF23C10/002F23C10/10

Inventor 杨海瑞岳光溪吕俊复张海刘青张建胜

Owner 北京杰创华睿科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com