Multi-system shared cooling tower for electric locomotive

An electric locomotive, multi-system technology, applied in the direction of locomotive, transformer/inductor cooling, cooling/ventilation/heating renovation, etc. The effect of improving operation economy, reducing cleaning and maintenance, and reducing maintenance and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

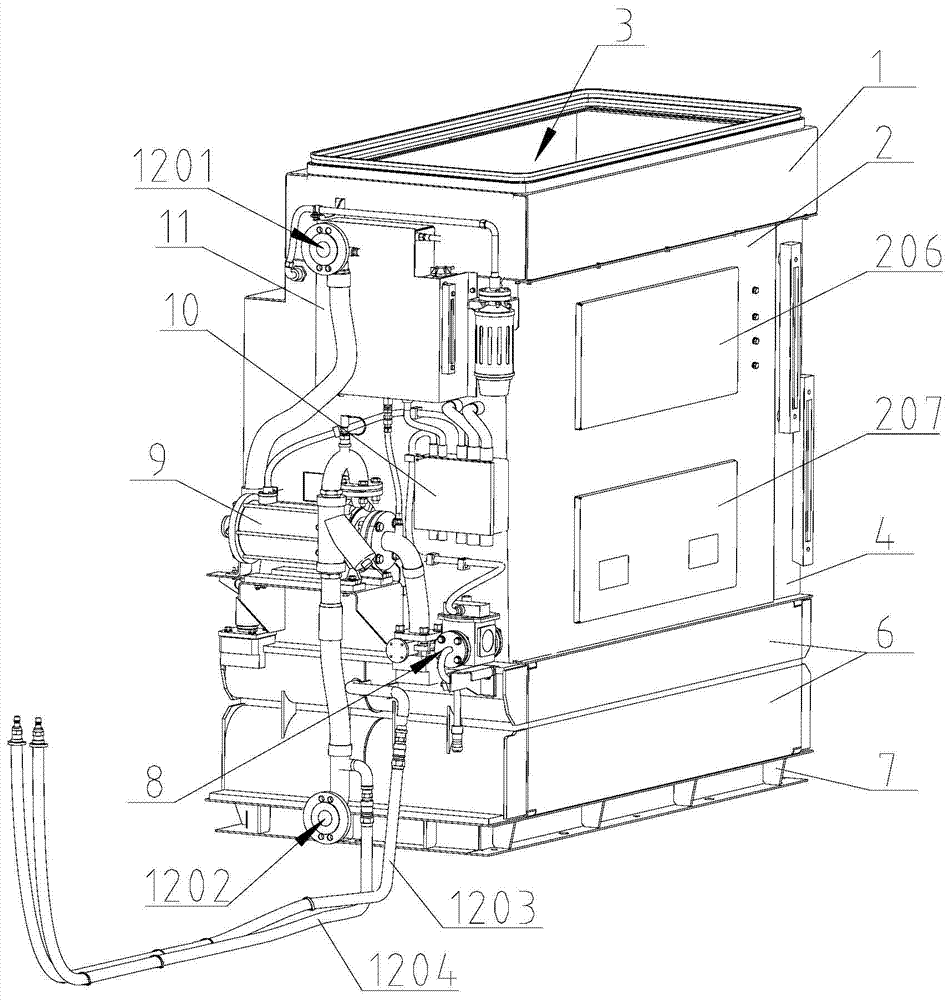

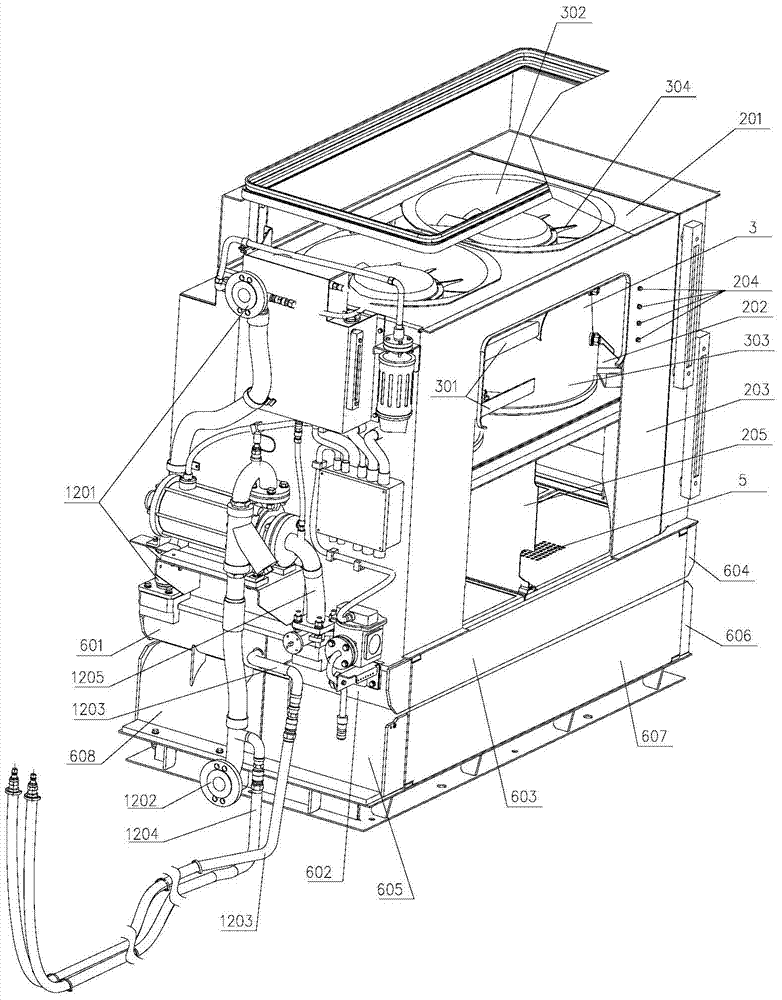

[0038] Such as figure 1 , figure 2 As shown, a cooling tower shared by multiple systems of an electric locomotive includes three cooling systems including a traction transformer cooling system, a traction converter cooling system, and a train power supply cabinet cooling system, specifically including a top air intake box 1, a middle box body 2, Double-row axial flow fan 3, air filter device 5, three-channel double-flow radiator 6, bottom bearing frame 7, water pump 9, expansion water tank 11, auxiliary oil tank 4, water pipeline (traction converter outlet pipe 1201, traction converter Water inlet pipe 1202, train power supply cabinet outlet pipe 1203, train power supply cabinet water inlet pipe 1204, water pump water inlet pipe 1205), oil pipeline, electrical connector 10, gas relay 8 and other components.

[0039] The top air intake box 1, the middle box body 2, the double-row axial flow fan 3, the air filter device 5, the three-channel double-flow radiator 6, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com