Patents

Literature

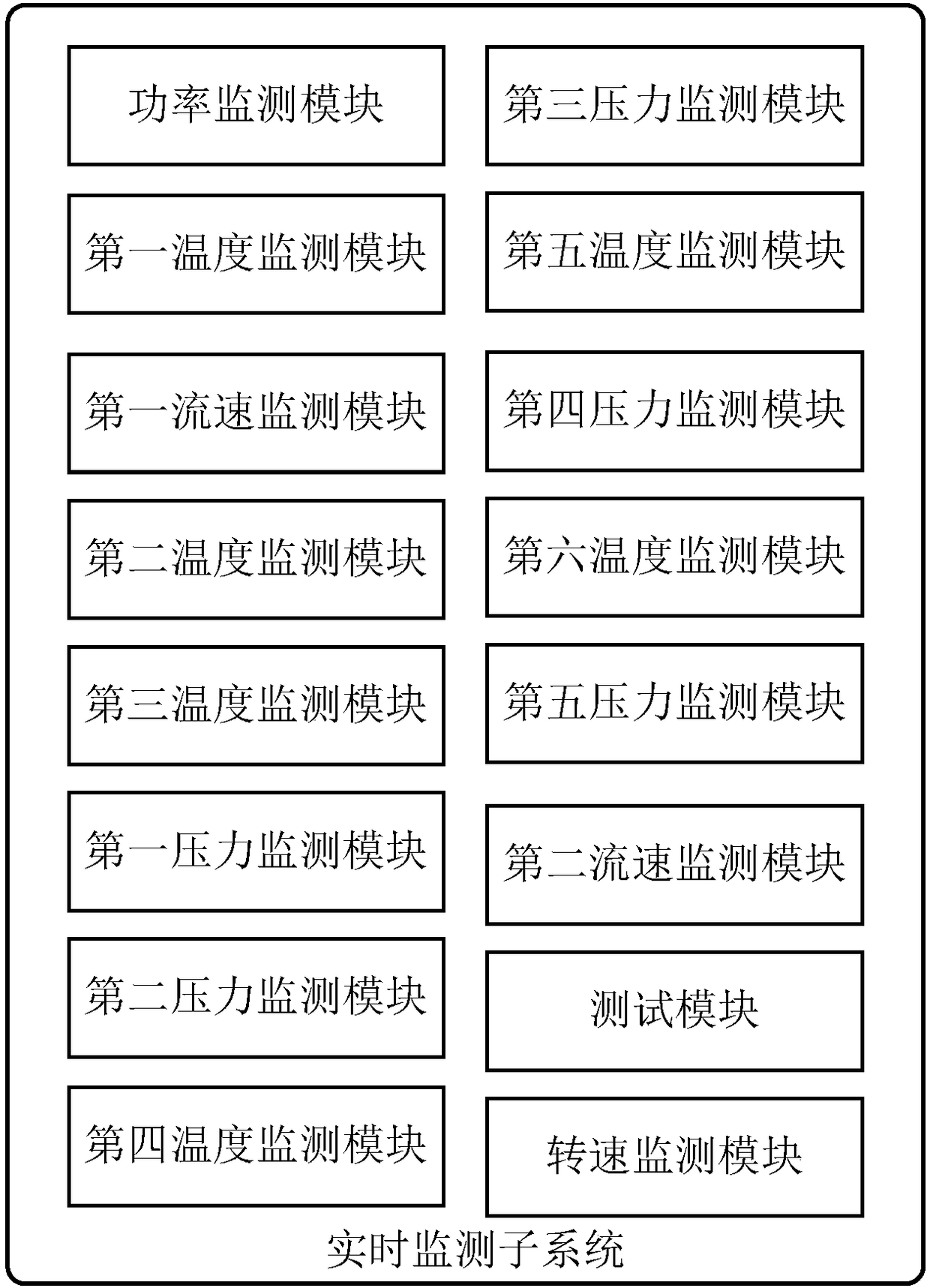

34results about How to "Reduce auxiliary power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

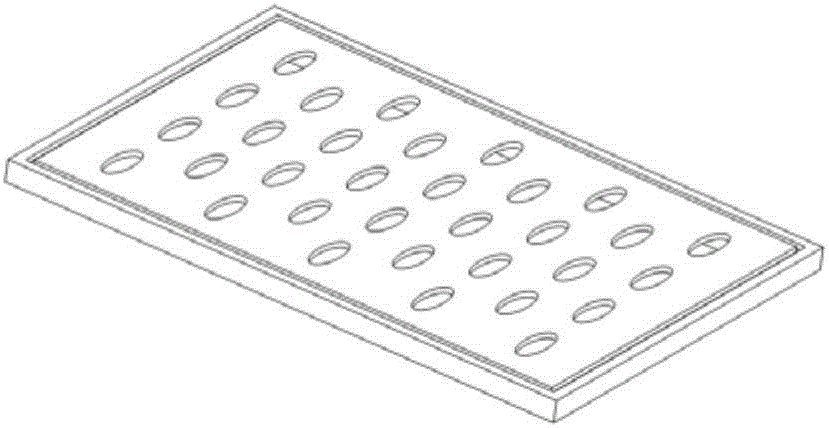

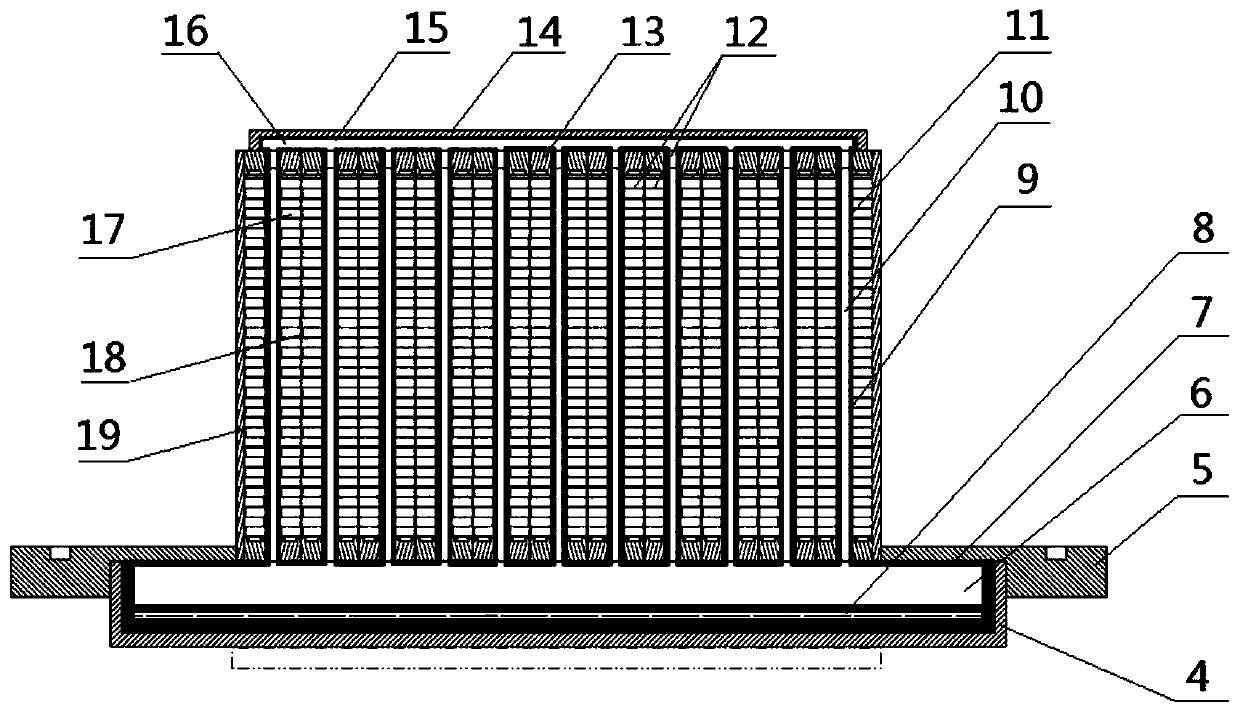

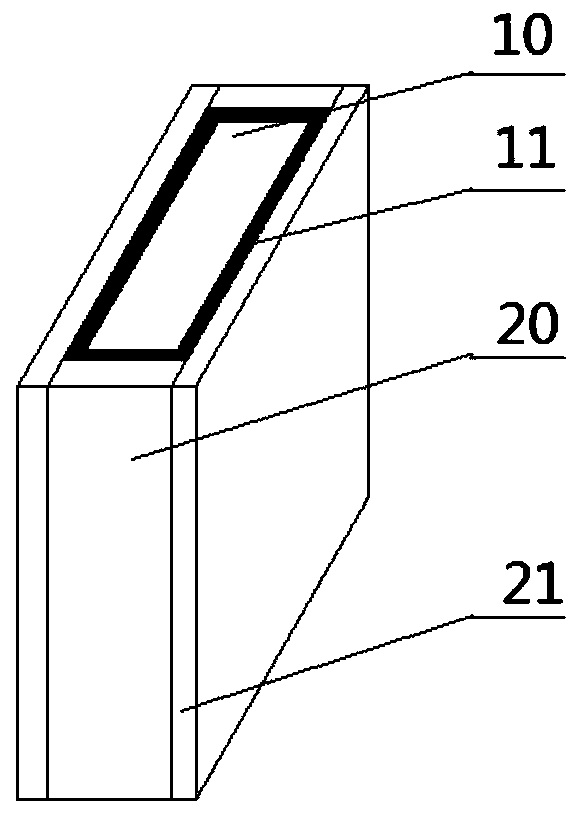

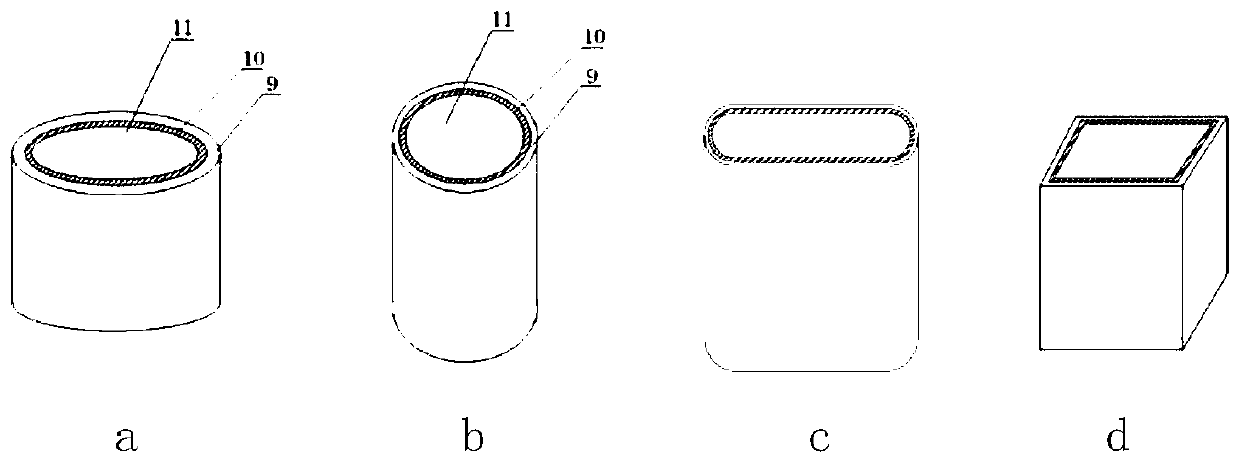

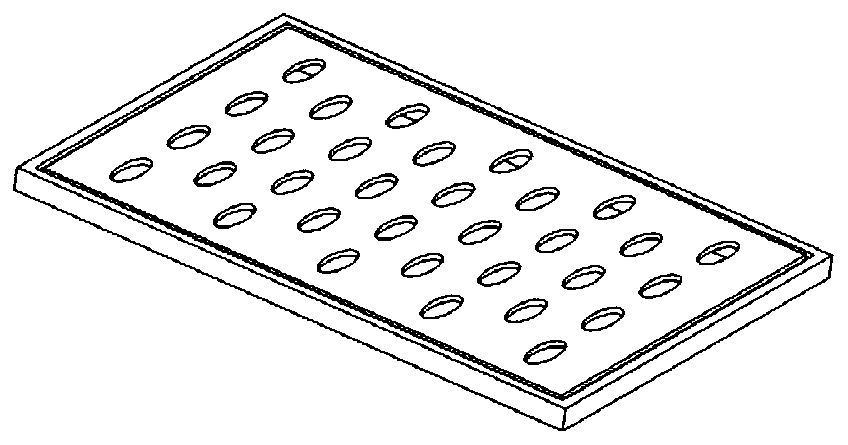

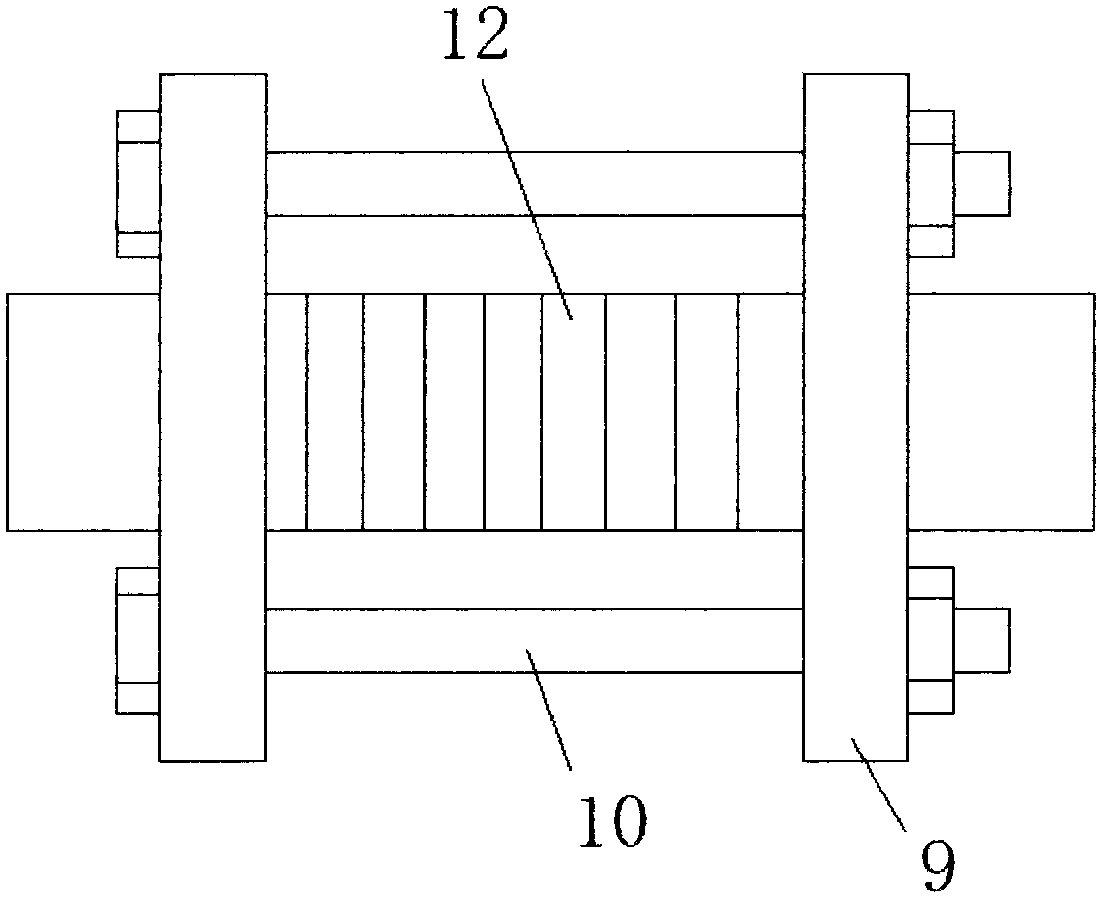

Plate fin type micro-circulation radiator and micro-circulation heat exchange system

ActiveCN106304805ACompact and efficient heat exchange systemEasy to installModifications by conduction heat transferHeat transfer efficiencyEngineering

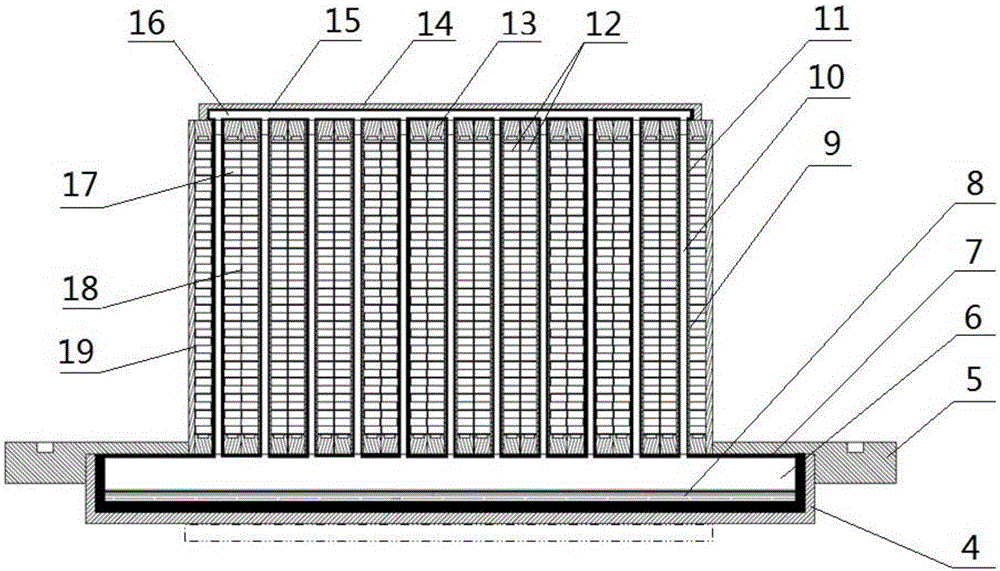

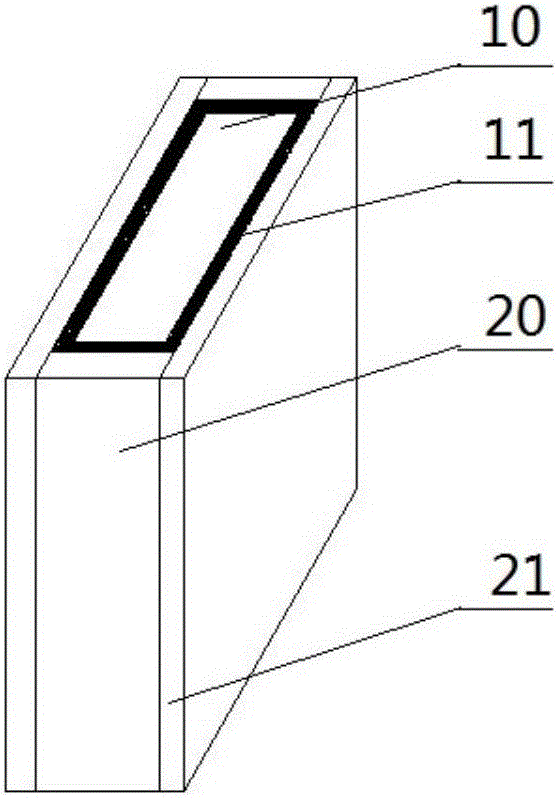

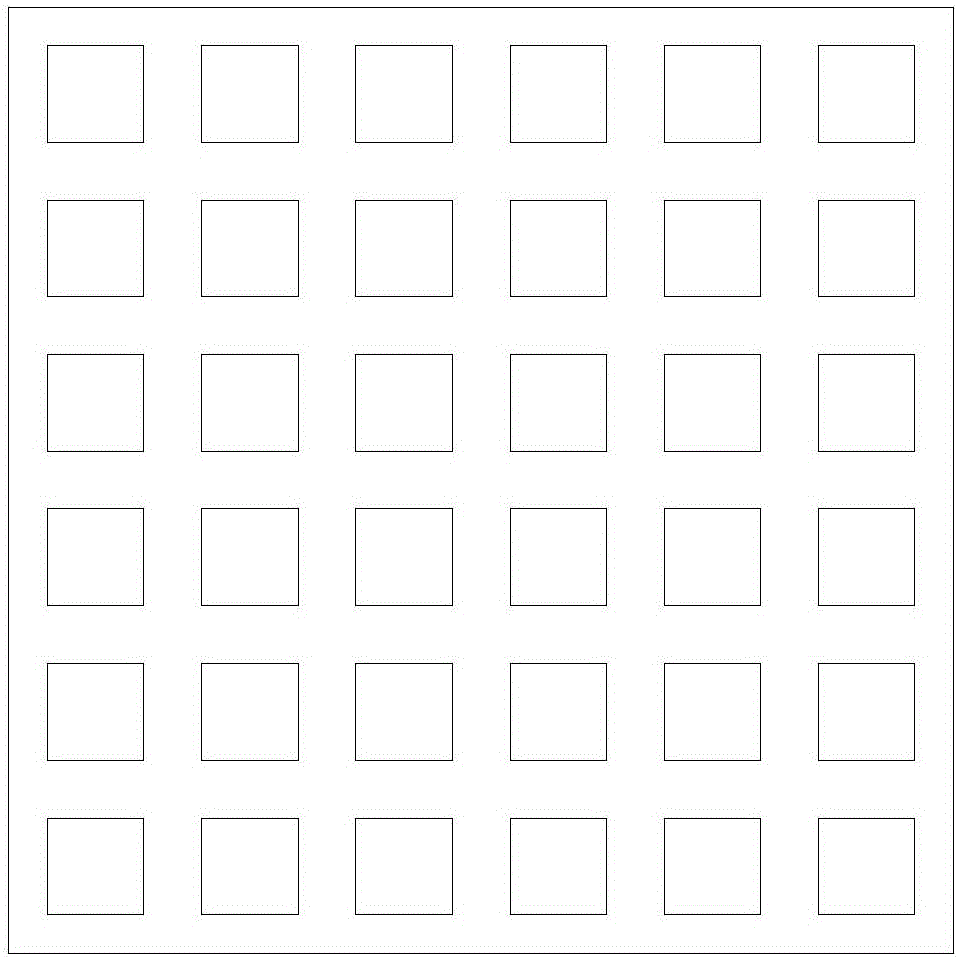

The invention discloses a plate fin type micro-circulation radiator and a micro-circulation heat exchange system. The plate fin type micro-circulation radiator comprises a heat source module mounting plate, a radiator mounting plate and a heat dissipation assembly, wherein the heat source module mounting plate and the radiator mounting plate are fixed to each other, main working medium chambers used for containing mediums are formed in the heat source module mounting plate and the radiator mounting plate, the heat dissipation assembly is mounted on the radiator mounting plate and comprises a micro-circulation heat dissipation module and a cooling air passage which are arranged at an interval, the interior of the micro-circulation heat dissipation module is a sub-working medium chamber, and the inner walls of both the main working medium chambers and the sub-working medium chamber are provided with imbibition micro-passages of a capillary structure. The plate fin type micro-circulation radiator and the micro-circulation heat exchange system are compact in structure, high in heat transfer efficiency, relatively low in noise, low in assisting power consumption, high in reliability, capable of well solving the main bottleneck problem, namely the heat dissipation problem of industrial development of electronic components, and broad in market prospect.

Owner:CRRC DALIAN INST CO LTD

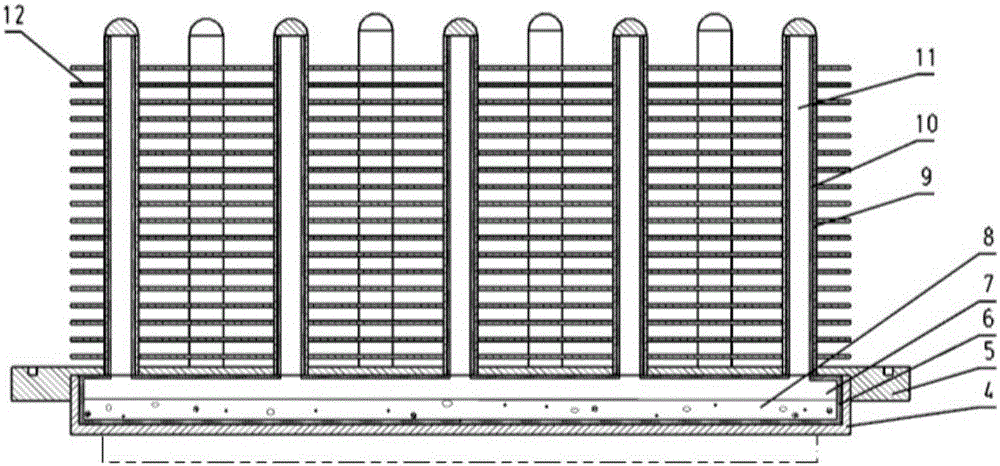

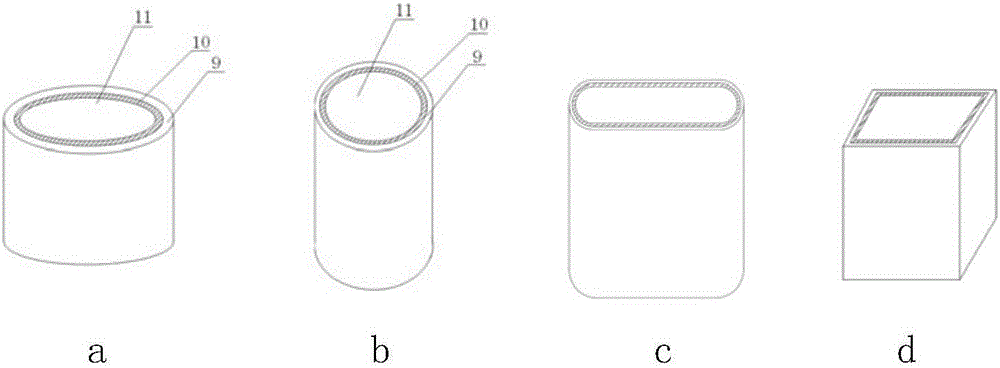

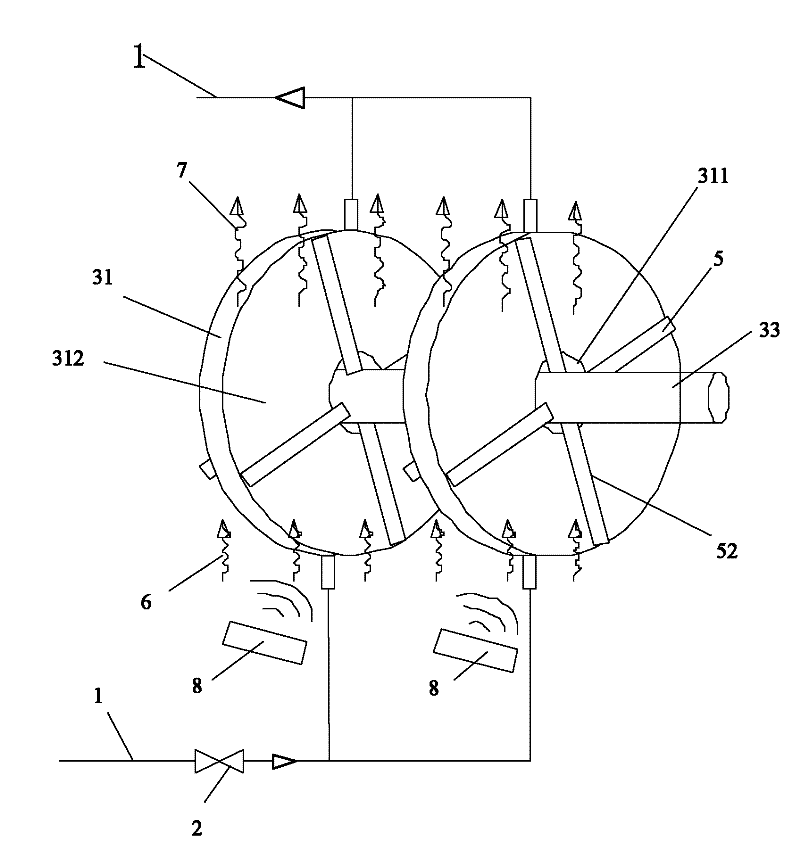

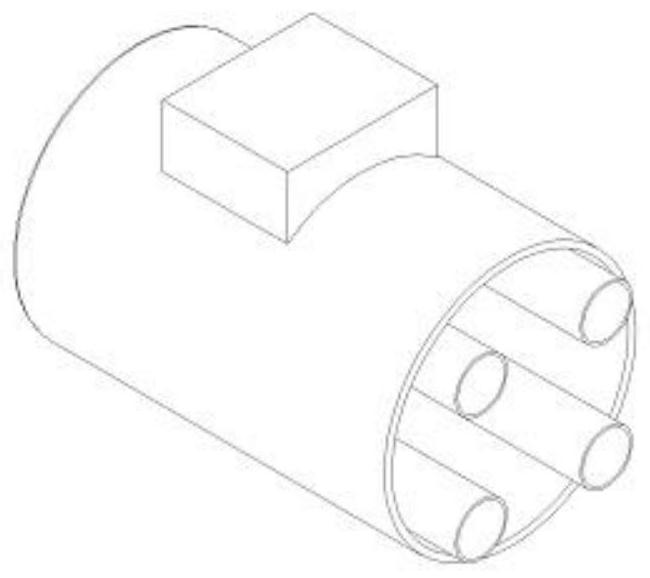

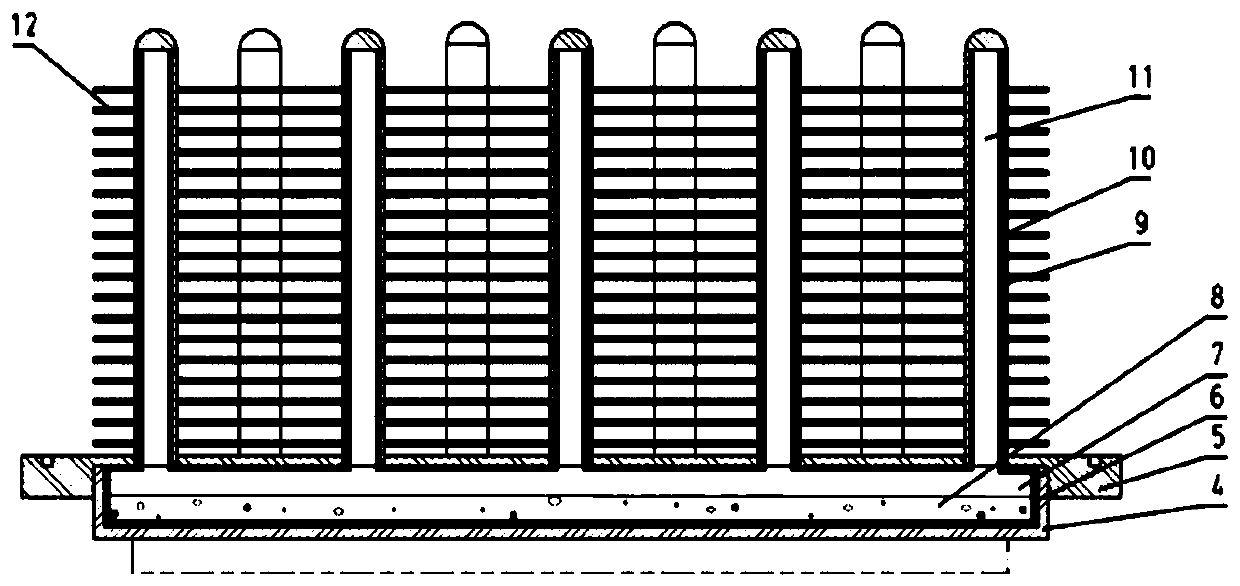

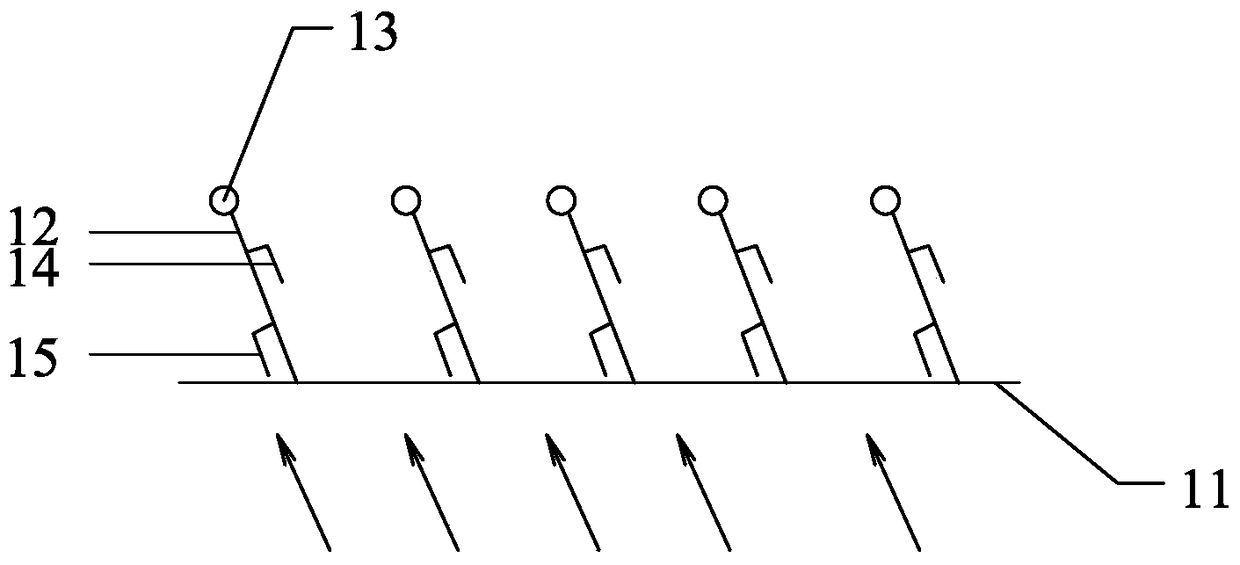

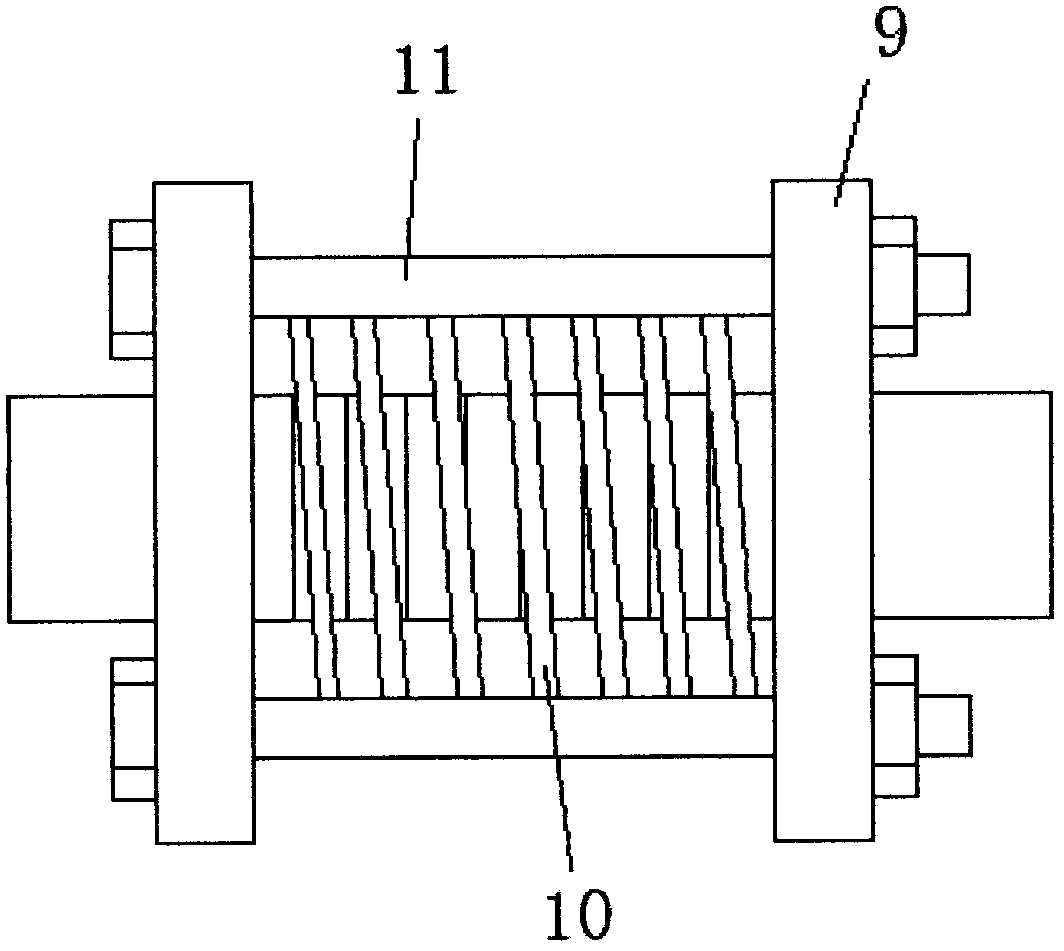

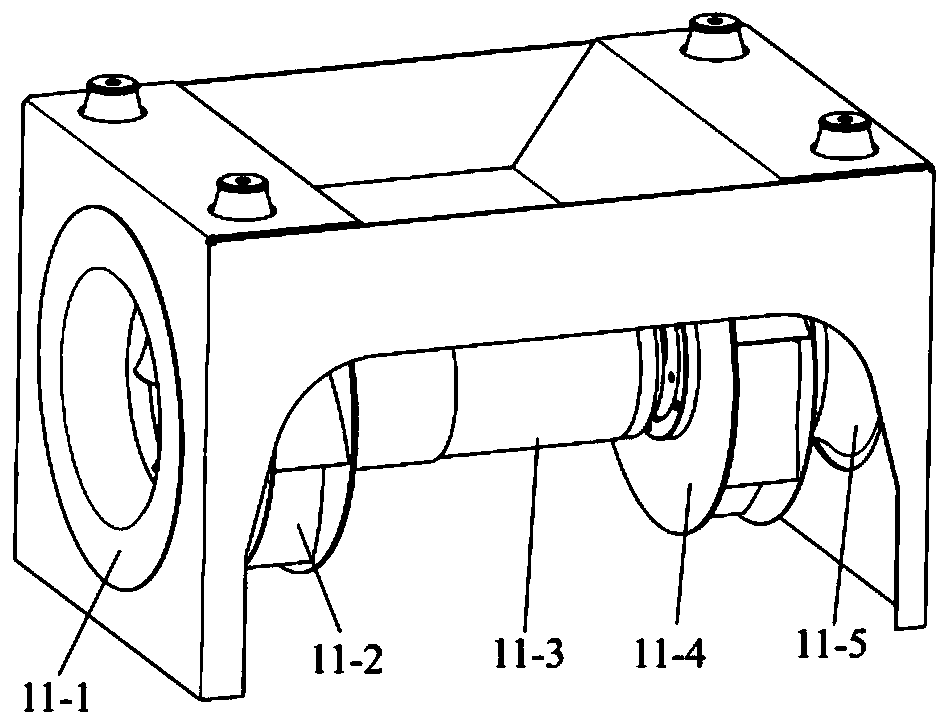

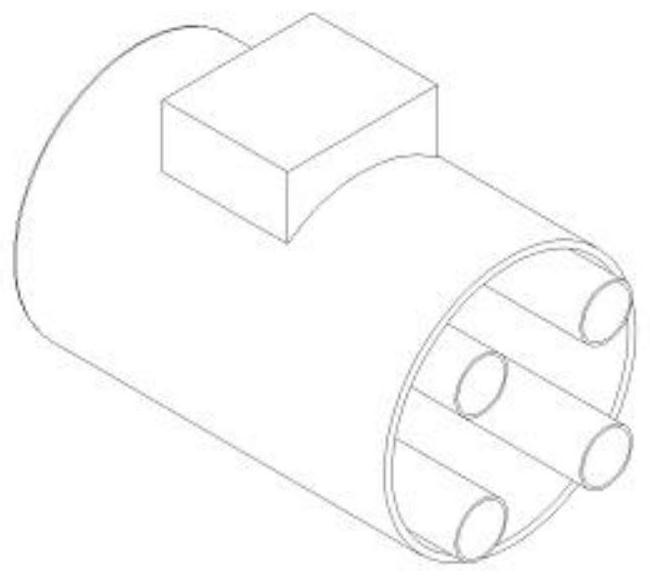

Segment-type microcirculation radiator and microcirculation heat exchange system

ActiveCN106255396AFast heat conductionEasy to installCooling/ventilation/heating modificationsCapillary channelHeat transfer efficiency

The invention discloses a segment-type microcirculation radiator and a microcirculation heat exchange system. The segment-type microcirculation radiator comprises a heat source module installation plate, a radiator installation plate and a heat dissipation assembly, wherein the heat source module installation plate and the radiator installation plate are fixed to each other and a main working medium cavity for accommodating a working medium is formed in the heat source module installation plate and the radiator installation plate; the heat dissipation assembly comprises a plurality of radiating fins which are stacked at certain distances, and microcirculation heat dissipation modules; the microcirculation heat dissipation modules are arranged in the corresponding radiating fins in a penetrating manner; each microcirculation heat dissipation module is of a tubular structure of which one end is opened and the other end is closed and a branch working medium cavity is formed in each microcirculation heat dissipation module; each branch working medium cavity communicates with the main working medium cavity; and liquid-absorbing micro-channels with capillary structures are arranged in the inner walls of the main working medium cavity and the branch working medium cavities and capillary channels of the liquid-absorbing micro-channels communicate with each other. The segment-type microcirculation radiator and the microcirculation heat exchange system are compact in structure, high in heat transfer efficiency, lower in noise, lower in auxiliary power consumption, high in reliability and wide in market prospect, and the problem of a main bottleneck in electron component industry development is well solved.

Owner:CRRC DALIAN INST CO LTD

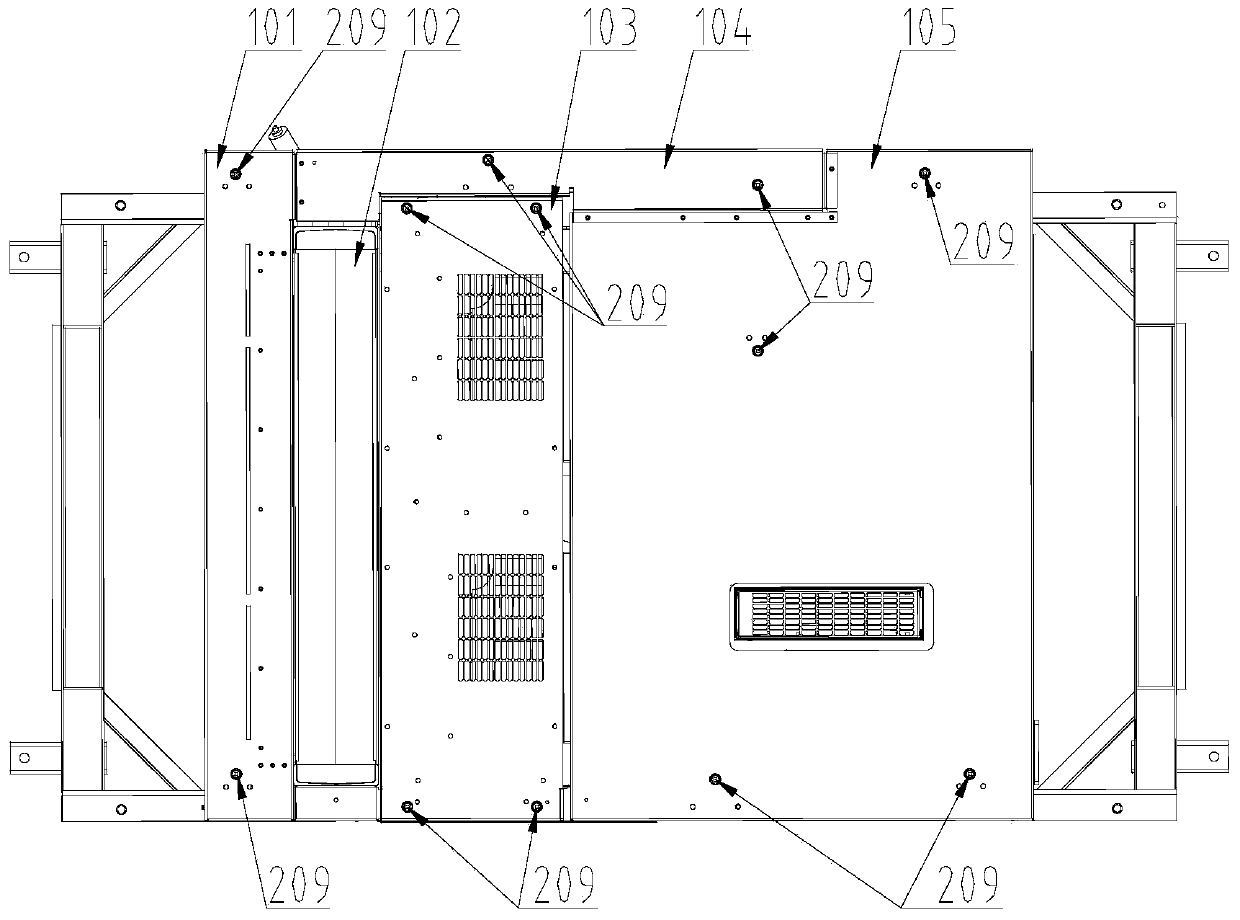

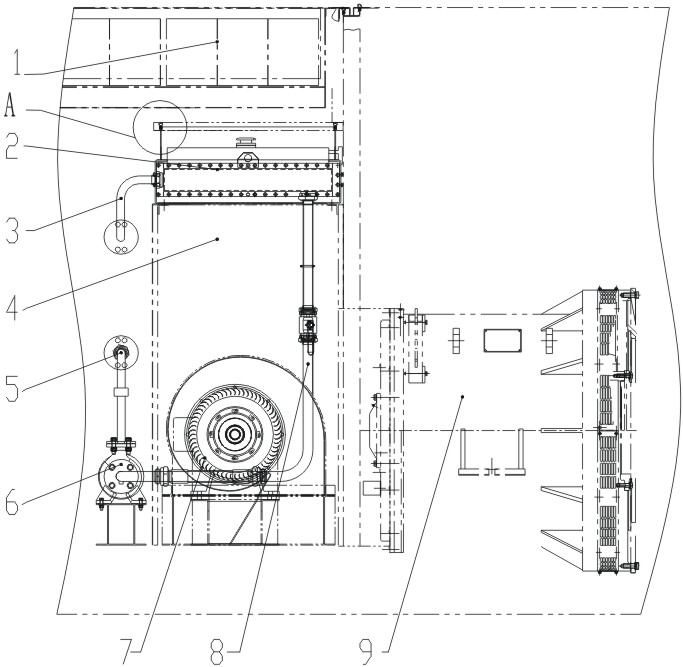

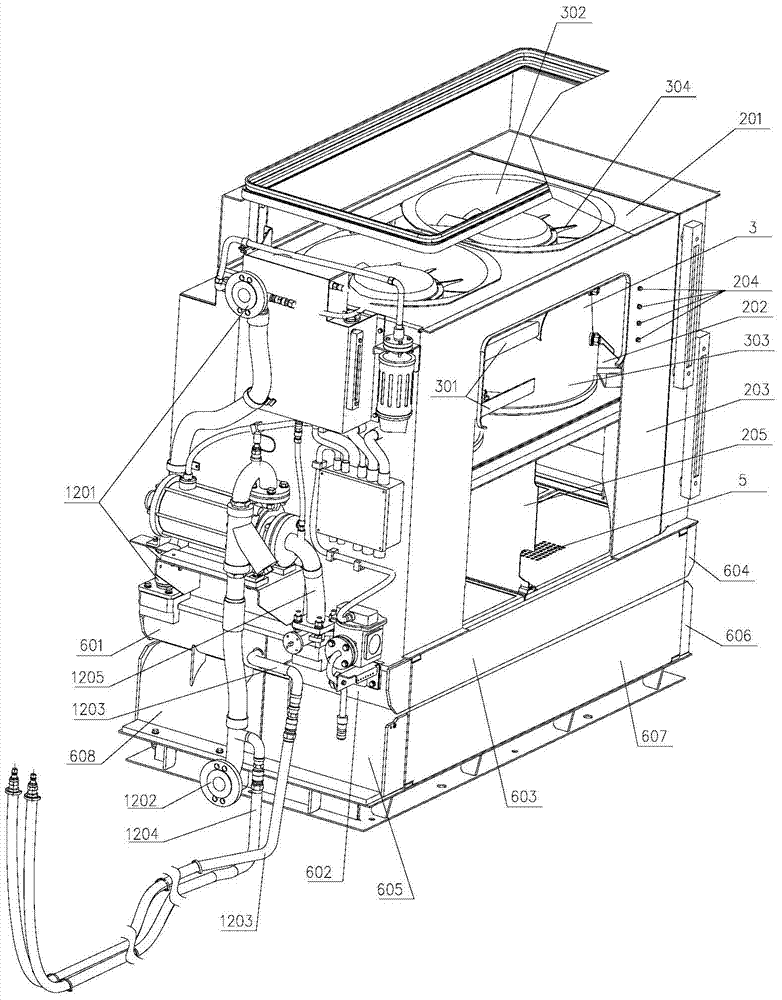

Cooling unit for traction converter

ActiveCN104201901AQuick changeLow maintenanceAc-ac conversionCooling/ventilation/heating modificationsFiltrationAir filter

The invention discloses a cooling unit for a traction converter. According to the cooling unit, by carrying out the simulated analysis on the flow behavior of cooling air and the flow behavior of water, the resistance property of an air filter, a radiator, a blower case body and other components is determined; by the adoption of the matching technology, a blower of a cooling air system is guaranteed to work in a high-efficiency working area, and a cooling water system is guaranteed to work in a water pump high-efficiency working area, so that the optimized matching among heat exchange capability, auxiliary power consumption and noise is realized. On the given working condition, the heat exchange requirement of the cooling systems is satisfied; the dust filtration and water filtration efficiency of a filter is improved, and air resistance is lowered simultaneously, so that auxiliary power consumption is reduced; the adopted security measures can prevent a baseplate of the cooling unit from dropping off so as to improve both reliability and security; the cooling unit is suitable for a motor train unit at the speed of 300-350 kilometers per hour, and can further be suitable for the motor train unit in other speed grades by variant design.

Owner:CRRC DALIAN INST CO LTD

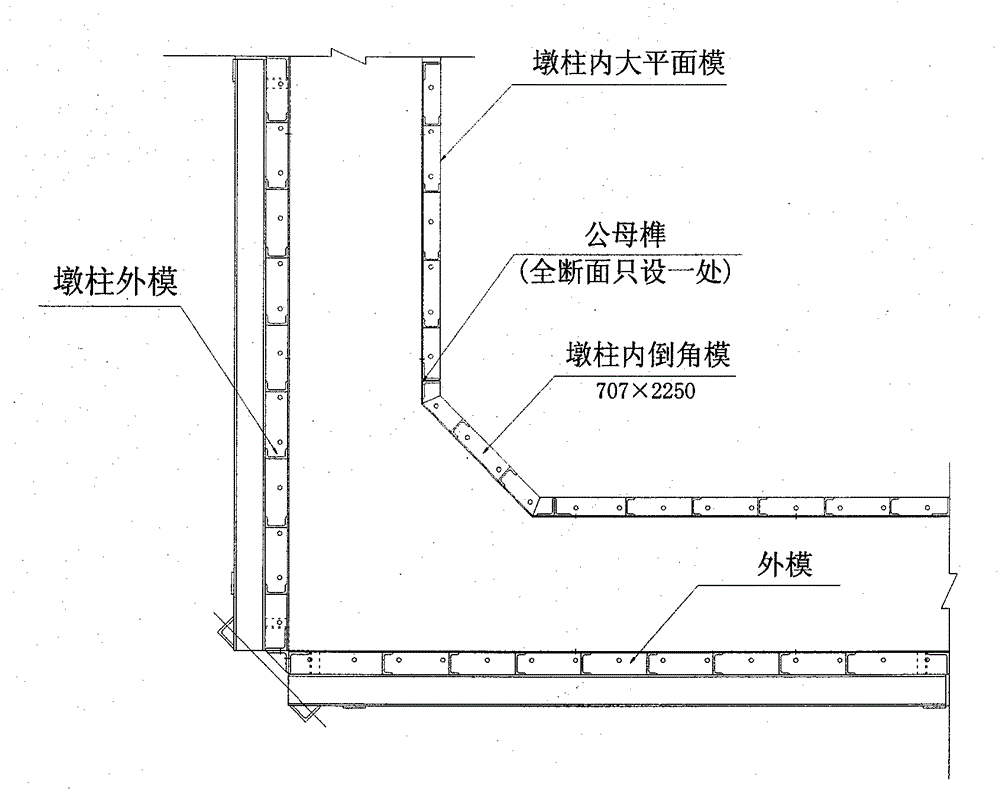

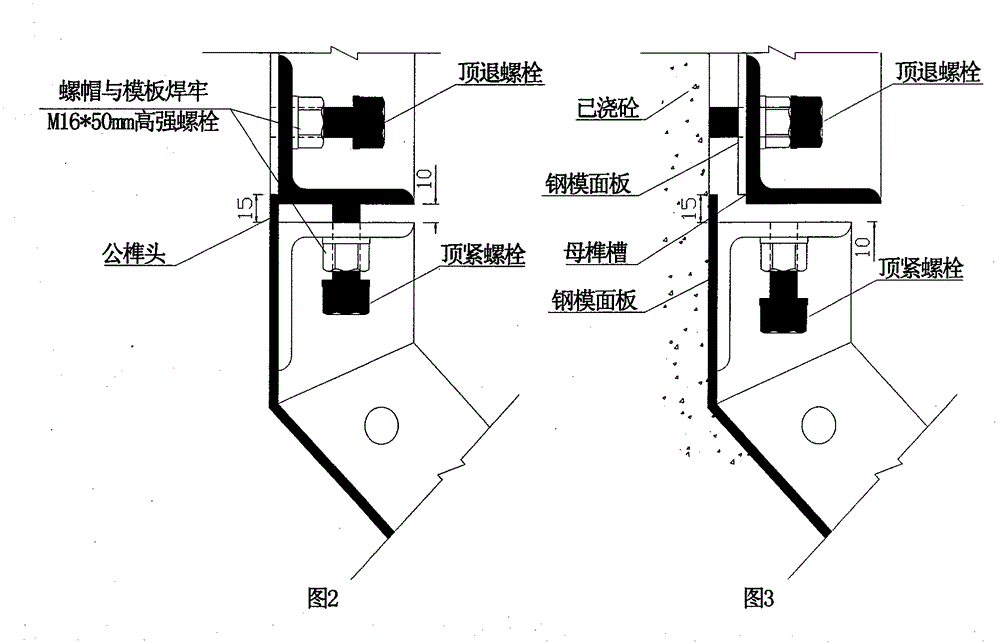

Hollow thin-walled pier internal mold bolt ejection removal technology

InactiveCN104695332AReduce use costHigh quality and precisionBridge erection/assemblyTemplate designSlurry

The invention discloses a hollow thin-walled pier internal mold bolt ejection removal technology, and relates to an internal mold. The hollow thin-walled pier internal mold bolt ejection removal technology comprises template design and a construction method; in the template design, designing a mortise and a tenon, ejection bolts and puller bolts is included, the mortise and the tenon are arranged on two templates at one chamfer of the internal mold, the mortise is arranged on a chamfer template, the tenon is arranged on a big plane mold, the ejection bolts are arranged on the vertical frame of the mortise template, and the puller bolts are arranged between vertical joint connecting bolts on the vertical frame of the tenon template; during the installation, the template surface is screwed by the ejection bolts, and the puller bolts and the vertical joint connecting bolts are screwed down; during mold removal, the connecting bolts of the tenon template are removed, the puller bolts are screwed up, and the ejection bolts are screwed down from bottom to top. The technology solves the problems that a hollow thin-walled pier internal mold is difficult to install and detach, slurry is easy to leak, materials are wasted, the template is easy to deform, the concrete is easy to knock and pry and the like, and is suitable for internal mold design and construction of engineering.

Owner:重庆巨能建设集团路桥工程有限公司

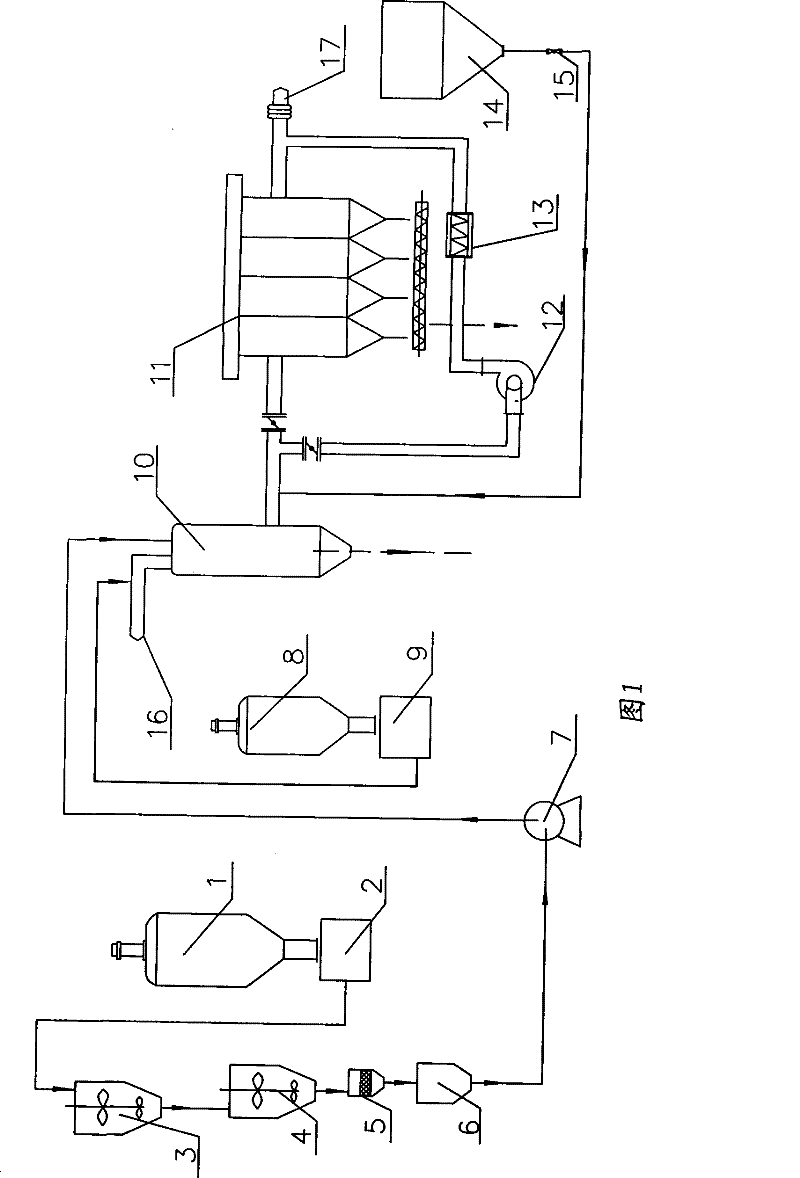

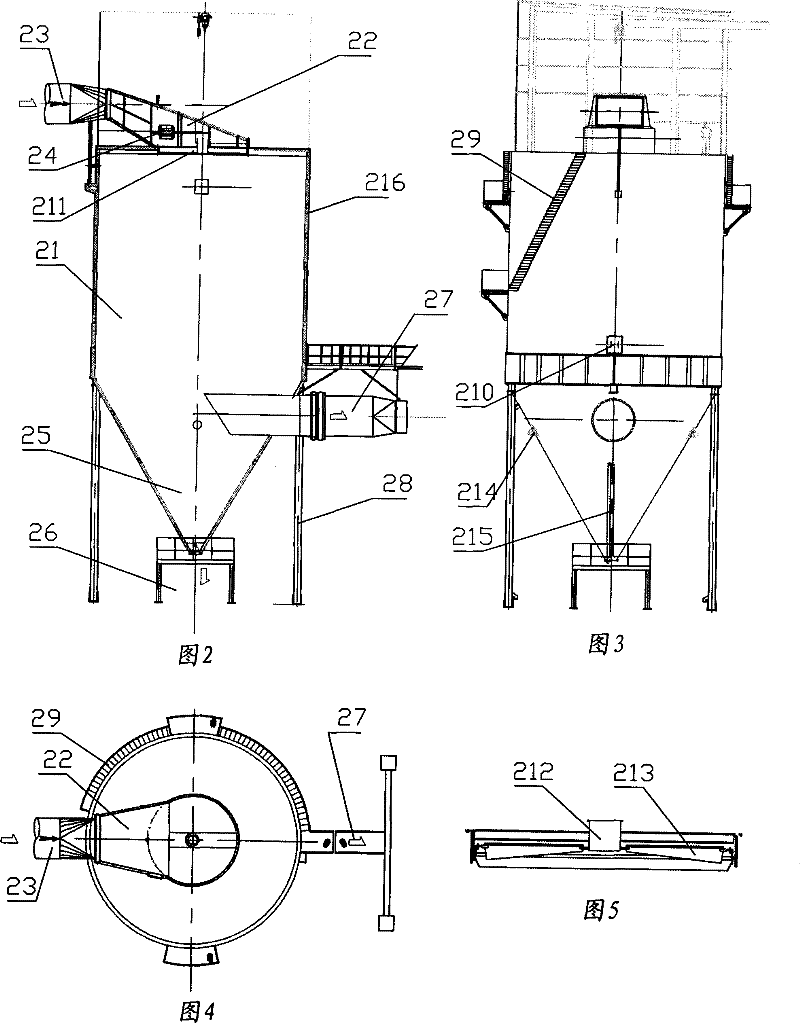

Semi-dry method refuse burning fume cleaning treatment method and system thereof

ActiveCN101310835BEvenly distributedImprove absorption efficiencyDispersed particle separationChemical reactionWater discharge

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

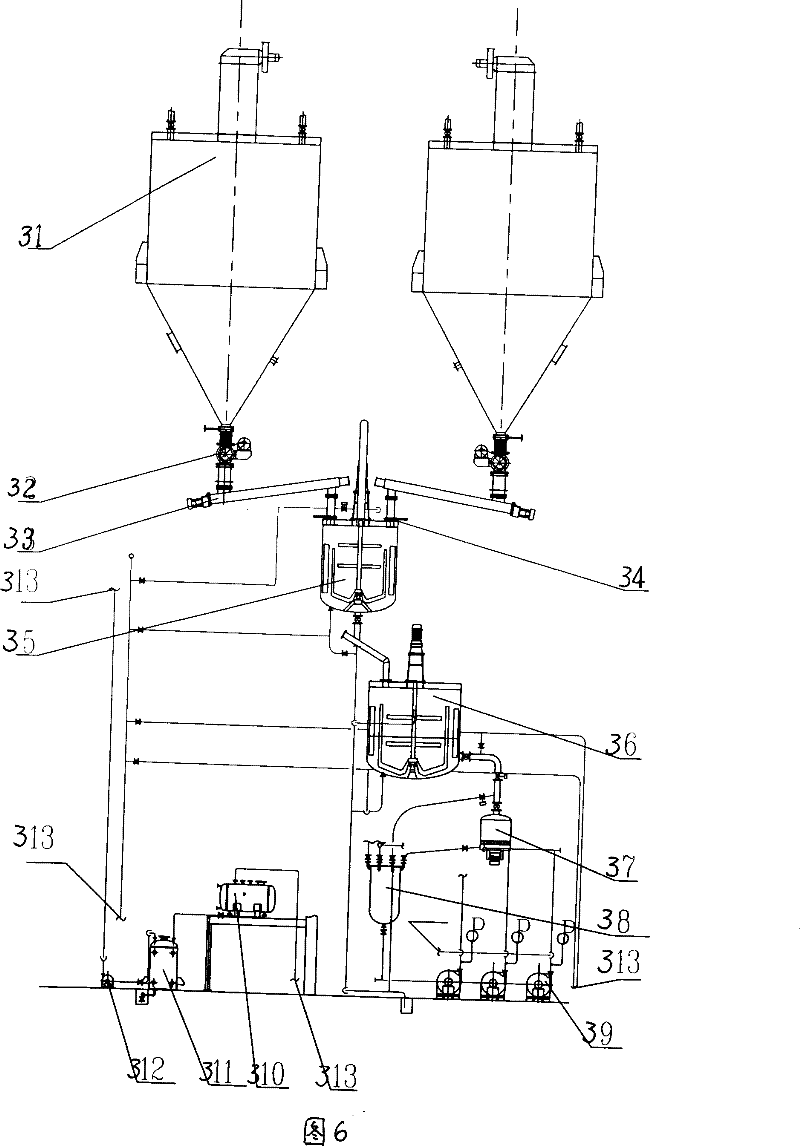

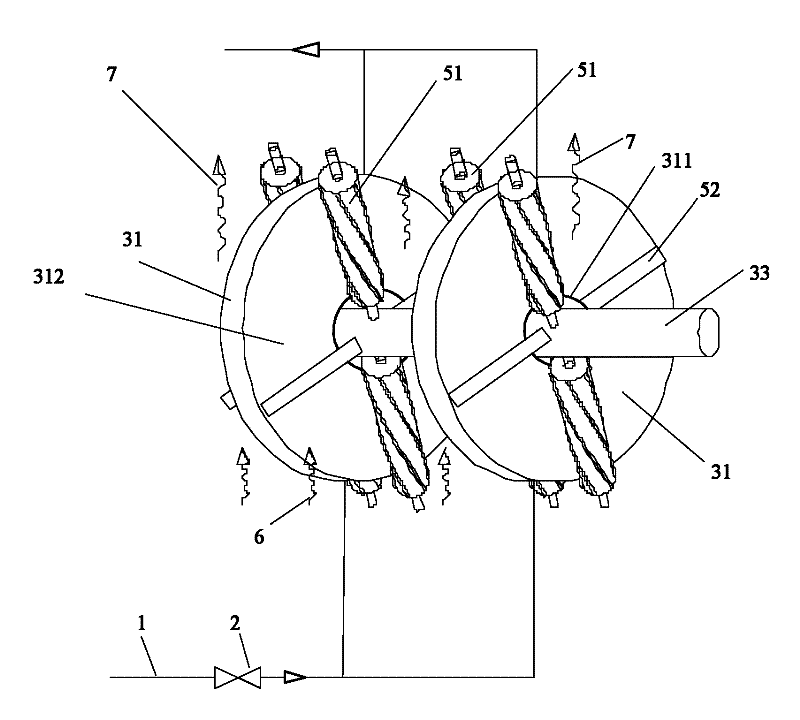

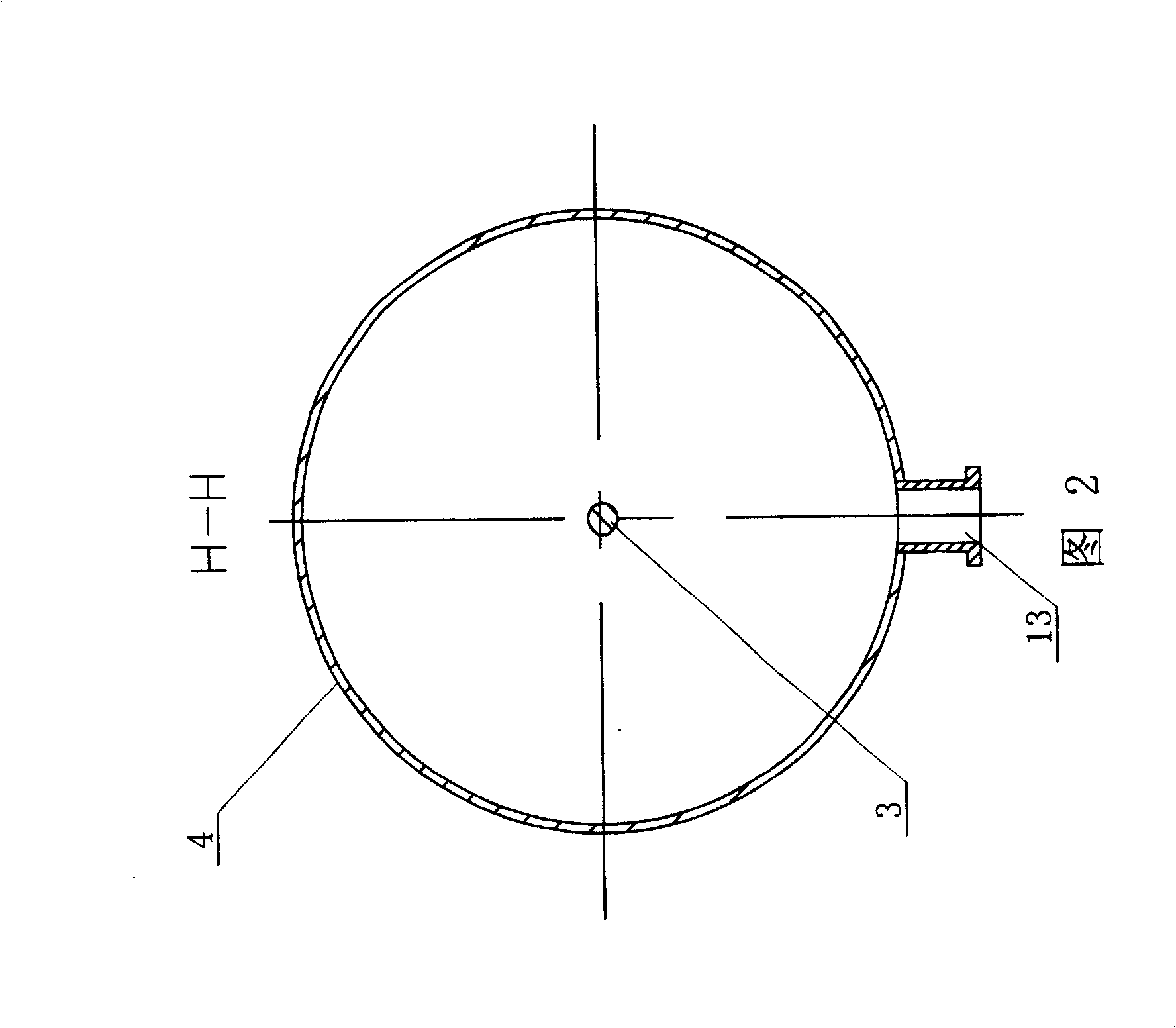

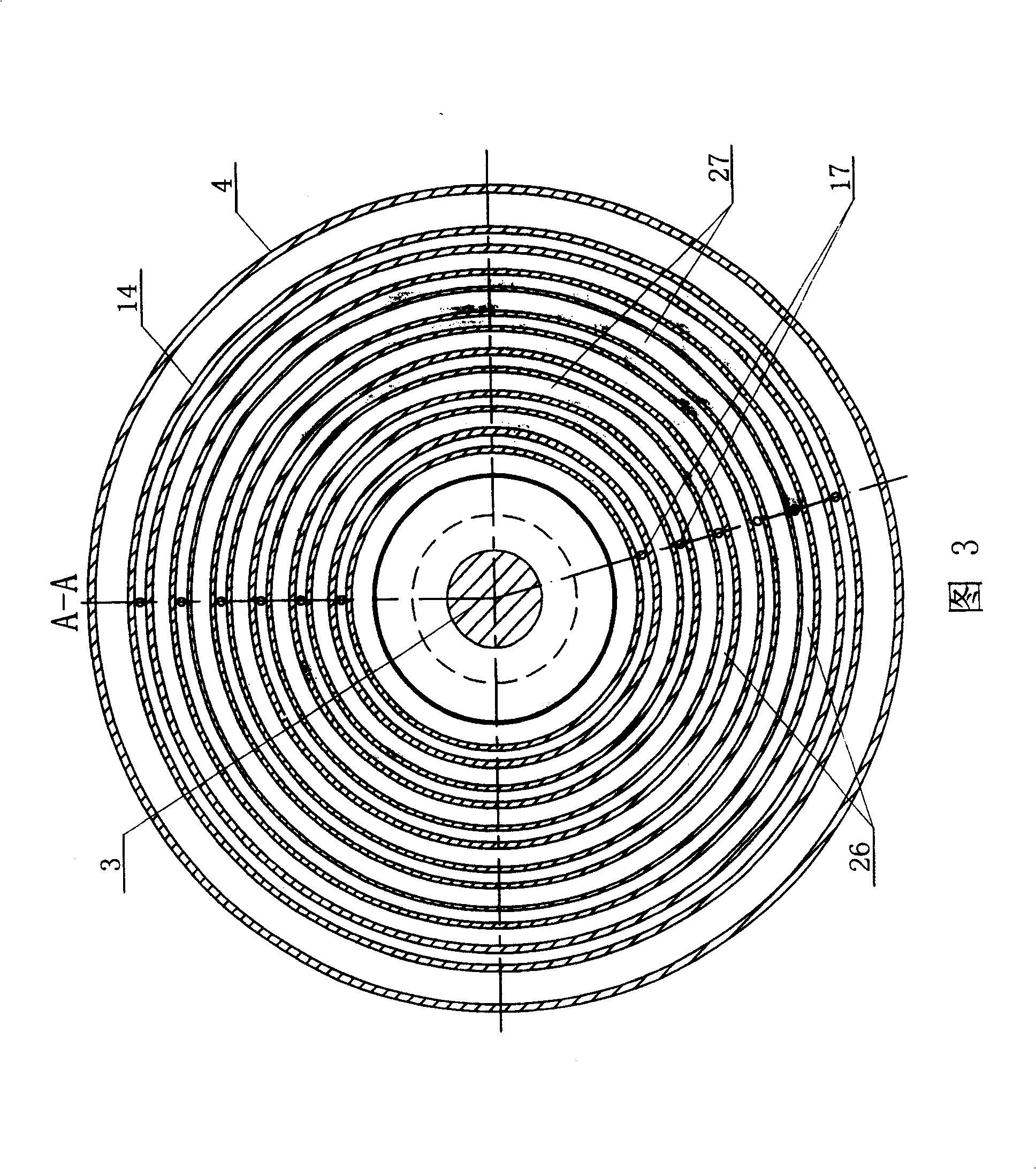

Method and device for preparing fluidized ice slurry with disc type double-sided scraped-surface heat exchanger

InactiveCN102410683AReduce Auxiliary Power ConsumptionImprove liquidityLighting and heating apparatusIce productionEngineeringSlurry

The invention discloses a method and device for preparing fluidized ice slurry with a disc type double-sided scraped-surface heat exchanger. The device comprises a disc type double-sided scraped-surface heat exchanger, an ice crystal ager and a delivery pump, wherein the ice crystal ager is located above the scraped-surface heat exchanger; an inlet of the ice crystal ager is communicated with the scraped-surface heat exchanger; a discharge hole of the ice crystal ager is connected with the delivery pump; the scraped-surface heat exchanger comprises a refrigeration disc, a scraper and a rotary shaft; a through hole is formed in the middle of the refrigeration disc; the rotary shaft vertically passes through the through hole; the refrigeration disc comprises two refrigeration surfaces; and the scraper is close to the refrigeration surfaces and is fixed on the rotary shaft. The device disclosed by the invention has the advantages of simple structure, good heat transfer effect and low energy consumption.

Owner:秦贯丰 +1

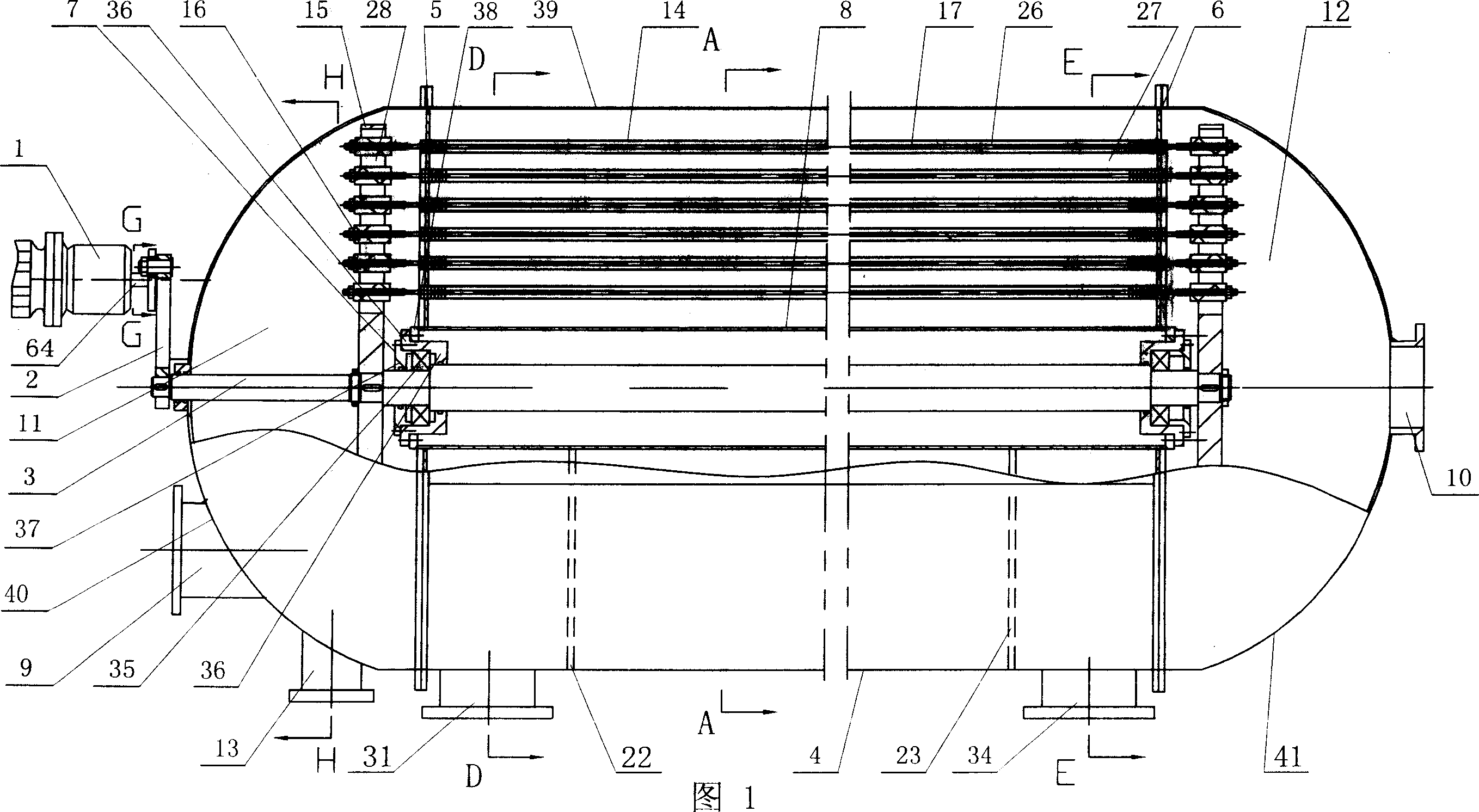

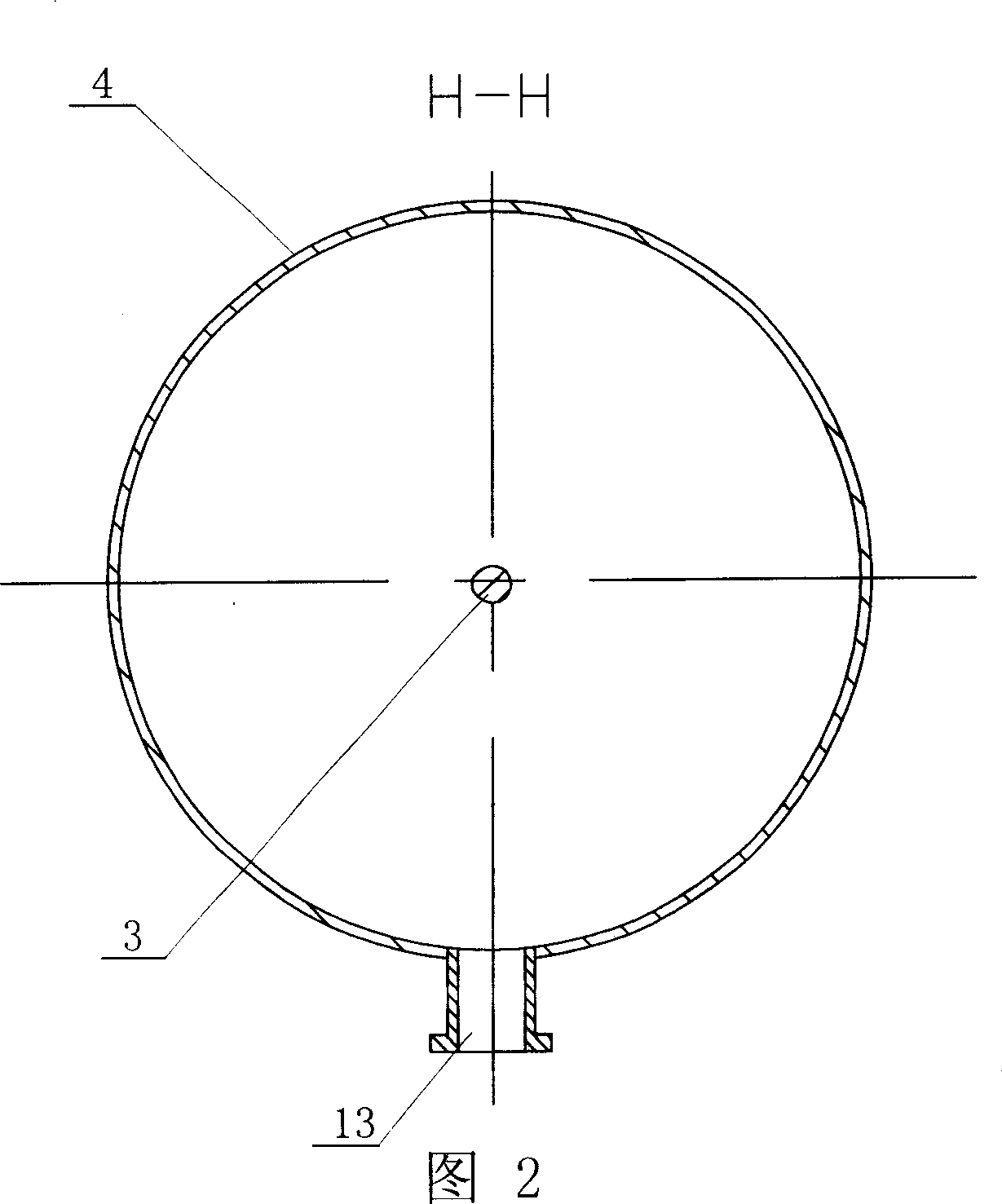

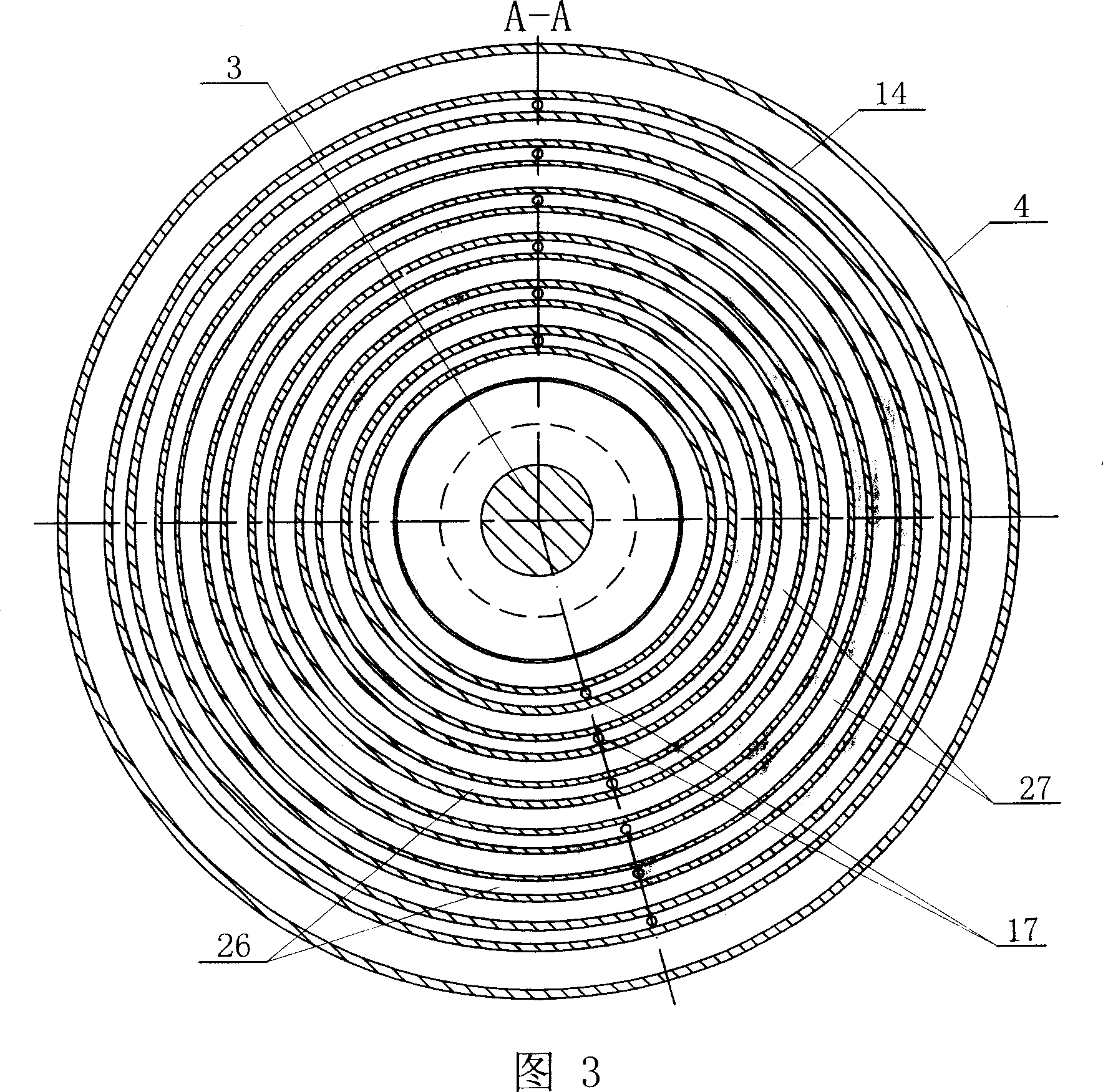

Online pollution repellent, heat exchanger equipment and method for tube cluster of cold and heat sources from sewage and surface water

InactiveCN101004330AHigh heat transfer efficiencyStrong anti-blocking functionRotary device cleaningStationary plate conduit assembliesPollutantEngineering

An on-line pollution proof heat exchange device of cylinder cluster using wasted water and surface water as cooling and heating sources is prepared for connecting outlet and inlet of water source to source water inlet layer of cylinder cluster, connecting inlet and outlet of media to be heated to heat exchange layer of media to be heated, setting brush rod in water source inlet layer and forming cylinder cluster by sheathing a set of cylinders in coaxial and equal lengthy to each other. Its heat exchanging method is also disclosed.

Owner:HARBIN INST OF TECH

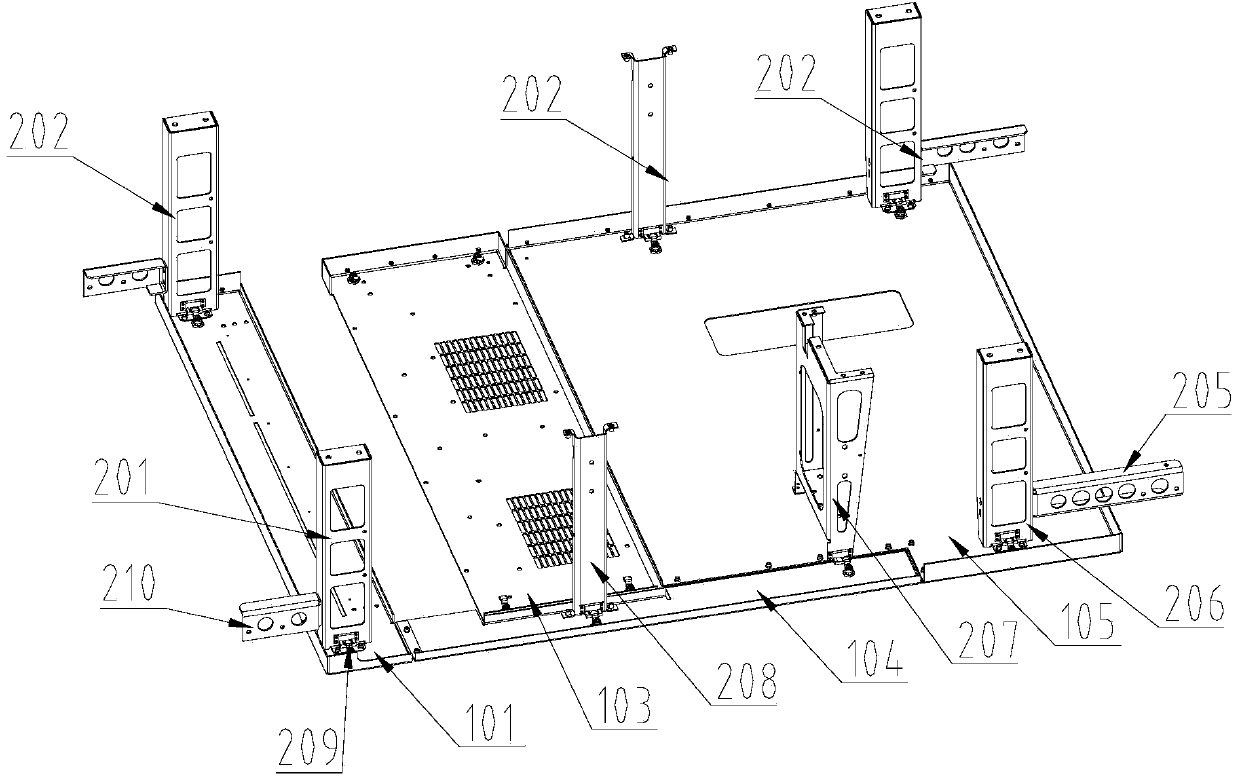

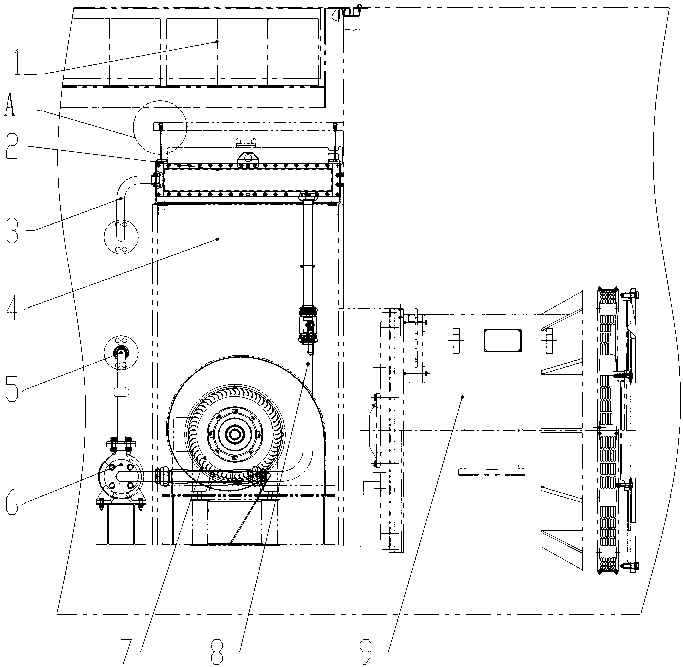

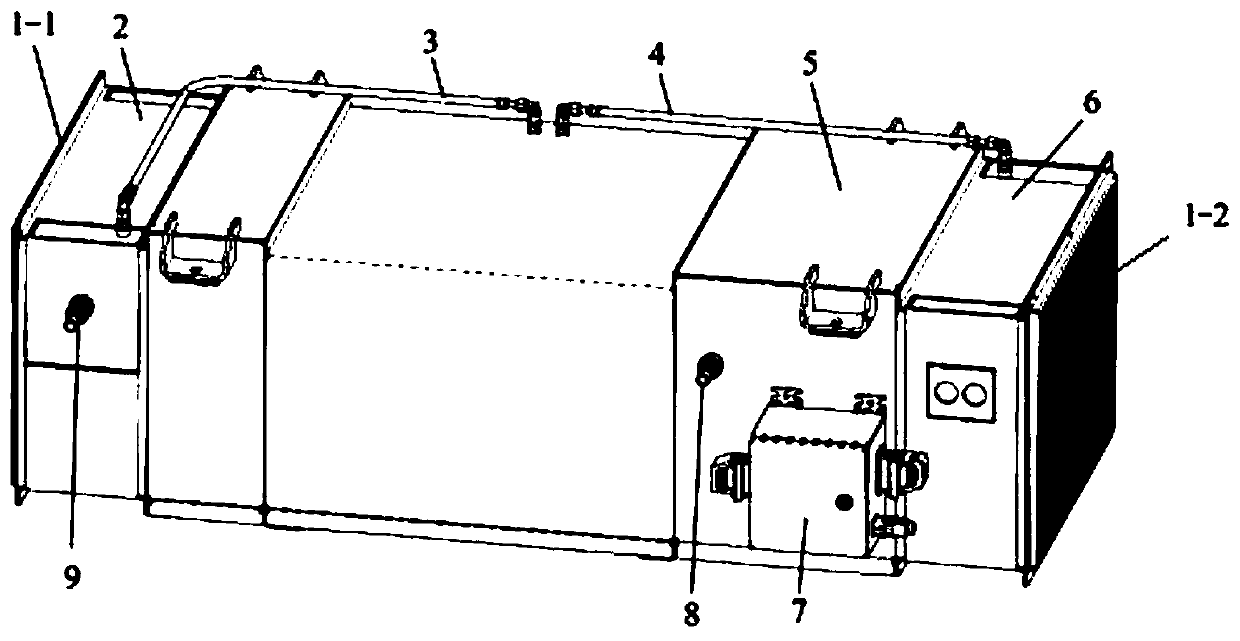

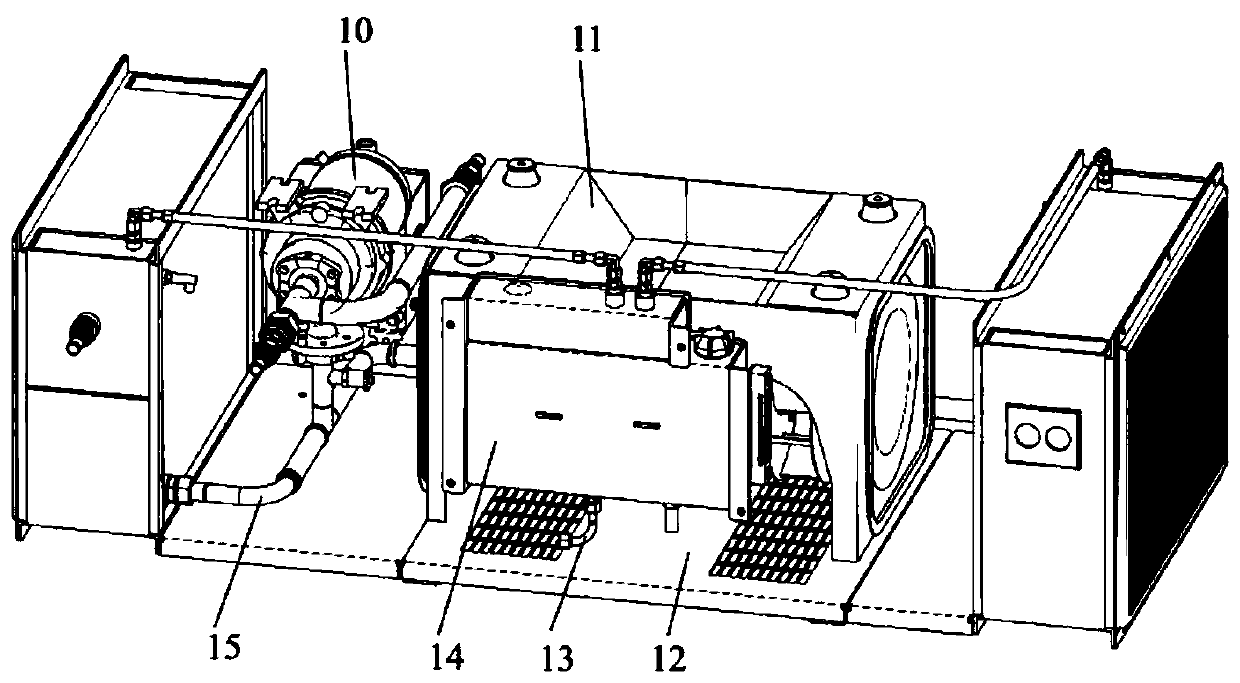

Modularized cooling device for internal combustion locomotive

InactiveCN103573376AImprove heat transfer effectImprove structural strengthLiquid coolingInternal combustion piston enginesCombustionModularity

The invention discloses a modularized cooling device for an internal combustion locomotive. The modularized cooling device for the internal combustion locomotive comprises a water cooling system, a pressurized air cooling system, a transmission oil cooling system, a static-pressure oil cooling system, a fan set and a steel frame and is characterized in that the steel frame is composed of a fan rack and a cooling device mounting rack fixed at the lower end of the fan rack, a fan drum is arranged inside the fan rack, and the fan set is arranged inside the fan drum; the water cooling system, the pressurized air cooling system, the transmission oil cooling system and the static-pressure oil cooling system are arranged inside the cooling device mounting rack. The modularized cooling device for the internal combustion locomotive is compact in structure and reasonable in matching; has good heat exchange capacities and relatively low air pressure losses and accordingly saves energy sources; simplifies the manufacturing process and reduces the production costs; is dirt-proof and easy to maintain, thereby reducing the use cost; facilitates working environment improvement due to appropriate noise reduction measures.

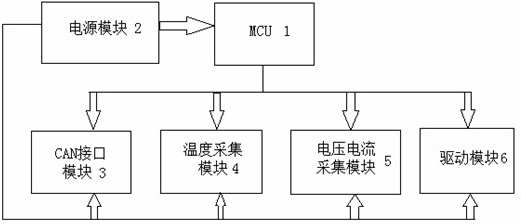

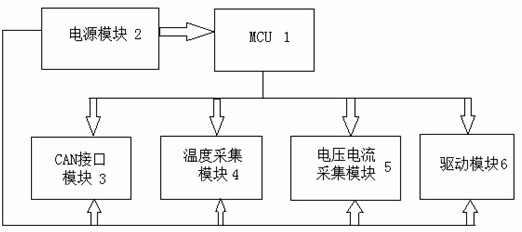

Radiating fan controller structure for standby power supply of fuel cell

InactiveCN102536870AReduce Auxiliary Power ConsumptionFlexible controlPump controlNon-positive displacement fluid enginesArea networkPower flow

The invention discloses a radiating fan controller structure for a standby power supply of a fuel cell. The radiating fan controller structure comprises a central processing unit, and a controller area network (CAN) interface module, a temperature acquisition module, a voltage and current acquisition module and a drive module which are connected with the central processing unit, wherein a power module is used for providing power for the central processing unit and all the modules. The structure is flexible in control and high in accuracy; and due to the adoption of the structure in combination with a good control method, the rotating speed of a radiating fan can be controlled in real time according to requirements of a standby power supply system to achieve the effects of reducing auxiliary power consumption, improving the operating efficiency of the system and enhancing the reliability of the system, so that the system is positioned in the optimal operating state.

Owner:KUSN FUERSAI ENERGY

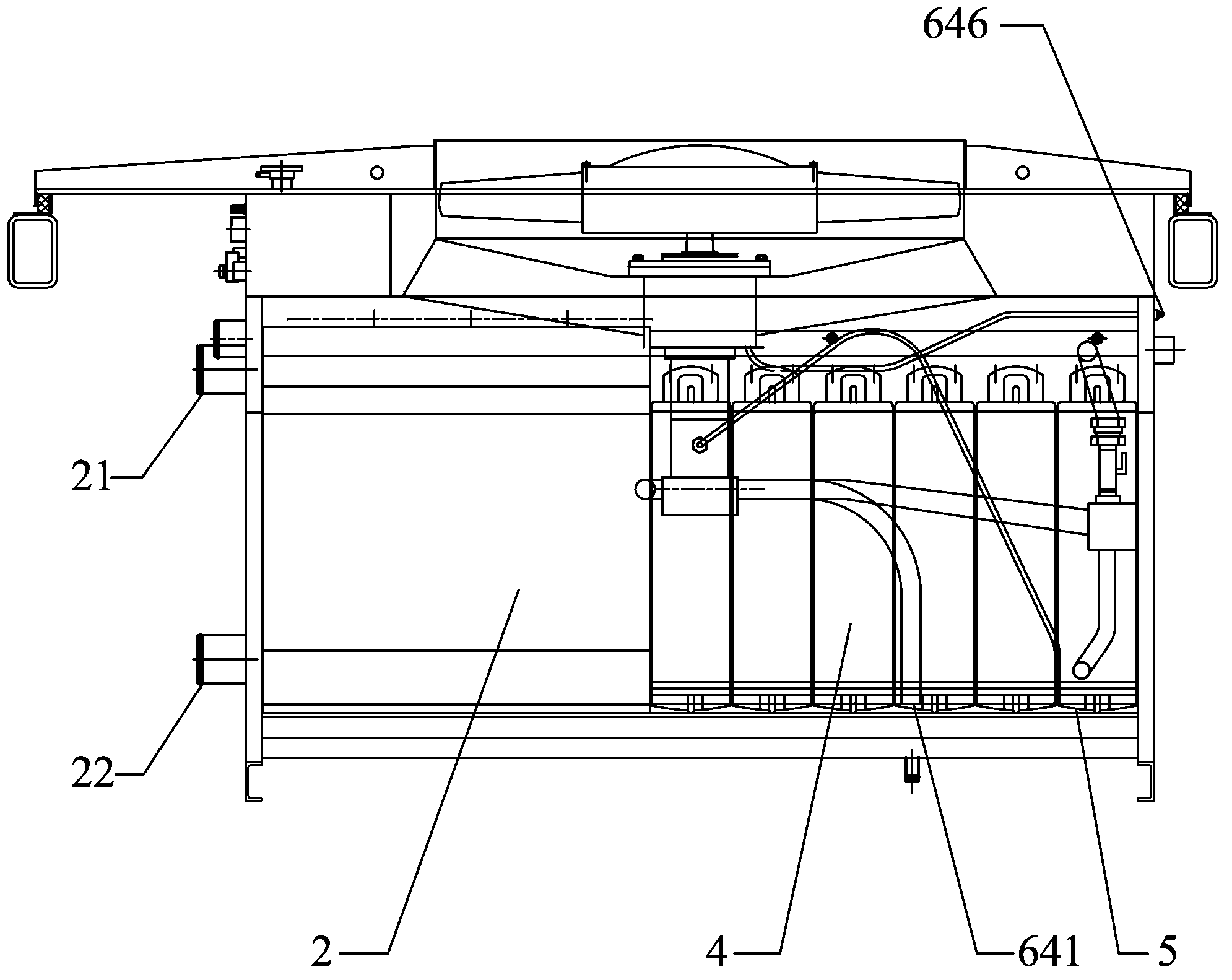

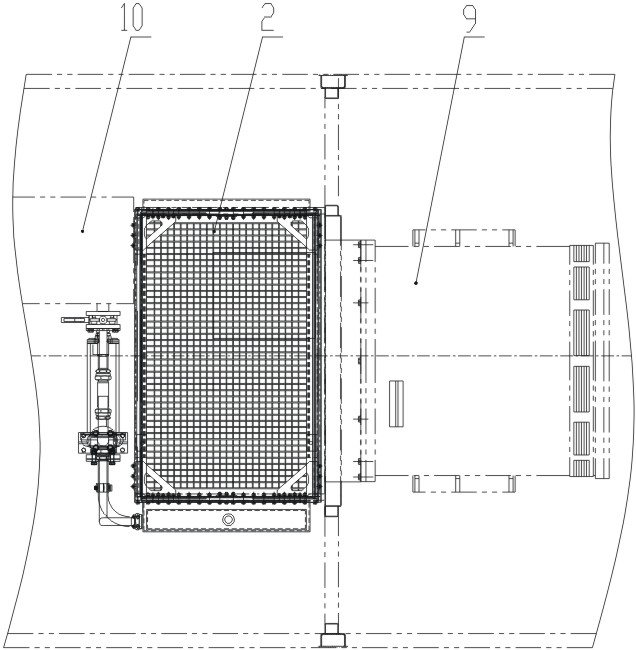

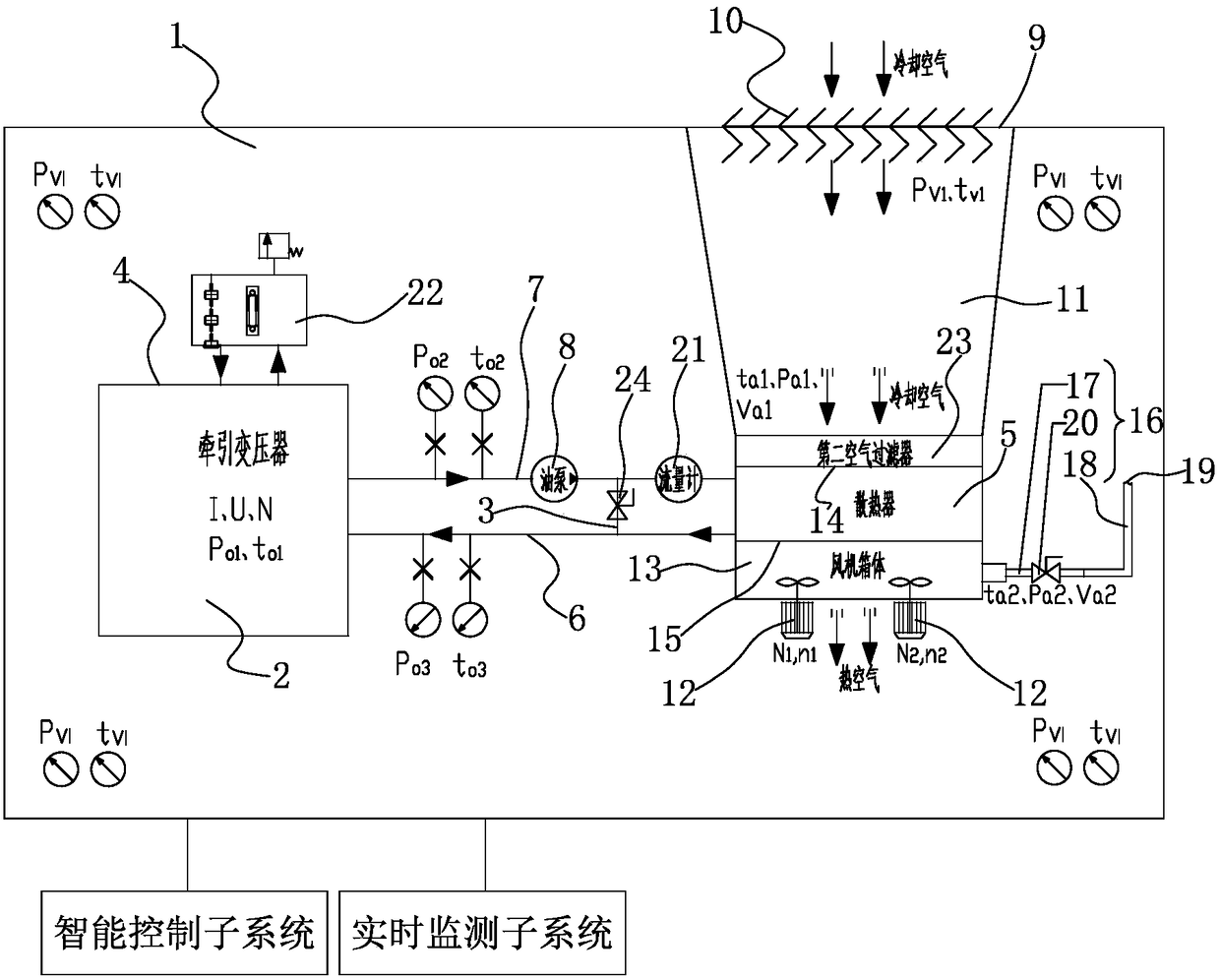

Cooling unit for traction transformers

ActiveCN104252946ARealize heat exchangeAchieving Auxiliary Power ConsumptionTransformers/inductances coolingDistribution transformerEngineering

The invention discloses a cooling unit for traction transformers of motor train units. The cooling unit has the advantages that matching technologies are optimized, so that fans of a cooling air system can assuredly work in high-efficient working areas, the heat exchange capacity, auxiliary power consumption and noise can be optimally matched with one another, the cooling unit is applicable to the motor train units with the speeds per hour of 300-350 kilometers, and requirements on the heat dissipation performance of the cooling unit can be met without increasing the weight of the cooling unit under the conditions of 380V and 50Hz or 440V and 60Hz three-phase alternating currents; the structural strength of the cooling unit can be reinforced by the aid of safety measures, and bottom plates can be prevented from falling off; the noise of the cooling unit can be lowered by the aid of comprehensive noise reduction measures.

Owner:CRRC DALIAN INST CO LTD

Cooling system for converter of diesel locomotive

ActiveCN102361392ASimple structureEasy to connectCooling/ventilation/heating modificationsPower conversion systemsDiesel locomotiveHeat spreader

The invention discloses a cooling system for a converter of a diesel locomotive and belongs to the field of cooling systems for converters. An independent air inlet unit is arranged on the top of a radiator; the radiator is arranged on the top of an independent air chamber; a traction motor ventilator is arranged in the independent air chamber; the air inlet of a main generator is communicated with the independent air chamber; the independent air chamber is communicated with the independent air inlet unit; a water outlet pipeline of the radiator is connected with the water inlet of a water pump; the water outlet of the water pump is connected with a converter water inlet pipeline; the converter water inlet pipeline is connected with the water inlet of the converter; the water outlet of the converter is connected with a converter water outlet pipeline; the converter water outlet pipeline is connected with the water inlet of the radiator; and the water outlet of the radiator is connected with a radiator water outlet pipeline. The weight of the whole cooling system for the converter is reduced, so the space in the diesel locomotive is saved, the auxiliary power consumption is reduced, the reliability of the system is improved and the manufacturing cost is reduced.

Owner:CRRC ZIYANG CO LTD

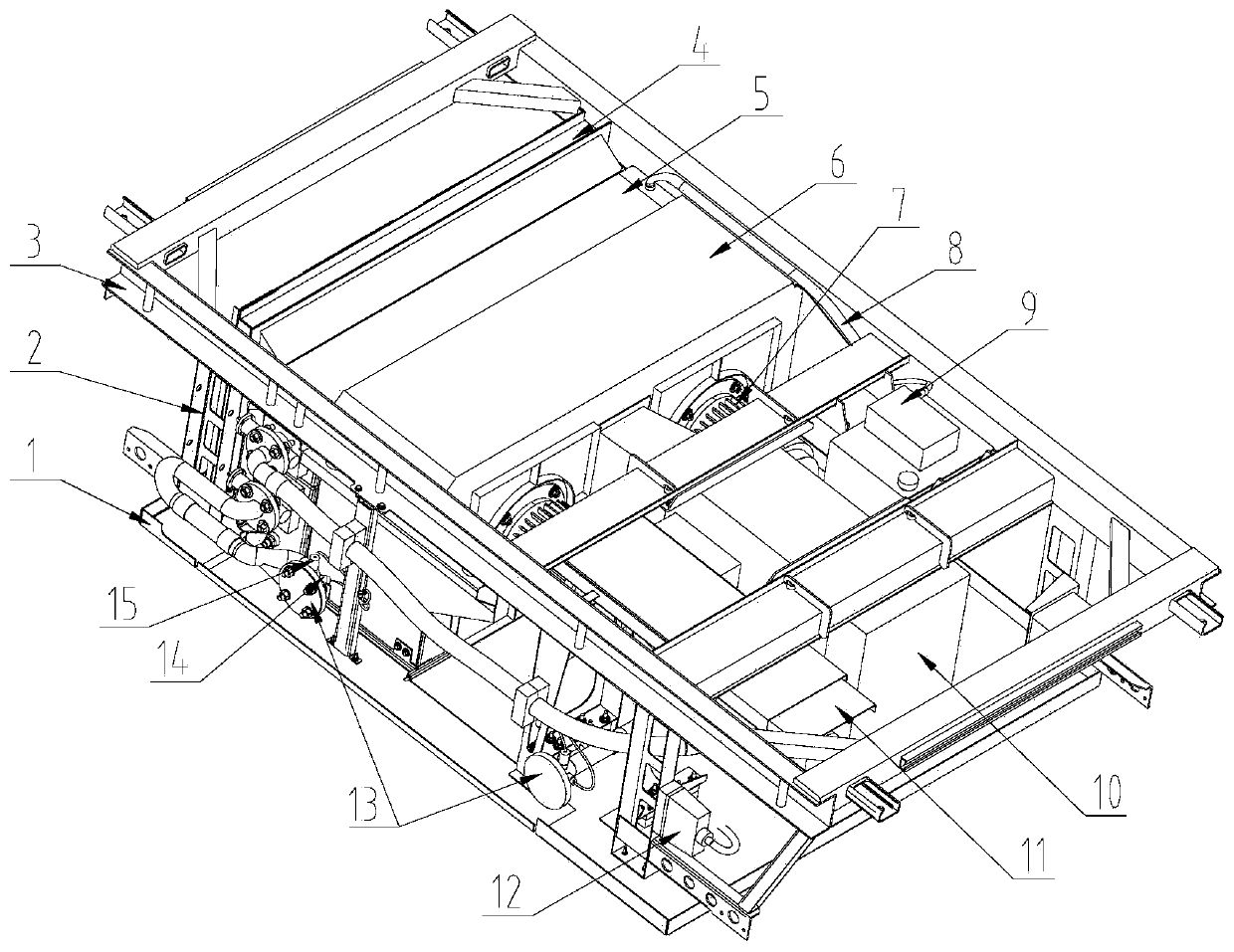

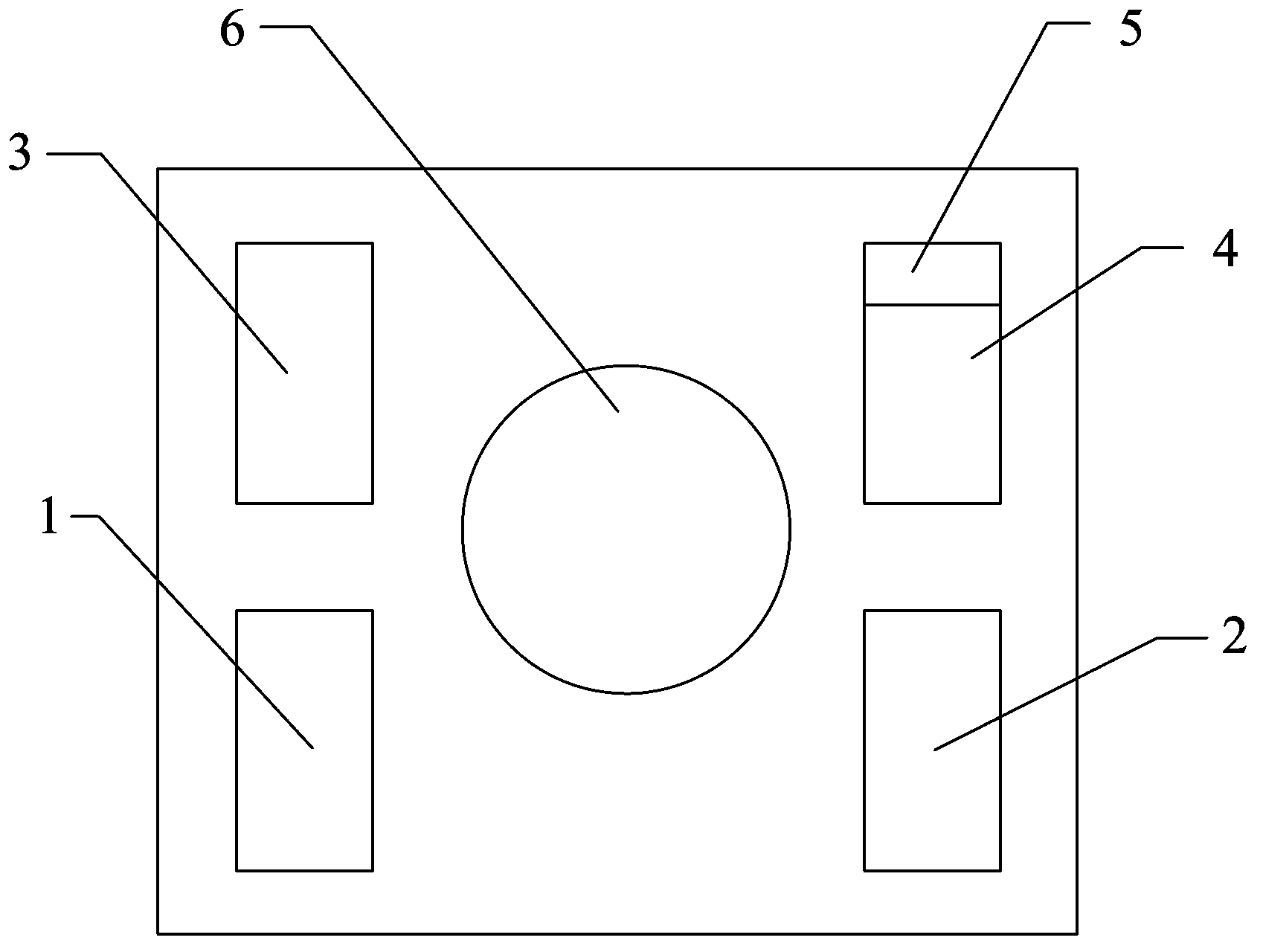

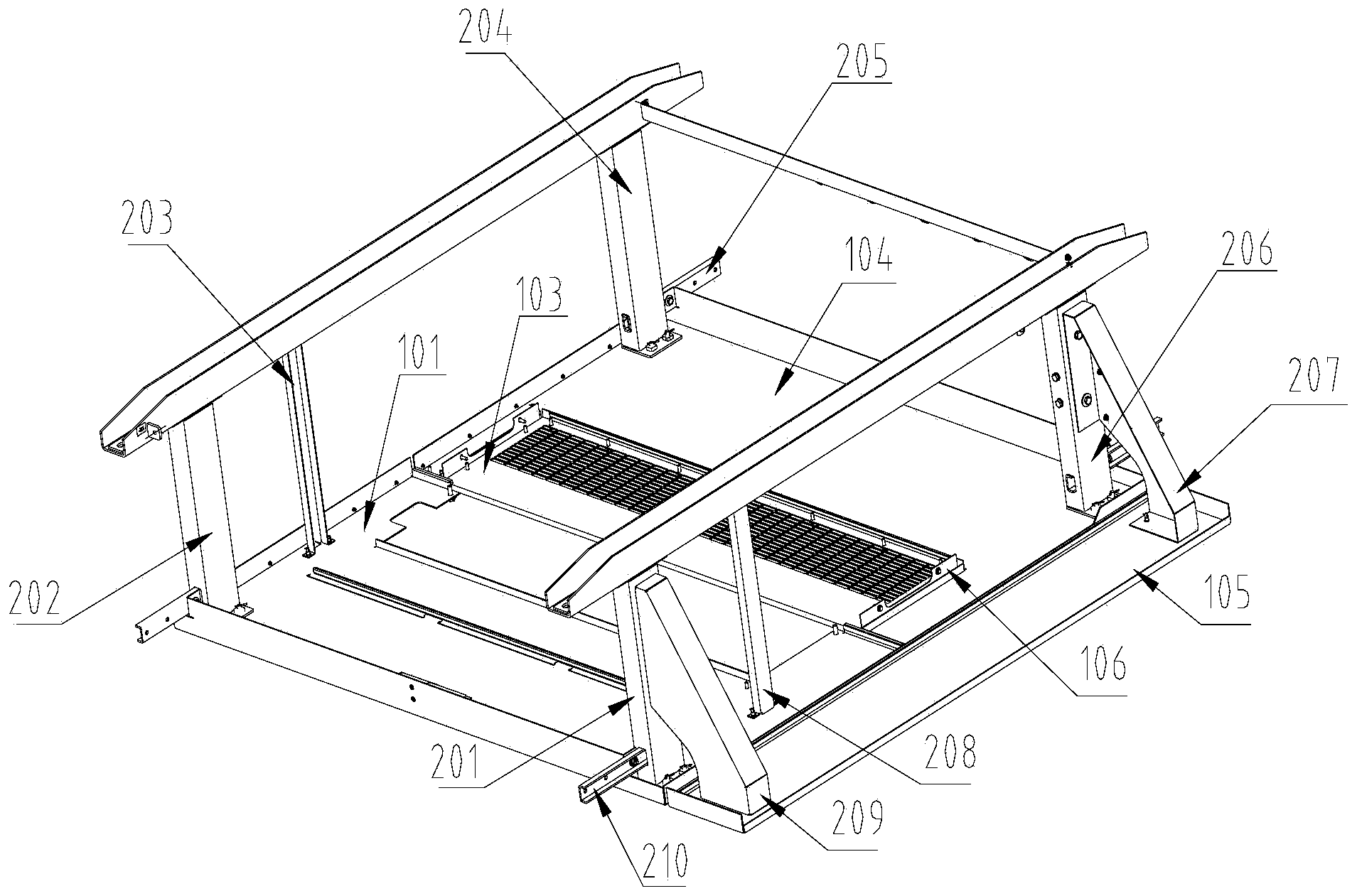

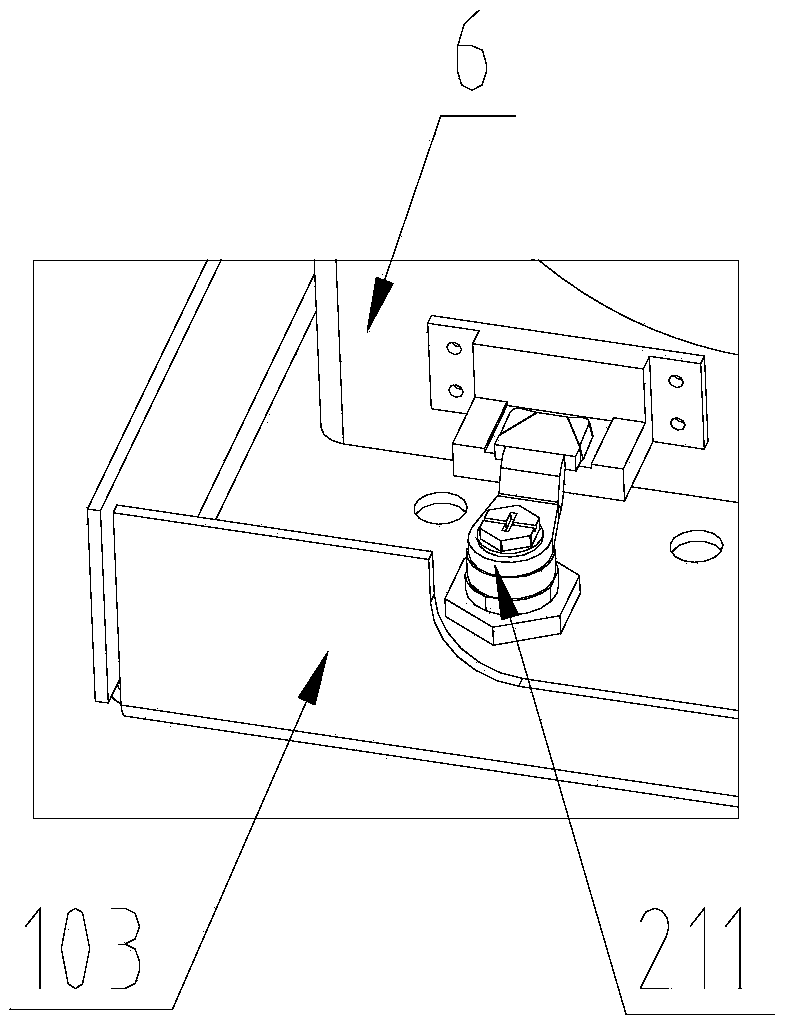

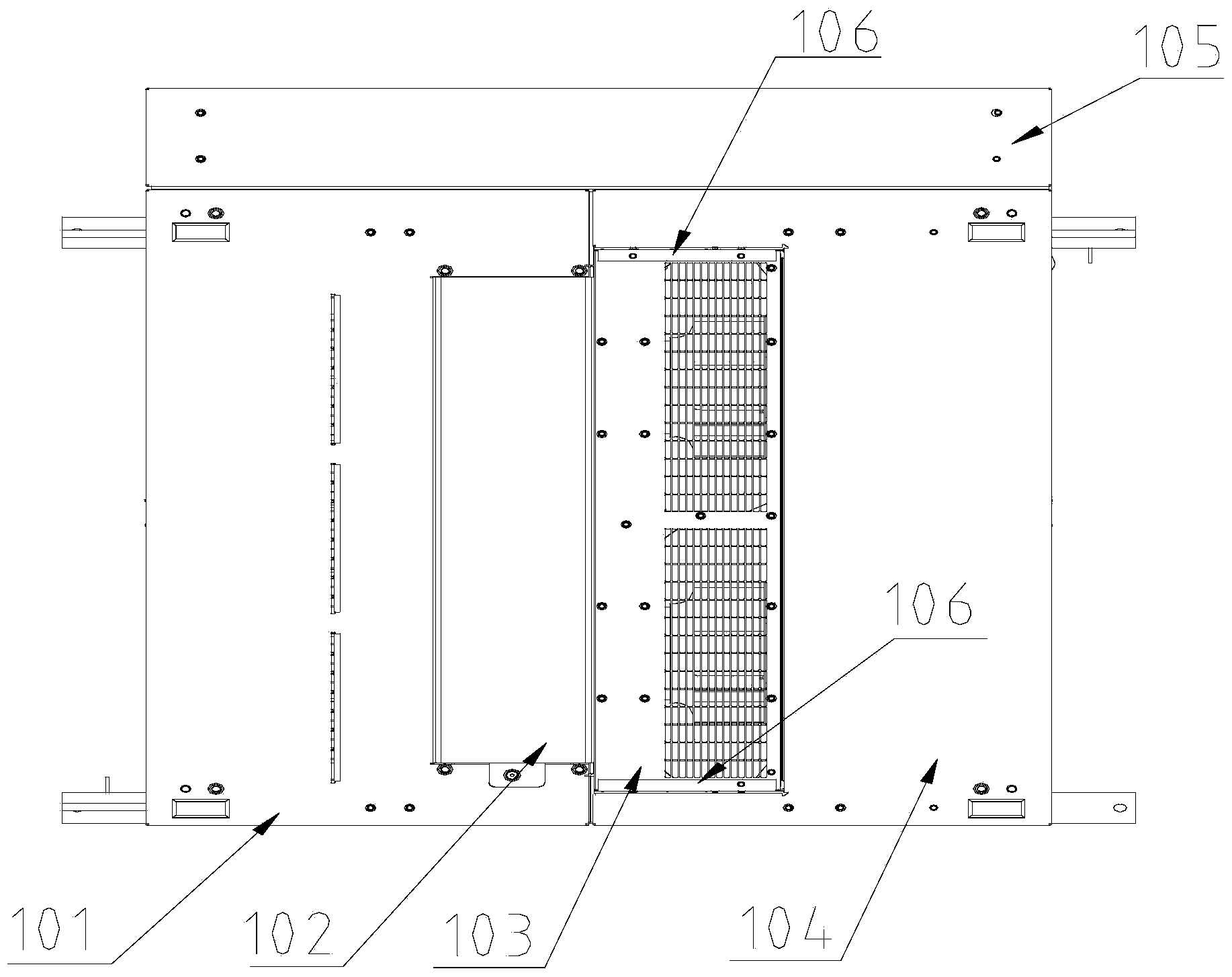

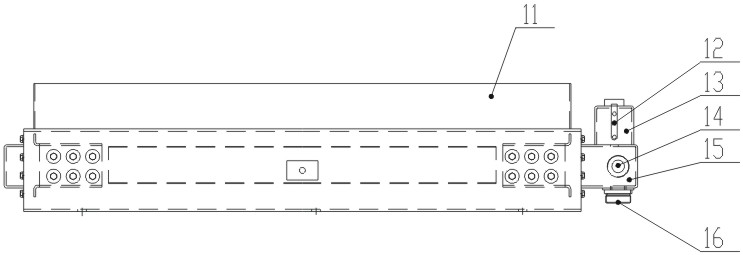

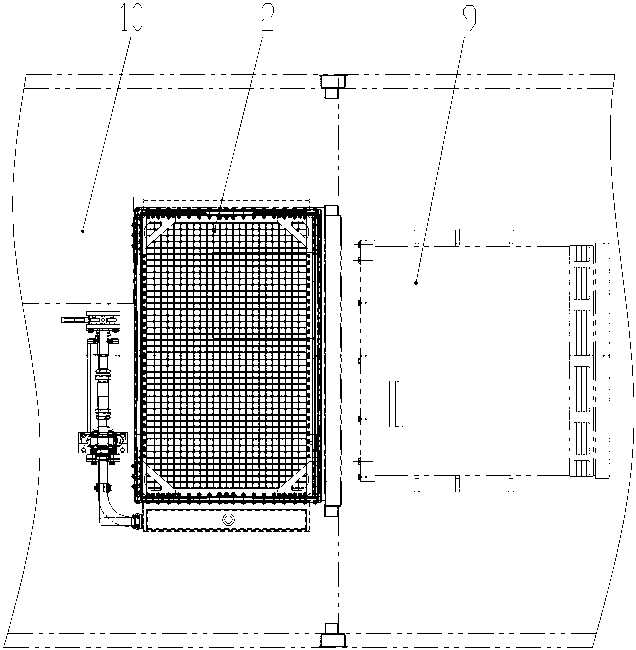

Heat exchange module for locomotive

ActiveCN105438192AReduce volumeReduce maintenance and repair workloadLocomotivesLow noiseEngineering

The invention discloses a heat exchange module for a locomotive, which is characterized by comprising an air intake filter, a two-circuit radiator, a fan set, an electric reactor and an air discharge grille which are sequentially arranged along an air flow direction as well as a box structure for containing the components; the air intake filter is arranged on a front end plate of the box structure, and the two-circuit radiator and the electric reactor are respectively fixed on beams in the corresponding positions of the box structure through respective mounting bases by fasteners; an air duct mounting base of the fan set is used for connecting the fan set and the box structure through a vibration absorber; a pipeline is arranged on a water collecting chamber of the two-circuit radiator; and the air discharge grille is arranged on a rear end plate of the box structure. According to the invention, by adopting an overall matching design method, the same heat exchange module is used for simultaneously meeting the requirement of heat dissipation of a traction converter power module and the electric reactor; and the heat exchange module has the advantages of small volume, light weight, compact structure, low noise, convenience in maintenance, low auxiliary power consumption, high reliability, low life cycle cost and the like.

Owner:CRRC DALIAN INST CO LTD

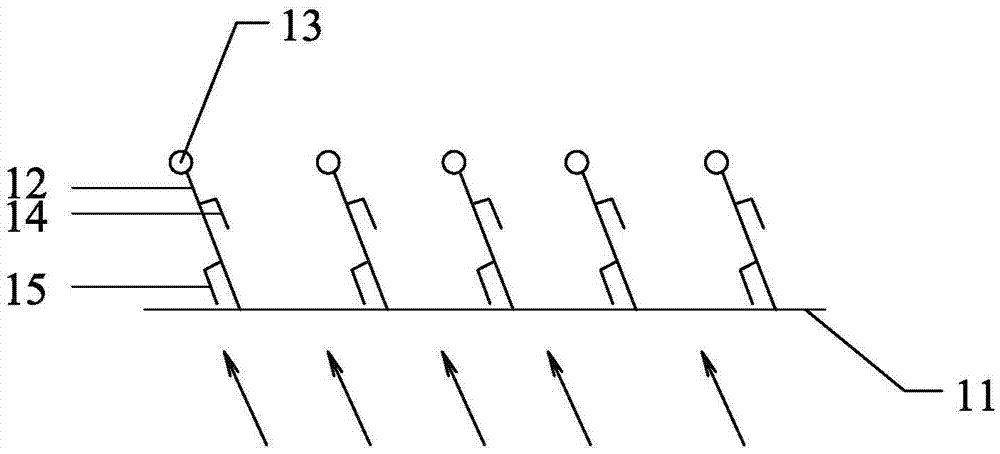

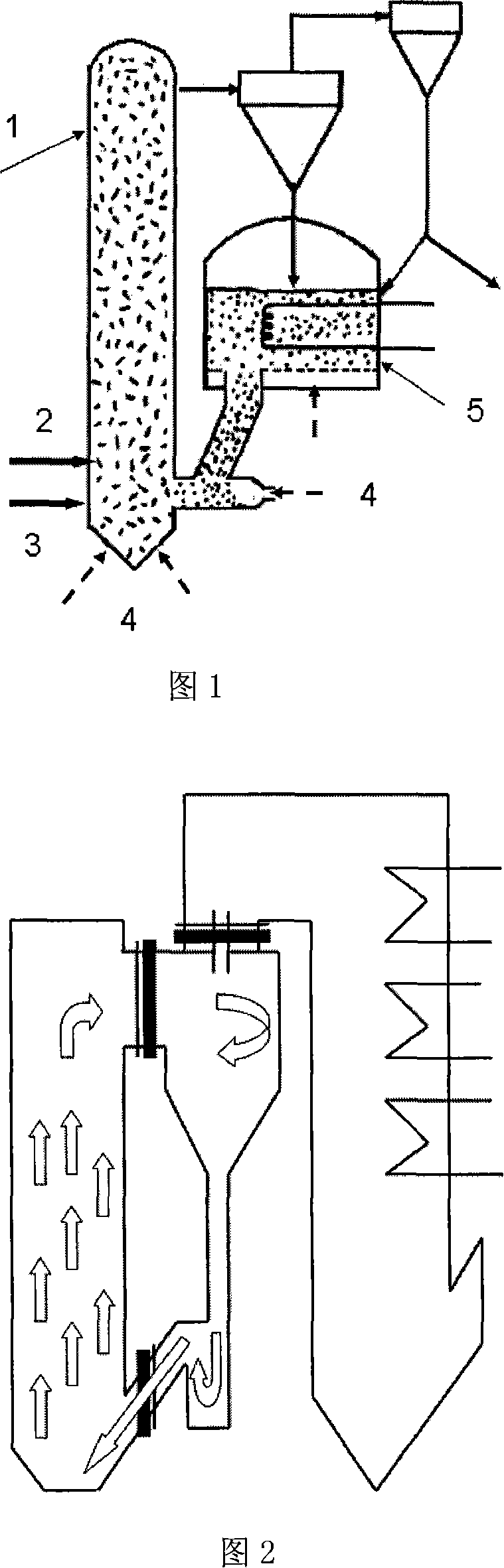

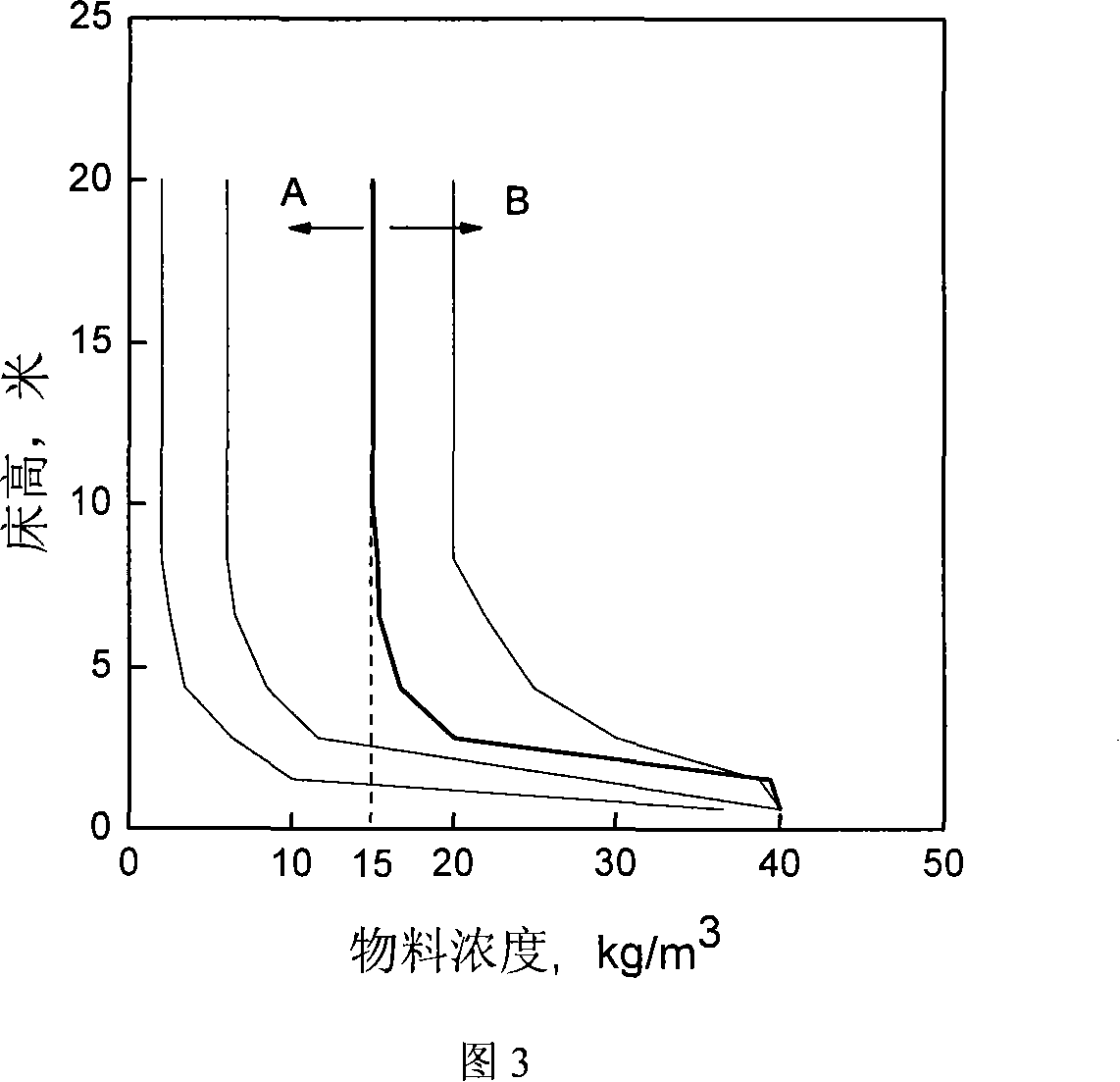

Low bed pressure-reducing circulated fluid bed boiler combustion process

ActiveCN101149146AReduce auxiliary power consumptionPromote combustionFluidized bed combustionApparatus for fluidised bed combustionWinding machineCirculating fluidized bed boiler

This invention is a low bed pressure drop circulating fluidized bed boiler combustion technical method, which relates to rapid circulating fluidized bed boiler combustion technique. It makes sure the circulating fluidized bed rapid bed fluid state. The inner bed temperature is controlled within 850-930 degree. The fluidizing wind speed is 4-6.2m / s. The average particle size of circulating materials is smaller than 300mum. The material concentration of the space above combustion chamber second air port is kept 1-15Kg / m3 rapid bed state. This invention can greatly reduce the pressure head of first and second wind machines. Thus, it effectively reduces the power dissipation of assisting engines. In addition, as the space material concentration decreased, gas mixture improved, combustion intensified, the combustion efficiency of boiler is further increased. This invention can also reduce the attrition rate of combustion chamber water-cooled wall heating surface.

Owner:北京杰创华睿科技有限公司

A plate-fin microcirculation radiator and a microcirculation heat exchange system

ActiveCN106304805BFast heat conductionEasy to installModifications by conduction heat transferHeat transfer efficiencyEngineering

The invention discloses a plate fin type micro-circulation radiator and a micro-circulation heat exchange system. The plate fin type micro-circulation radiator comprises a heat source module mounting plate, a radiator mounting plate and a heat dissipation assembly, wherein the heat source module mounting plate and the radiator mounting plate are fixed to each other, main working medium chambers used for containing mediums are formed in the heat source module mounting plate and the radiator mounting plate, the heat dissipation assembly is mounted on the radiator mounting plate and comprises a micro-circulation heat dissipation module and a cooling air passage which are arranged at an interval, the interior of the micro-circulation heat dissipation module is a sub-working medium chamber, and the inner walls of both the main working medium chambers and the sub-working medium chamber are provided with imbibition micro-passages of a capillary structure. The plate fin type micro-circulation radiator and the micro-circulation heat exchange system are compact in structure, high in heat transfer efficiency, relatively low in noise, low in assisting power consumption, high in reliability, capable of well solving the main bottleneck problem, namely the heat dissipation problem of industrial development of electronic components, and broad in market prospect.

Owner:CRRC DALIAN INST CO LTD

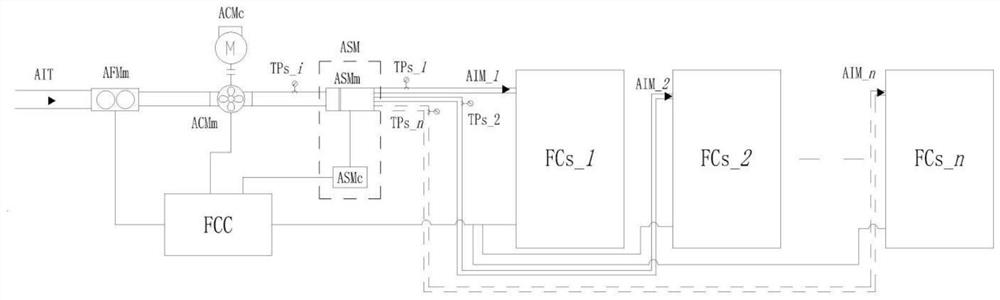

Fuel cell gas flow distribution device and control method

The embodiment of the invention provides a fuel cell gas flow distribution device and a control method. The fuel cell gas flow distribution device comprises a mass flow meter which is used for measuring the actual mass flow of reaction gas in a gas inlet manifold, a pressurization module which is used for increasing pressure for reaction gas in the gas inlet manifold to enable the reaction gas toenter the flow distribution module, a master controller which is used for sending a preset signal to the flow distribution module,and aflow distribution module which is used for determining a corresponding preset control strategy according to the preset signal, so that the flow distribution module is only communicated with one target air inlet branch pipe each time, and circularly and repeatedly inflates each air inlet branch pipe. According to the embodiment of the invention, reaction gas is alternately provided for each fuel cell stack through the flow distribution module, so that the function of simultaneously providing the reaction gas for a plurality of fuel cell stacks through one compressor is realized, and the auxiliary power consumption and the cost of a fuel cell power system arereduced; the problems of energy loss and waste are solved, and the efficiency of a fuel cell power system is improved.

Owner:CRRC IND INST CO LTD

Cooling system for converter of diesel locomotive

ActiveCN102361392BFew partsReduce noiseCooling/ventilation/heating modificationsPower conversion systemsDiesel locomotiveHeat spreader

The invention discloses a cooling system for a converter of a diesel locomotive and belongs to the field of cooling systems for converters. An independent air inlet unit is arranged on the top of a radiator; the radiator is arranged on the top of an independent air chamber; a traction motor ventilator is arranged in the independent air chamber; the air inlet of a main generator is communicated with the independent air chamber; the independent air chamber is communicated with the independent air inlet unit; a water outlet pipeline of the radiator is connected with the water inlet of a water pump; the water outlet of the water pump is connected with a converter water inlet pipeline; the converter water inlet pipeline is connected with the water inlet of the converter; the water outlet of the converter is connected with a converter water outlet pipeline; the converter water outlet pipeline is connected with the water inlet of the radiator; and the water outlet of the radiator is connected with a radiator water outlet pipeline. The weight of the whole cooling system for the converter is reduced, so the space in the diesel locomotive is saved, the auxiliary power consumption is reduced, the reliability of the system is improved and the manufacturing cost is reduced.

Owner:CRRC ZIYANG CO LTD

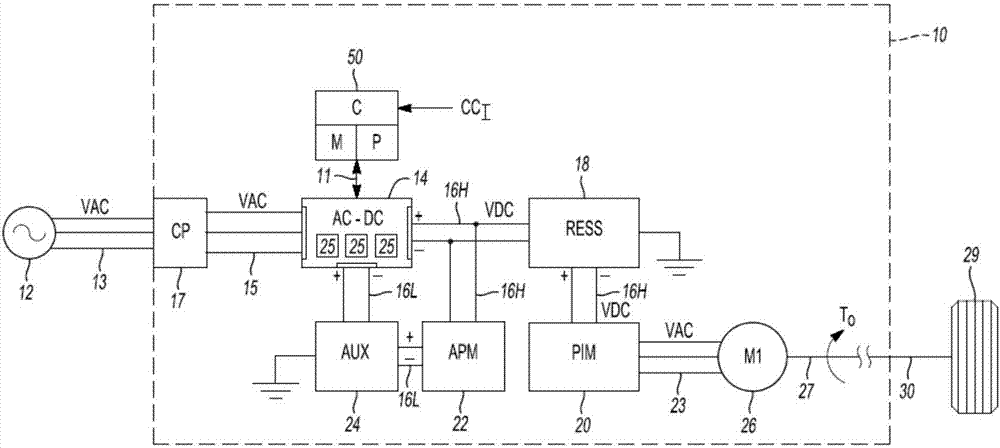

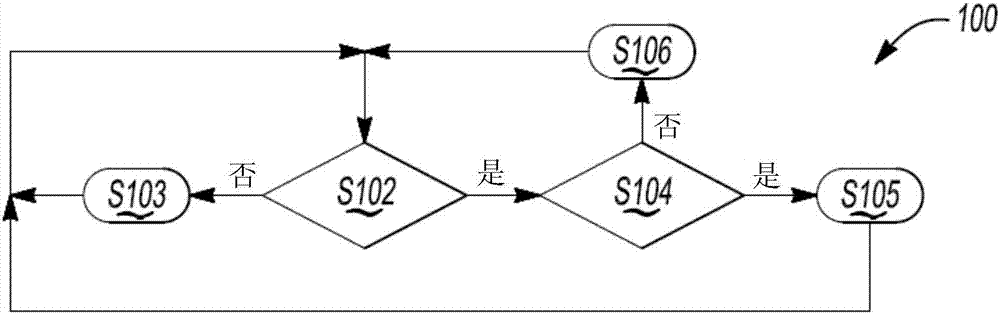

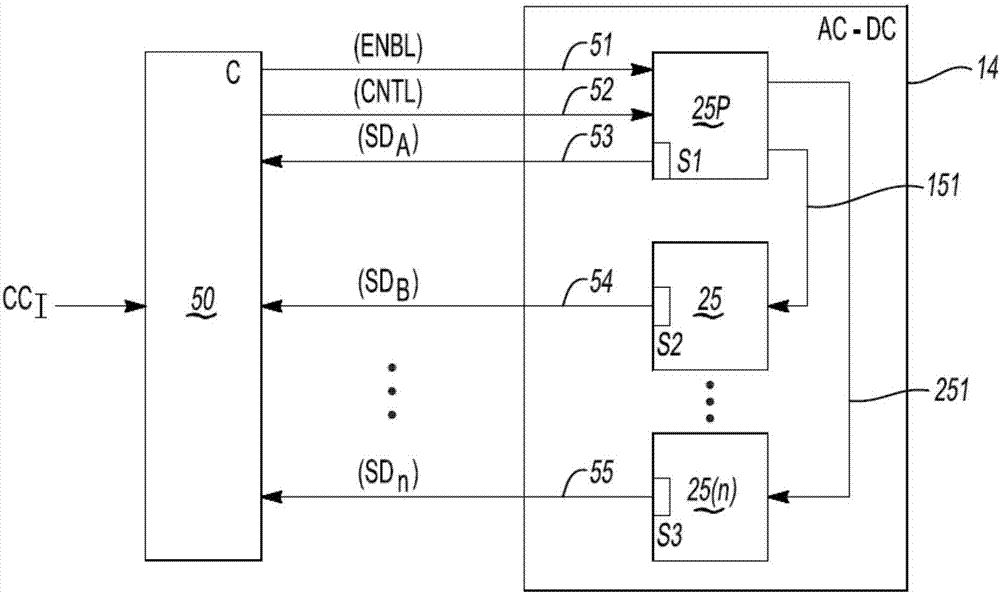

Multiphase converter auxiliary power reduction

ActiveCN107346942AReduce auxiliary power consumptionAc-dc conversion without reversalCharging stationsElectrical batteryEngineering

An electrical system for use with an AC power supply having multiple phase voltages, e.g., three phase voltages, may include a high-voltage battery pack or other high-voltage DC device, a 12 VDC battery or other auxiliary-voltage DC device providing auxiliary power to the electrical system, multiple AC-DC converters, and a controller. The AC-DC converters each provide a DC output voltage to the high-voltage DC device, and are operable for converting a respective one of the phase voltages from the AC power supply into the DC output voltage. The controller selectively disables the AC-DC converters in response to a detected predetermined operating condition to thereby reduce consumption of the auxiliary power within the electrical system. A vehicle may include a high-voltage DC battery pack, an auxiliary-voltage DC battery providing auxiliary power, an onboard charging module, a charging port, an auxiliary power module, an electric machine, and a controller.

Owner:GM GLOBAL TECH OPERATIONS LLC

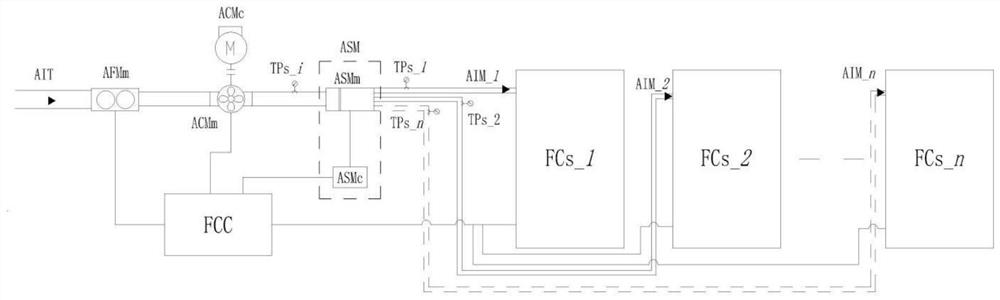

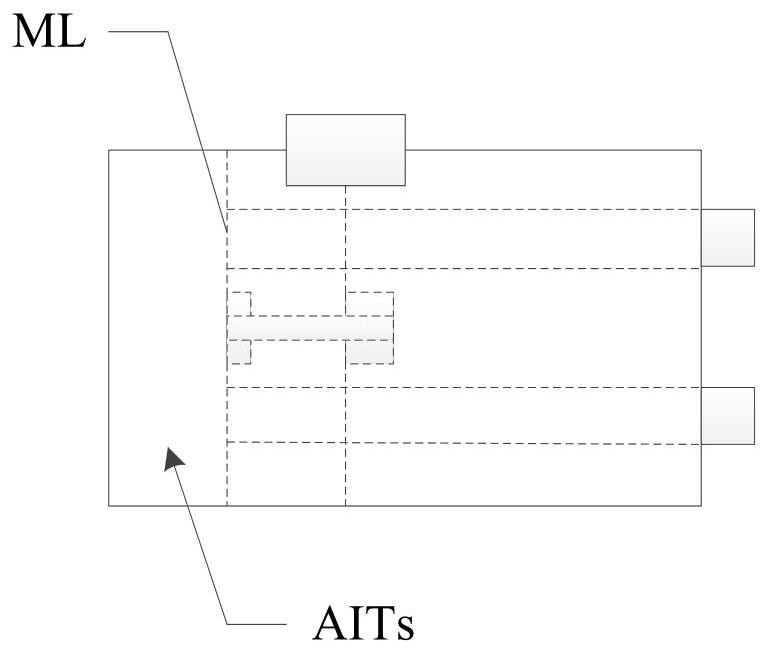

Intelligent Cooling System for Traction Transformer of EMU

ActiveCN106449036BReasonable useGuaranteed safe operationTransformers/inductances coolingMeasurement devicesIntelligent lightingFuel tank

The invention discloses an intelligent cooling system for a traction transformer of an electric multiple unit. The electric multiple unit is provided with an equipment compartment, wherein the traction transformer is arranged in the equipment compartment, the traction transformer comprises a heat source part placed in an oil box, the cooling system comprises a cooling device arranged in the equipment compartment, heat generated by the heat source part is taken away by cooling oil flowing out of the oil box, the cooling device comprises a heat sink and an oil pump, the heat sink communicates with the oil box through a cooling oil circulation pipeline, the cooling oil circulation pipeline comprises an oil inlet pipeline and an oil outlet pipeline, the oil pump is arranged on the oil outlet pipeline, the cooling oil flowing out of the oil box passes through the oil outlet pipeline and the oil pump and enters the heat sink, the heat sink is used for transferring the heat to cooling air from the cooling oil, and the cooling oil passes through the oil inlet pipeline and returns to the oil box after the heat is released. By the intelligent cooling system, the cooling intensity can be automatically adjusted, and the energy utilization efficiency is improved.

Owner:CRRC DALIAN INST CO LTD

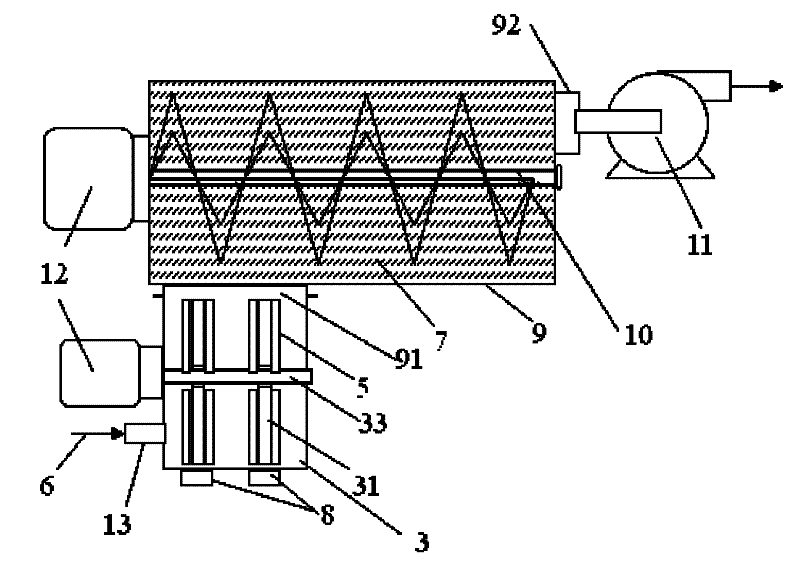

A tube-fin microcirculation radiator and a microcirculation heat exchange system

ActiveCN106255396BFast heat conductionEasy to installCooling/ventilation/heating modificationsCapillary channelHeat transfer efficiency

The invention discloses a segment-type microcirculation radiator and a microcirculation heat exchange system. The segment-type microcirculation radiator comprises a heat source module installation plate, a radiator installation plate and a heat dissipation assembly, wherein the heat source module installation plate and the radiator installation plate are fixed to each other and a main working medium cavity for accommodating a working medium is formed in the heat source module installation plate and the radiator installation plate; the heat dissipation assembly comprises a plurality of radiating fins which are stacked at certain distances, and microcirculation heat dissipation modules; the microcirculation heat dissipation modules are arranged in the corresponding radiating fins in a penetrating manner; each microcirculation heat dissipation module is of a tubular structure of which one end is opened and the other end is closed and a branch working medium cavity is formed in each microcirculation heat dissipation module; each branch working medium cavity communicates with the main working medium cavity; and liquid-absorbing micro-channels with capillary structures are arranged in the inner walls of the main working medium cavity and the branch working medium cavities and capillary channels of the liquid-absorbing micro-channels communicate with each other. The segment-type microcirculation radiator and the microcirculation heat exchange system are compact in structure, high in heat transfer efficiency, lower in noise, lower in auxiliary power consumption, high in reliability and wide in market prospect, and the problem of a main bottleneck in electron component industry development is well solved.

Owner:CRRC DALIAN INST CO LTD

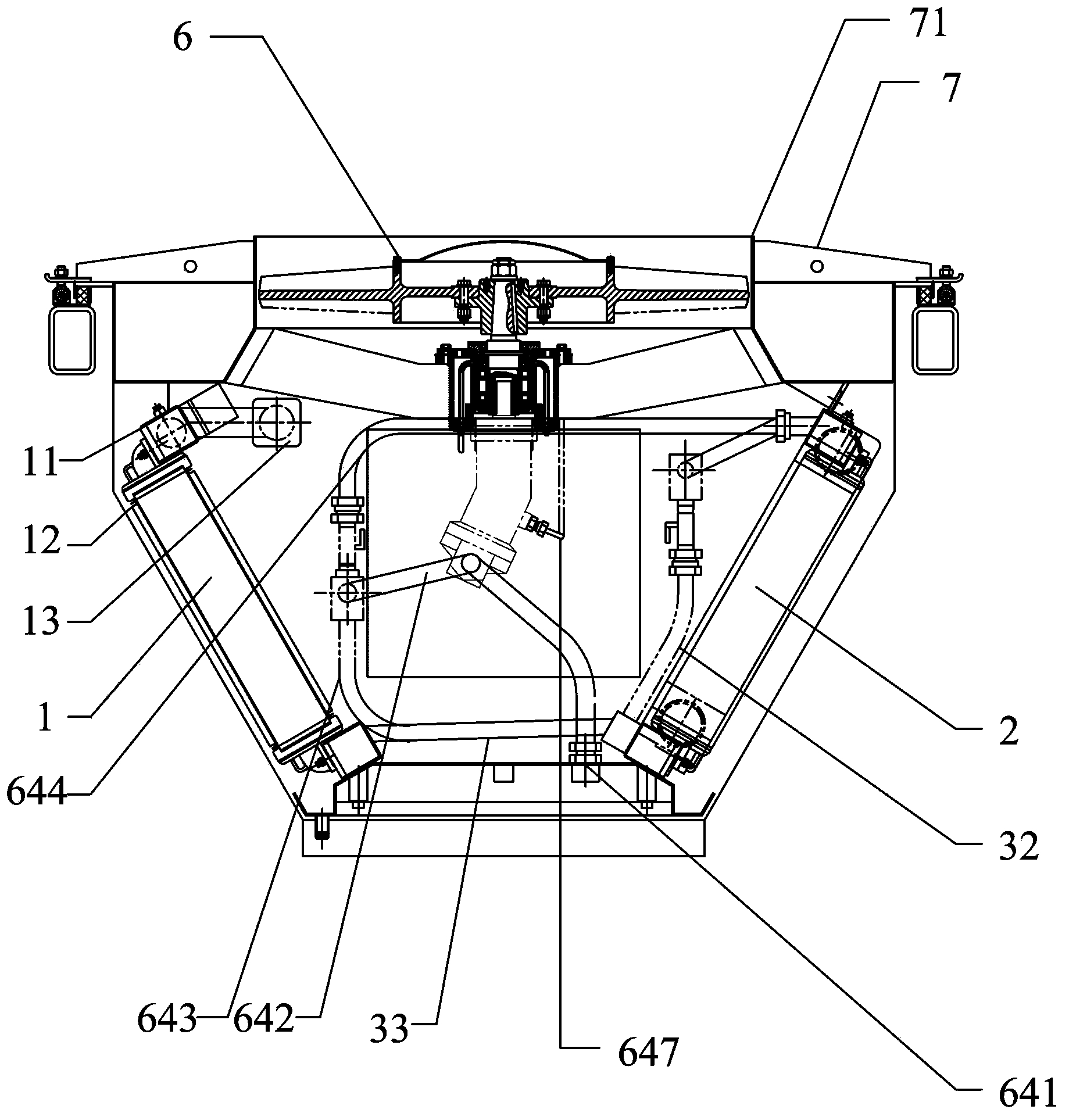

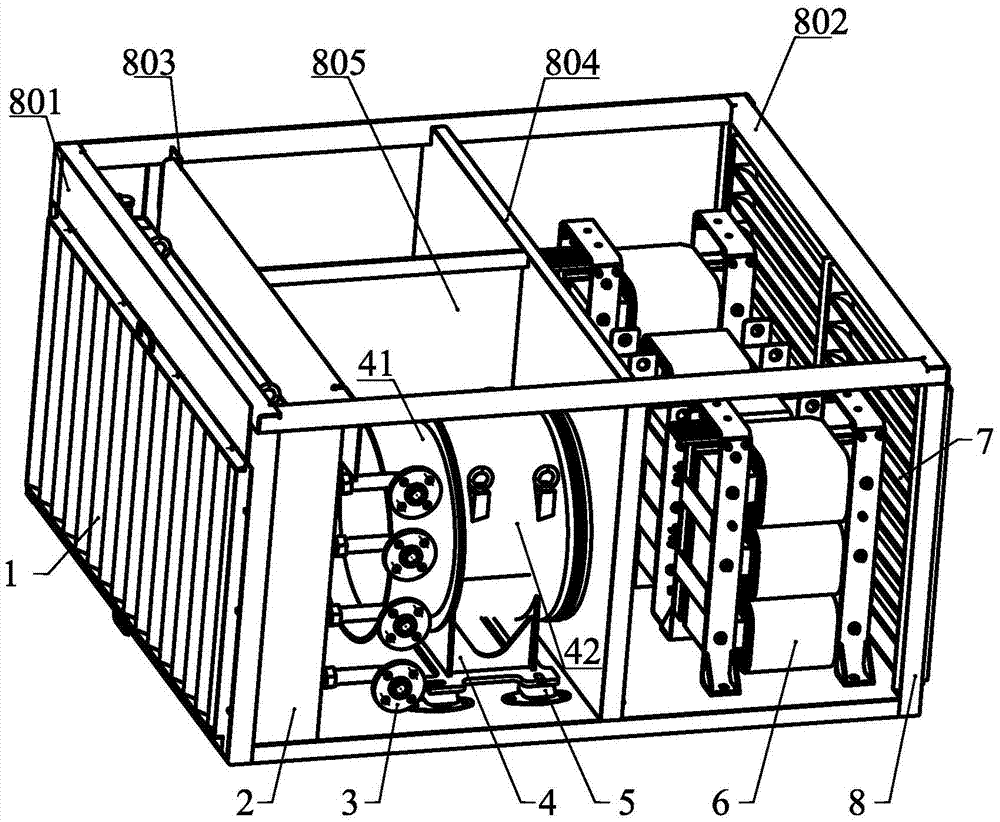

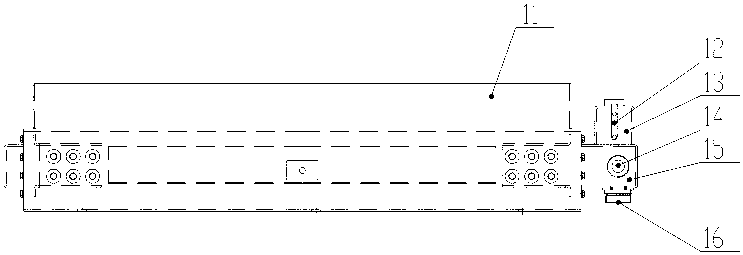

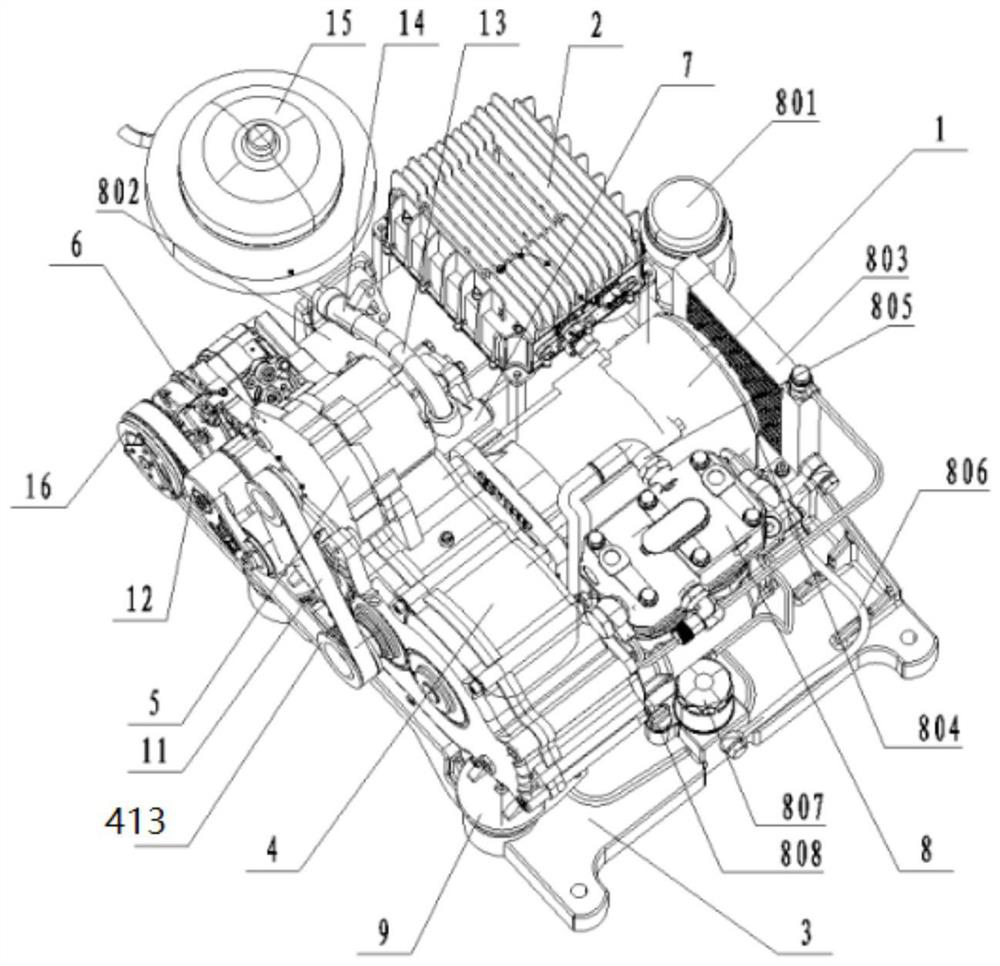

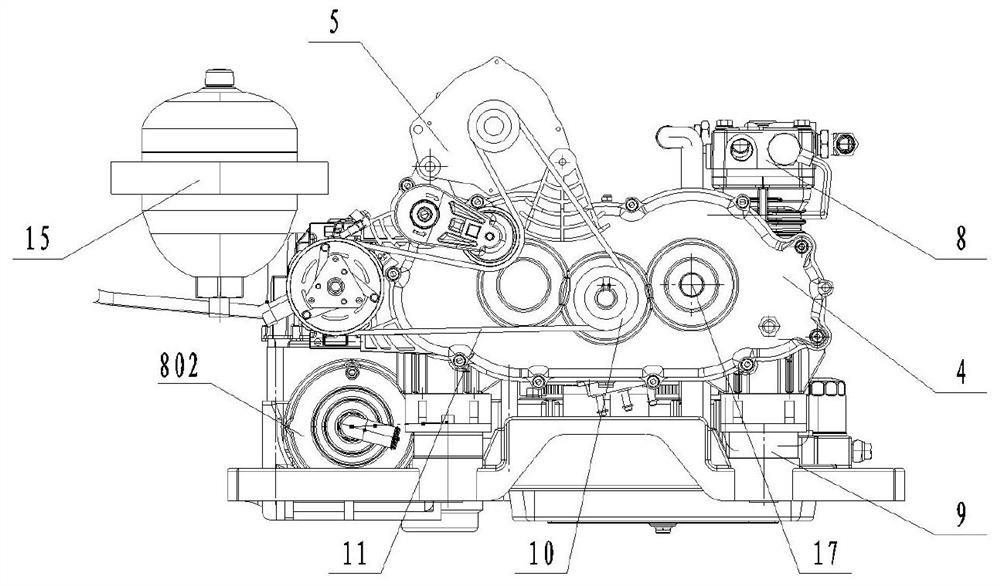

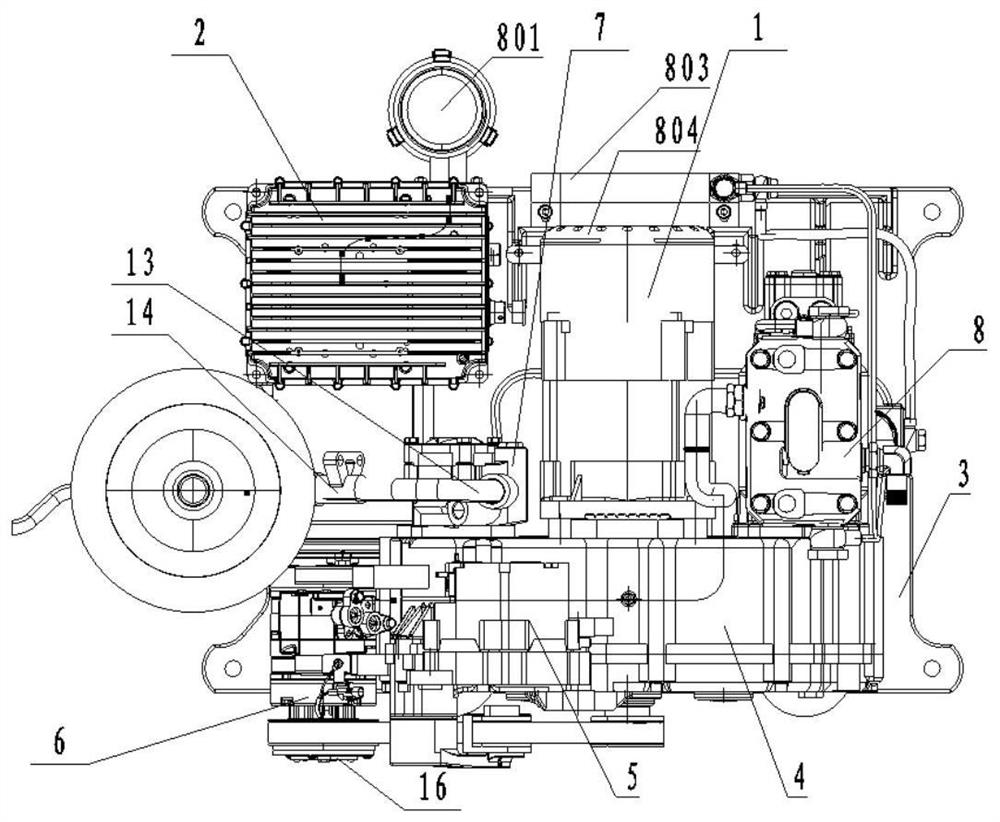

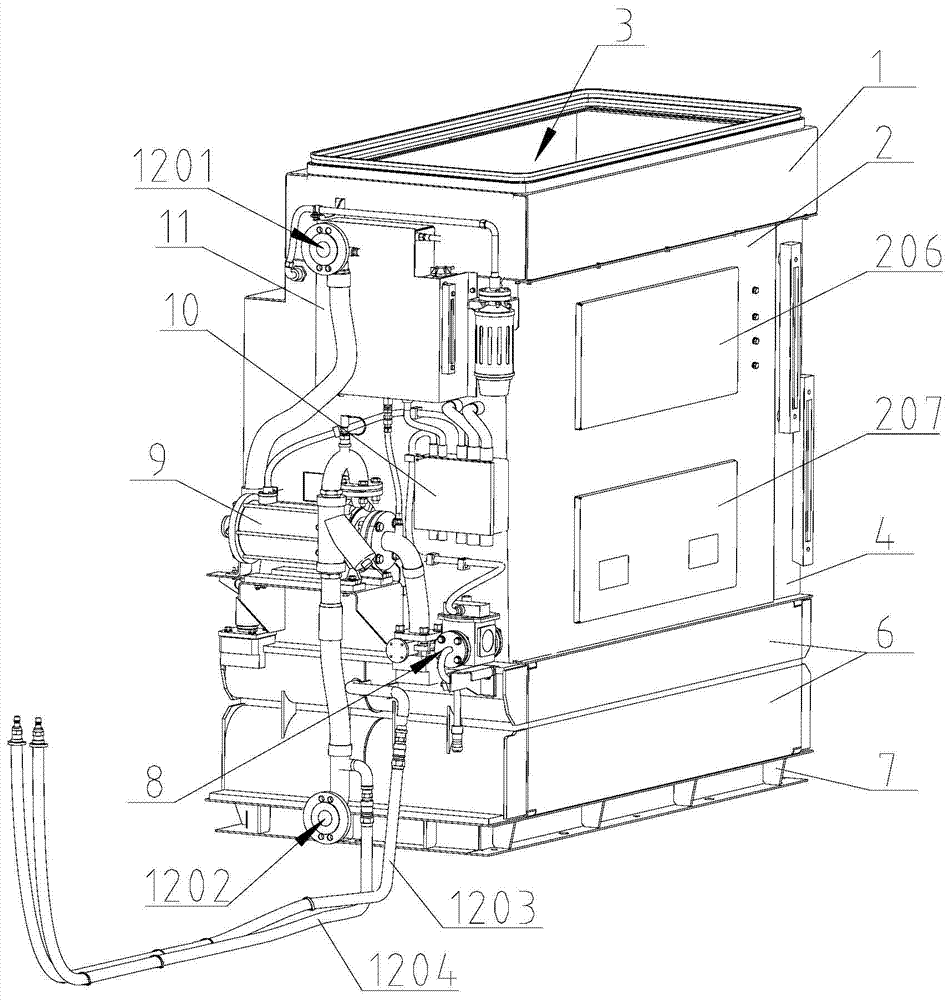

Integrated auxiliary system for pure electric commercial vehicle

PendingCN113858976AReduce auxiliary power consumptionImprove battery life and vehicle economyAir-treating devicesElectric propulsion mountingDrive motorElectric generator

The invention relates to an integrated auxiliary system for a pure electric commercial vehicle. The auxiliary system comprises a driving motor 1, a driving motor controller 2, a support 3, a transmission system, an air compressor 8, a steering system, an air conditioner compressor 5, a low-voltage generator 6, a cooling water pump and a cooling lubricating system. The air conditioner compressor 5 is located on the right side of the reduction gearbox 4, the low-voltage generator 6 is installed on the upper portion of the reduction gearbox 4 in a screwed mode, the main belt pulley 413 is simultaneously connected with a driven belt pulley of the air conditioner compressor 5 and a driven belt pulley of the low-voltage generator 6 through a belt 11, and the steering oil pump 7 is connected to the right rear side of the reduction gearbox 4 in a screwed mode. The output shaft of the drive motor 1 is fixedly connected with the input shaft of the steering oil pump 7. The air compressor gear 420 is meshed with a second gear 407 in the reduction gearbox 4, the driving motor controller 2 is located on the rear portion of the steering oil pump 7, and the air compressor 8 is located on the left rear side of the reduction gearbox 4. The system is high in integration level, compact in structure, reasonable in performance and arrangement, simple to control, low in cost and light in weight.

Owner:BEIBEN TRUCKS GRP

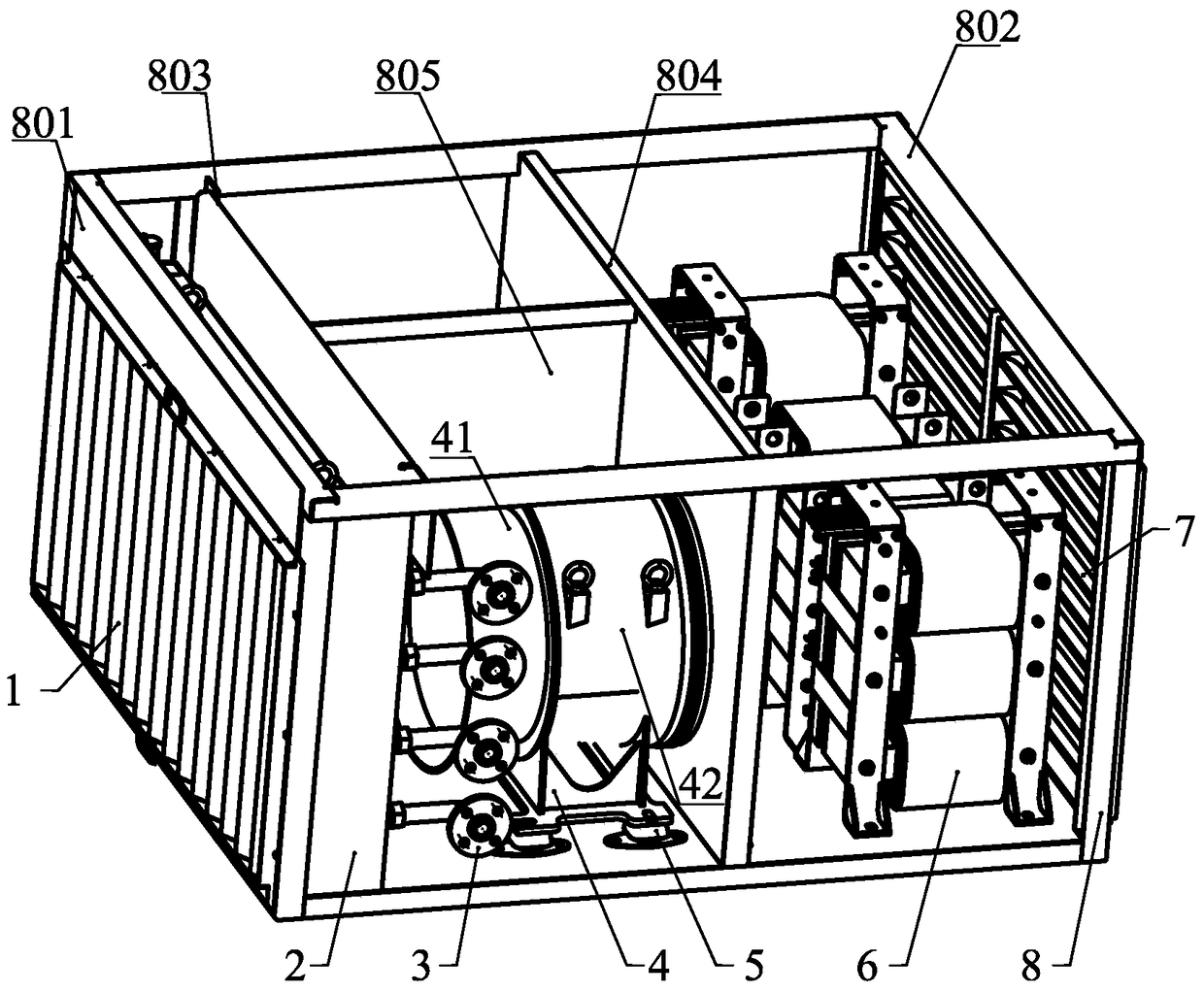

A heat exchange module for a locomotive

ActiveCN105438192BReduce volumeReduce maintenance and repair workloadLocomotivesLow noiseHeat exchanger

The invention discloses a heat exchange module for a locomotive, which is characterized by comprising an air intake filter, a two-circuit radiator, a fan set, an electric reactor and an air discharge grille which are sequentially arranged along an air flow direction as well as a box structure for containing the components; the air intake filter is arranged on a front end plate of the box structure, and the two-circuit radiator and the electric reactor are respectively fixed on beams in the corresponding positions of the box structure through respective mounting bases by fasteners; an air duct mounting base of the fan set is used for connecting the fan set and the box structure through a vibration absorber; a pipeline is arranged on a water collecting chamber of the two-circuit radiator; and the air discharge grille is arranged on a rear end plate of the box structure. According to the invention, by adopting an overall matching design method, the same heat exchange module is used for simultaneously meeting the requirement of heat dissipation of a traction converter power module and the electric reactor; and the heat exchange module has the advantages of small volume, light weight, compact structure, low noise, convenience in maintenance, low auxiliary power consumption, high reliability, low life cycle cost and the like.

Owner:CRRC DALIAN INST CO LTD

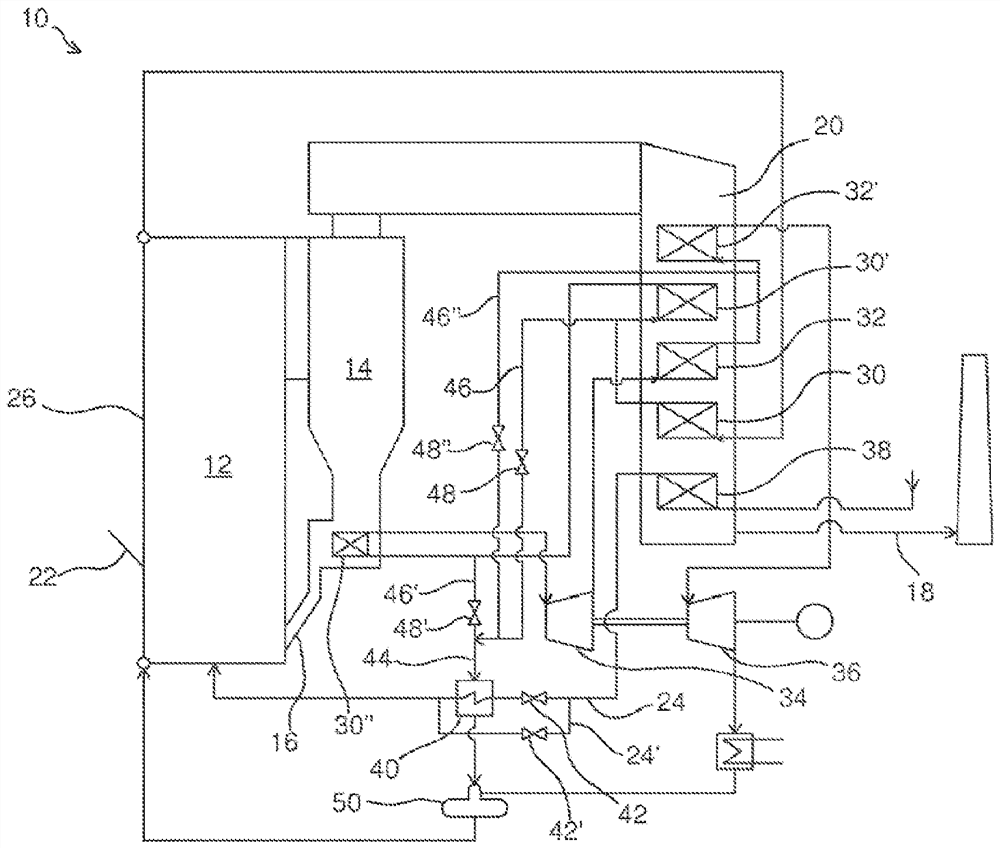

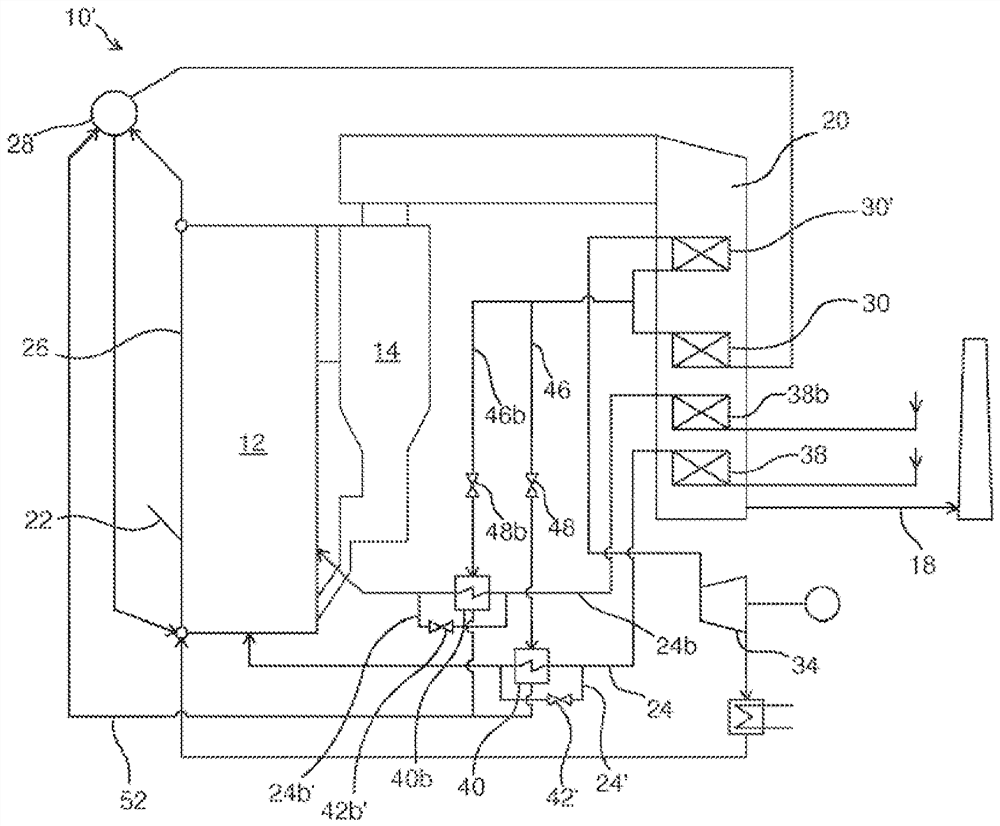

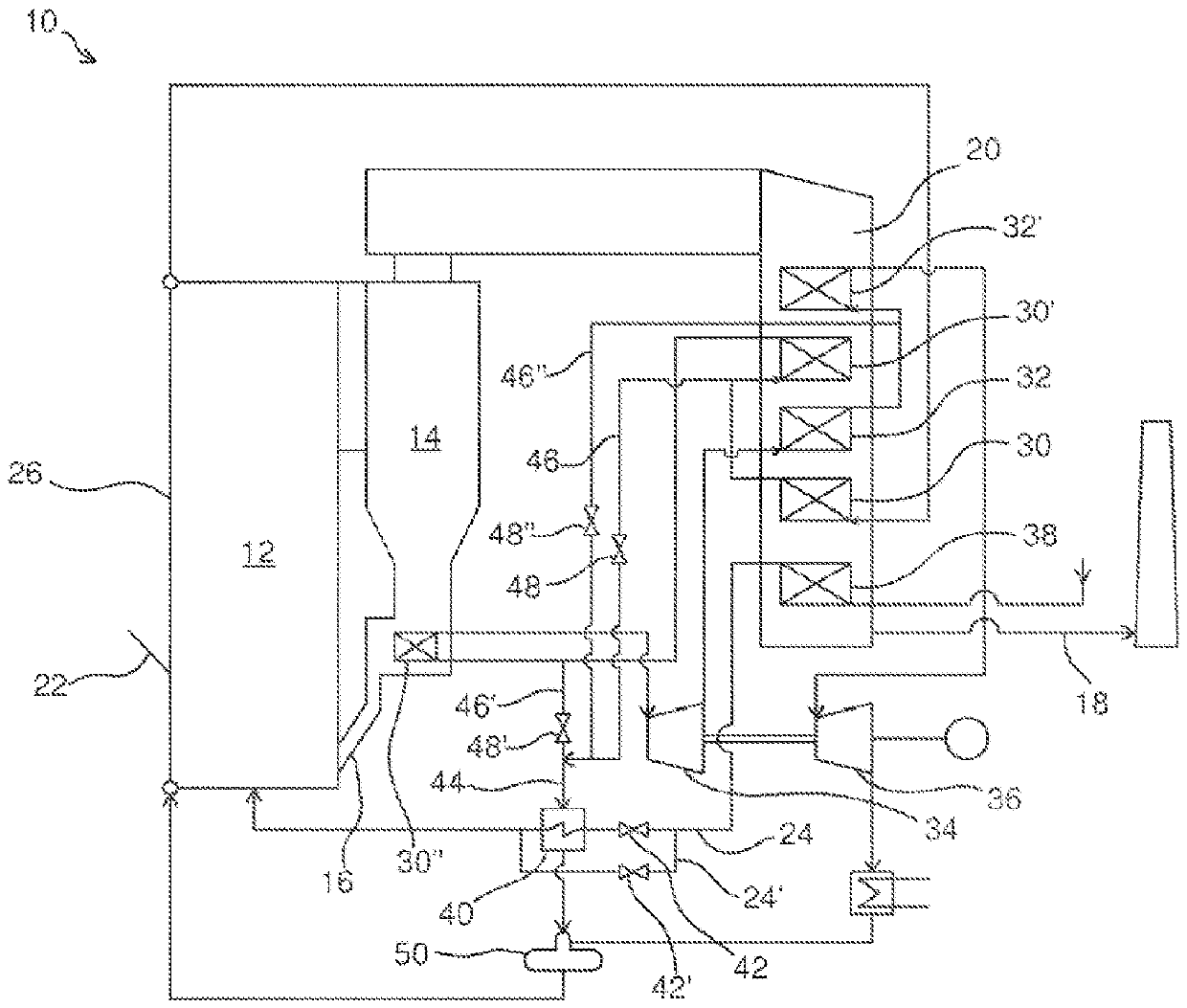

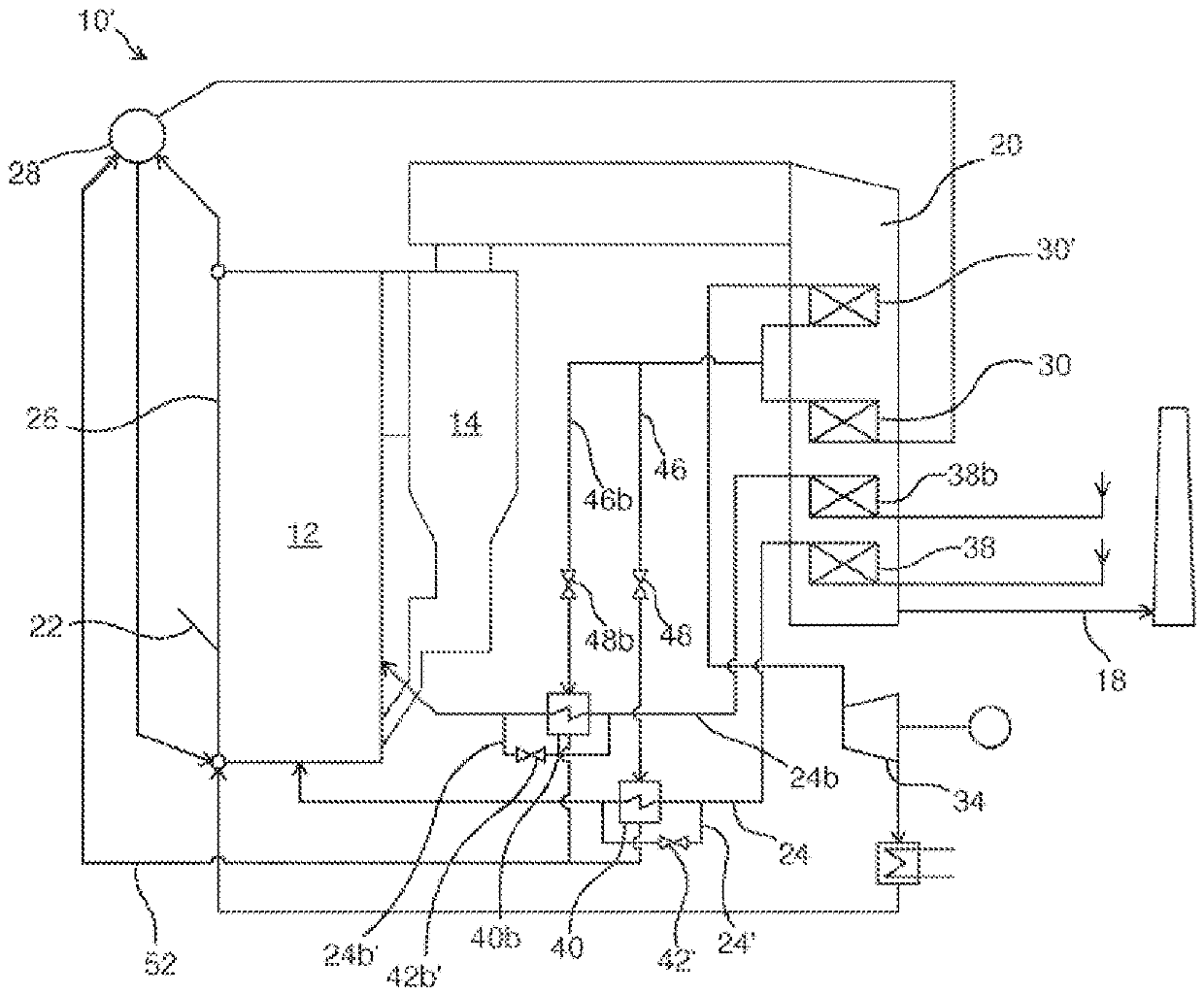

Fluidized bed boiler plant and method for preheating combustion gas in fluidized bed boiler plant

ActiveCN110914594BHigh furnace temperatureLower air factorFluidized bed combustionSteam useCombustionBoiler plant

A fluidized bed boiler plant (10) and a method for preheating combustion gases in a fluidized bed boiler plant comprising a furnace (12) and combustion gas channels (24, 24b), and water-steam cycle, the water-steam cycle includes: an evaporator section (26); a superheater section including a final superheater (30') and a steam turbine (34) and a The evaporator section (26) is delivered via the superheater section to the superheat path of the steam turbine; and a first combustion gas preheater (38, 38b), wherein the fluidized bed boiler plant comprises a second two combustion gas preheaters (40, 40b), and a steam extraction line (46, 46b), said steam extraction line (46, 46b) being located upstream of said last superheater (30') from said first A second combustion gas preheater is attached in flow connection with said superheating path for delivering steam from said superheating path to said second combustion gas preheater (40, 40b), wherein said for The method of preheating combustion gases comprises conveying steam from said superheating path to said second combustion gas preheater (40) via said steam extraction line (46, 46b) from a location upstream of said last superheater , 40b); and transferring heat from the steam to the combustion gas in the second combustion gas preheater.

Owner:住友重机械福惠能源有限公司

Internal combustion locomotive anti-vibration cooling system

PendingCN109139226ALarge thermal expansion and contraction compensation capabilityImprove cooling effectMachines/enginesEngine cooling apparatusPlate heat exchangerCombustion

The invention relates to the technical field of rail train equipment and auxiliary equipment, and discloses an internal combustion locomotive anti-vibration cooling system. The internal combustion locomotive anti-vibration cooling system is characterized by comprising multiple cooling sections, each cooling section comprises a cooling pipe and fins, a liquid inlet and a liquid outlet are formed inthe two ends of each cooling pipe, the cooling pipes penetrate into and are inserted in the fins in a multi-bending manner, the liquid inlets of the cooling pipes and a heat exchanger outlet of an internal combustion machine form abut-joint connectors, liquid outlets of the cooling pipes and a heat exchanger inlet of the internal combustion machine form abut-joint connectors, each abut-joint connector is connected through an anti-vibration unit, the anti-vibration units comprise connecting plates, bolts, springs and flexible pipe joints, , the connecting plates are fixed to the two ends of the abut-joint connectors, the springs are arranged between the connecting plates, connection through the bolts is achieved, the abut-joint connectors are connected through the flexible pipe joints, andthe cooling sections are connected with multiple heat exchangers of the internal combustion machine. Vibration of a locomotive can be buffered and absorbed, and meanwhile, large heat expansion and cold shrinkage compensation capacity is achieved.

Owner:WUXI JINXIN GRP CO LTD

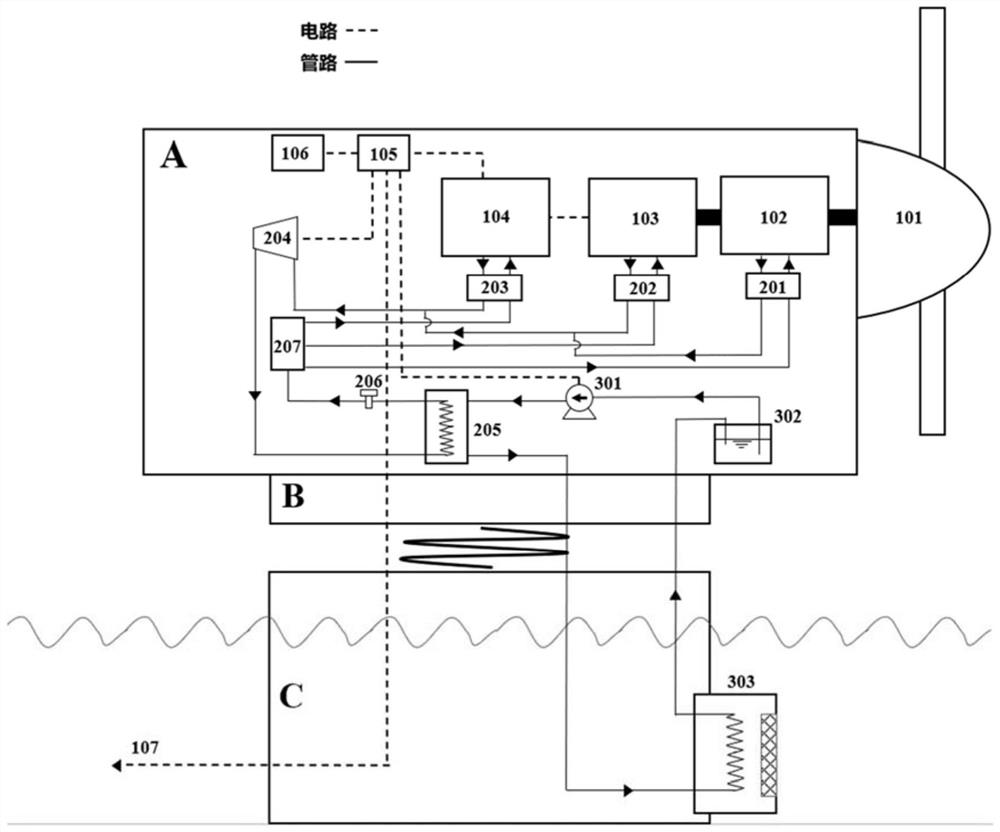

Offshore wind power seawater source heat pump cooling system and method

ActiveCN113915082AAvoid enteringIncrease redundancyWind motor combinationsMachines/enginesThermal dilatationWater source

The invention provides an offshore wind power seawater source heat pump cooling system and a method. A multi-circulation mode is adopted in the system, heat in all heating devices is taken away to a cooling system in a cabin through an evaporation radiator, the cooling system in the cabin efficiently exchanges heat with fluid in the seawater source cooling system in a heat exchanger through heat pump circulation, and the seawater source cooling system exchanges heat with seawater through the heat exchanger; firstly, high-corrosivity seawater is prevented from entering circulating corrosion equipment, and the service life of the equipment is shortened; secondly, different heat exchange fluids can be used in each circulation, so that the heat exchange efficiency is enhanced, and the overall weight is reduced; thirdly, different pressure and circulation modes, such as compression-heat exchange-expansion and the like, can be adopted in each circulation, so that the overall heat exchange efficiency of the system is enhanced; and fourthly, each circulation runs independently, the redundancy is high, and repair and replacement are convenient.

Owner:XIAN THERMAL POWER RES INST CO LTD

Online pollution repellent, heat exchanger equipment and method for tube cluster of cold and heat sources from sewage and surface water

InactiveCN100455972CSolve the problem of not being able to prevent soft dirt onlineIncrease flow rateRotary device cleaningStationary plate conduit assembliesWater sourceEngineering

An on-line pollution proof heat exchange device of cylinder cluster using wasted water and surface water as cooling and heating sources is prepared for connecting outlet and inlet of water source to source water inlet layer of cylinder cluster, connecting inlet and outlet of media to be heated to heat exchange layer of media to be heated, setting brush rod in water source inlet layer and forming cylinder cluster by sheathing a set of cylinders in coaxial and equal lengthy to each other. Its heat exchanging method is also disclosed.

Owner:HARBIN INST OF TECH

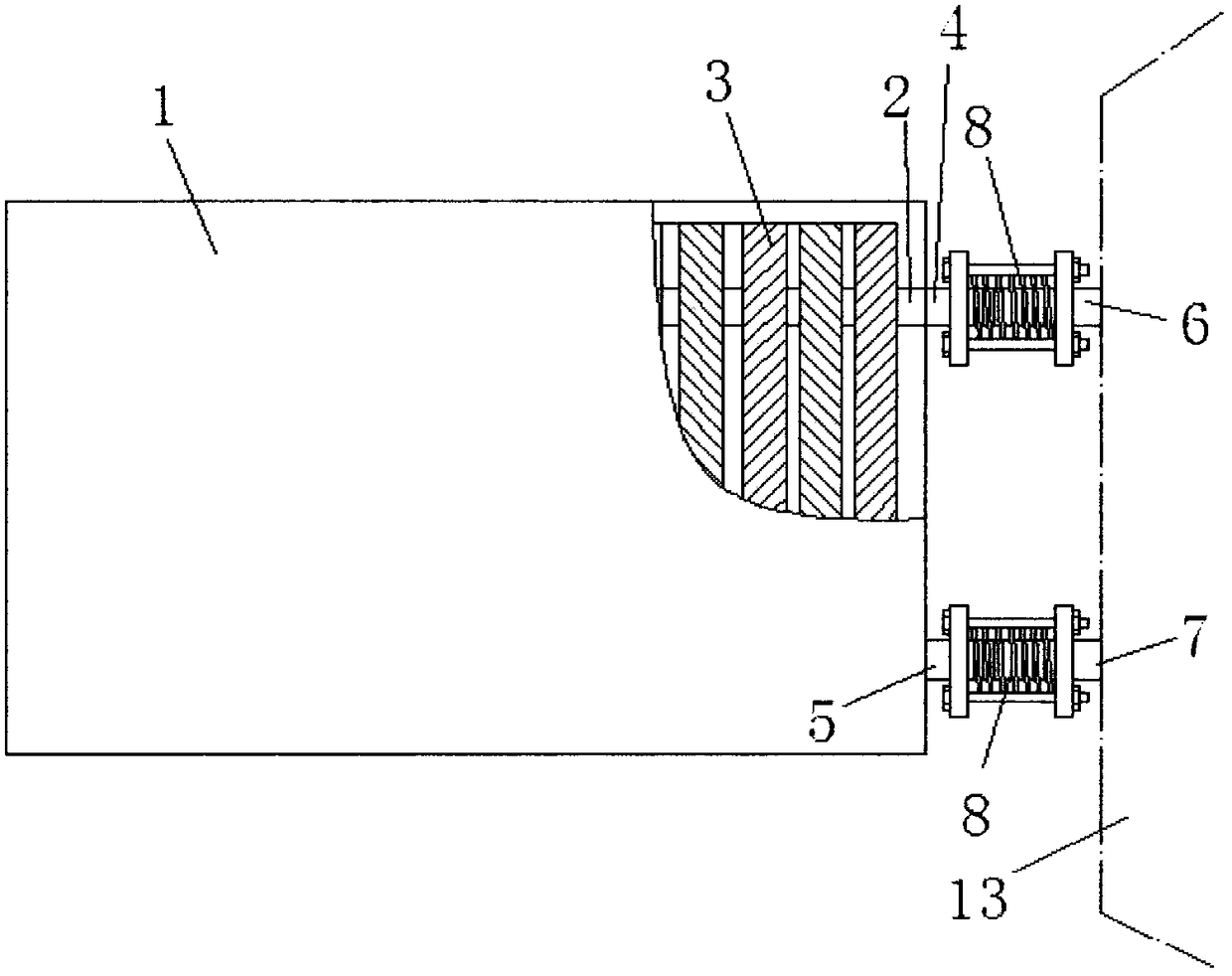

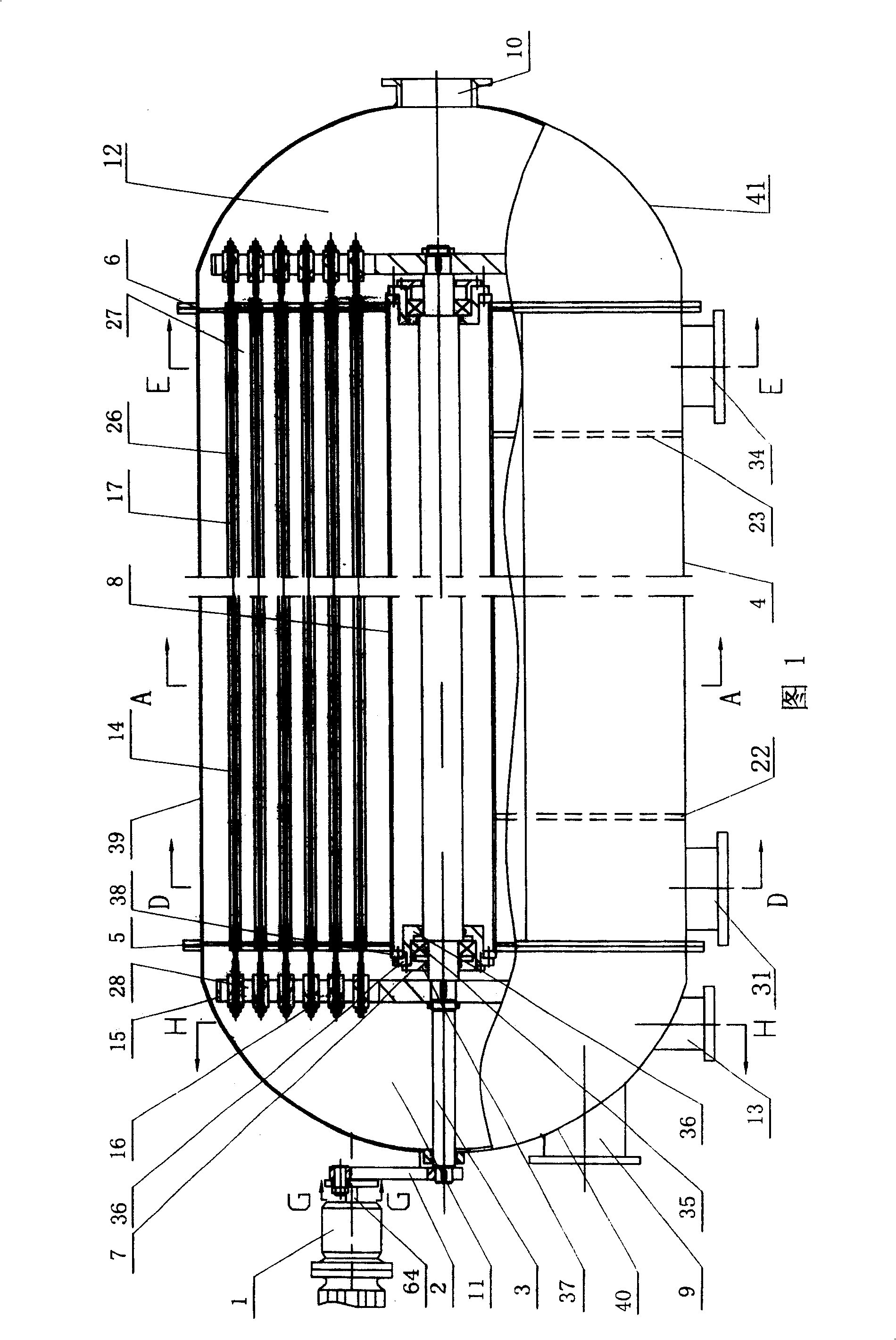

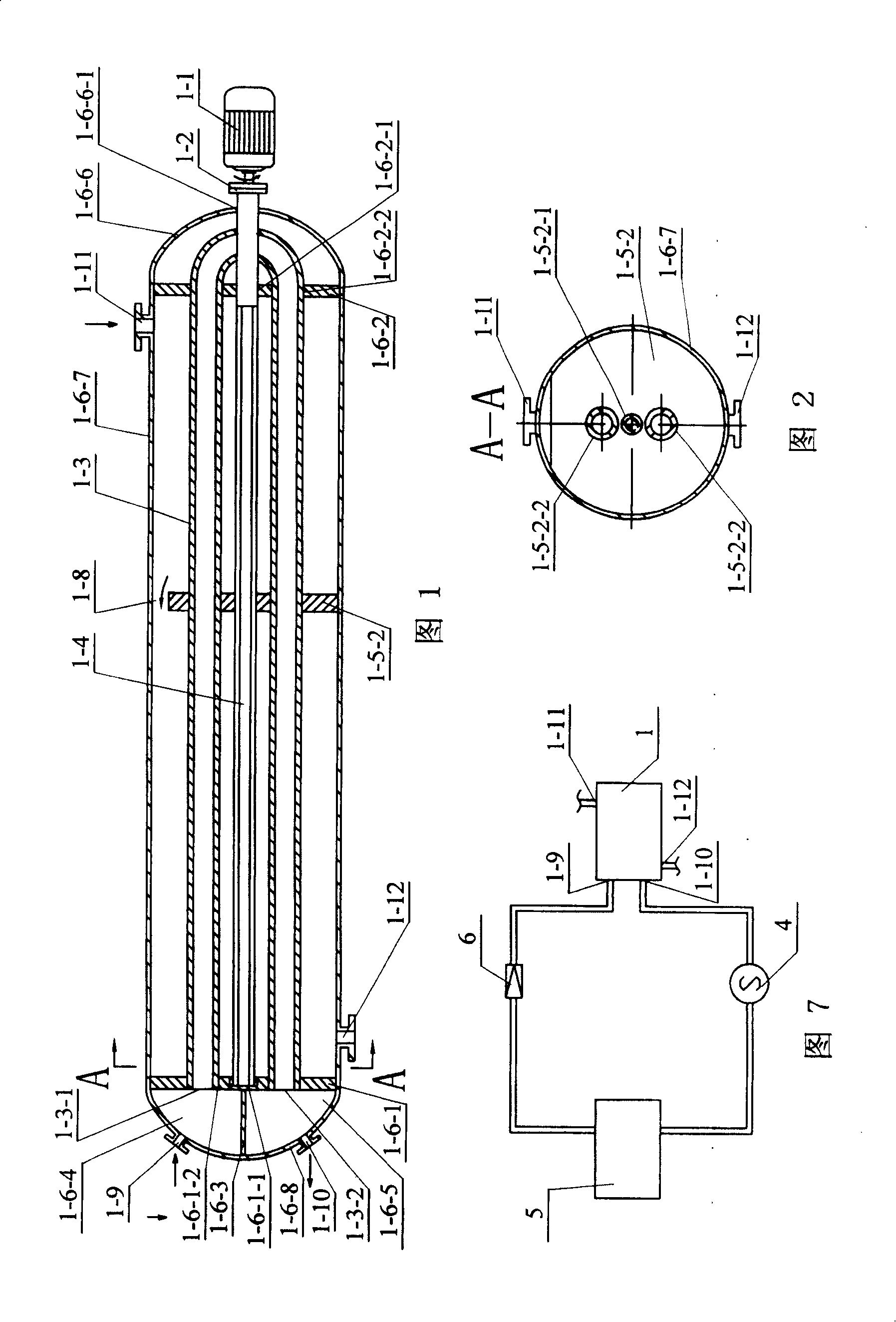

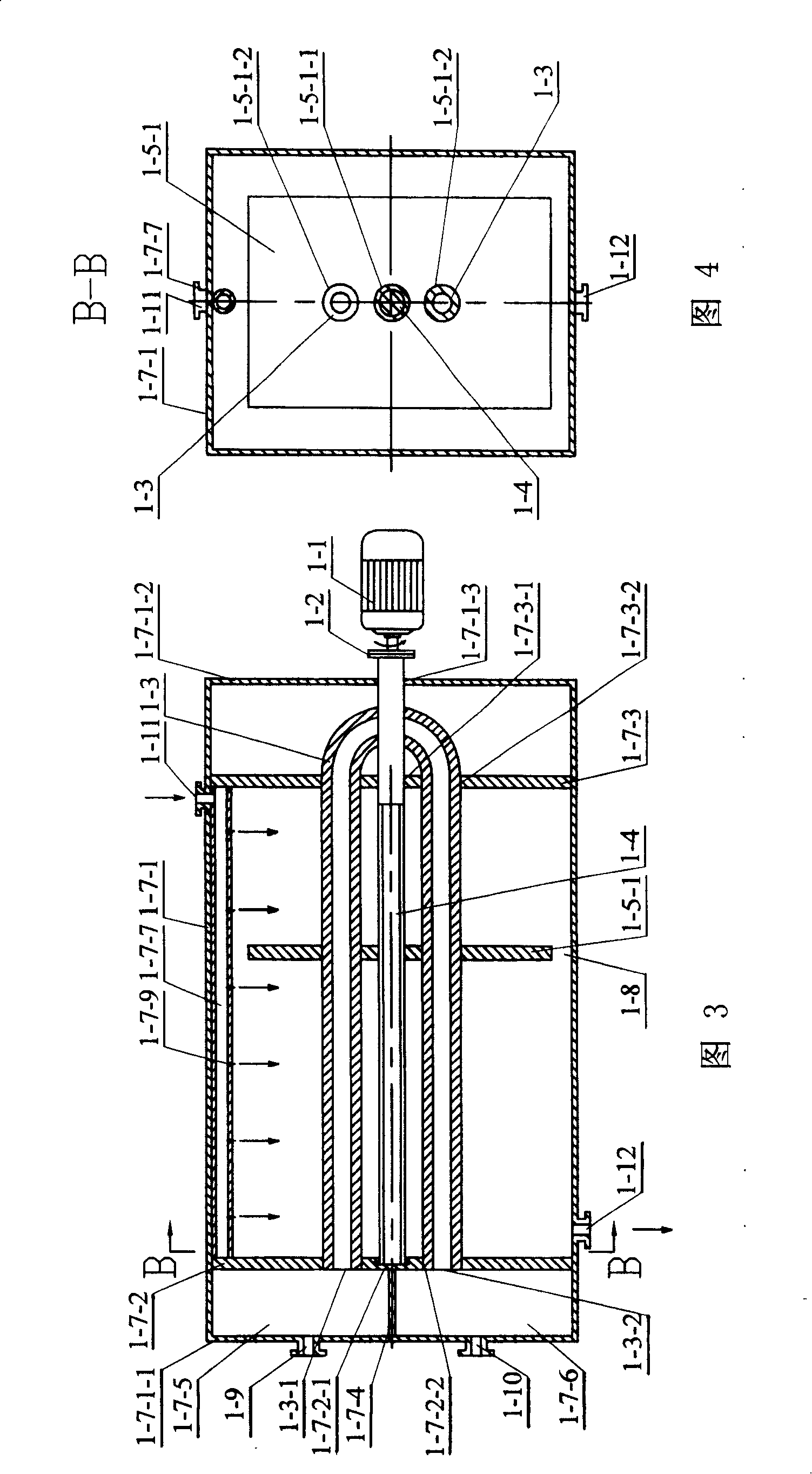

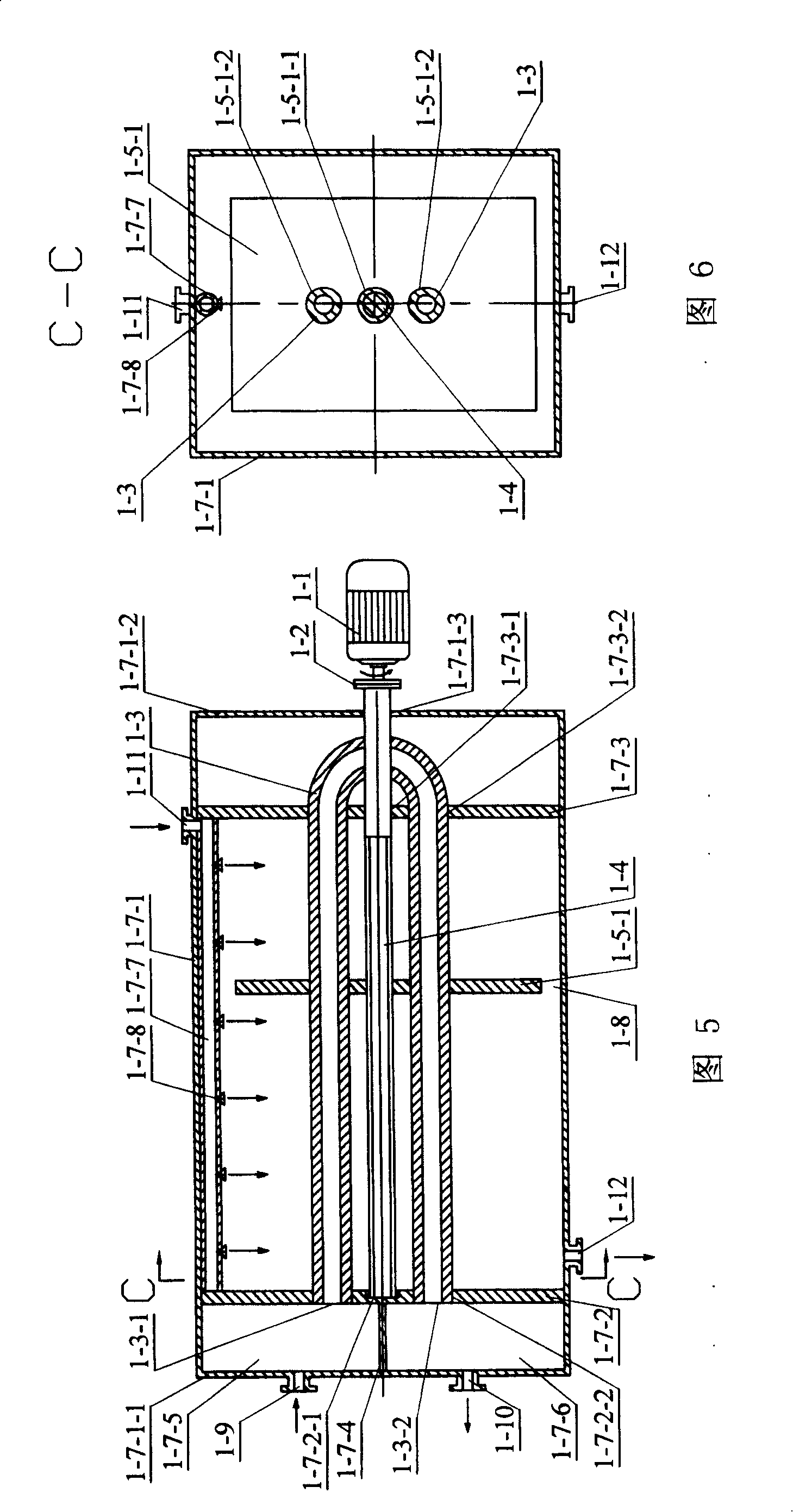

Solidification heat utilization and pollution preventing device for surface water source heat pump

InactiveCN100401001CReduce Auxiliary Power ConsumptionSmall Auxiliary Power ConsumptionHeat pumpsHeat exchanger casingsWater sourceHot melt

The invention relates to a ground water heat pump system solidified heat utilization and anti-pollution device, which can solve the defects of present product that uses the hot melt method with complex process and uses the mechanical vibration to remove ice with large energy consumption. In said invention, one end of screw bolt (1-4) is mounted inside the case along the length of case, while it comprises at least one porous plate connecting the screw of them; another end of screw bolt (1-4) via the speed reducer (1-2) is connected to the motor (1-1) and through the heat exchange pipe inlet (1-3-1) is connected to the heat exchange carrier inlet (1-9) of case, and through the heat exchange outlet (1-3-2) of porous plate is connected to the heat exchange carrier outlet (1-10) of case, while the case has a water inlet (1-11) and a water outlet (1-12). The invention uses the ground water solidified heat to attain ice, uses the oscillating motion of porous plate to remove the ice and dirt, with simple structure, lower cost and high heat exchange efficiency.

Owner:HARBIN INST OF TECH

A fluidized bed boiler plant and a method of preheating combustion gas in a fluidized bed boiler plant

ActiveCN110914594AHigh furnace temperatureLower air factorFluidized bed combustionSteam useCombustionBoiler plant

A fluidized bed boiler plant (10) and a method of preheating combustion gas fluidized bed boiler plant, the boiler plant comprising a furnace (12) and a combustion gas channel (24, 24b), and a water-steam cycle comprising an evaporator section (26), a superheater section comprising a last superheater (30') and a steam turbine (34), and a superheating path for conveying steam from the evaporator section (26) via the superheater section to the steam turbine, and a first combustion gas preheater (38, 38b), wherein the fluidized bed boiler plant comprises a second combustion gas preheater (40, 40b), a steam extraction line (46, 46b) attached in flow connection with the second combustion gas preheater and with the superheating path in a location upstream of the last superheater (30') for conveying steam from the superheating path to the second combustion gas preheater (40, 40b), wherein the method for preheating combustion gas comprises conveying steam from the superheating path from a location upstream of the last superheater via the steam extraction line (46, 46b) to the second combustion gas preheater (40, 40b), and transferring heat from the steam to the combustion gas in the secondcombustion gas preheater.

Owner:住友重机械福惠能源有限公司

Multi-system shared cooling tower for electric locomotive

ActiveCN105197025BImprove cooling effectReduce volumeTransformers/inductances coolingLocomotivesAir filtrationExpansion tank

The invention discloses a cooling tower shared by multiple systems of an electric locomotive, comprising three cooling systems in total, a traction transformer cooling system, a traction converter cooling system, and a train power supply cabinet cooling system, specifically including a top air intake box, a middle box body, a double Axial flow fan, air filter device, three-channel double-flow radiator, bottom bearing frame, water pump, expansion tank, water pipeline, auxiliary oil tank, oil pipeline, electrical connector, gas relay and other components. The present invention adopts the overall matching design method, and the traction transformer, traction converter, and train power supply cabinet cooling system are integrated in the same cooling tower, and on the premise of meeting the heat dissipation requirements of the traction transformer, traction converter, and train power supply cabinet at the same time, it has It has the advantages of compact structure, strong heat dissipation, light weight, small size, low auxiliary power consumption, low noise, convenient use and maintenance, and high reliability.

Owner:CRRC DALIAN INST CO LTD

Water cooling device for permanent magnet direct drive system of urban rail vehicle

PendingCN110843817AGuaranteed heat exchange effectReduce weightLocomotivesPropulsion coolingBogieThermodynamics

The embodiment of the invention discloses a water cooling device for a permanent magnet direct drive system of an urban rail vehicle. The water cooling device comprises a box body frame, wherein the box body frame is provided with a first cooling branch and a second cooling branch in a distributed mode; and the first cooling branch and the second cooling branch are arranged in the box body frame in an axial symmetric mode, and the first cooling branch / the second cooling branch can inhale low-temperature air from the two sides of the box body frame correspondingly, so that cooled cooling liquidflows into the interior of a first bogie permanent magnet direct drive system / a second bogie permanent magnet direct drive system to carry out liquid-cooling heat exchange on the first bogie permanent magnet direct drive system / the second bogie permanent magnet direct drive system while the low-temperature air is blew to a rail after completing the convection heat exchange process with high-temperature cooling liquid flowing out of the first bogie permanent magnet direct drive system / the second bogie permanent magnet direct drive system. According to the water cooling device for the permanentmagnet direct drive system of the urban rail vehicle, the purpose of simultaneously cooling the two permanent magnet direct drive systems is achieved, and meanwhile, the water cooling device integrates a control system so that the auxiliary power loss and noise can be effectively reduced while the water cooling device is protected.

Owner:CRRC DALIAN INST CO LTD

A fuel cell gas flow distribution device and control method

The embodiment of the present invention provides a fuel cell gas flow distribution device and control method, including a mass flow meter for measuring the actual mass flow of the reaction gas in the intake manifold; a booster module for increasing the pressure of the reaction gas in the intake manifold , so that the reaction gas enters the flow distribution module; the general controller is used to send a preset signal to the flow distribution module; the flow distribution module is used to determine the corresponding preset control strategy according to the preset signal, so that the flow distribution module only It communicates with a target intake branch pipe, and reciprocates to inflate each intake branch pipe. In the embodiment of the present invention, the flow distribution module alternately provides reactive gas to each fuel cell stack, realizing the function of simultaneously providing reactive gas to multiple fuel cell stacks through one compressor, and making the auxiliary power of the fuel cell power system Consumption and cost are reduced; the problem of energy loss and waste is solved, and the efficiency of the fuel cell power system is improved.

Owner:CRRC IND INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com