Solidification heat utilization and pollution preventing device for surface water source heat pump

A surface water source heat pump and solidification heat technology, applied in heat pumps, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of high heat energy consumption, large energy consumption, and system instability, and achieve low auxiliary energy consumption, Improve heat transfer efficiency and enhance the effect of water flow disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

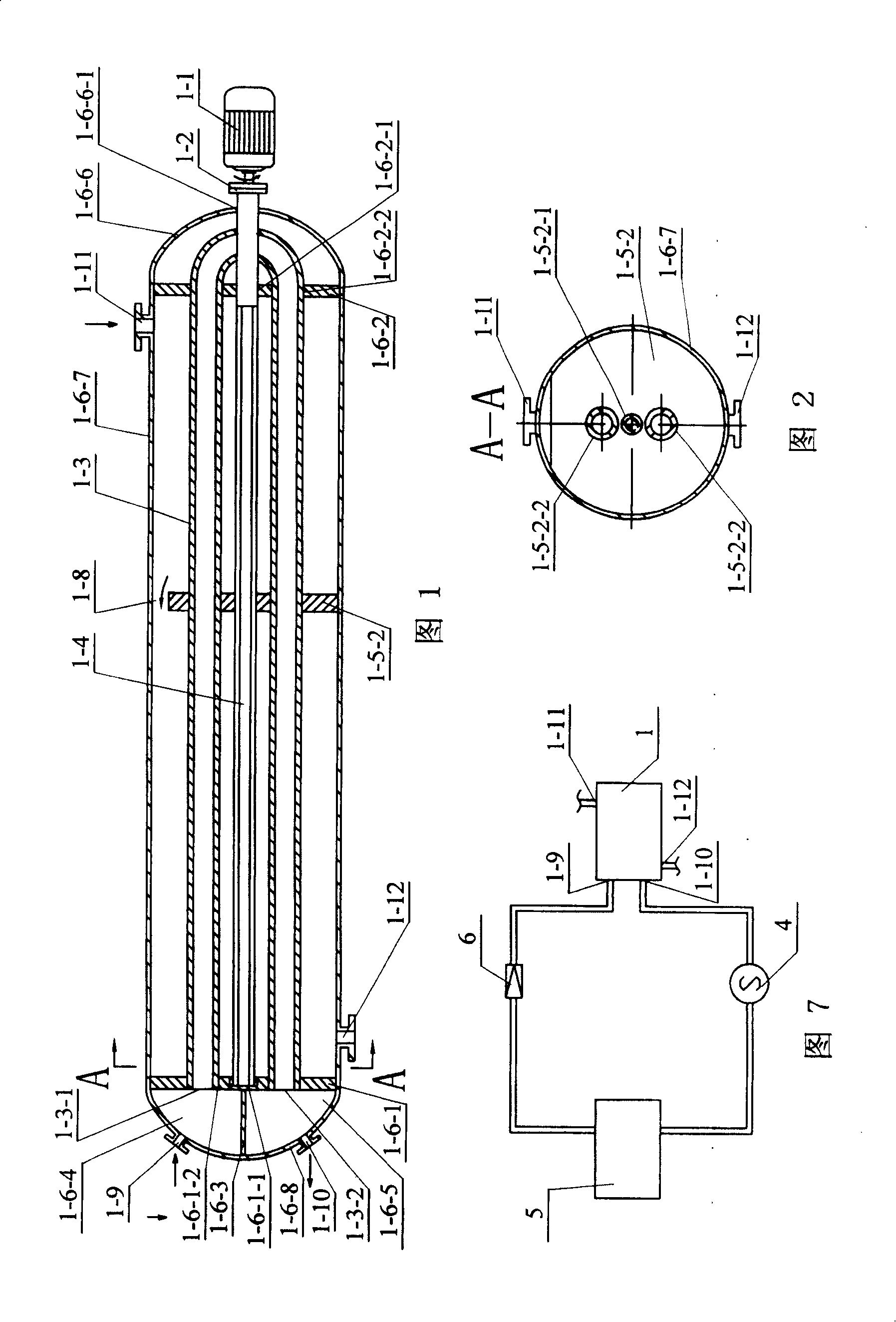

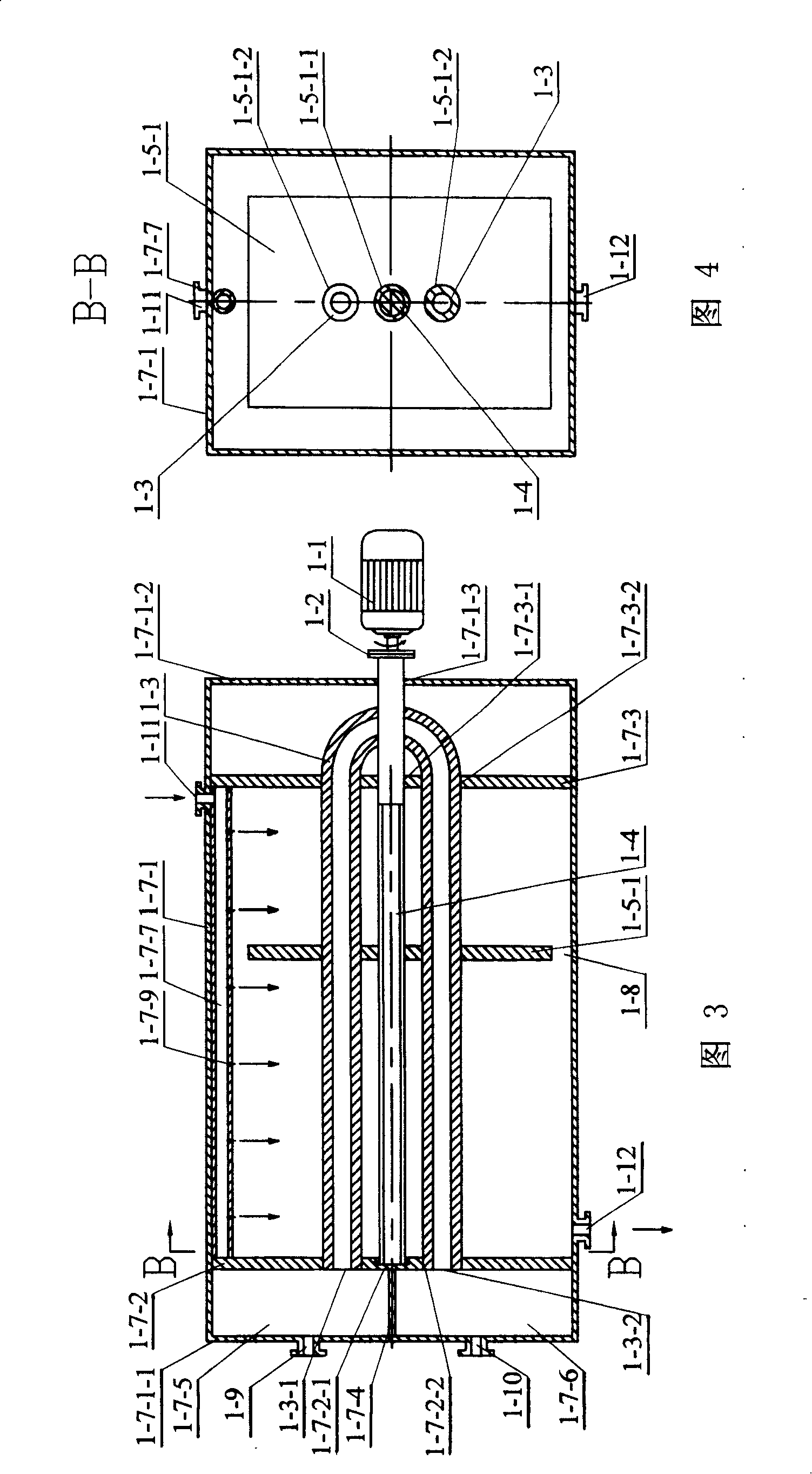

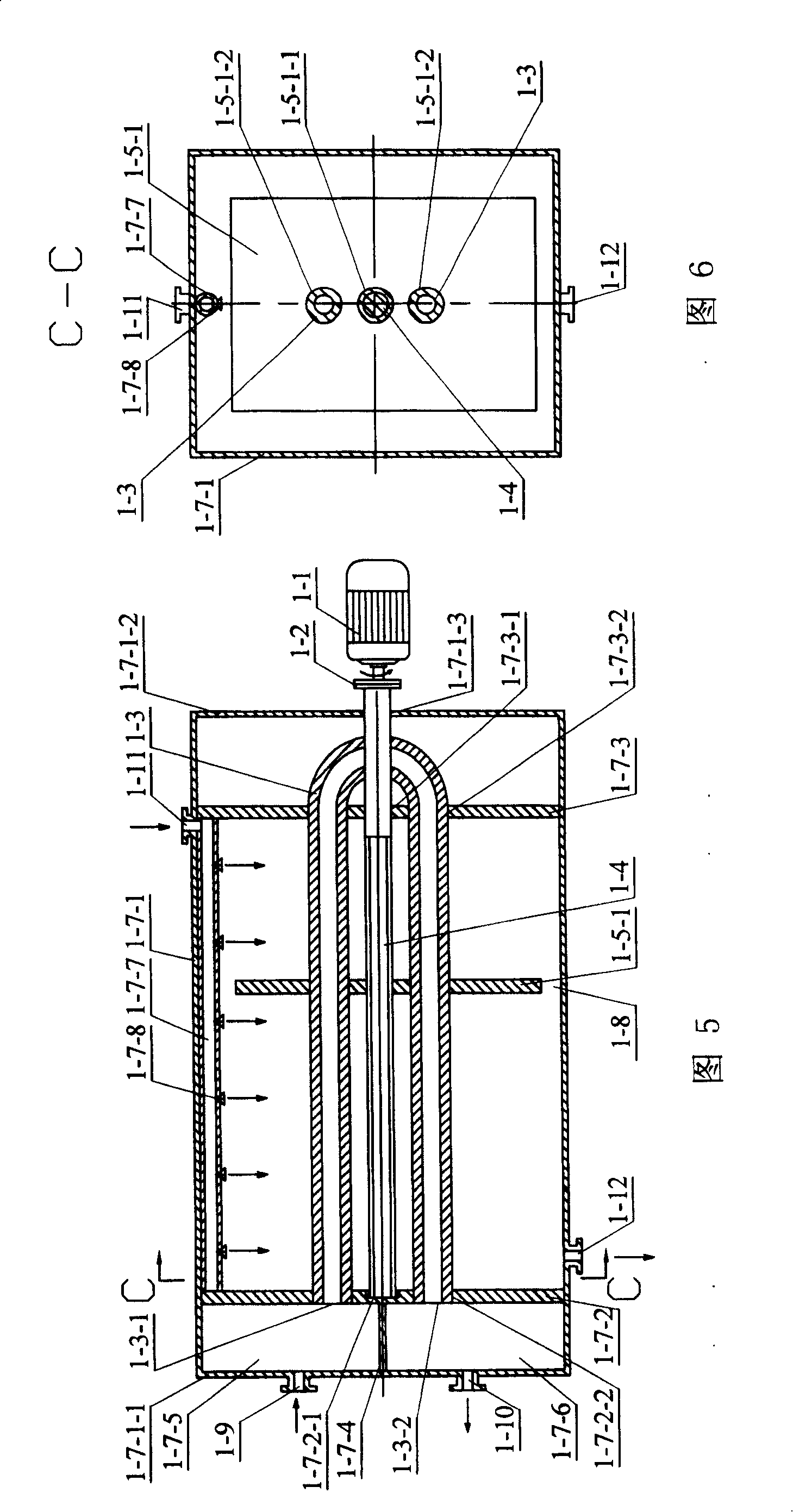

[0008] Specific embodiment 1: Combining Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7 illustrates this embodiment, this embodiment is composed of heat exchanger 1, compressor 4, expansion valve 6, condenser 5; the heat exchanger 1 is composed of a motor 1-1, a reducer 1-2, a heat exchange tube 1-3, a screw 1-4, an orifice plate, and a shell; one end of the screw 1-4 is along the shell The length direction is installed in the shell, the screw 1-4 installed in the shell is equipped with an orifice plate which is threadedly connected with the screw 1-4, and there are water flow channels 1-8 and screw 1-4 between the orifice plate and the inner wall of the shell. The other end is connected to the output shaft of the motor 1-1 through the reducer 1-2, the heat exchange tube inlet 1-3-1 passes through the heat exchange carrier inlet cavity or enters the cavity and the heat exchange carrier inlet 1-9 on the shell The heat exchange tube outlet 1-3-2 is connected to the heat excha...

specific Embodiment approach 2

[0013] Second embodiment: This embodiment will be described with reference to FIG. 11. The difference between this embodiment and the first embodiment is that the screw 1-4 in the housing of this embodiment is equipped with a set of orifice plates that are threadedly connected with the screw 1J. With the above structure, work efficiency can be improved. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: This embodiment will be described with reference to Figure 1, Figure 2, and Figure 11. The difference between this embodiment and the first embodiment is: the case of this embodiment is a cylindrical case; the cylindrical case The body is composed of a cylindrical shell, a first fixed plate 1-6-1, a second fixed plate 1-6-2 and a partition 1-6-3; the cylindrical shell is composed of a cylindrical cylinder 1-6- 7 and the first head 1-6-8 and the second head 1-6-6 welded to the two ends of the cylindrical cylinder 1-6-7 respectively; the first fixed plate 1-6-1 and the second The fixed plates 1-6-2 are respectively installed on the two ends of the cylindrical cylinder 1-6-7 and welded to the inner wall of the cylindrical cylinder 1-6-7. The first fixed plate 1-6-1 is provided with There are concave holes 1-6-1-1, the second fixing plate 1-6-2 is provided with a center hole 1-6-2-1, and the second head 1-6-6 is provided with the center The hole 1-6-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com