A fuel cell gas flow distribution device and control method

A gas flow and flow distribution technology, which is applied in fuel cells, electrical components, circuits, etc., can solve the problems of increased power consumption, fuel cell system power increase, and energy waste, so as to improve efficiency, improve system integration, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

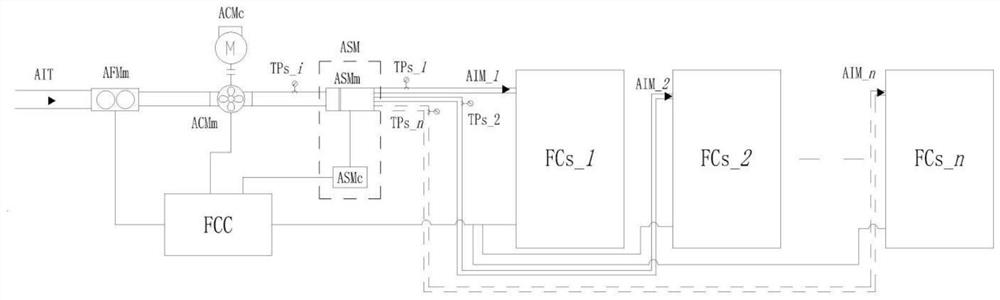

[0105] As mentioned above, the structure of the embodiment of the present invention is obviously different from that of the existing fuel cell power system, and can realize the ability of a single compressor to supply reaction gas to multiple stacks at the same time. The specific implementation method is:

[0106] (1) Under the condition that the external power supply is stable and the hydrogen supply pressure of the fuel cell is normal, the FCc is activated, and the fuel cell power system control unit (i.e. the master controller) starts to work, and the FCc controls the power-on of AFMm, ACMc and ASMc.

[0107] (2) After the ASMc is powered on, first determine the position of the rotating blade CP in the ASMm. If the rotating blade CP is at the preset position, it can ensure that there is no reactive gas remaining in the fuel cell stack and the pipeline of the intake branch pipe. After confirming that the pipeline is in the closed position, ASMc drives ASMm to start working, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com