Modularized cooling device for internal combustion locomotive

A technology for cooling devices and internal combustion locomotives, applied in engine cooling, internal combustion piston engines, liquid cooling, etc., can solve the problems of large space, energy waste, inconvenient maintenance, etc., and achieve the goal of reducing use costs, reducing production costs, and facilitating maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

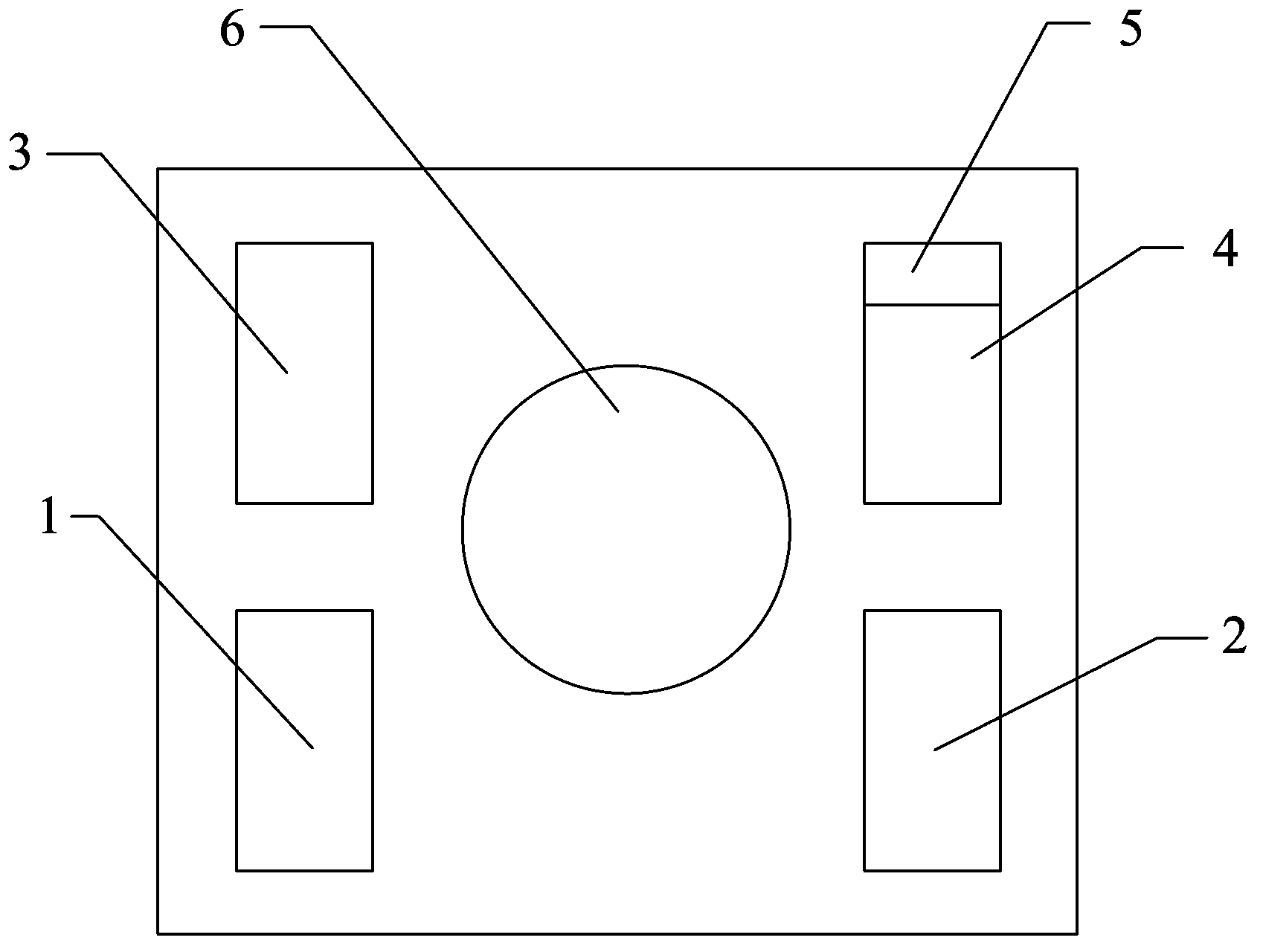

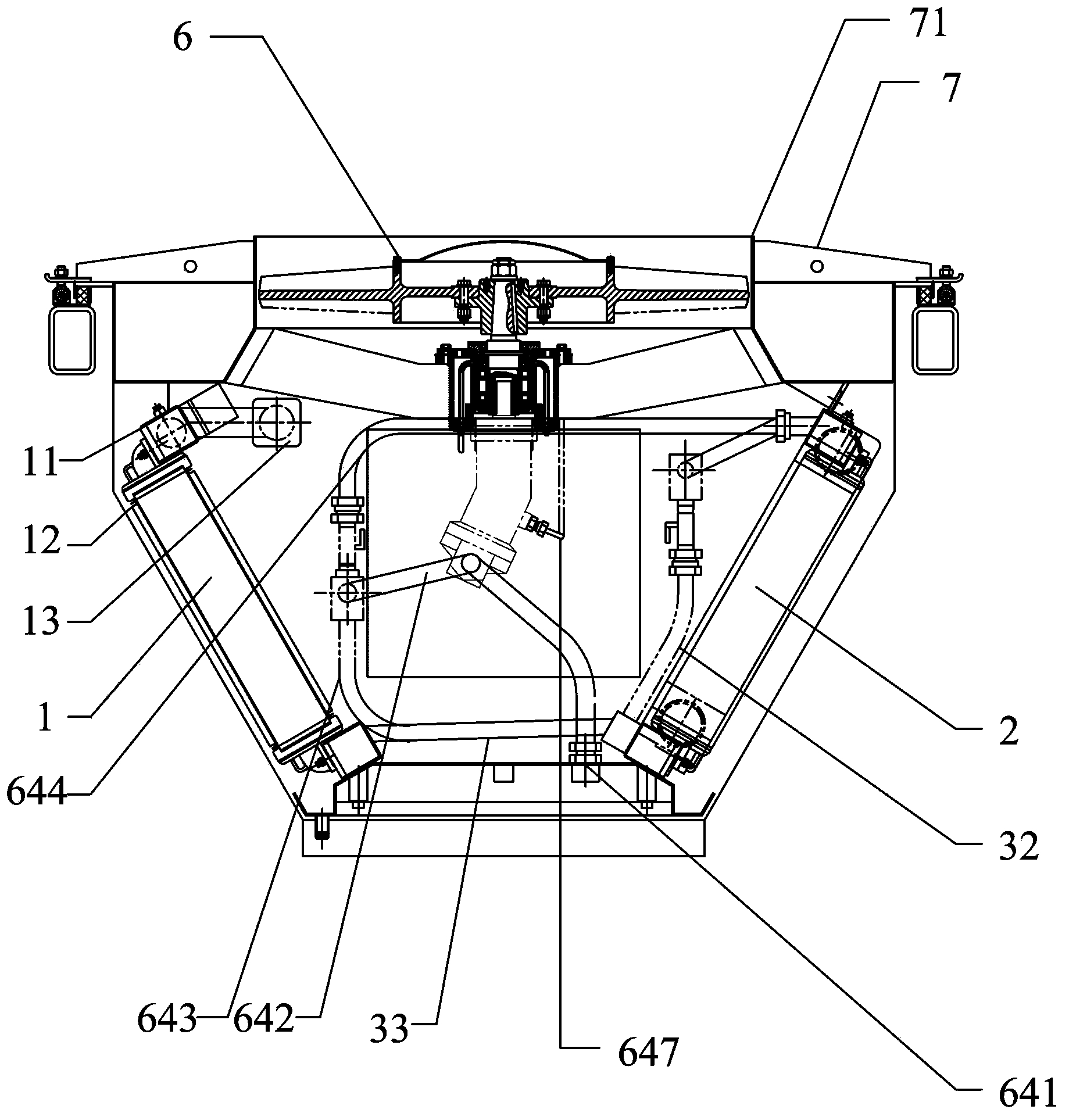

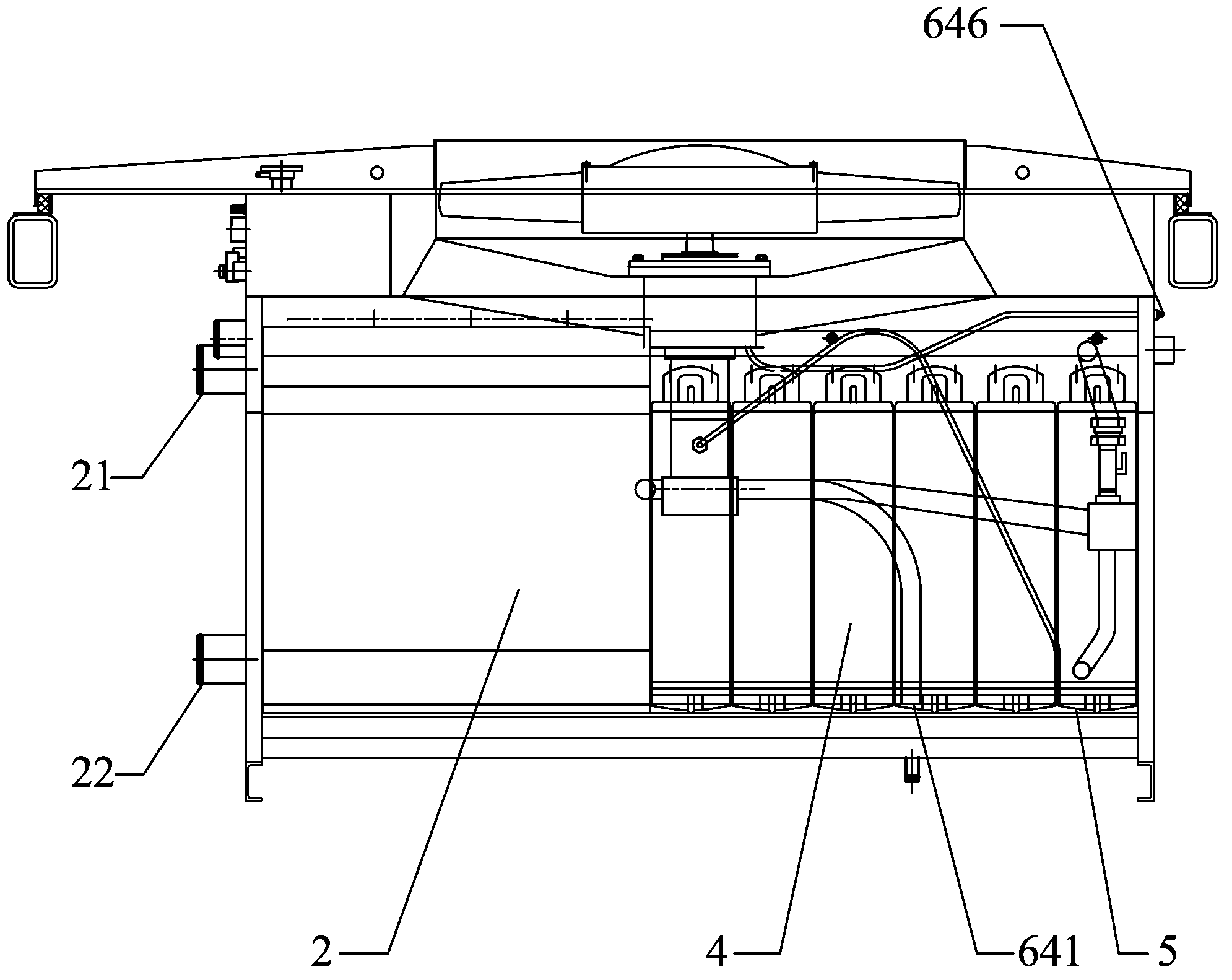

[0034] like figure 1 As shown, a modular cooling device for a diesel locomotive includes a water cooling system 1, a charge air cooling system 2, a transmission oil cooling system, a static pressure oil cooling system 5, a fan unit 6 and a steel frame 7. like figure 2 As shown, the steel frame 7 is composed of a fan frame and a cooling device installation frame fixed at the lower end of the fan frame. , the fan unit 6 is arranged in the air cylinder 71, the fan unit 6 (such as Figure 5 shown) includes a fan cover 61 arranged above the impeller 62, a bearing box 63 with a bearing sleeve arranged below the impeller 62, and a motor 64 arranged below the bearing box 63, and the lower end of the motor 64 communicates with a motor inlet Oil pipe 641, motor oil outlet pipe I 642, motor oil outlet pipe II 643, motor oil outlet pipe III 644 and motor oil outlet pipe IV 645, the upper end of the motor 64 is also connected with a lubricating oil inlet pipe 646 and a motor oil drain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com