Segment-type microcirculation radiator and microcirculation heat exchange system

A radiator and fin-type technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problem that the radiator cannot meet the heat dissipation requirements, and achieve auxiliary power saving, convenient installation, The effect of increasing the secondary heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

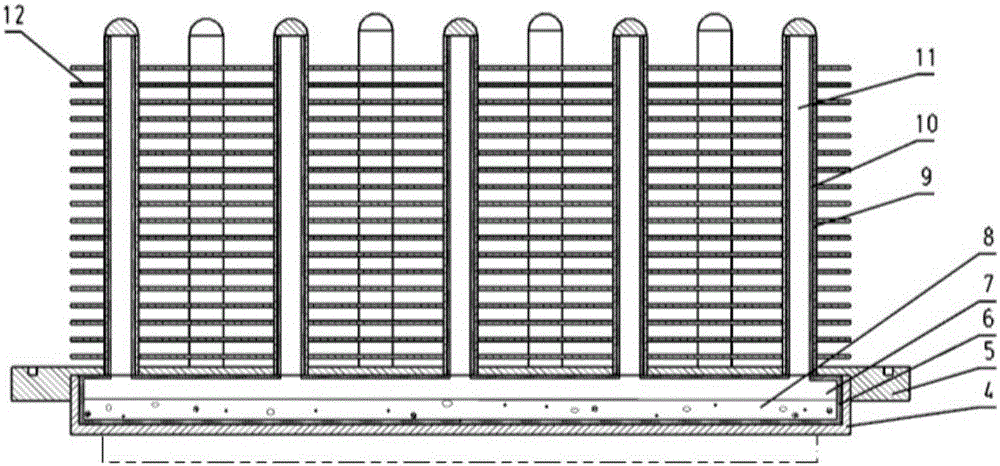

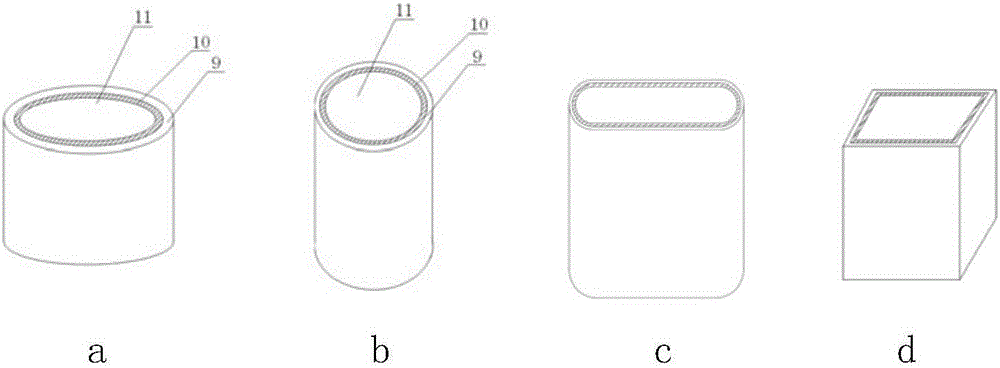

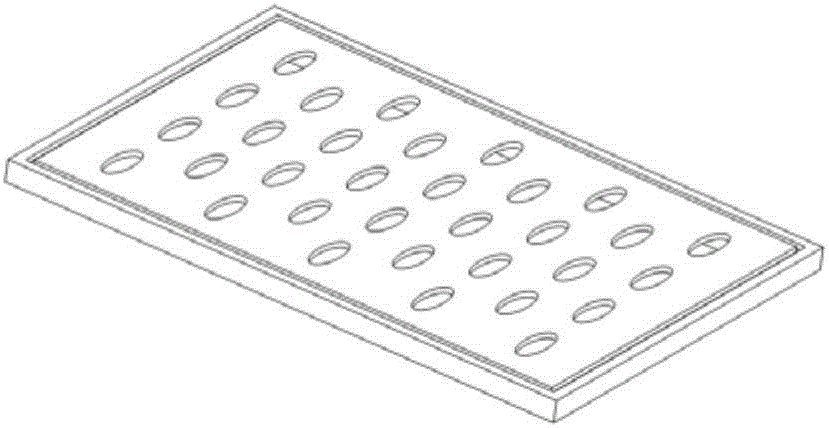

[0040] Such as Figure 1 to Figure 3 As shown, a tube-fin microcirculation radiator includes a heat source module mounting plate 4 for installing a heat source module 3, a radiator mounting plate 5 and a heat dissipation assembly, and the heat source module mounting plate 4 and the radiator mounting plate 5 are fixed to each other And the main working medium cavity 7 for accommodating the working medium 8 is formed inside. The heat dissipation assembly includes a plurality of heat dissipation fins 12 stacked at a certain distance and a microcirculation heat dissipation module 9 penetrating in the heat dissipation fins 12. The microcirculation heat dissipation module 9 is a tubular structure with one end open and one end closed. The inside of the microcirculation dispersion module 9 is a division cavity 11. The radiator mounting plate 5 is provided with an installation port. The opening end of the microcirculation dispersion module 9 Installed at the installation opening on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com