Hollow thin-walled pier internal mold bolt ejection removal technology

A hollow thin-walled and bolted technology, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of difficult installation and dismantling of hollow thin-walled piers, easy knocking of concrete, easy deformation of formwork, etc., so as to improve the appearance. Quality and forming accuracy, saving labor and materials, easy fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

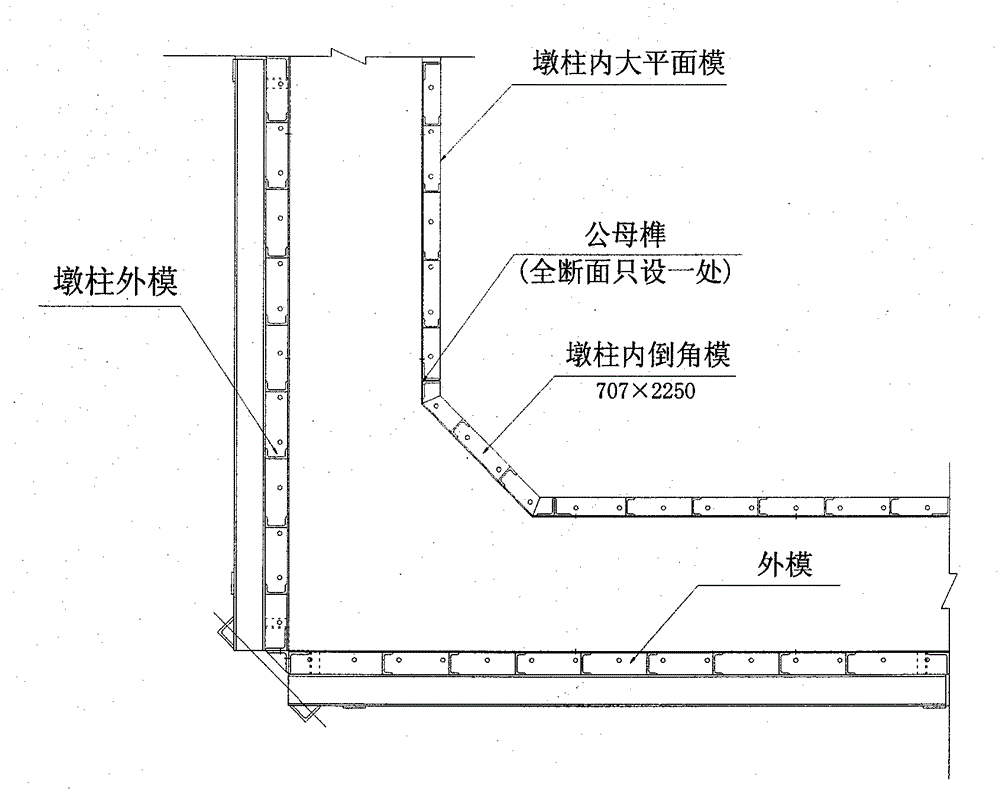

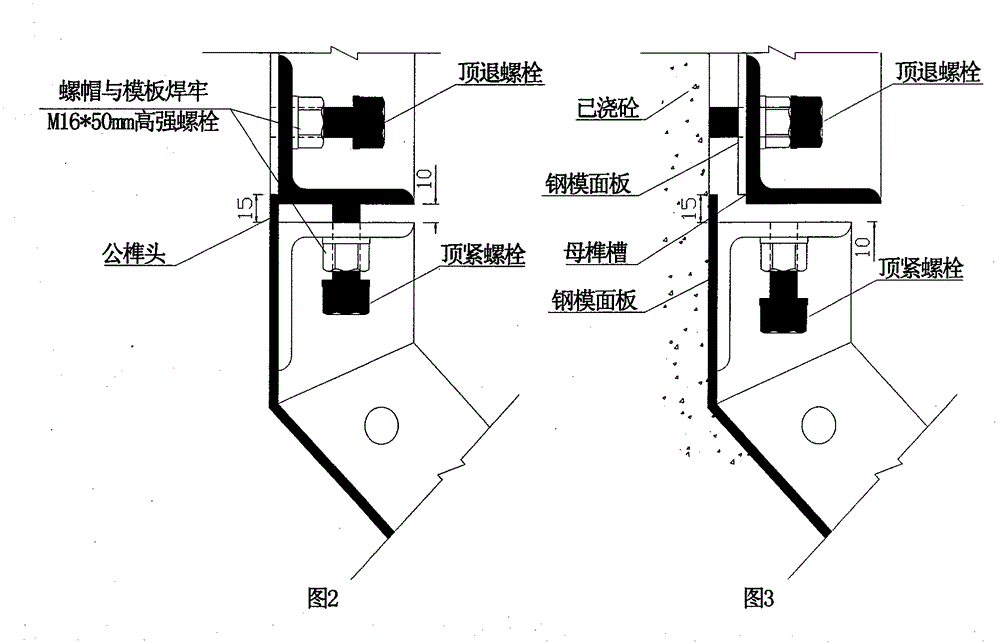

[0014] Template design: The male and female tenons are set on two templates at a chamfer of the inner mold, the male tenon is set on the chamfering template, the length of the male tenon is 15mm, and the female tenon is set on the large plane mold, and the depth of the female tenon is 5mm. The jacking bolts are set on the vertical frame of the female tenon formwork with a spacing of 600mm, and the jacking bolts are set between the vertical seam connecting bolts on the vertical frame of the male tenon formwork with a spacing of 400mm. The vertical frame of the two templates of the male and female tenon is installed The spacing is 10mm, and the vertical seam connection bolts at the male and female tenons are consistent with other vertical seams.

[0015] Installation: Back off the bolts to flatten the formwork surface, and stick transparent tape on the contact between the formwork surface and the bolts to prevent slurry leakage; tighten the jacking bolts and vertical seam connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com