Fluidized bed boiler plant and method for preheating combustion gas in fluidized bed boiler plant

A technology of fluidized bed boiler and combustion gas, which is applied in the field of fluidized bed boiler equipment and preheating combustion gas in fluidized bed boiler equipment, and can solve problems such as increasing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

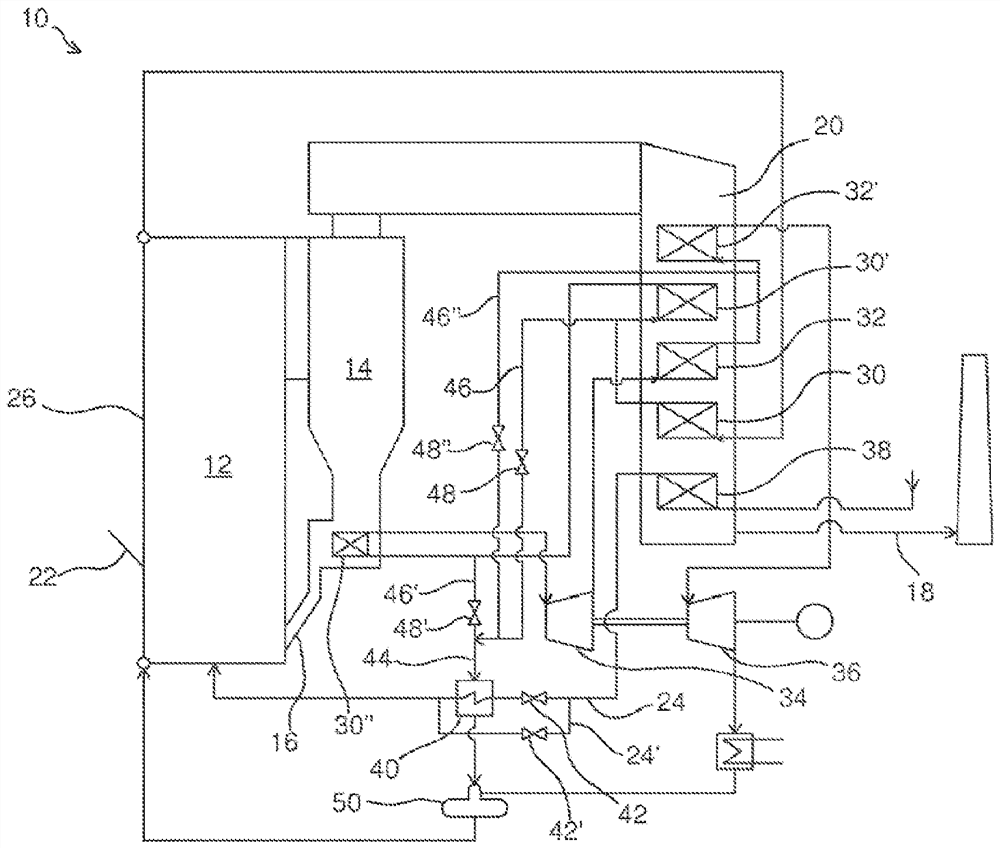

[0021] figure 1 The diagram in the diagram schematically shows a fluidized bed boiler plant 10 according to a preferred embodiment of the present invention, said boiler plant comprising a furnace 12, a cyclone separator 14 with a return leg 16 and a heat recovery zone 20 Flue gas channel 18 . A feeder 22 for feeding fuel to the furnace and a combustion gas channel 24 for feeding combustion gas, such as air or other oxygen-containing gas, to combust the fuel and fluidized bed particles in the furnace are connected to the lower part of the furnace. Furnace and boiler plants also include many other conventional elements, such as means for feeding sulfur binder or inert bed particles to the furnace, fans for conveying flue gas and combustion gases, and equipment for cleaning the flue gas, However, these elements are not shown in the figure 1 , as it is irrelevant to the present invention.

[0022] Steam is generated in a once-through boiler plant 10 in a water-steam cycle compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com