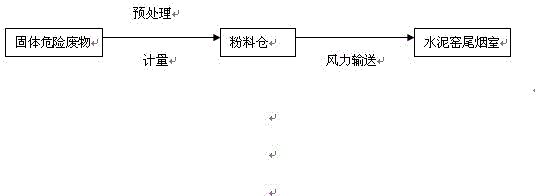

Cement kiln co-processing process for hazardous solid wastes

A hazardous waste and co-processing technology, which is applied in the direction of cement production and waste content reduction, can solve the problems of inability to dispose of dioxin, occupy land resources, and secondary pollution of waste gas, and achieve resource saving and significant economic benefits. The effect of high temperature and large amount of material to be processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Incineration fly ash from a grate furnace of a municipal solid waste incineration plant, Cl - The content is 8.94%, Al 2 o 3 , CaO, SiO 2 , the contents were 9.56%, 19.11%, and 25.98% respectively, accounting for 54.65% of the total. The composition of the incineration fly ash is similar to that of shale, the raw material for cement production, so it can replace part of shale to burn cement and save the amount of shale used.

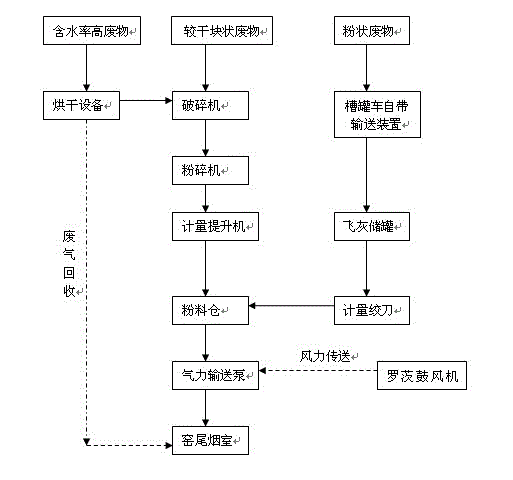

[0028]The incineration fly ash produced by the domestic waste incineration plant is transported to the cement plant by a tank truck, and then the fly ash is transported to the fly ash storage tank by the pneumatic conveying device attached to the tank truck. According to the ratio of cement plant raw materials and incineration fly ash to replace cement raw materials by 0.5%, adjust the transmission rate of the metering screw cutter scale to 0.83 tons / hour, and the measured incineration fly ash is transported to the powder silo through the meter...

Embodiment 2

[0030] In the polluted soil of an urban chemical plant, the total Cl content is 0.329%, and the main components of the contaminated soil are 76.77% Si, 11.53% Al, 4.38% Fe, 2.68% Ca, and 1.23% Mg, accounting for the total 96.59%. Among them, Si and Ca components are the main components in cement production raw materials, so they can replace part of cement production raw materials to burn cement and save cement raw materials.

[0031] After the polluted soil arrives at the factory, it is conveyed to the drying equipment through a closed conveyor belt for drying treatment. The waste gas generated during the drying process is collected by the waste gas collection device and then transported to the tail smoke chamber of the cement kiln for treatment through a closed pipeline. After the sludge is discharged, it directly enters the crusher for crushing, and the crushed polluted soil enters the crusher for crushing. The polluted soil crushed into powder is replaced by 4% of the ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com