A plate-fin microcirculation radiator and a microcirculation heat exchange system

A radiator and plate-fin technology, applied in the field of plate-fin microcirculation radiators and microcirculation heat exchange systems, can solve the problem that the radiator cannot meet the heat dissipation requirements, and achieve the effects of saving auxiliary power, convenient installation and pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

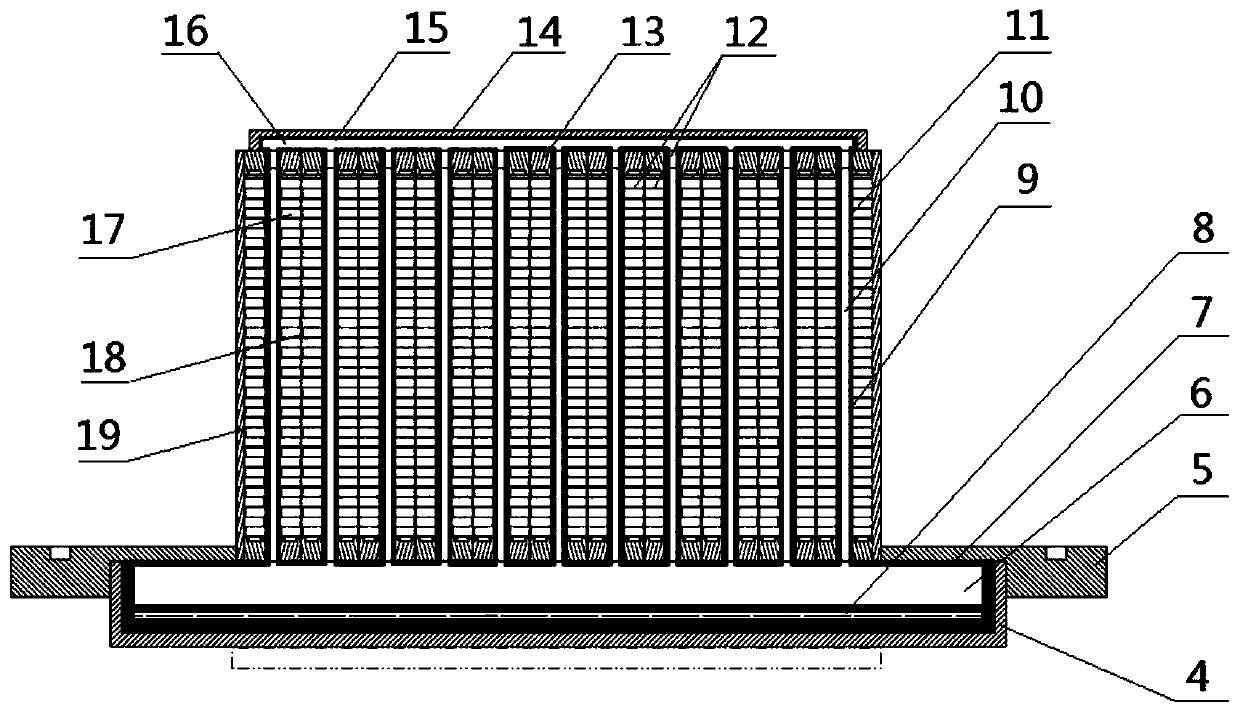

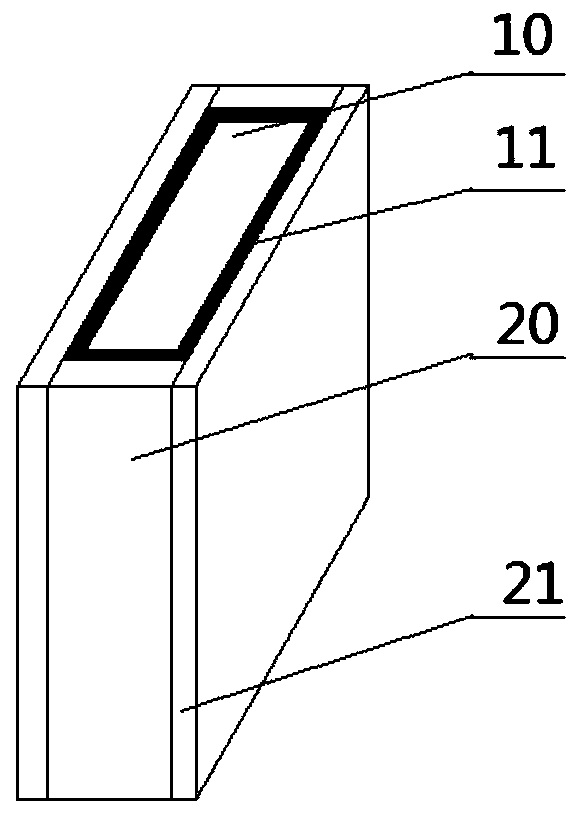

[0037] Such as figure 1 and figure 2 As shown, a plate-fin microcirculation radiator includes a heat source module mounting plate 4 for installing a heat source module 3, a radiator mounting plate 5 and a heat dissipation assembly, and the heat source module mounting plate 4 and the radiator mounting plate 5 are fixed to each other And the main working medium cavity 6 for accommodating the working medium 8 is formed inside. The heat dissipation assembly is installed on the radiator mounting plate 5. The heat dissipation assembly includes microcirculation heat dissipation modules 9 and cooling air passages 17 arranged at intervals. The microcirculation heat dissipation module 9 includes two partitions 21 and the division mass cavity seal 20 arranged at the two ends of the partition 21, the partition 21 and the division mass cavity seal 20 surround the division mass cavity 10 on all sides, and the cooling air channel 17 There are heat dissipation fins 12 inside, and the divisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com