Method and device for preparing fluidized ice slurry with disc type double-sided scraped-surface heat exchanger

A heat exchanger and fluidization technology, which is applied in the field of making fluidized ice slurry by a butterfly double-sided scraped surface heat exchanger, can solve the problems of design and manufacturing difficulties, large heat exchanger volume, and increased manufacturing costs. , to achieve the effect of eliminating ice blockage, improving heat transfer effect and reducing auxiliary energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

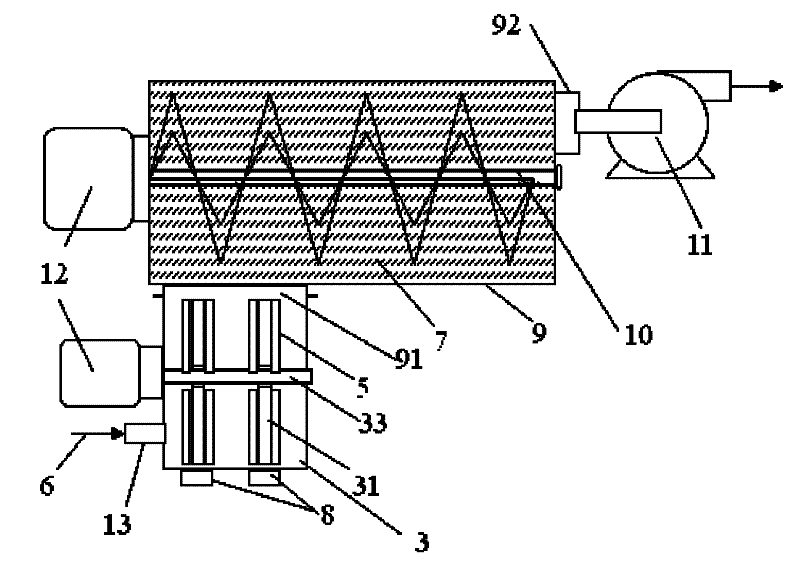

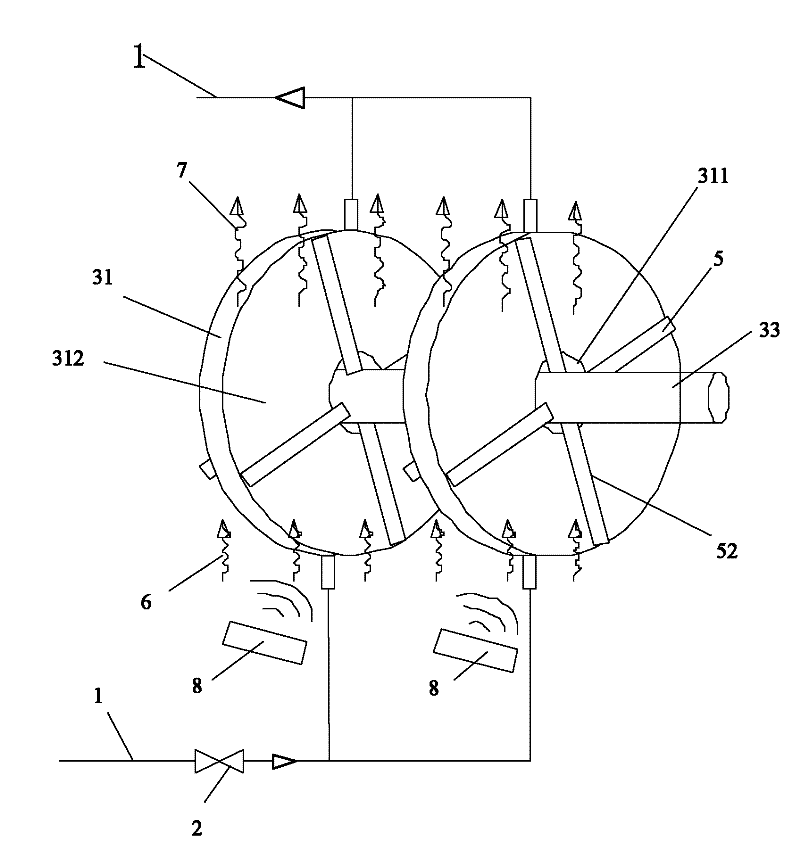

[0050] Example 1 of a device for preparing fluidized ice slurry using a dish-type double-sided scraped surface heat exchanger of the present invention is as figure 1 with figure 2 As shown, it includes a dish-type double-sided scraped surface heat exchanger 3, an ice crystal ripening device 9 and a delivery pump 11. The ice crystal ripening device 9 is located above the scraped surface heat exchanger 3, and the inlet 91 of the ice crystal ripening device 9 It is connected to the scraped surface heat exchanger 3, and the discharge port 92 of the ice crystal ripening device 9 is connected to the delivery pump 11. The scraped surface heat exchanger 3 includes a refrigerating disc 31, a scraper 5 and a rotating shaft 33. The refrigerating disc 31 is opened in the middle. Through the perforation 311, the rotating shaft 33 passes through the perforation 311 vertically. The refrigerating disc 31 includes two refrigerating surfaces 312. Both sides of the refrigerating surface are provid...

Embodiment 2

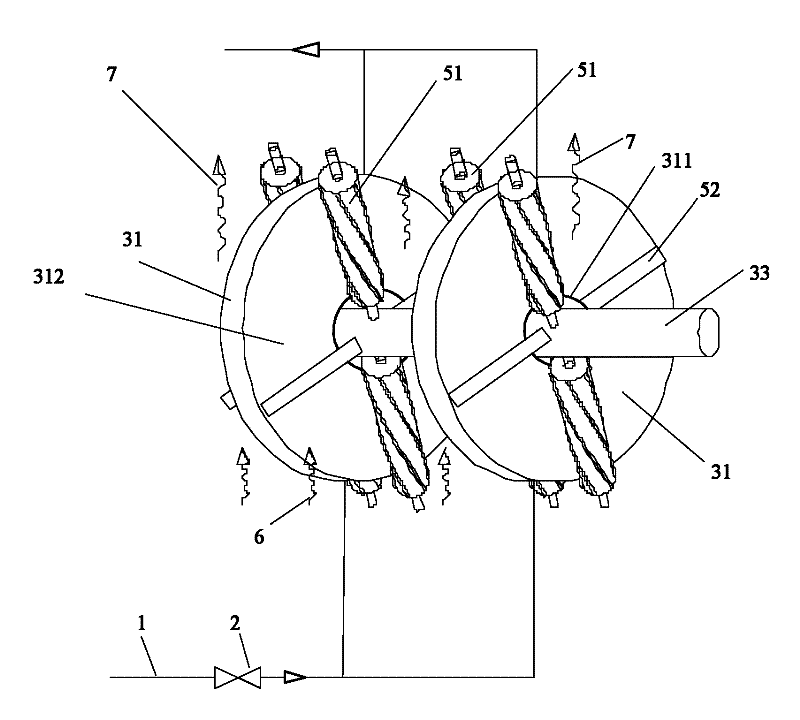

[0063] Example 2 of a device for preparing fluidized ice slurry using a dish-type double-sided scraped surface heat exchanger of the present invention is as image 3 with Figure 4 As shown, the difference from Embodiment 1 is that the scraper 5 is composed of a plurality of spiral blade hobs 51 and a straight blade 52. Specifically, the shape of the blade 511 of the spiral blade hob 51 is composed of forward and reverse threads. The distance between the blade 51 of the spiral blade hob and the cooling surface 312 is 0.4-0.8 mm.

[0064] When the cooled water is an aqueous solution, the ice crystals formed in the aqueous solution are usually agglomerated by a large number of dendritic crystals, which are relatively soft and easy to scrape off; when the cooled pure water is pure water, the ice crystals formed in the water are usually brittle and hard , Stronger adhesion to the cooling surface 312, relatively harder to scratch

[0065] drop. Therefore, a scraper 5 composed of a spi...

Embodiment 3

[0068] A method for preparing fluidized ice slurry using a device for preparing fluidized ice slurry using a dish-type double-sided scraped surface heat exchanger of the present invention, such as Figure 1 to Figure 4 As shown, it includes the following steps:

[0069] Step A: Pass the refrigerant 1 into the refrigerating disc of the scraped surface heat exchanger, and the cooled water or aqueous solution 6 forms ice crystals on the two refrigerating surfaces 312 of the refrigerating disc 31, and the ice crystals are attached to the refrigerating surface 312 up;

[0070] Step B: The rotating shaft 33 drives the scraper 5 to rotate, and at the same time the ultrasonic transducer 8 is activated to generate ultrasonic vibration and act on the cooled water or aqueous solution 6 and the refrigerating disc 31, and the scraper 5 scrapes off the ice crystals on the refrigerating surface 312;

[0071] Step C: The scraped ice crystals float up to the entrance 91 of the ice crystal riper 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com