Heat exchange module for locomotive

A technology for heat exchange modules and locomotives, which is applied to locomotives, etc., can solve the problems of locomotives with large total space, high total auxiliary power consumption, and uncompact structure, and achieve the goals of prolonging the maintenance cycle, compact structure, and reducing maintenance and operation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

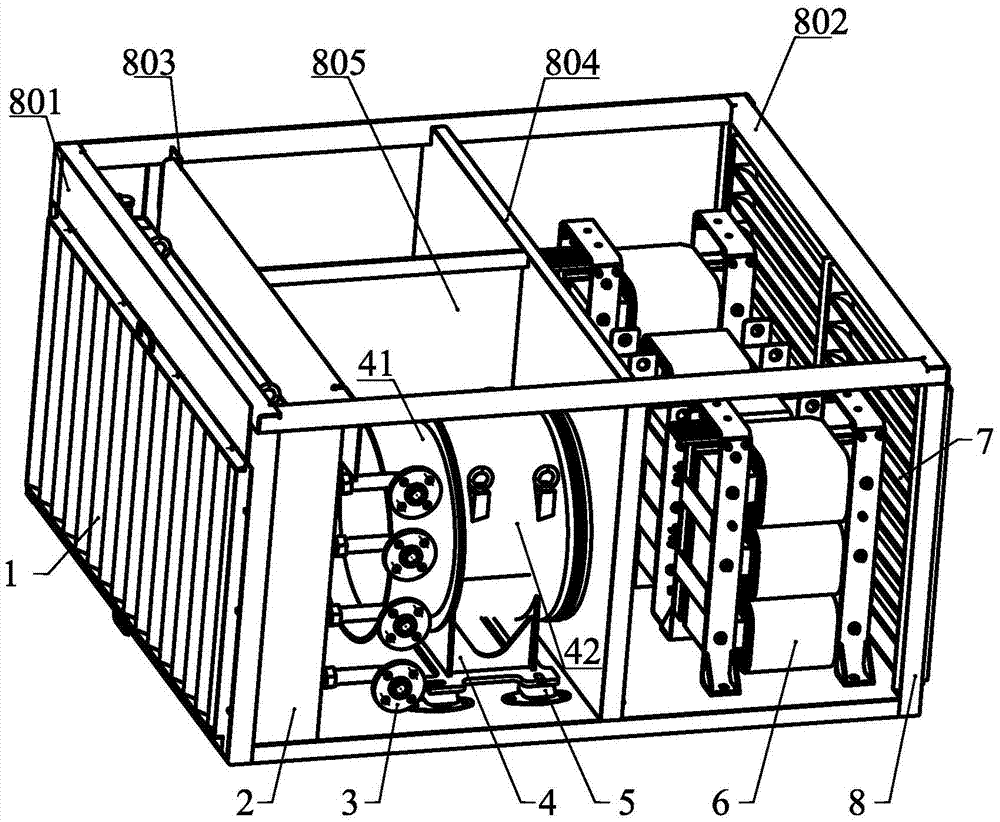

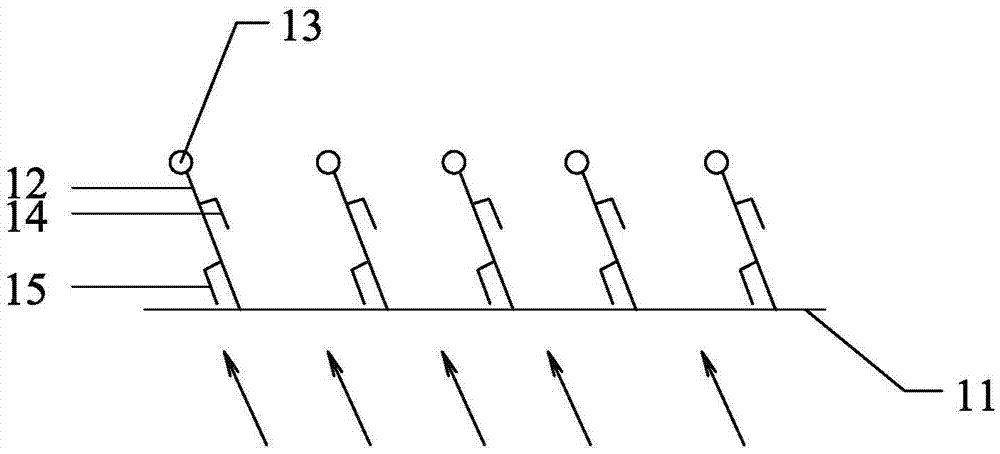

[0028] Such as figure 1 As shown, a heat exchange module for a locomotive, the heat exchange module includes an air intake filter device 1, a double-circuit radiator 2, a fan unit 4, a reactor 6, and an air outlet grille 7 arranged in sequence along the air flow direction And a box frame 8 for accommodating the above-mentioned components.

[0029] The air inlet filter 1 is arranged on the front end plate 801 of the box frame 8, and the dual-circuit radiator 2 and the reactor 6 are respectively fixed on the box by fasteners through their respective mounting seats. body frame 8 on the corresponding position of the beam; the air duct installation seat of the fan unit 4 connects the fan unit with the box frame 8 through the shock absorber 5; the pipeline 3 is arranged on the double-circuit radiator 2; the outlet grille 8 is set on the rear end plate 802 of the box frame 8.

[0030] The box frame 8 is a four-chamber structure, which are respectively a radiator room, a fan unit ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com