Cooling system for converter of diesel locomotive

A technology for diesel locomotives and cooling systems, which is used in cooling/ventilation/heating transformation, output power conversion devices, electrical components, etc., to achieve the effects of simple system structure and connection method, cost reduction, and reduction of converter cooling system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

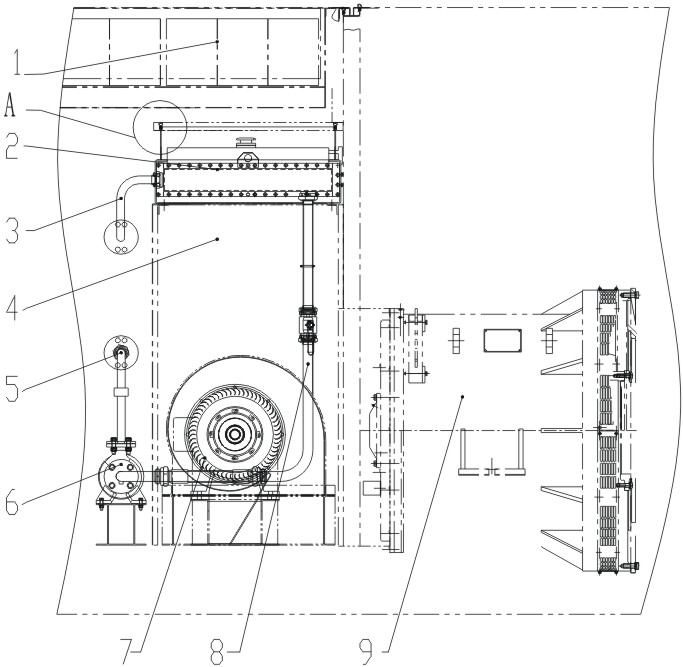

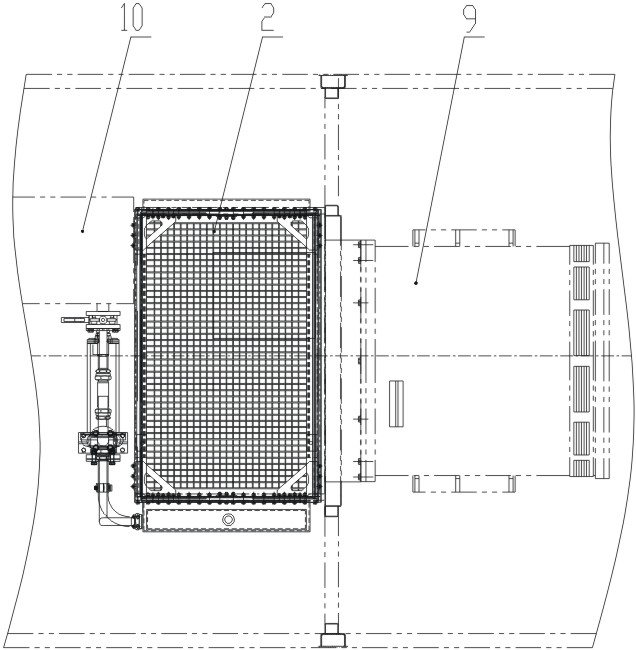

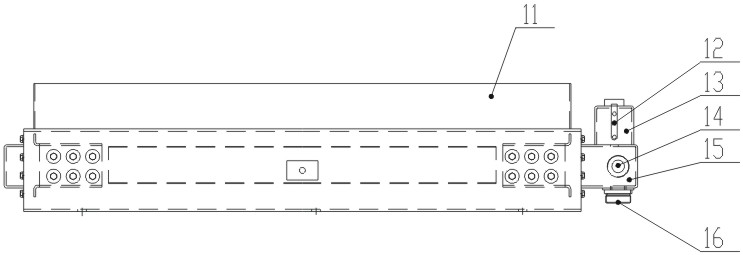

[0026] Such as Figure 1-Figure 5 As shown, the diesel locomotive converter cooling system of the present invention includes an independent air intake unit 1 located on the roof, an independent air chamber 4 located in the vehicle, a traction motor in the vehicle, a main generator 9, a radiator 2, and a converter 10 , the traction motor ventilator 7 and the water pump 6, wherein the traction motor is a motor in a diesel locomotive, which is not shown in the figure. The radiator 2 includes a front end water chamber 15 and a rear end water chamber 17, between the front end water chamber 15 and the rear end water chamber 17 is a cooling water flow channel, and the front end water chamber 15 is provided with radiator water inlets communicating with each other 14. The radiator water outlet 16 and the radiator water tank 13 are provided with a water level gauge 12 and a water filling port 18 on the radiator water tank 13 . The independent air inlet unit 1 is arranged on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com