Boiler smoke and steam energy-saving low-carbon haze reducing system

A boiler and flue gas technology, applied in the field of boiler flue gas energy-saving, low-carbon and haze reduction systems, can solve problems such as unfavorable haze pollution, high temperature, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

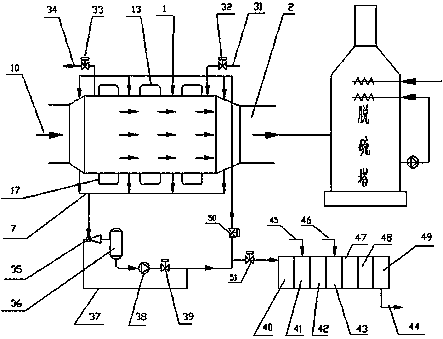

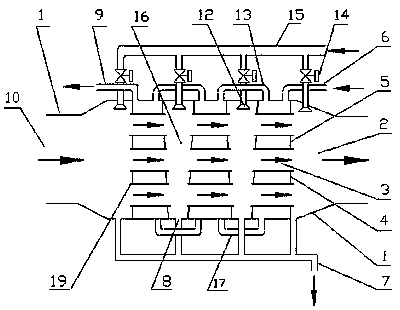

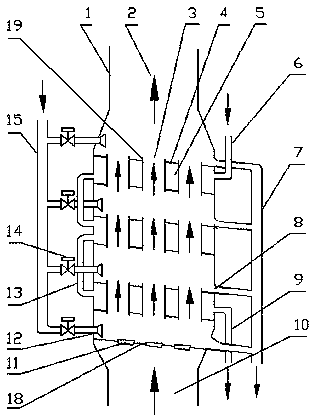

[0046] see Figure 1-Figure 3 , the present invention provides a boiler flue gas energy-saving low-carbon haze reduction system, which includes:

[0047] Boiler smoke and steam energy-saving micro-exhaust device is used to treat the flue gas discharged from the boiler, complete the four-phase shunt function of water vapor condensation, flue gas discharge, condensed water extraction and dust deposition, and send the condensed water drawn out through the condensed water discharge pipe Condensed water recovery device, the water vapor condensation refers to the water vapor contained in the flue gas condenses when it is cold during heat exchange, and is separated from the flue gas; the flue gas discharge refers to the flue gas after the water vapor is separated Discharged from the flue gas outlet; the condensed water is drawn out by setting a water retaining weir on the end face of each heat exchange tube to form a diversion groove, and setting a water collecting funnel on the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com