Non-ventilation-pipeline inducing type ventilation and smoke exhaust system and ventilation and smoke exhaust method thereof

A smoke exhaust system and induction technology, which is applied in ventilation systems, heating and ventilation control systems, heating and ventilation safety systems, etc. The effect of increasing disturbance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiment:

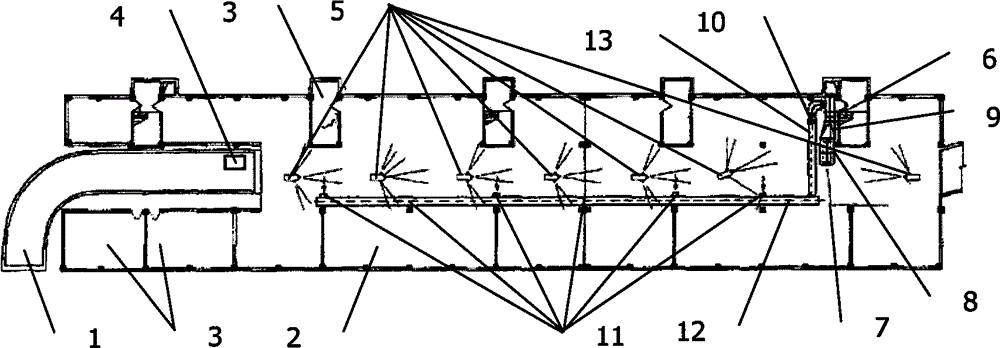

[0022] An induced ventilation and smoke exhaust system without ventilation ducts, including an independent smoke exhaust system and an induced ventilation system without underground ventilation ducts; the independent smoke exhaust system includes a smoke exhaust fan 10, a smoke exhaust port 11, and a smoke exhaust duct 12 , Smoke exhaust fire damper 13, described smoke exhaust blower 10 can share one according to the size of the smoke prevention sub-area, and can also be set separately, if each smoke prevention sub-area is smaller, can share a smoke exhaust fan 10 , if each smoke prevention partition is relatively large, it is necessary to install a smoke exhaust fan 10 in each smoke prevention partition; On the wall of the ceiling, in each smoke-proof zone, the horizontal distance between the smoke outlet and the farthest point shall not exceed 30m 2 , in the event of a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com