Flexible pipe joint having an annular flexible boot thermally or chemically insulating an annular elastomeric flexible element

a flexible pipe joint and annular flexible technology, applied in the direction of adjustable joints, drilling pipes, mechanical equipment, etc., can solve the problems of reducing performance and elastomeric flexible elements, and achieve the effects of less space, reliable installation, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

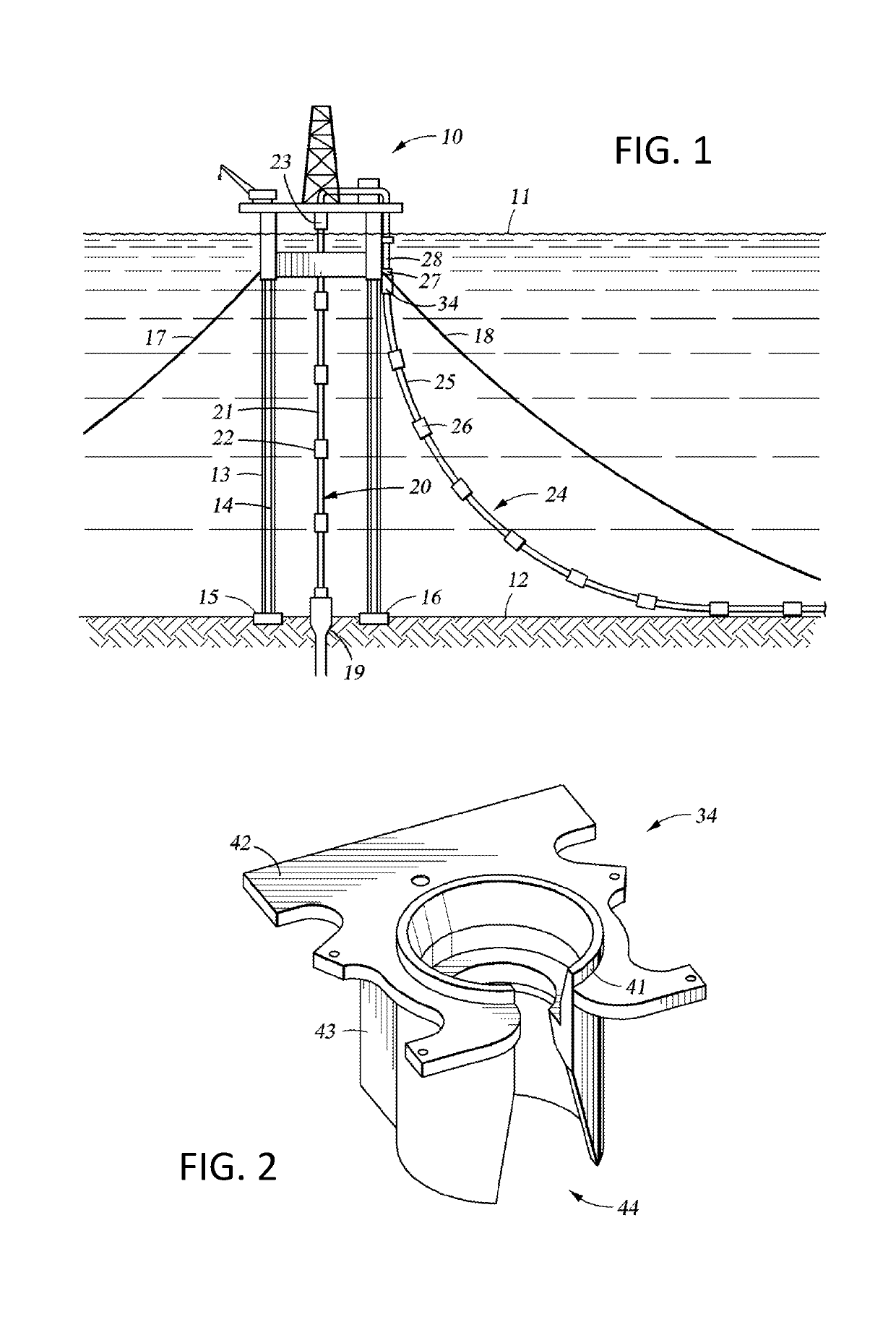

[0042]With reference to FIG. 1, there is shown an offshore drilling and production vessel generally designated 10 floating on a water surface 11. The floating vessel in particular is a tension leg platform (TLP) secured to the seabed 12 by means of tendons 13, 14 and foundation templates 15, 16. Although not visible in FIG. 1, there is a set of tendons depending from each of four corners of the TLP platform 10 to a respective one of four foundation templates 15, 16. In addition, each of the four lower corners of the TLP platform 10 is secured by a respective lateral mooring line 17, 18 used to move the platform laterally and to resist lateral storm loadings.

[0043]For conveying drilling fluids and a drill string from the TLP to a well bore 19 in the seabed 12, and for removing hydrocarbons from the well when drilling has been completed, a production riser generally designated 20 extends from the well bore 19 up to the TLP 10. The riser 20 consists of a number of rigid pipe sections 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com