Stirring device for improving oxidation characteristic

A stirring device and characteristic technology, applied in the direction of mixers with rotating stirring devices, chemical instruments and methods, mixers, etc., can solve the effect of oxidation and stirring, the pressure head of the oxidation air fan is large, and the energy of the oxidation air fan Problems such as large consumption, to achieve the effect of increasing utilization rate, reducing energy consumption, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

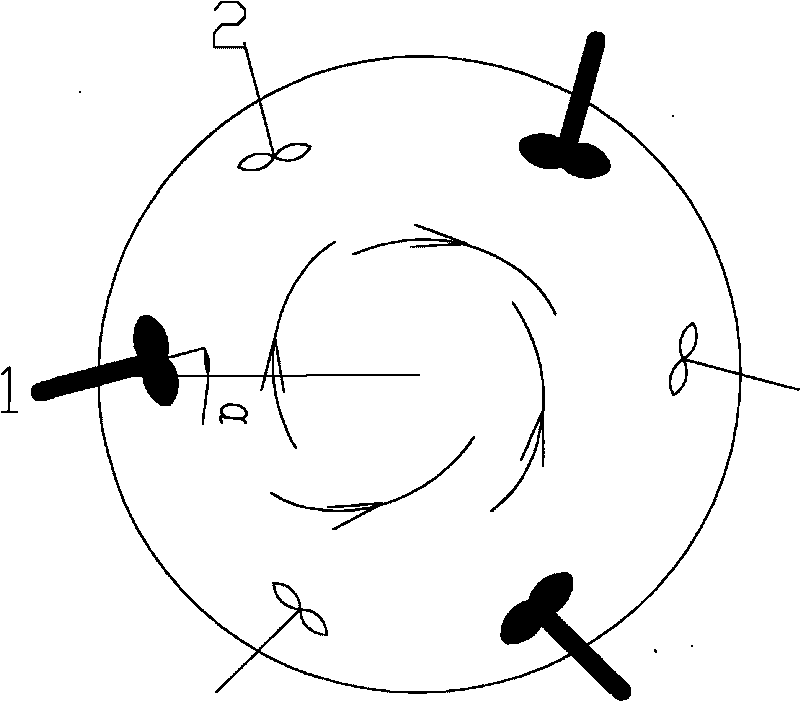

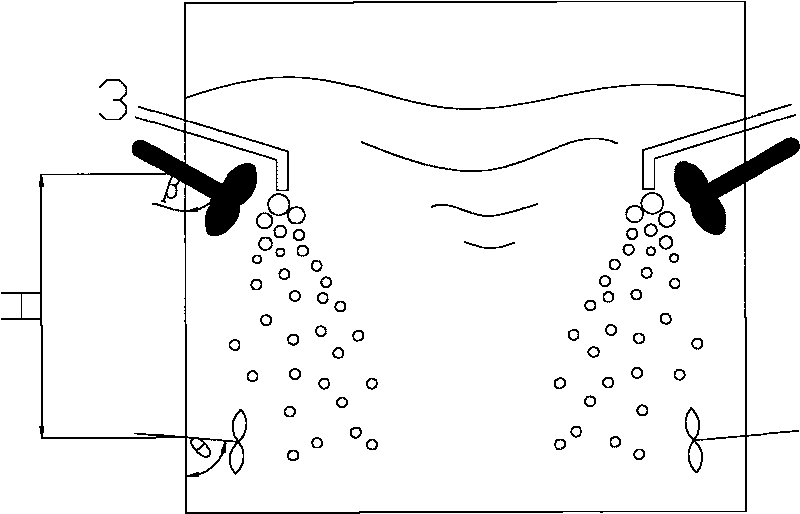

[0017] The stirring device for improving oxidation characteristics includes an upper-stage agitator 1 and a lower-stage agitator 2, and a certain number of agitators can be added between the two-stage agitators according to the height of the slurry pool.

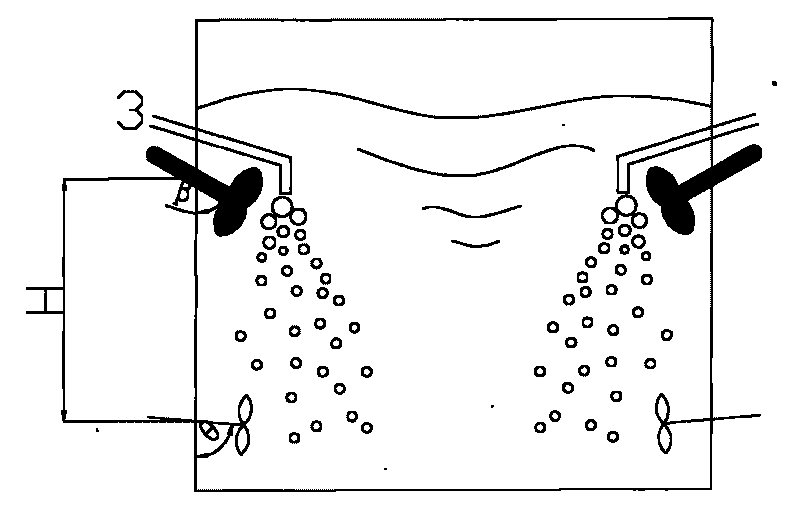

[0018] Upper newly absorbed SO 2 The slurry and oxidizing air move downward under the impetus of the upper-stage stirring system, and then are dispersed by the lower-stage stirring system, so that the oxidation reaction is more fully and rapidly. At the same time, the flow rate and pressure head of the oxidation fan are reduced, the pH value of the upper slurry is increased, and the reliability and stability of the desulfurization system operation are increased.

[0019] The stirring device of the present invention is composed of N (2≤N≤5) level stirrers, which are determined according to the height of the slurry pool.

[0020] The height difference between the various agitators is H (0.5≤H≤1), which is determined according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com