Bi-crucible low pressure casting method for magnesium alloy hub and equipment thereof

A low-pressure casting machine and double-crucible technology, which is applied in the direction of wheel hubs, transportation and packaging, and vehicle parts, can solve problems such as explosion, high tendency of hot cracking of castings, and unfavorable fatigue strength of wheel hubs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

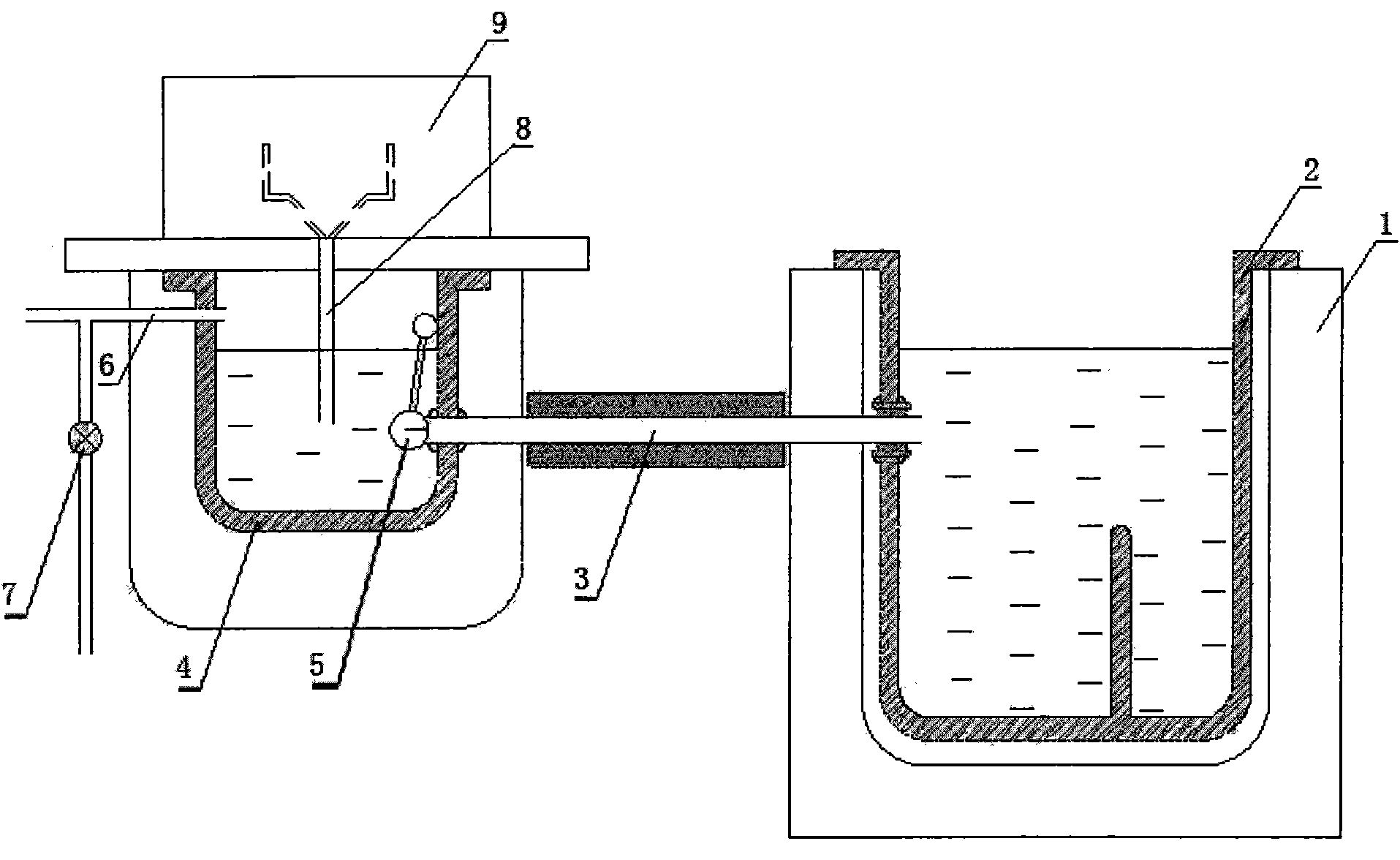

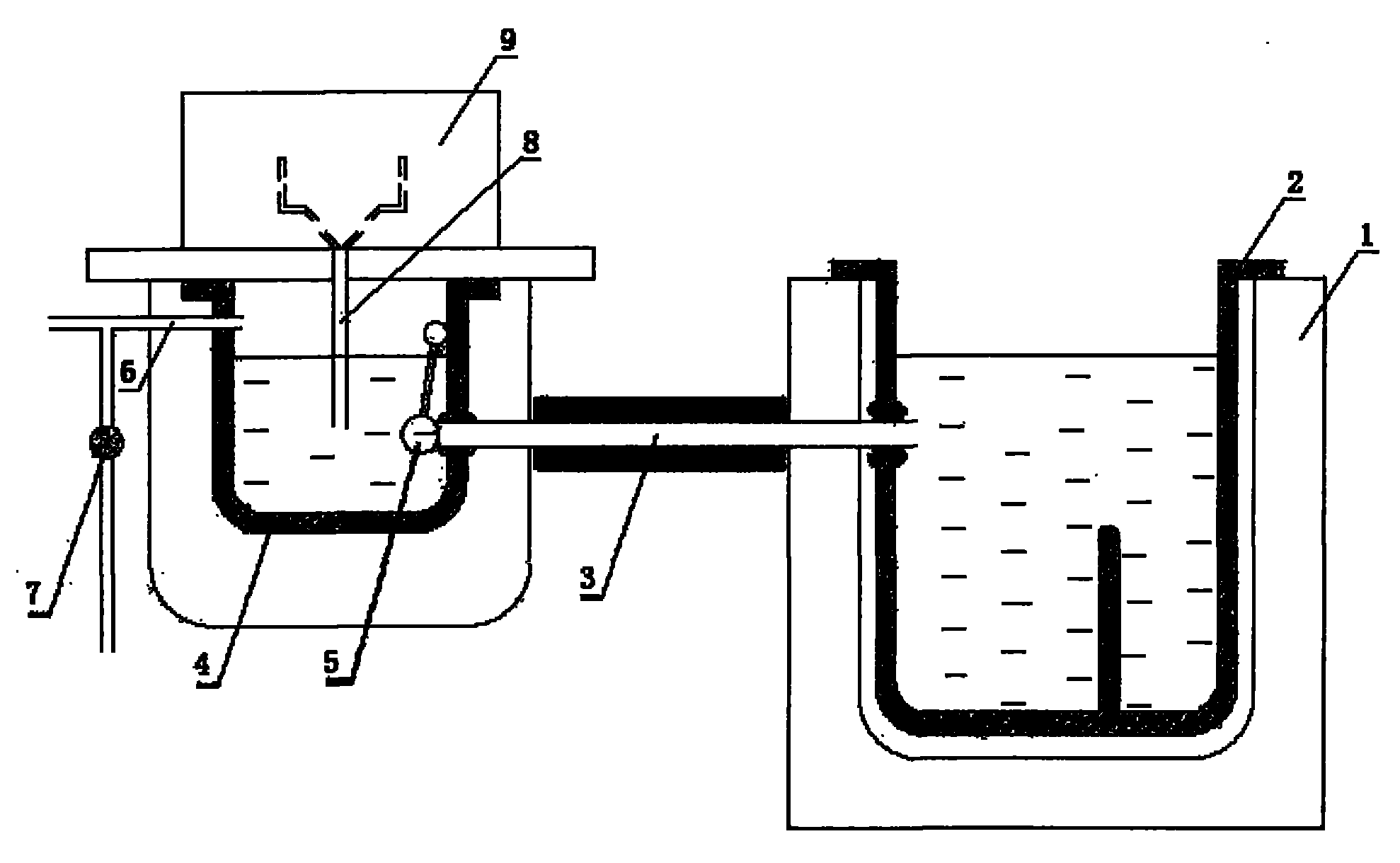

[0015] The melting and heat preservation crucible (2) communicates with the casting crucible (4) through the connecting pipe (3), and the molten metal in the melting heat preservation crucible (2) is supplied to the casting crucible (4) by the one-way valve (5) according to production needs. The high-chromium heat-resistant steel ball valve of the one-way valve (5), the ball handle is fixed as a swing rod, and it always stops at the nozzle under gravity, and the liquid in the melting and heat-preserving crucible (2) can push away the steel ball under the force of gravity. The ball automatically replenishes molten metal in the casting crucible (4) until the liquid levels of the two crucibles are basically the same. When the intake pipe (6) is filled with air, the ball valve blocks the mouth of the nozzle, so that the molten metal in the casting crucible (4) is pressurized during the filling and solidification process of the casting mold (9) along the riser (8). After the castin...

Embodiment 2

[0021] Double-crucible low-pressure casting process for a certain type of 17-inch magnesium alloy wheel hub

[0022] The 17-inch magnesium alloy wheel is made of AM60 alloy, the net weight of the wheel is 7.5Kg, the casting blank is 12.5Kg, and the casting mold is a combined forged steel mold. The low-pressure casting mold is a combination metal mold and has opening and closing locking devices. The die casting process mainly includes mold preheating temperature, mold coating, pouring temperature, filling, pressurization, pressure maintaining, cooling, mold opening and casting, etc. Compared with aluminum alloy, the casting performance of magnesium alloy is poor. In order to ensure complete mold filling, the mold preheating temperature reaches 300°C, and the cavity surface coating of the mold is an aqueous suspension of zinc oxide boric acid. The pouring temperature of the molten metal is 710°C, and the pressure after drying is controlled to start from 0.2Mpa when filling the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com