Patents

Literature

35results about How to "Compensation for pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centrifugal separator

InactiveCN101491793AReduce vibrationImprove separation efficiencyDispersed particle separationSingle direction vortexEngineeringAirflow

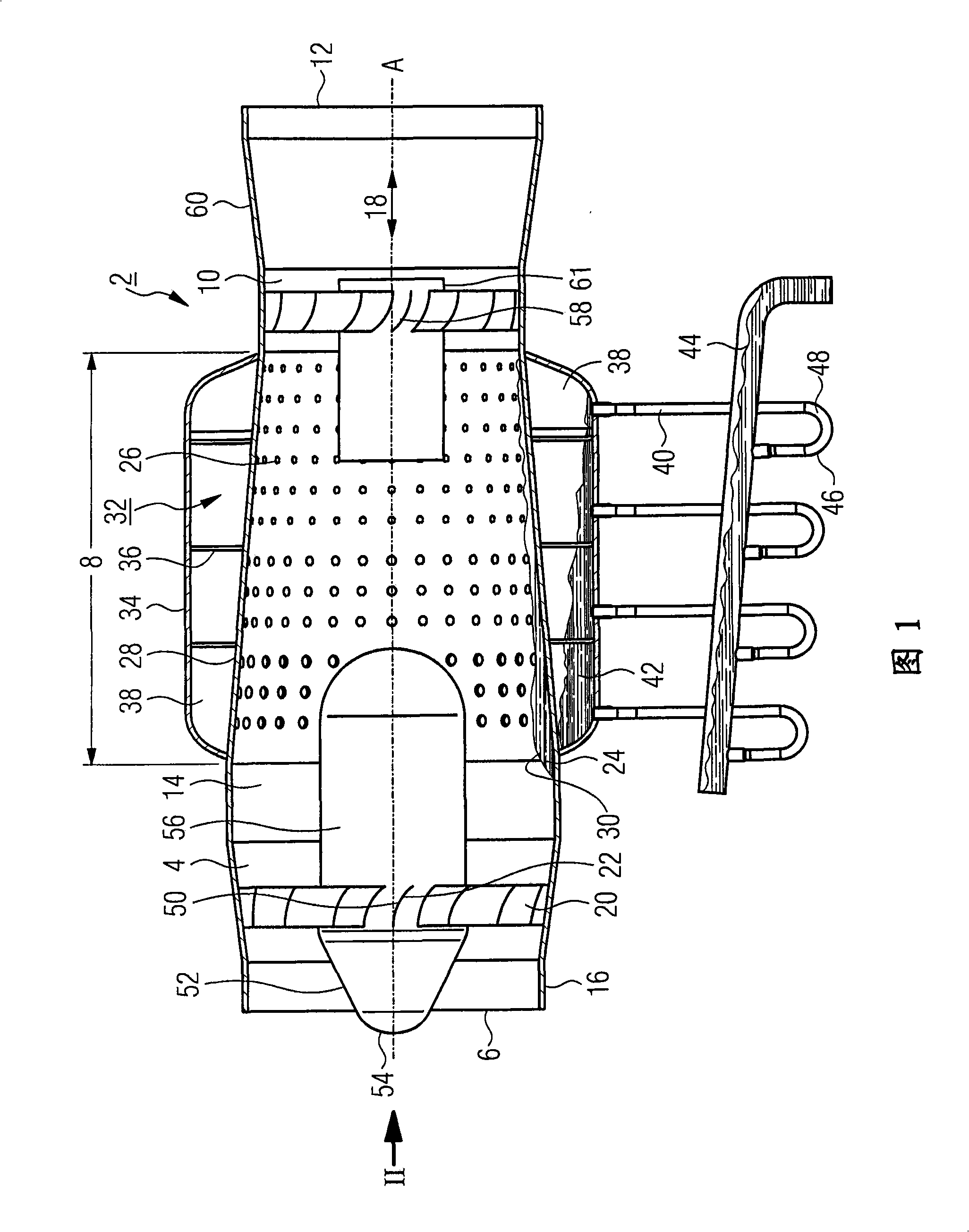

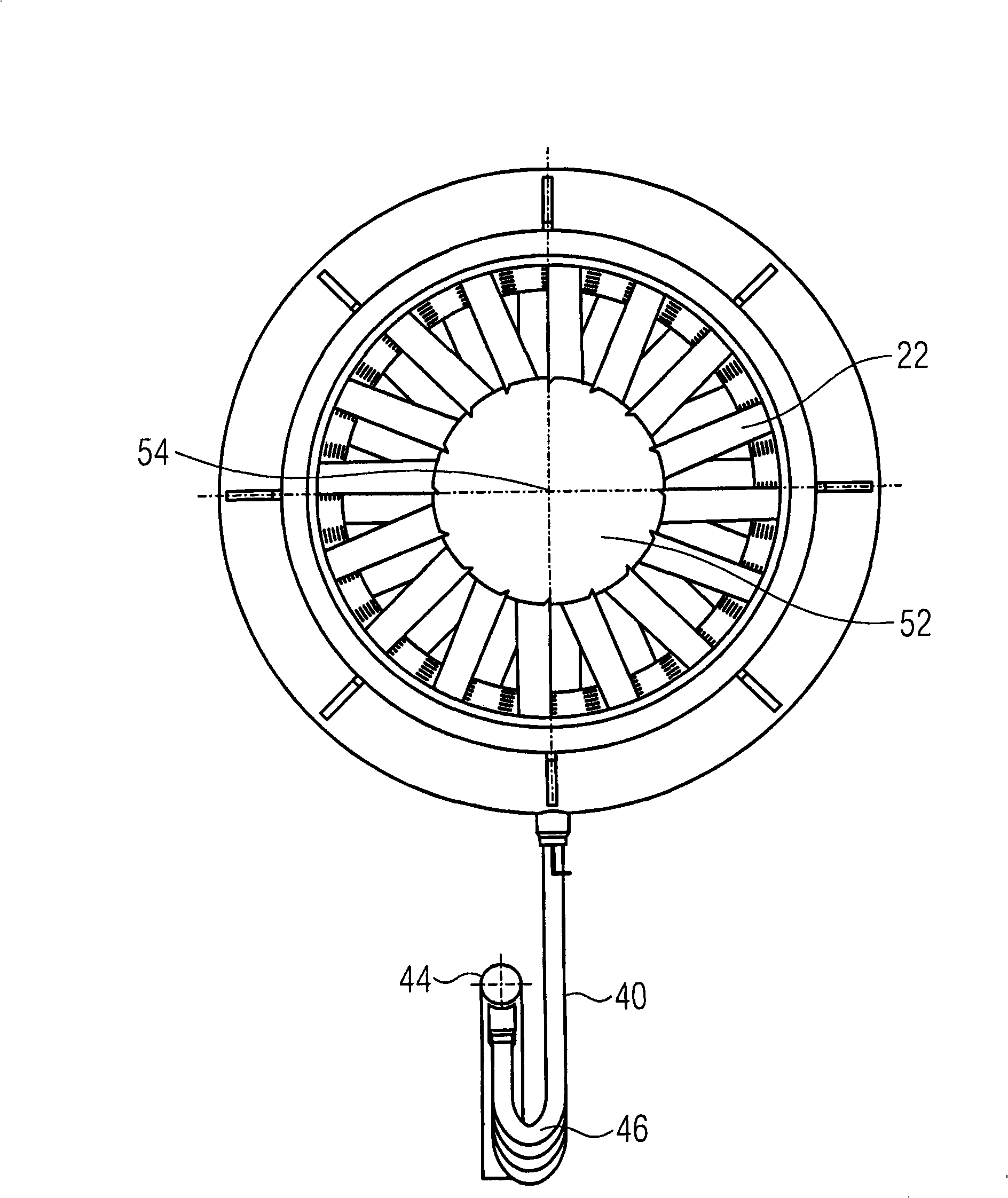

The invention relates to a centrifugal separator (2) for separating liquid from airflow carrying liquid or steam, which is provided with a flow path (14) limited by a secured inner shell (16) and aligned along an axial direction (18), where the separator (8) should be provided with particularly silent working property with less vibration under a condition of high separating efficiency. Therefore, according to this invention, the centrifugal separator (2) is provided with plural liquid collecting chambers (38) arranged one by one in the axial direction (18) in an area of a separated section (8) and disposed respectively around the inner shell (16) circularly, and sealed by a divided plate (36) to each other respectively, wherein each liquid collecting chamber (38) is connected with the flow path (14) through plural through holes (26) led into the inner shell (16) by flow technology.

Owner:FRAMATOME ANP

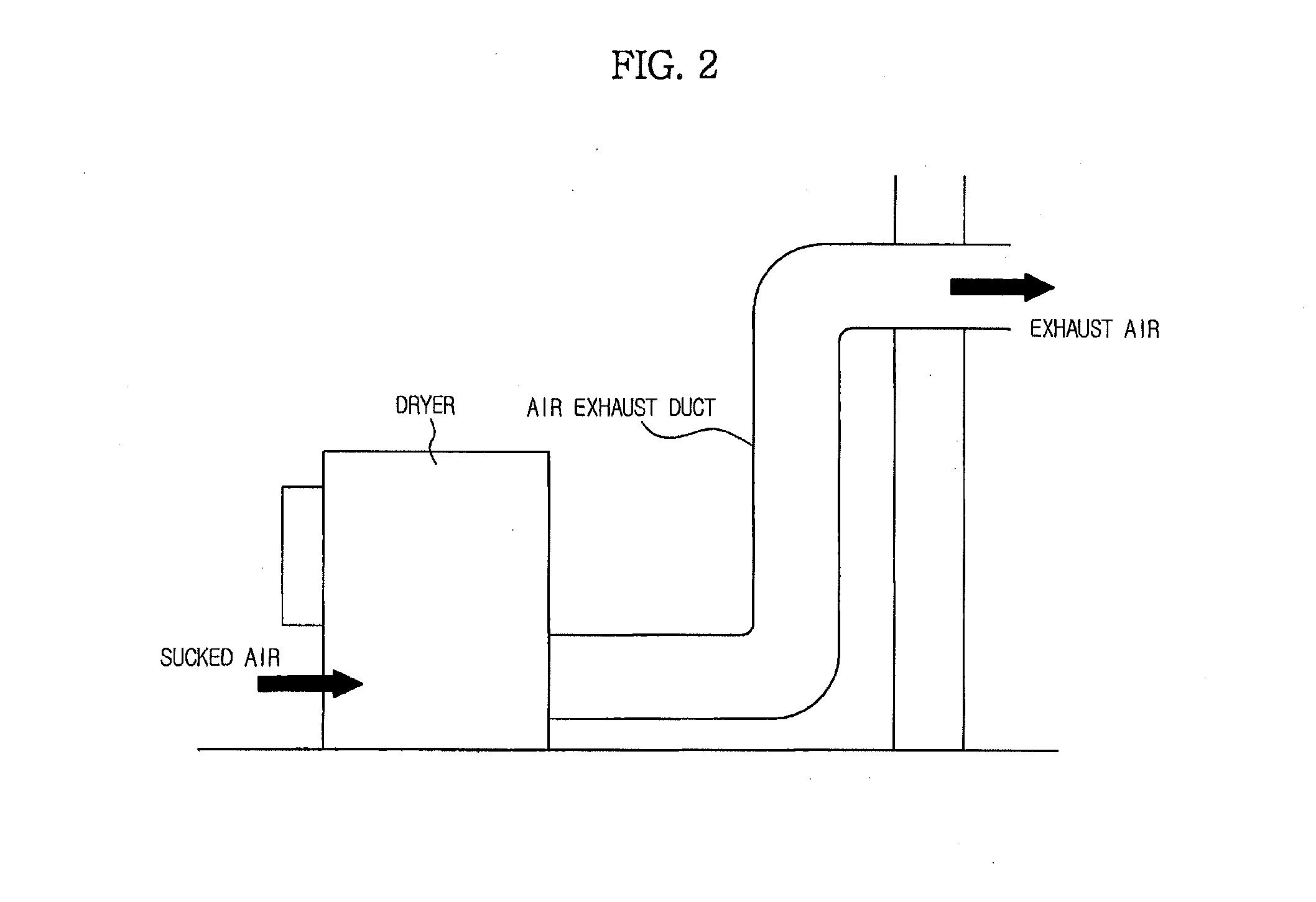

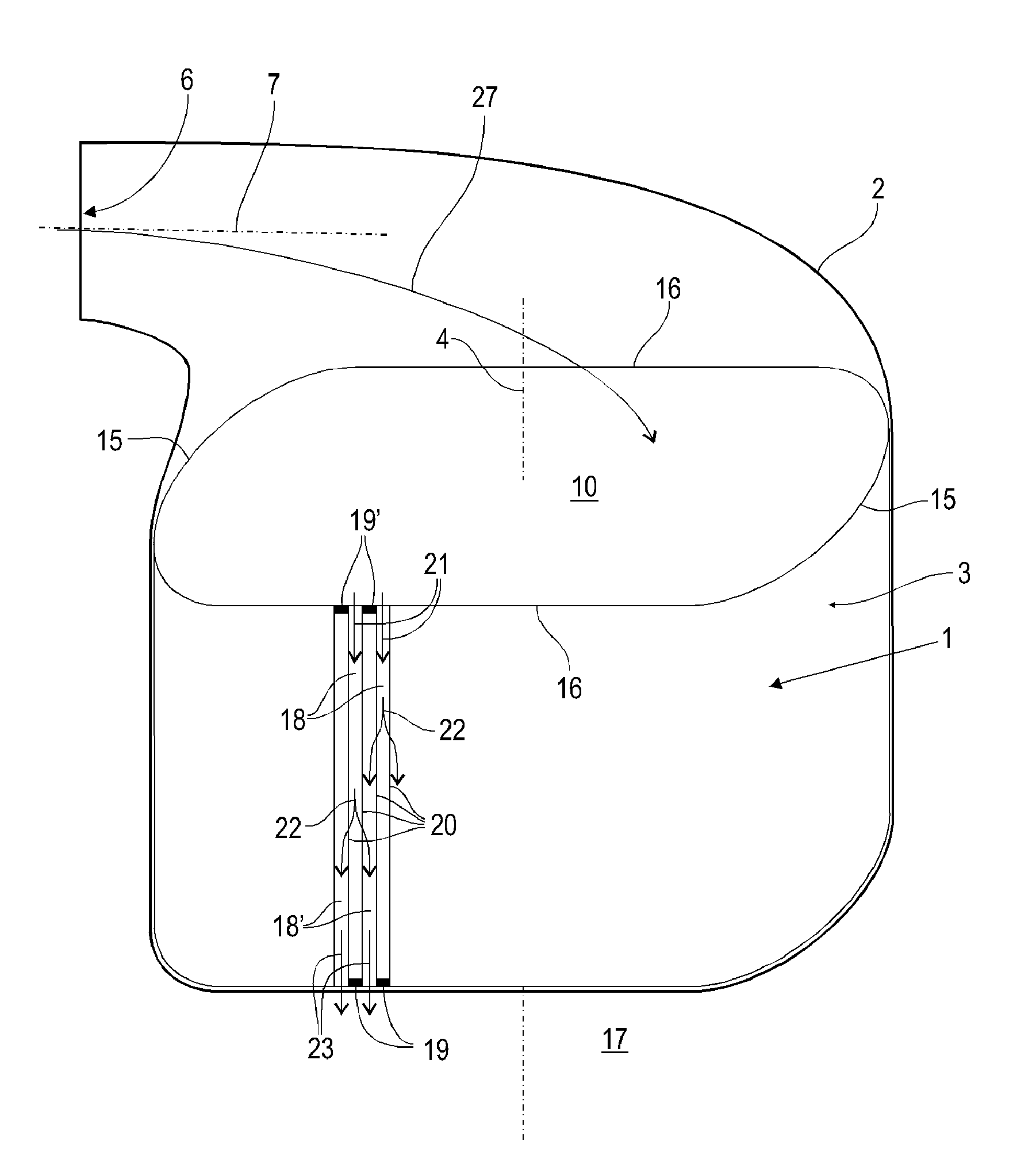

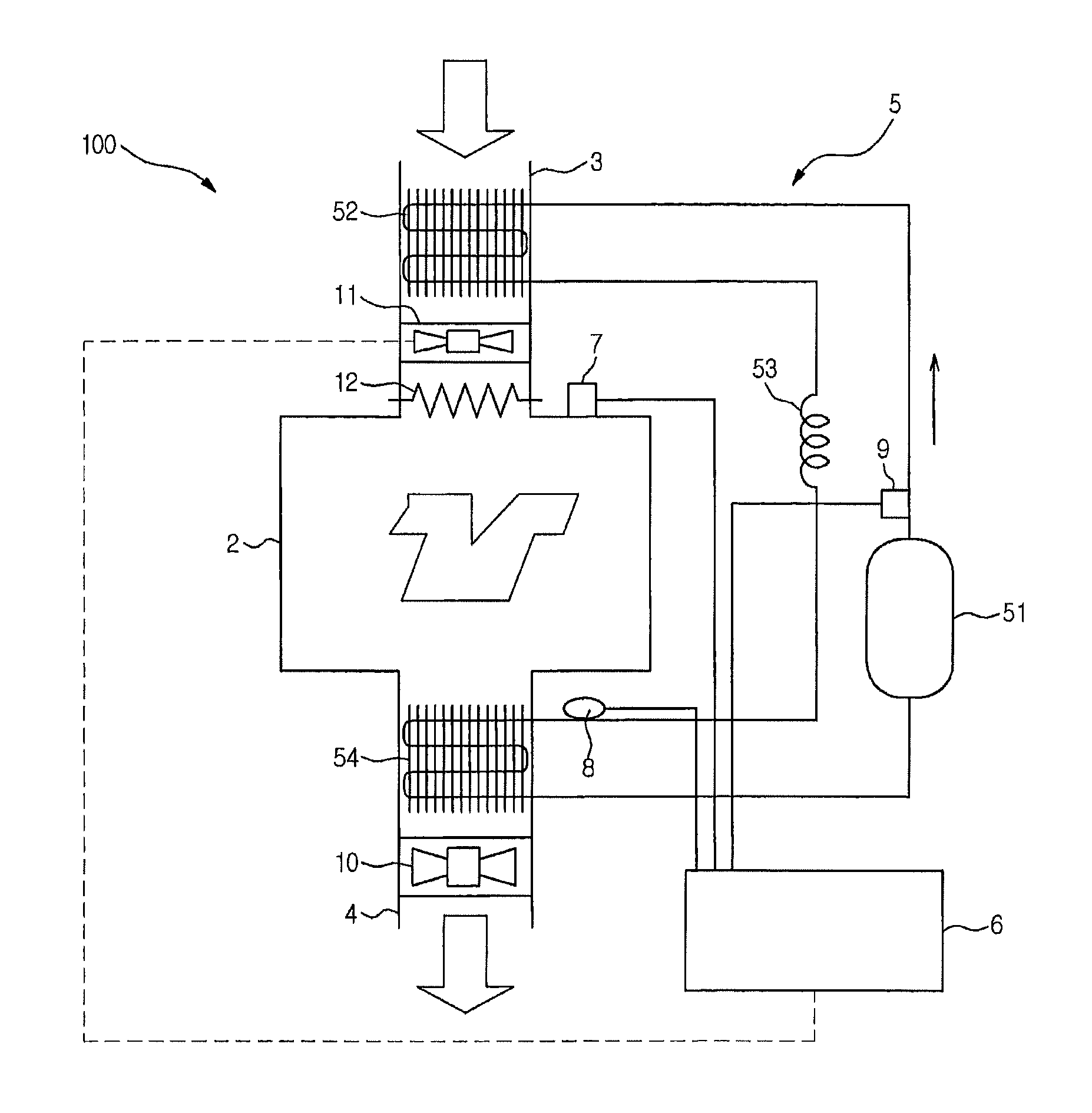

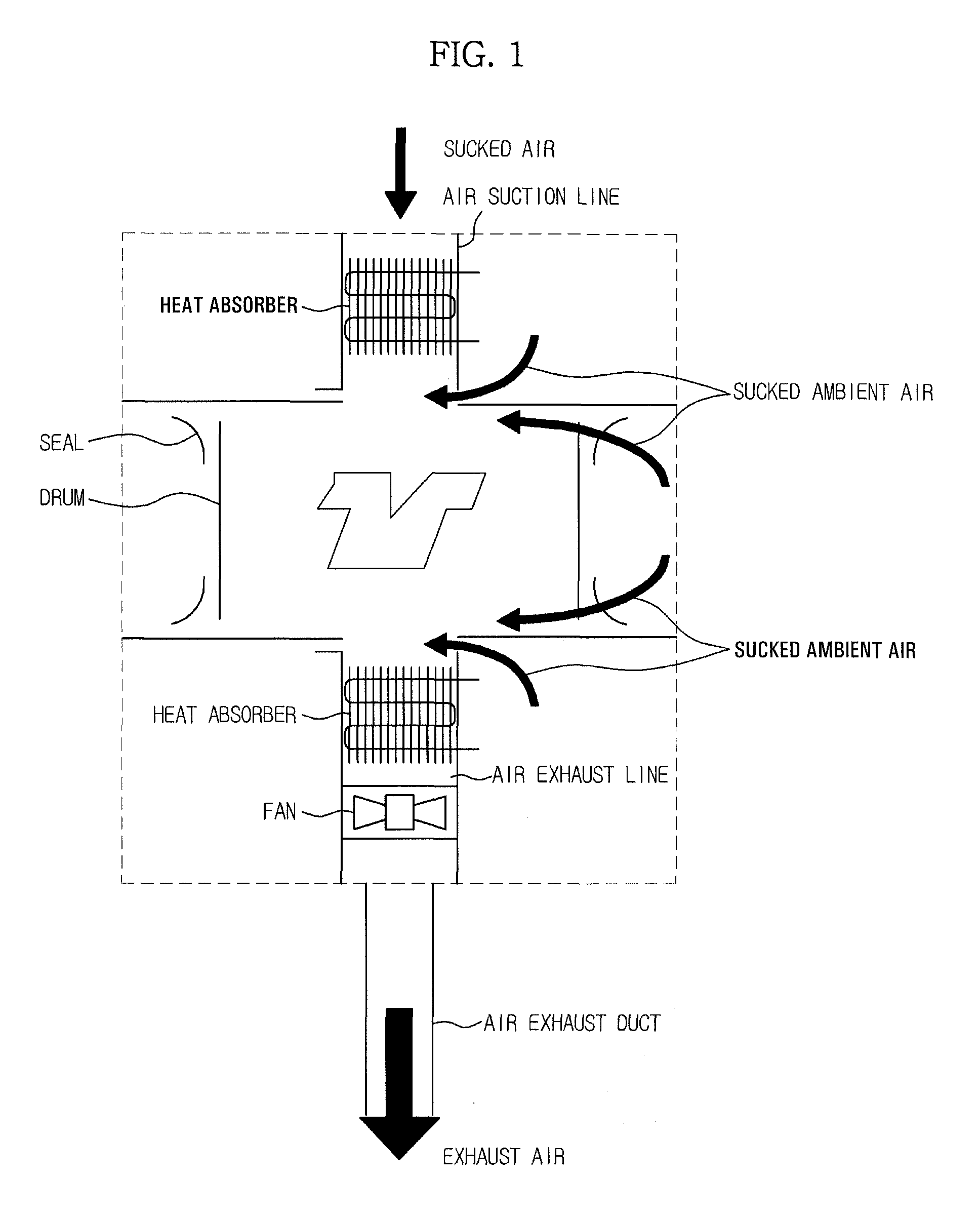

Heat pump type clothes dryer with secondary blowing mechanism

ActiveUS20120144693A1Reduce air volumeIncrease internal pressureDrying solid materials with heatDrying gas arrangementsLine tubingEngineering

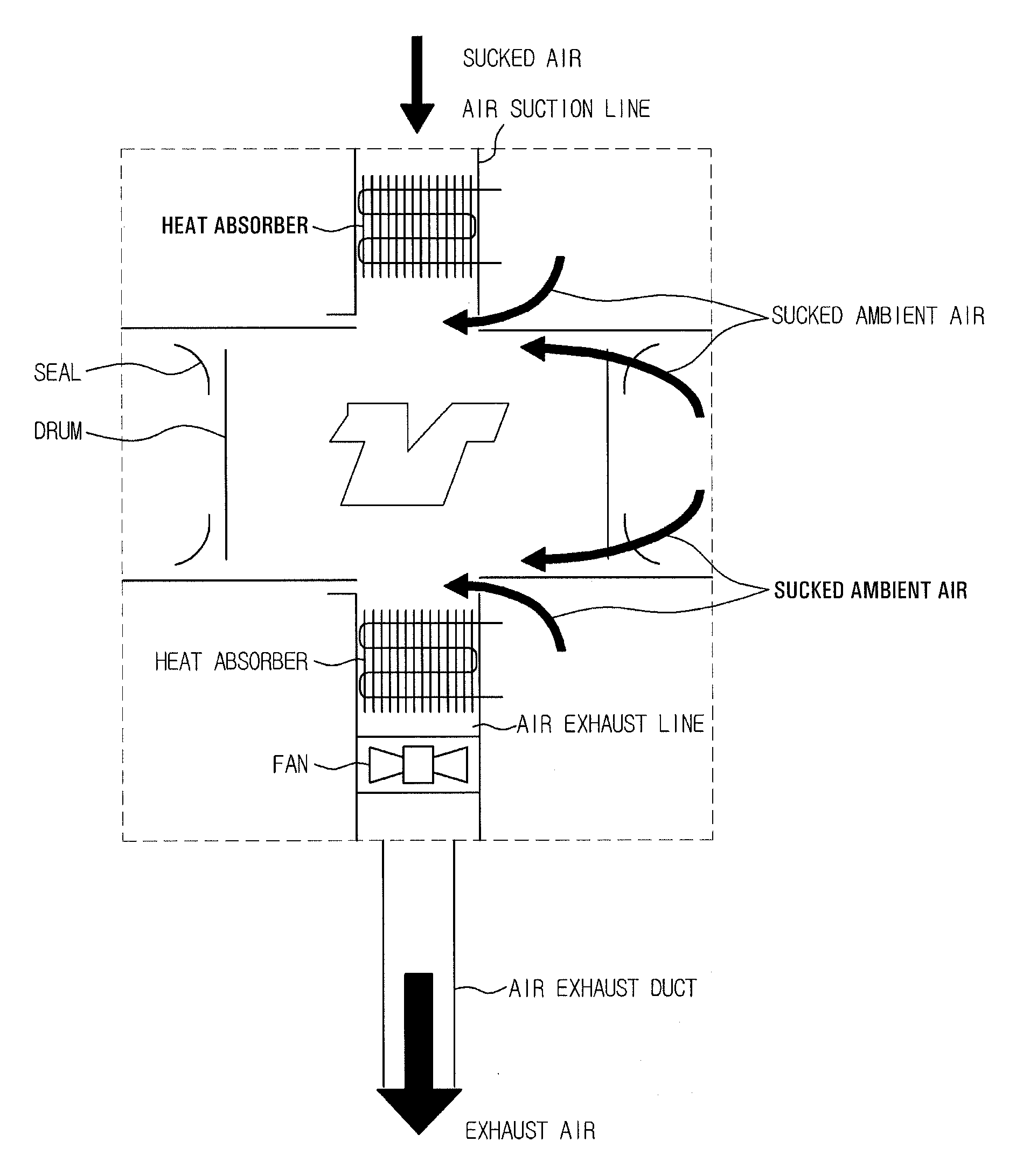

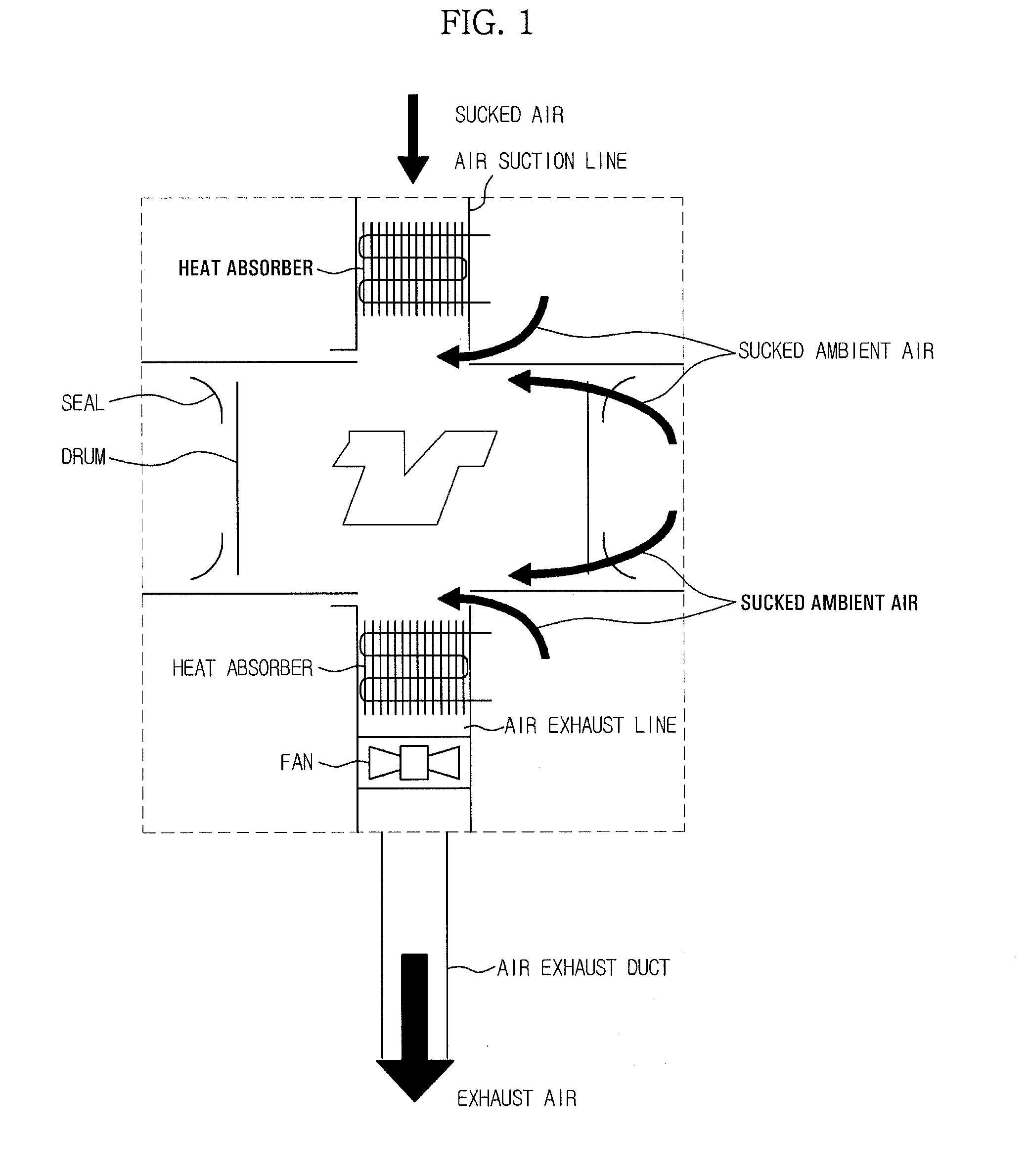

A heat pump type clothes dryer compensates for pressure loss caused by a radiator to increase the flow rate of air passing around the radiator, and suppressing introduction of ambient air through gaps formed in air flow lines to avoid degradation in drying capacity, while avoiding an increase in the power consumption or noise of a fan. The clothes dryer includes a drum to accommodate clothes, an air suction or intake line to suck air into the drum, an air exhaust line to exhaust air from the drum, a heat pump circuit including a compressor, a radiator, a pressure reducer, and a heat absorber, where the heat absorber is provided in the air exhaust line, and the radiator is provided in the air suction or intake line, a first blowing mechanism provided in the air exhaust line, and a second blowing mechanism provided in the air suction or intake line.

Owner:SAMSUNG ELECTRONICS CO LTD

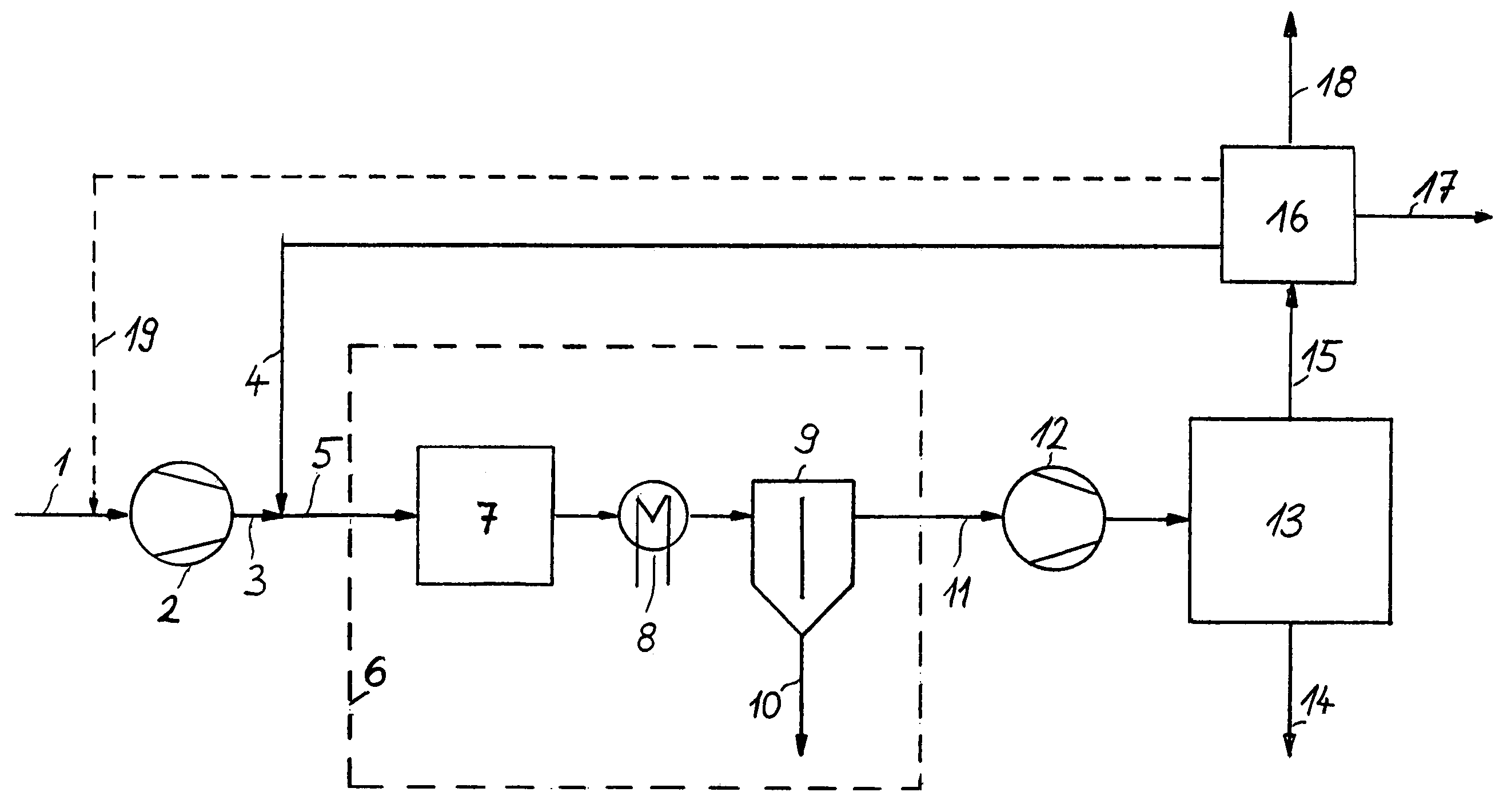

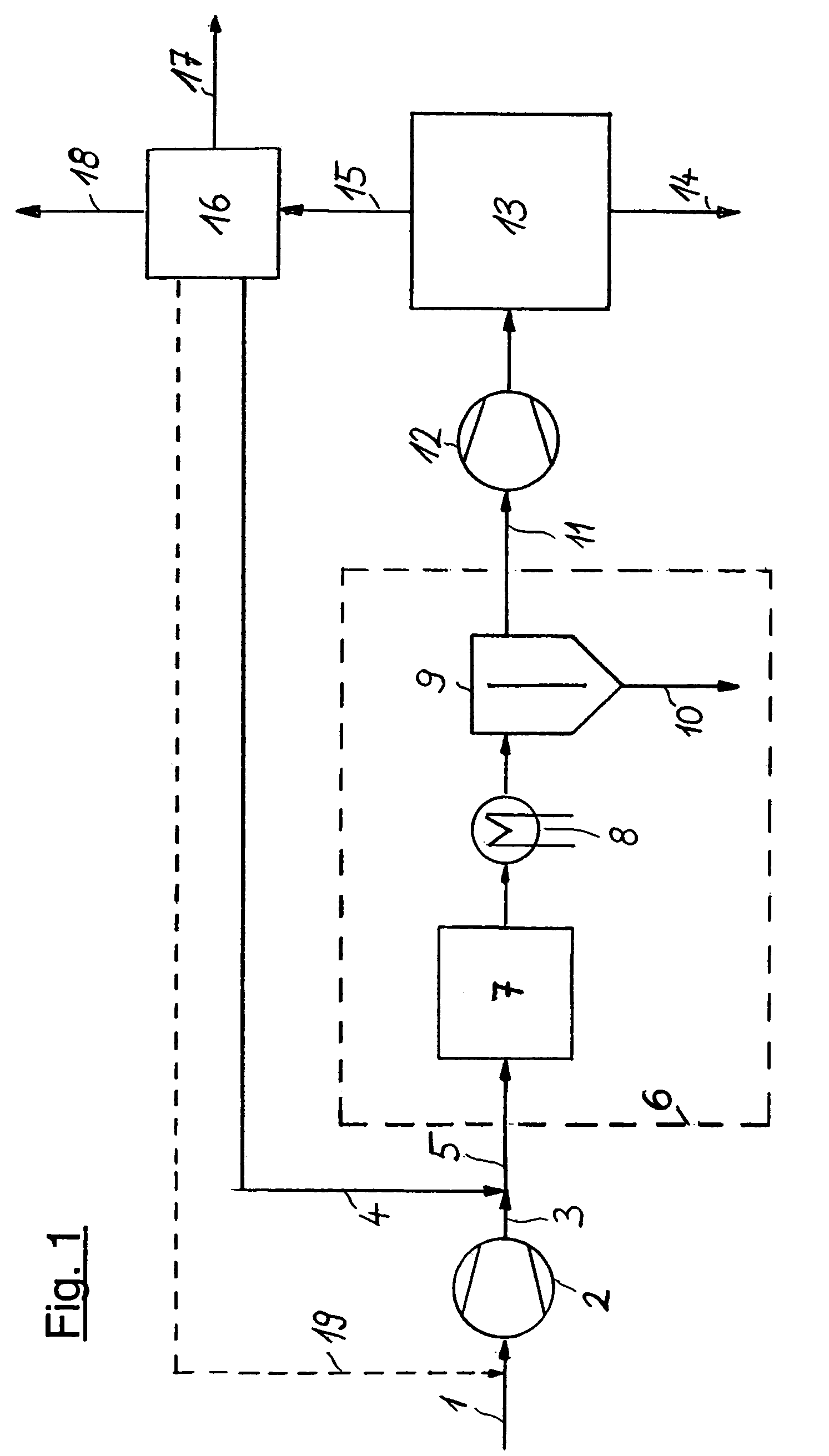

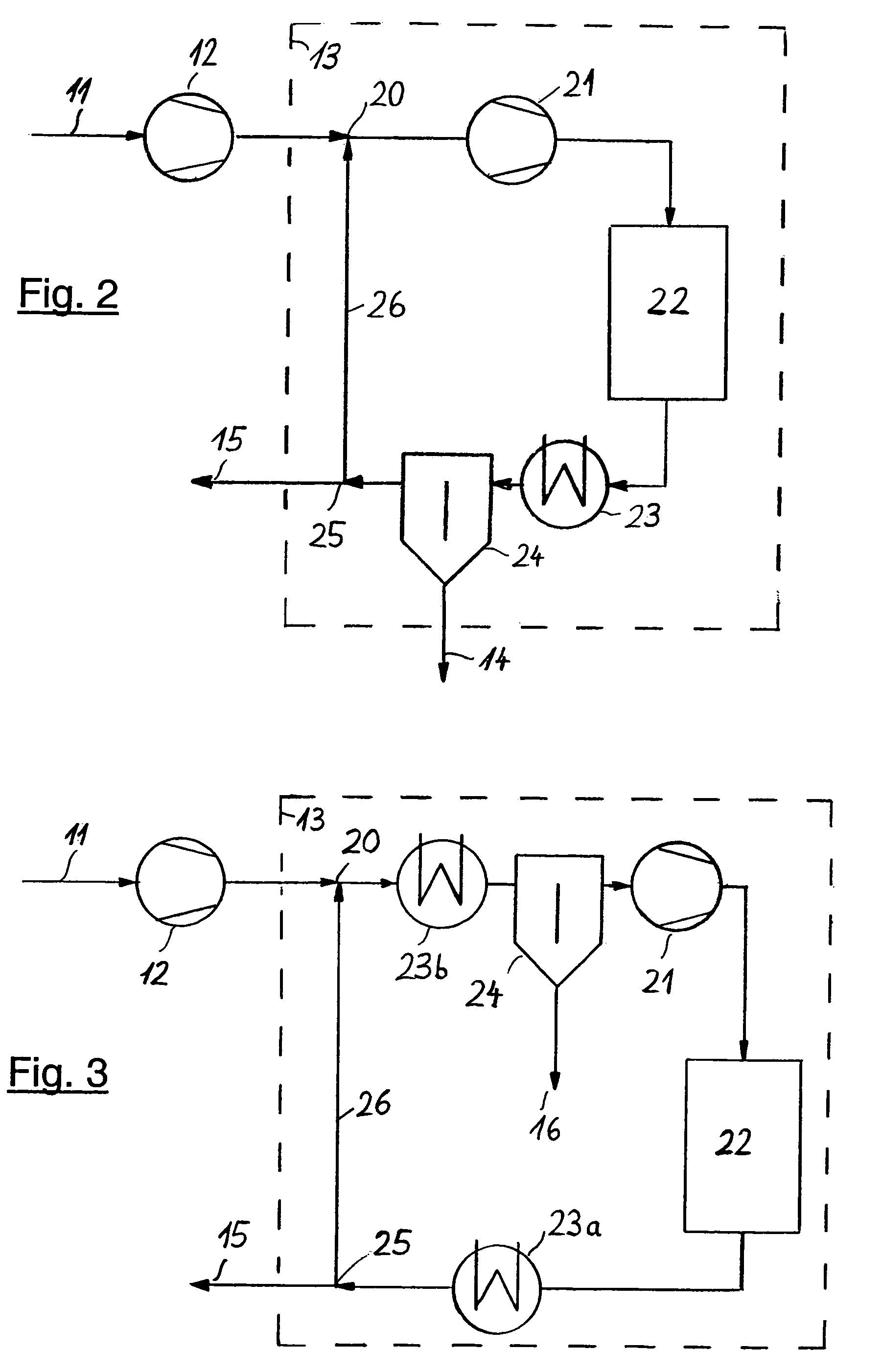

Multiple-pressure process for the production of ammonia

InactiveUS7070750B2Improve efficiencyReduce the amount requiredBulk chemical productionAmmonia preparation/separationHigh pressureAmmonia

The invention relates to a process for the production of ammonia from synthesis gas, the synthesis of ammonia from synthesis gas taking place in several lined-up synthesis systems, whereby ammonia is produced from a portion of the synthesis gas in each system with a part-stream being withdrawn and the respective downstream synthesis system being operated at a higher pressure than the respective upstream synthesis system.

Owner:UHDE GMBH

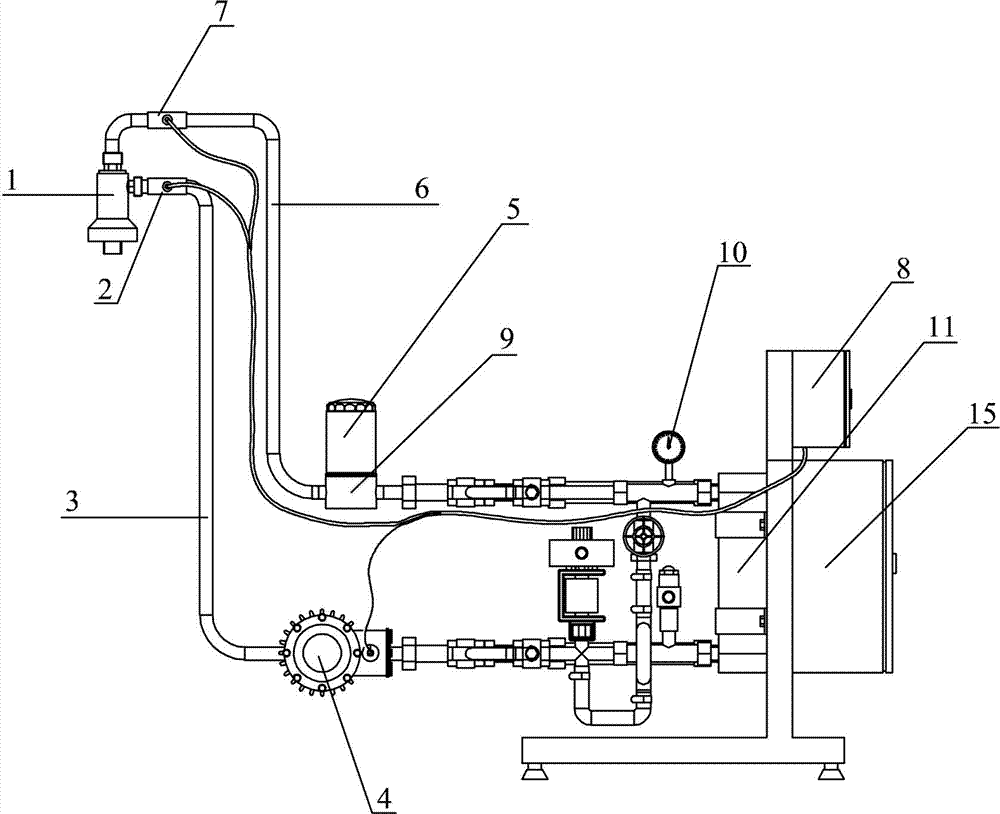

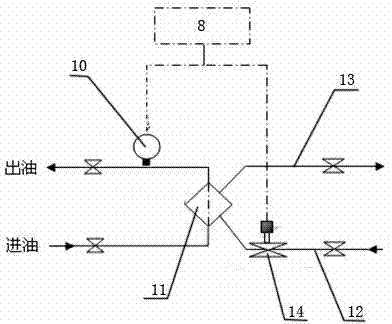

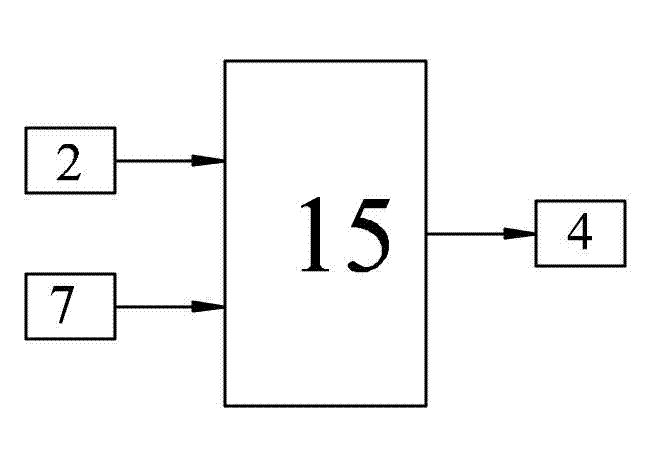

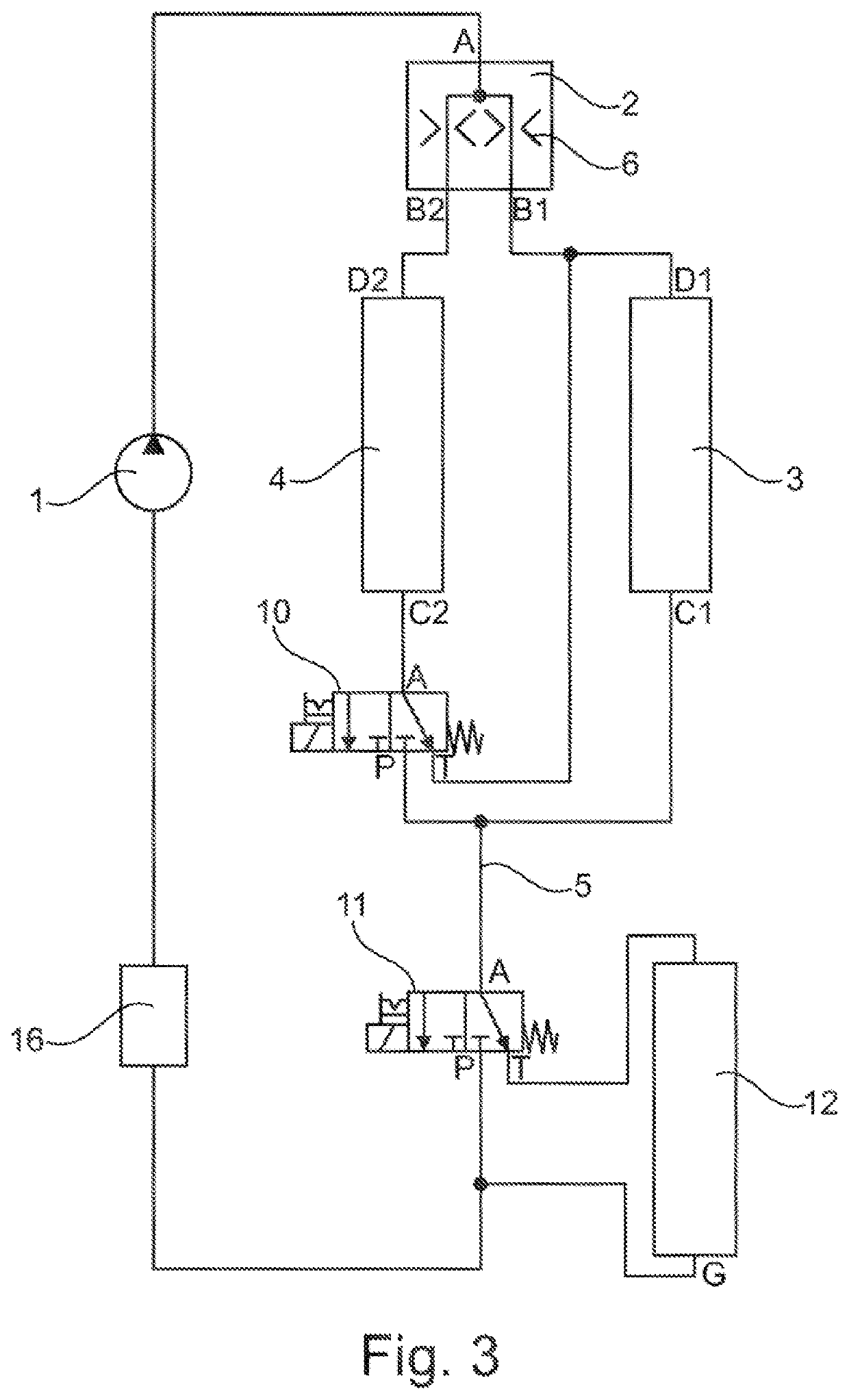

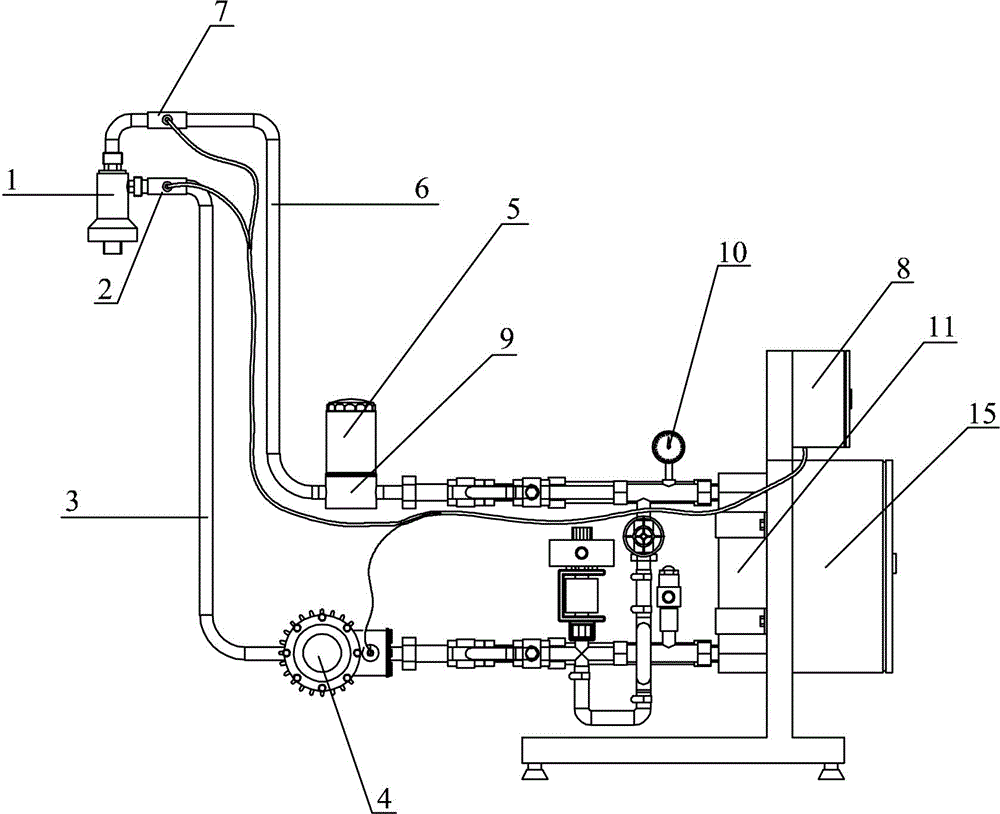

Engine oil outer cooling and circulating system of engine

InactiveCN103195536AImprove cooling effectImprove performanceMachines/enginesLubrication temperature controlTemperature controlControl signal

The invention relates to an engine oil outer cooling and circulating system of an engine. The engine oil outer cooling and circulating system comprises a constant-temperature control mechanism, wherein an oil inlet of the constant-temperature control mechanism is communicated with an oil outlet of a filter base of the engine through an oil inlet tube, and the oil outlet is communicated with an oil return port of the filter base of the engine through an oil outlet tube. The constant-temperature control mechanism comprises a temperature master control unit, a temperature detection mechanism and a cooling mechanism, wherein standard values of the temperature of the engine oil of the engine are stored in the temperature master control unit; the temperature detection mechanism is arranged in the oil outlet tube and can instantly transmit the detected engine oil temperature to the temperature master control unit connected with a signal output end of the temperature detection mechanism; the cooling mechanism receives control signals emitted by the temperature master control unit to cool the engine oil under different engine operation conditions by adjusting the flow and speed of self cooling liquid. The engine oil outer cooling and circulating system is simple in structure, can effectively ensure the temperature of the engine oil flowing into the engine, simultaneously ensures the pressure of the engine oil flowing into the engine, provides good operation environments for the engine and is suitable of engines of various vehicles.

Owner:GREAT WALL MOTOR CO LTD

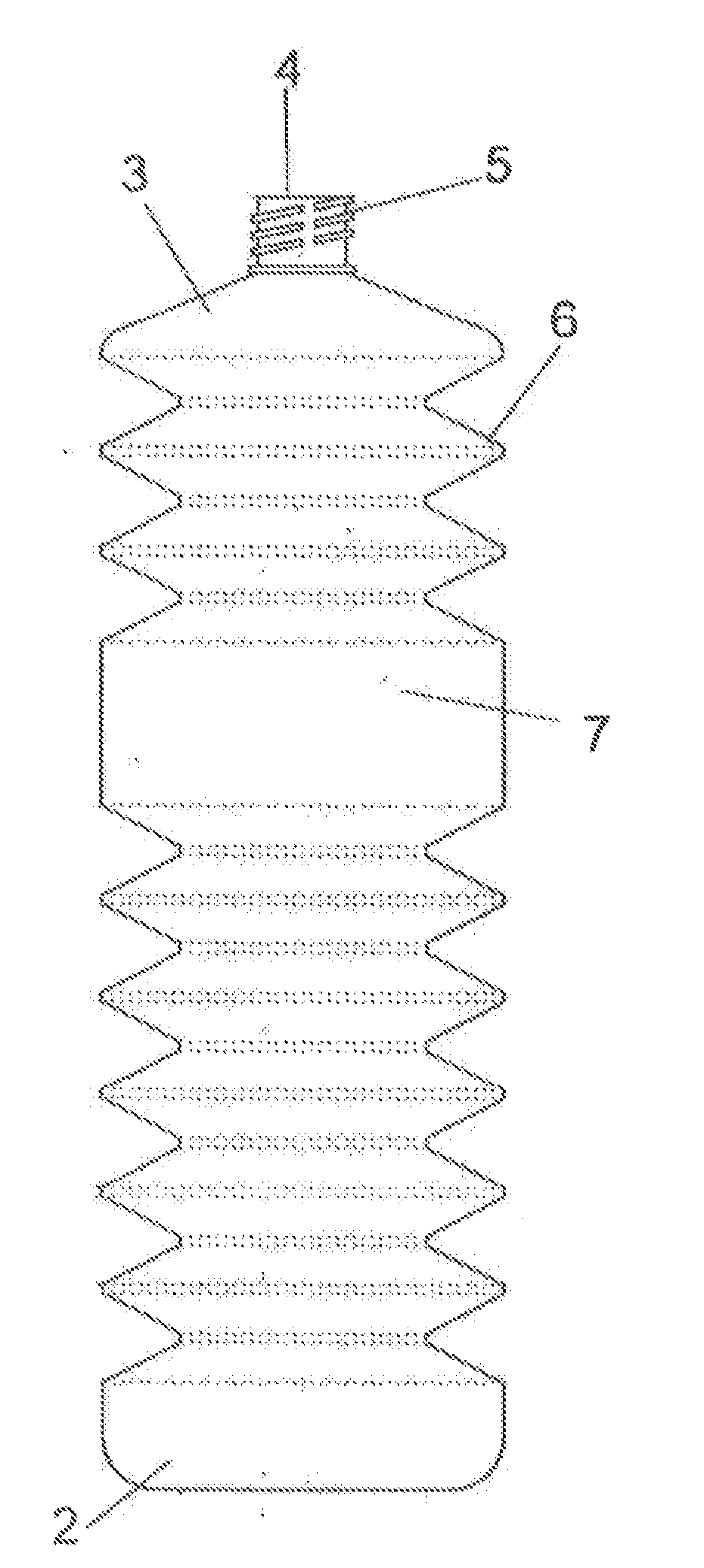

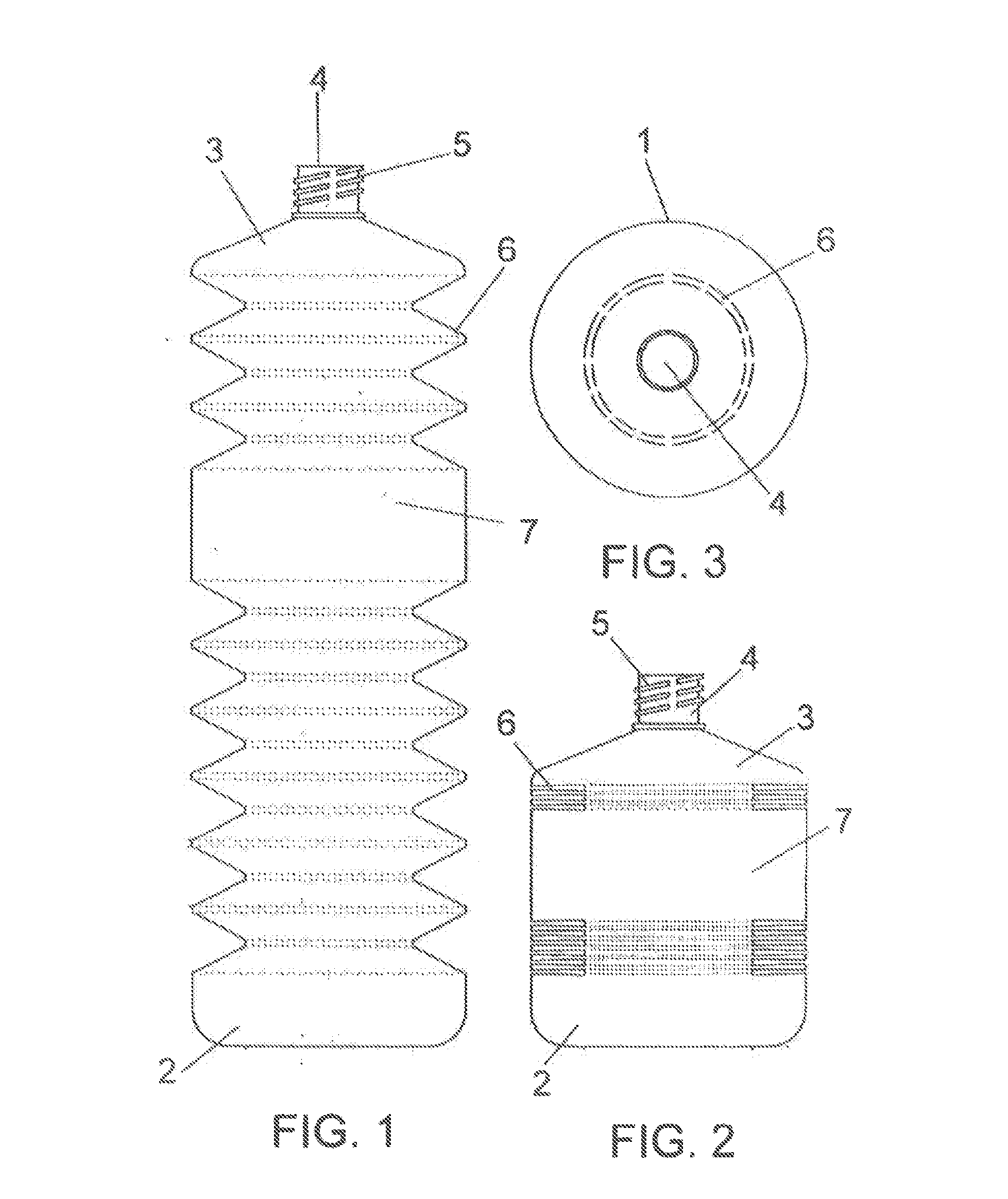

Variable-volume bellows bottle

InactiveUS20120152885A1Reducing or eliminating the air chamberCompensation for pressure lossContainer decorationsLevel indicationsEngineeringBottle

The invention relates to a variable-volume bottle made from PET and having an elastically deformable and plastic-deformation-resistant bellows structure, which allows the volume of the bottle to be adjusted according to the degree to which the peripheral annular folds are folded. The invention comprises one or more sectors without peripheral annular folds, intended for identification labels.

Owner:MUNOZ RODOLFO ENRIQUE

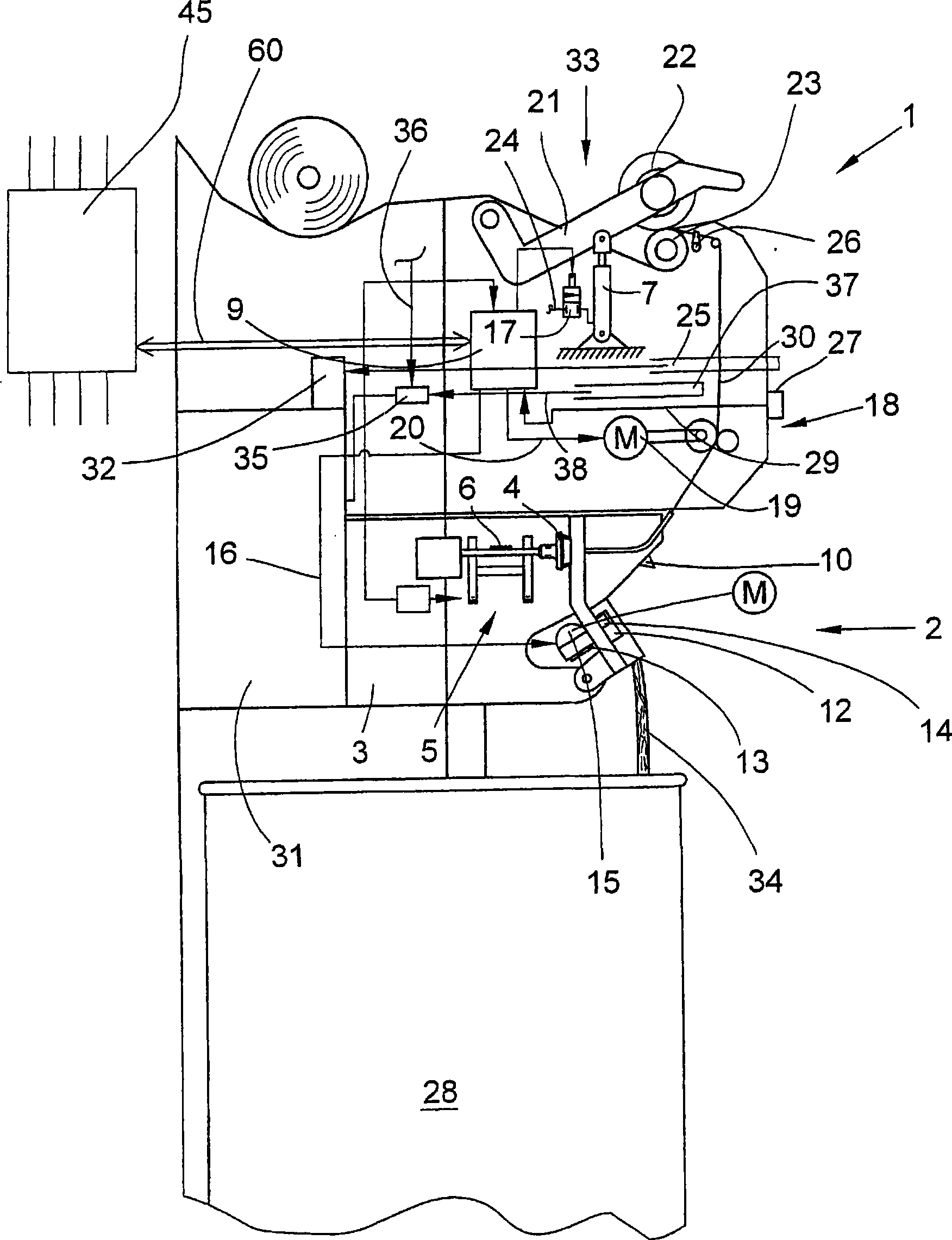

Method and device for operating spinning machine with free end rotor

ActiveCN101429690AReduce energy consumptionReliable handlingContinuous wound-up machinesOpen-end spinning machinesYarnBobbin

The invention relates to a method and device for operating a free end rotor spinner which comprises a plurality of work stations having a spinning device for producing yarns and a winding device for producing a cross winding bobbin, wherein the free end rotor spinner comprises a central control unit and a negative pressure system for the spinner, the negative system also comprises a second negative pressure source which can be turned on when needed besides a main negative pressure source. In the station region, a yarn storage spout subjected with negative pressure for receiving a yarn quantity required in connection with a spinning process and a suction nozzle subjected with the negative pressure which is used during a cross coil / empty case replacement are respectively arranged. According to the invention, the second negative pressure source (42) is arranged to be automatic turn-on as occasion requires.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

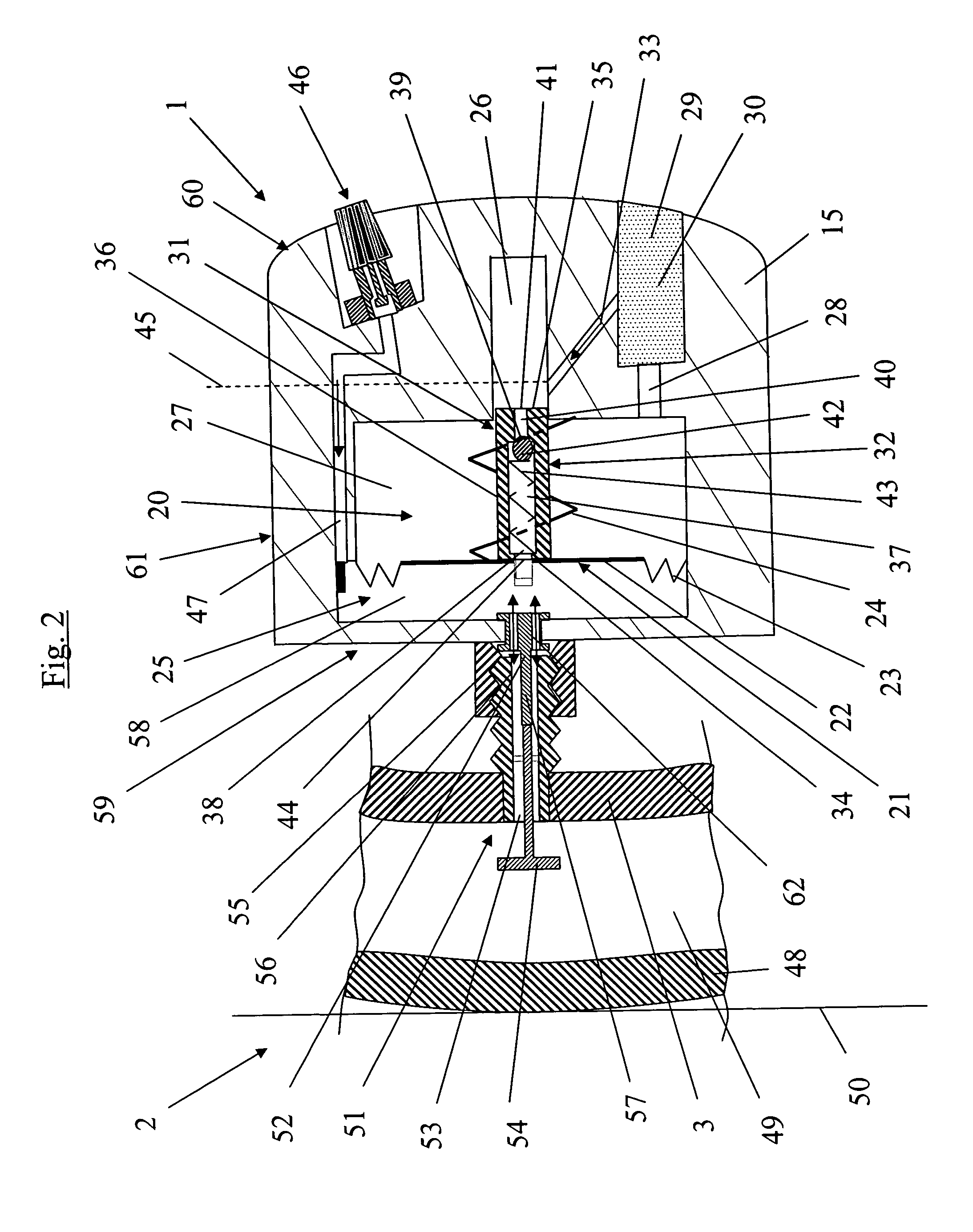

Automatic tire pressurizing device

InactiveUS20050279439A1Compensation for pressure lossLower the volumeTyre measurementsTyre-inflating valvesCompressed airTire pressure

The invention refers to a pneumatic tire pressurizing device for automatically pressurizing a load-bearing tire during rotation thereof over a surface, said tire comprising a tire volume comprising compressed air having a predetermined tire pressure. The pressurizing device comprises a compression unit connected to a movable device. The pressurizing device is connectable to a wheel comprising the tire, and when connected to the wheel the compression unit is arranged to compress air in the compression chamber when the movable device, starting from a negative position, is affected by a sudden increase of the tire pressure due to deformation of the tire when passing an irregularity in the surface, wherein said compression unit is arranged to feed the compressed air in the compression chamber to the tire volume via the pressure chamber.

Owner:FORD GLOBAL TECH LLC

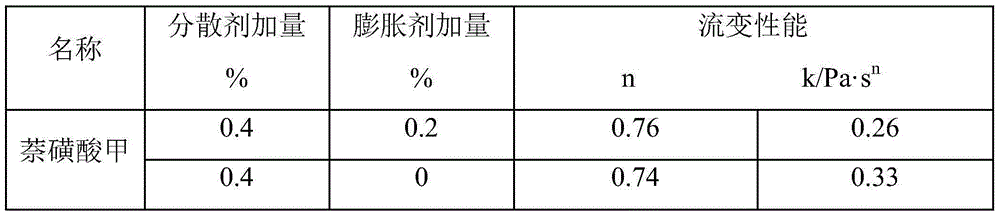

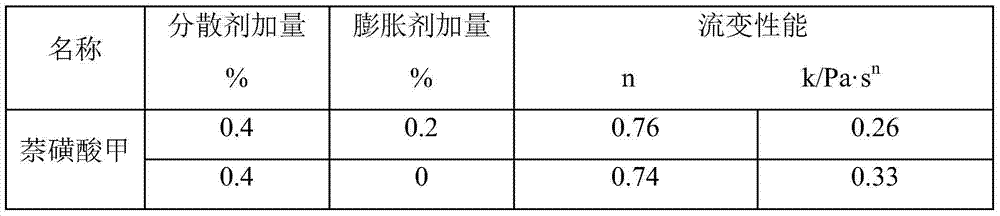

Oil well cement gas expansion agent

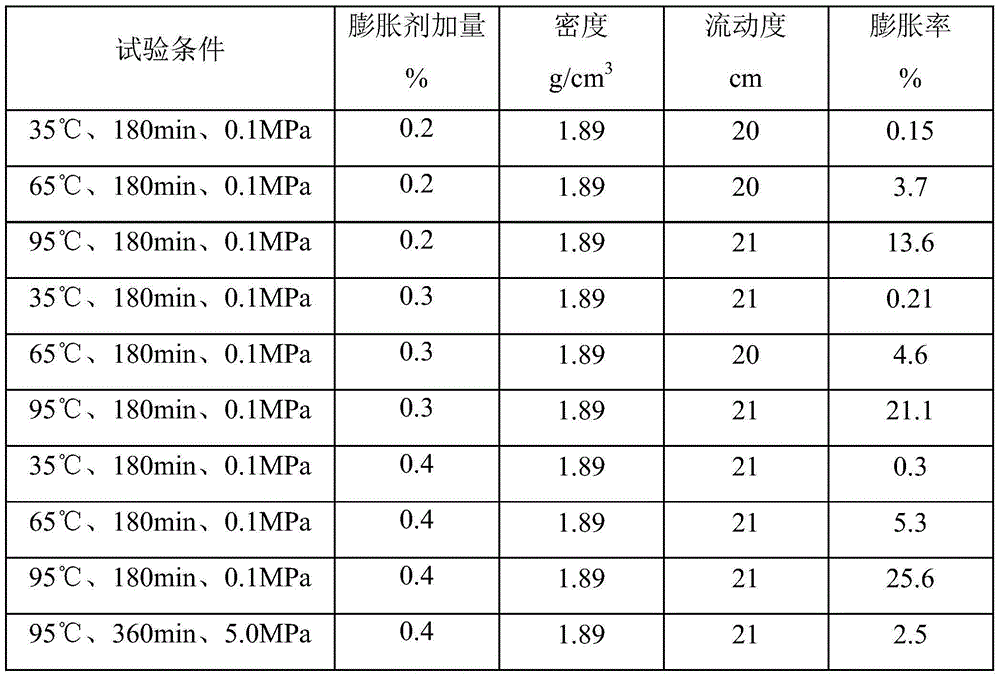

ActiveCN104818007APromote expansionAchieve swelling effectDrilling compositionCalcium silicateNitrogen

The invention discloses an oil well cement gas expansion agent, which consists of 30-40 parts by weight of a gas generating agent and 60-70 parts by weight of a stabilizer. The gas generating agent is a sulfohydrazide compound, and the stabilizer is at least one of silicon dioxide and calcium silicate. The oil well cement gas expansion agent can be used for daily dry blending work, and also can be used for on-the-spot wet blending work. When the oil well cement gas expansion agent acts on cement paste, the temperature reaches 35DEG C under an alkaline condition, nitrogen release starts. By means of the effect of the stabilizer in the components, small bubbles can be evenly distributed in the cement paste, and the only generated gas is nitrogen, which has no corrosion to pipes. In addition, the oil well cement gas expansion agent has good compatibility and compatibleness with other cement additives, also can effectively compensate the pressure loss and volume shrinkage when the cement paste solidifies, and prevents well cementing oil gas and water channeling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

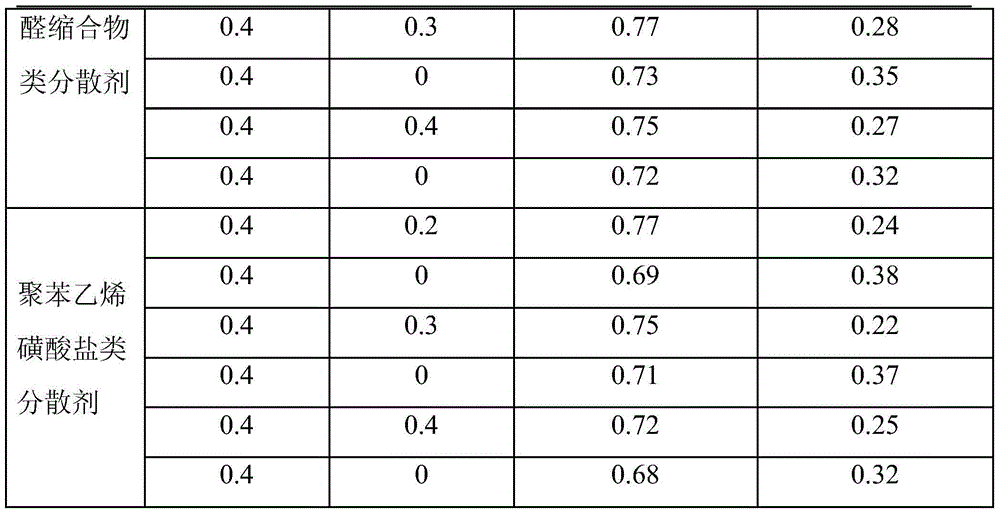

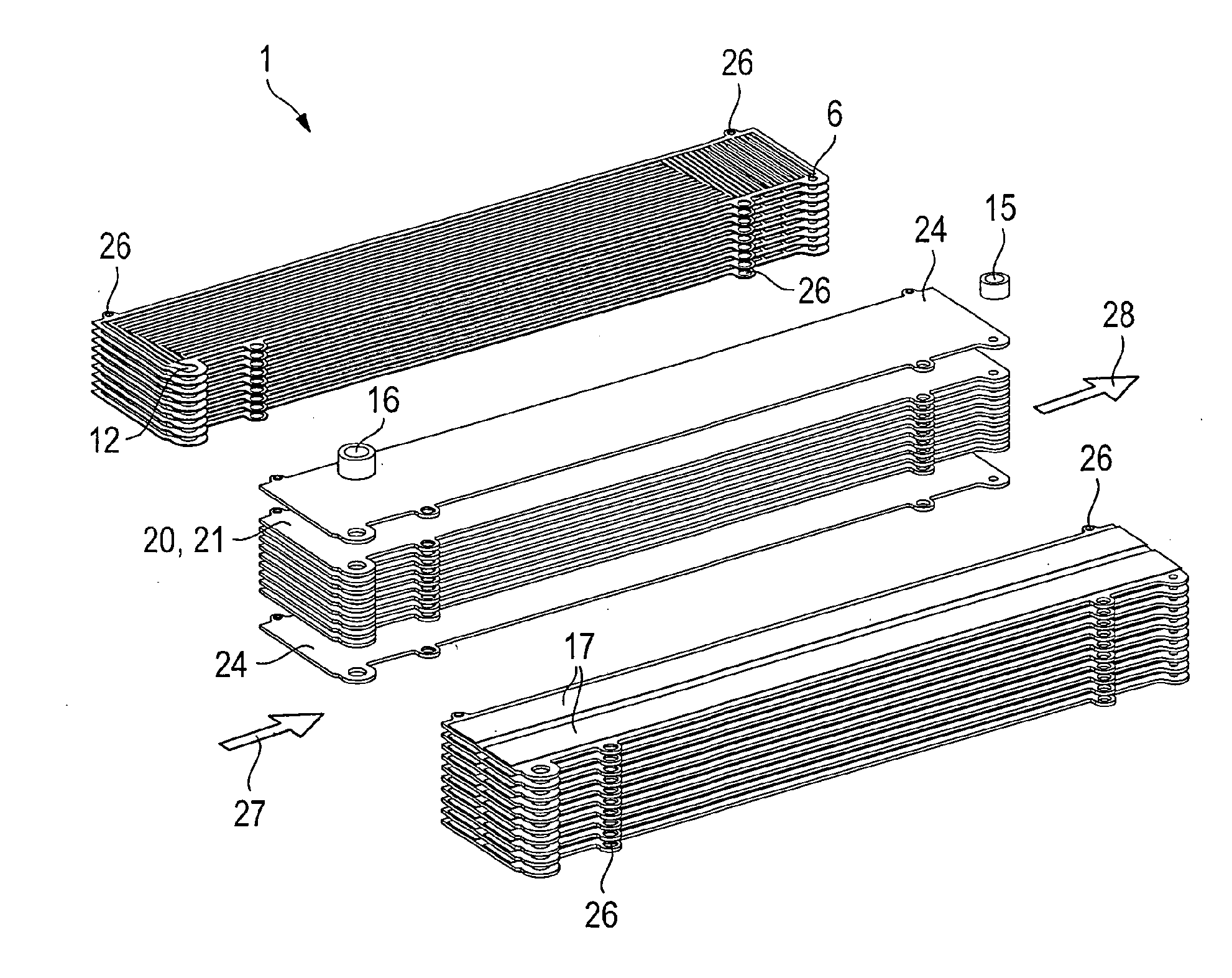

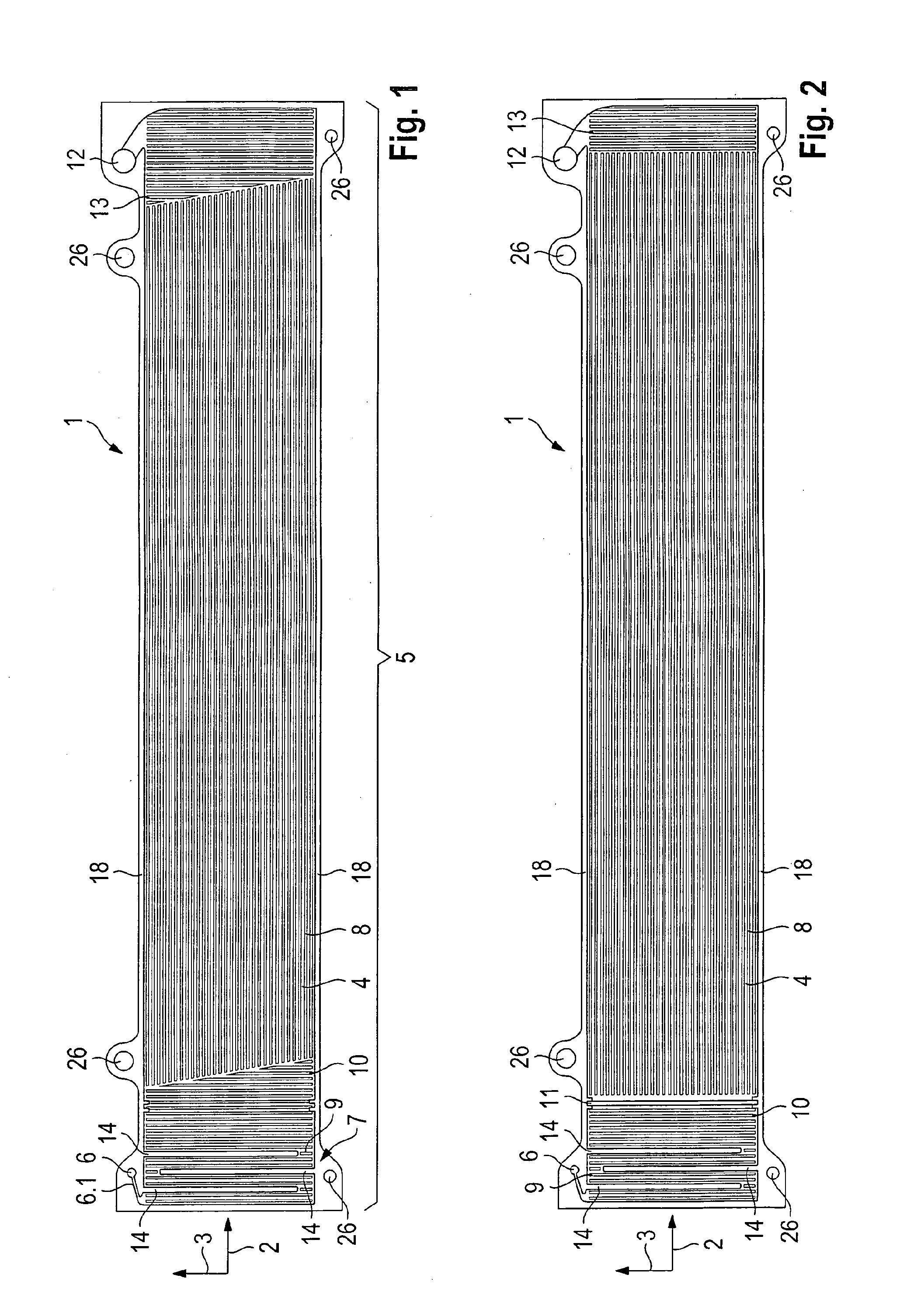

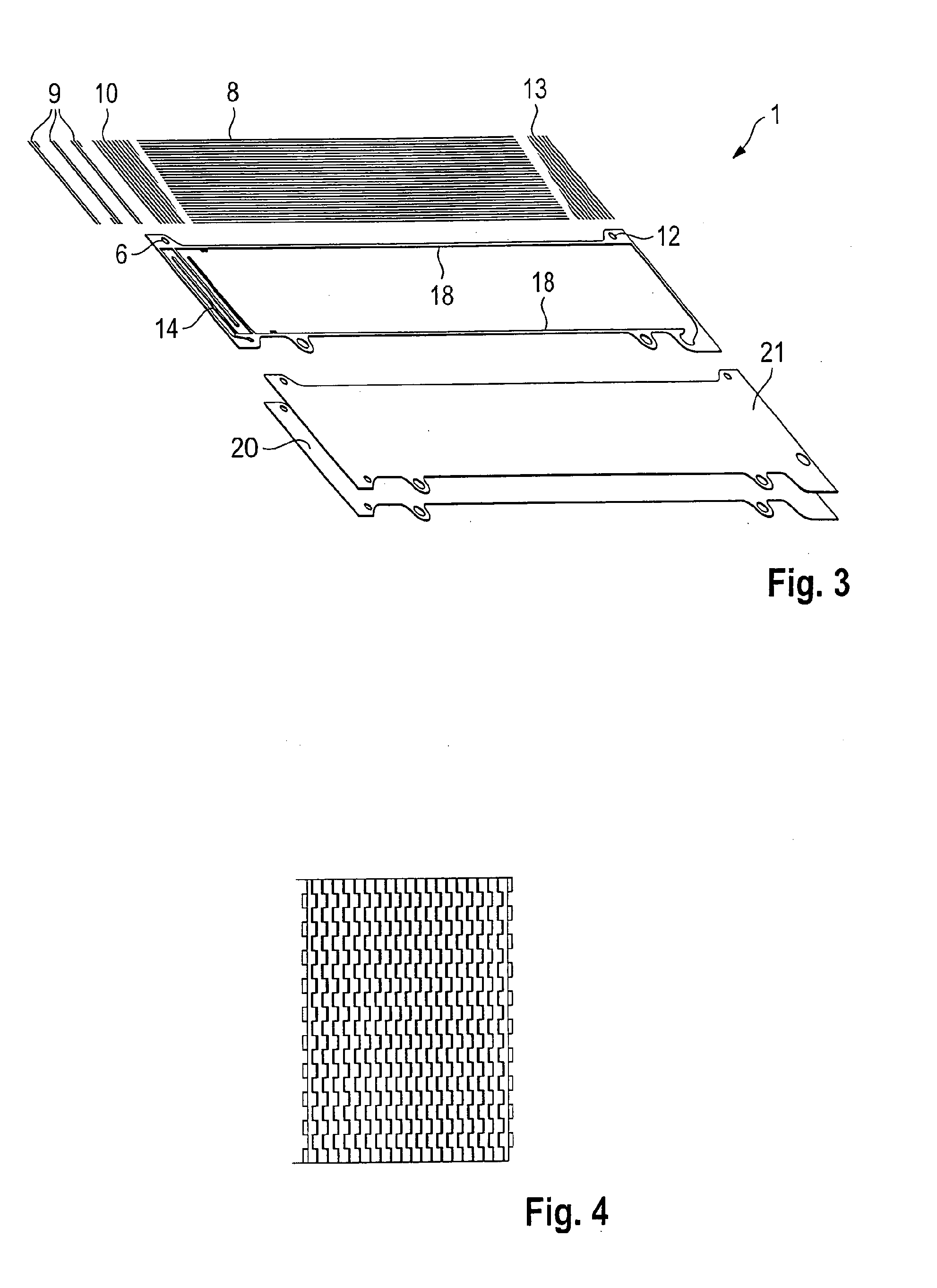

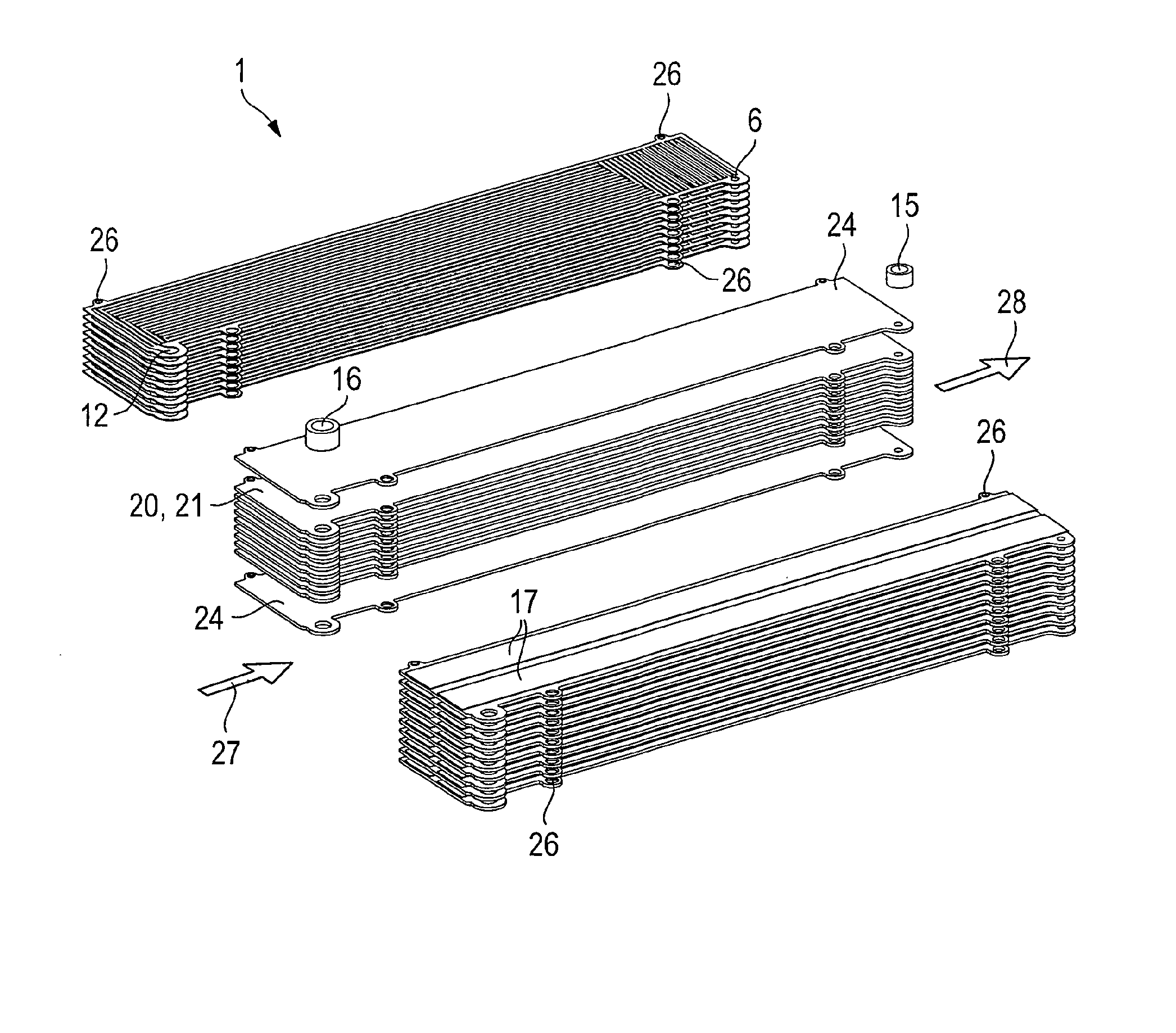

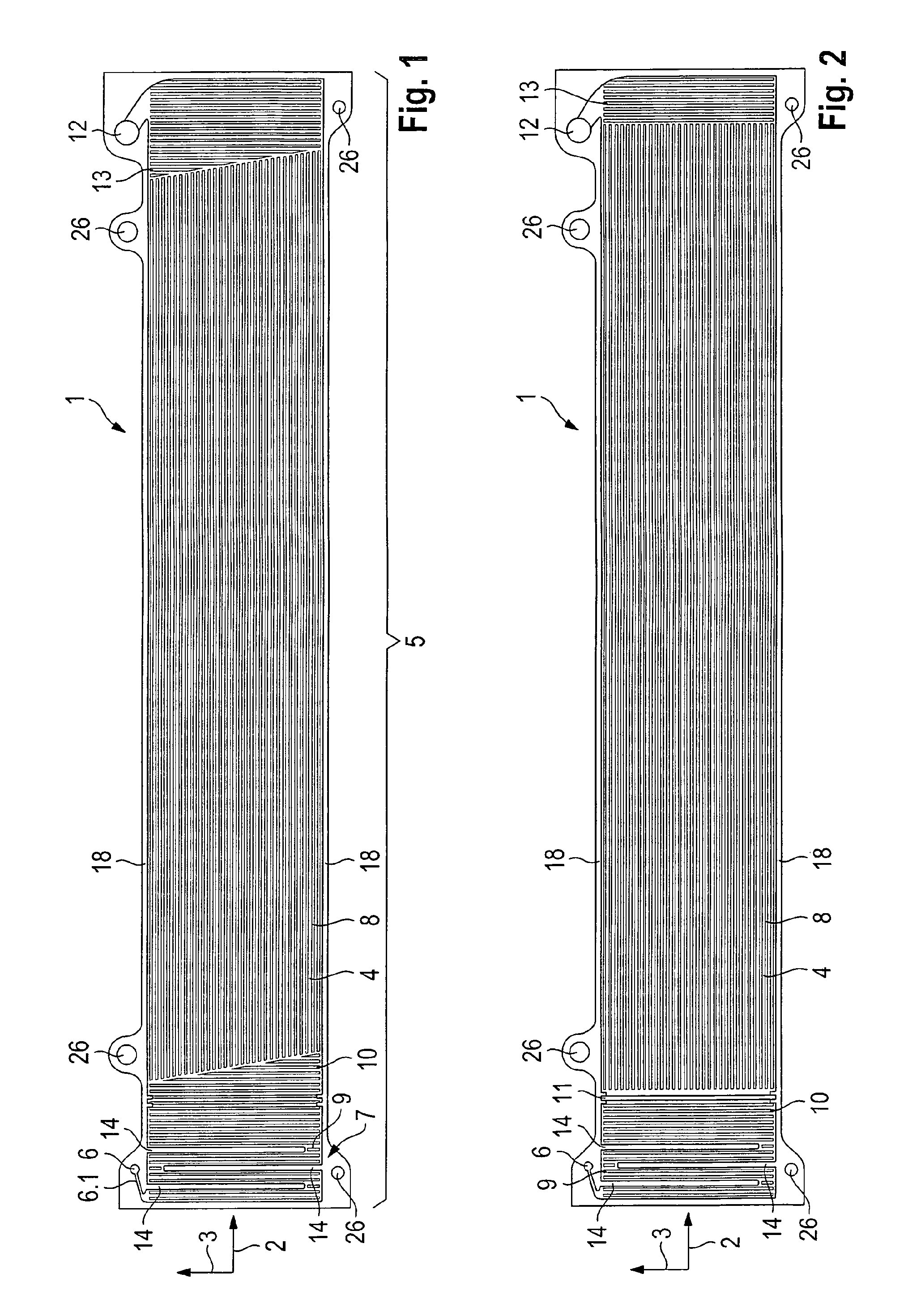

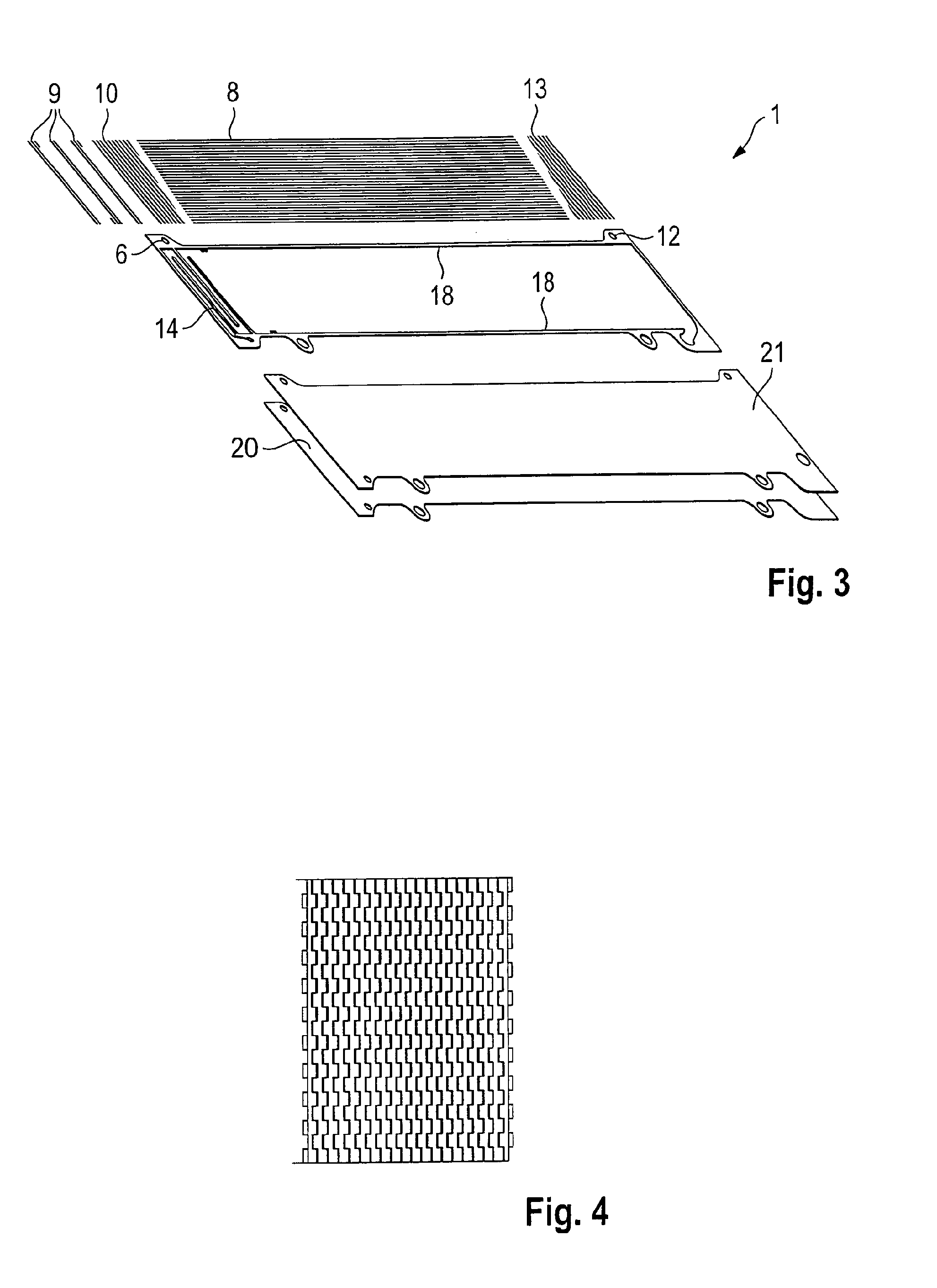

Heat exchanger plate and an evaporator with such a plate

InactiveUS20120255288A1Compensation for pressure lossEqually distributedExhaust apparatusSilencing apparatusTransverse axisEngineering

A heat exchanger plate for an evaporator includes a flow transverse distribution device. Disks of the flow transverse distribution device conduct the medium to be evaporated to the flow channel extending in the direction of the longitudinal axis. The disks include openings allowing a flow of the medium in the direction of the longitudinal axis with comparatively higher flow resistance than in the direction of the transverse axis. The number of disks arranged one behind the other in the direction of the longitudinal axis varies over the width of the heat exchanger plate in the direction of the transverse axis. On each width section, in which the entry of the medium into the disks arranged one behind the other is intended, the comparatively largest number of disks is provided one behind the other. As the distance from the entrance increases, the number decreases in the direction of the transverse axis.

Owner:STEAMDRIVE

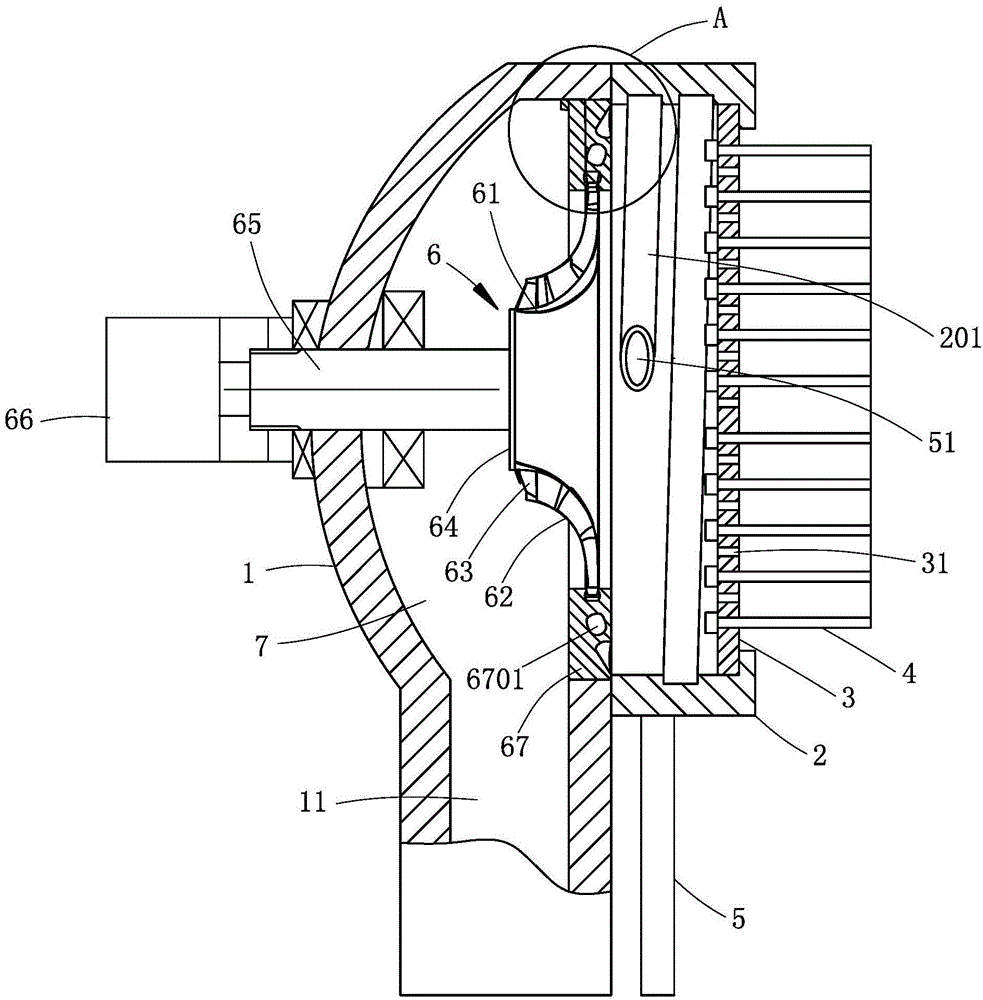

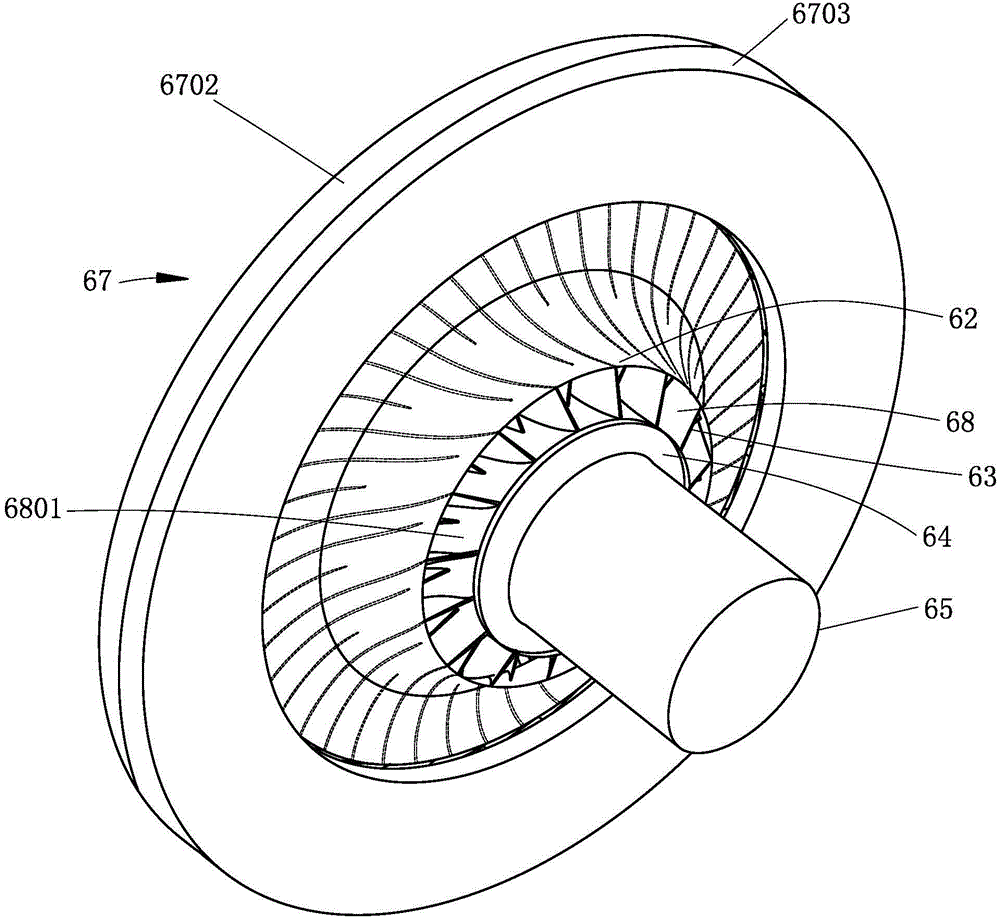

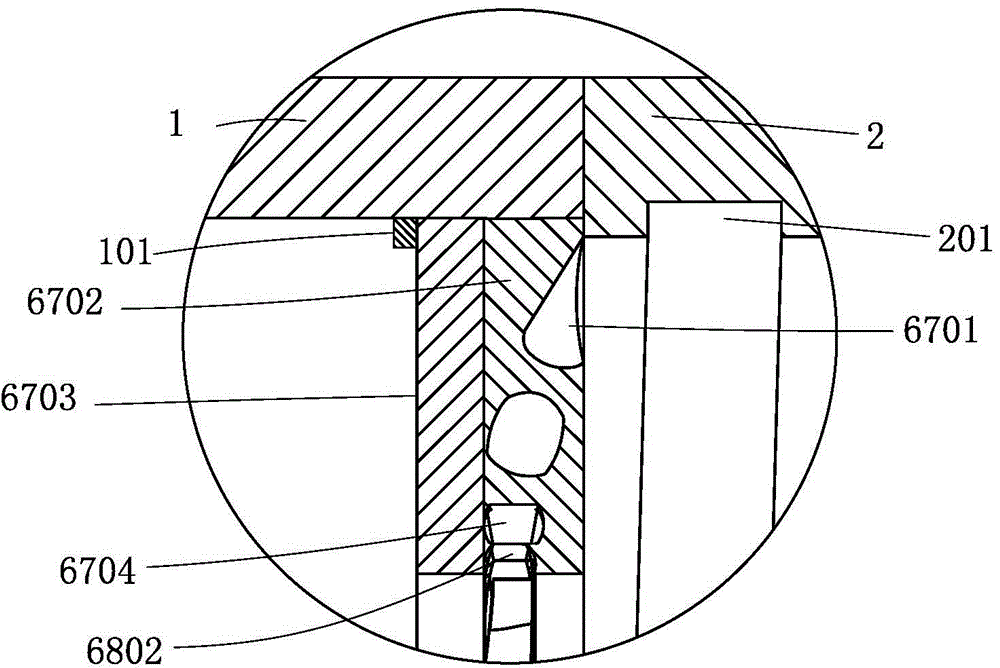

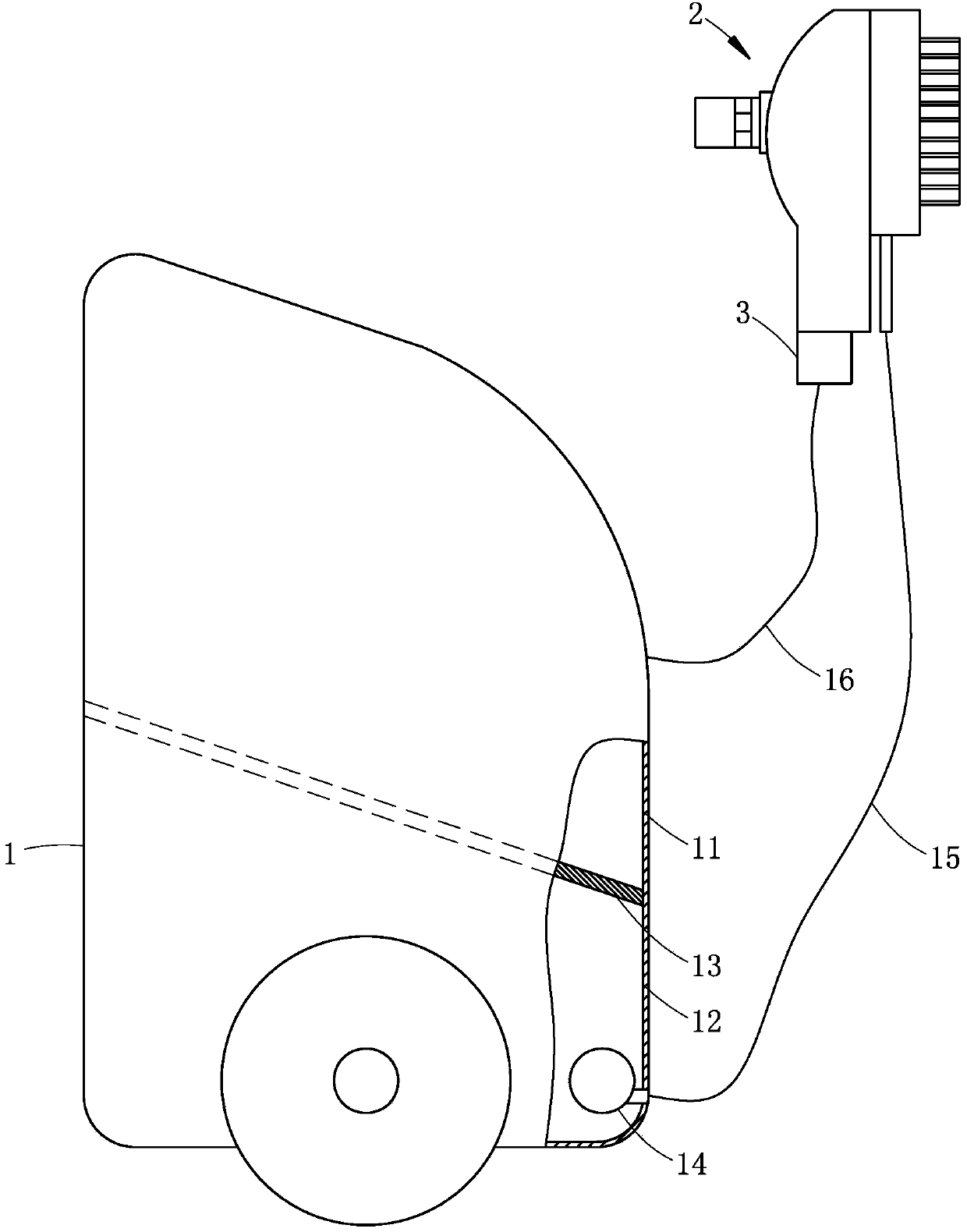

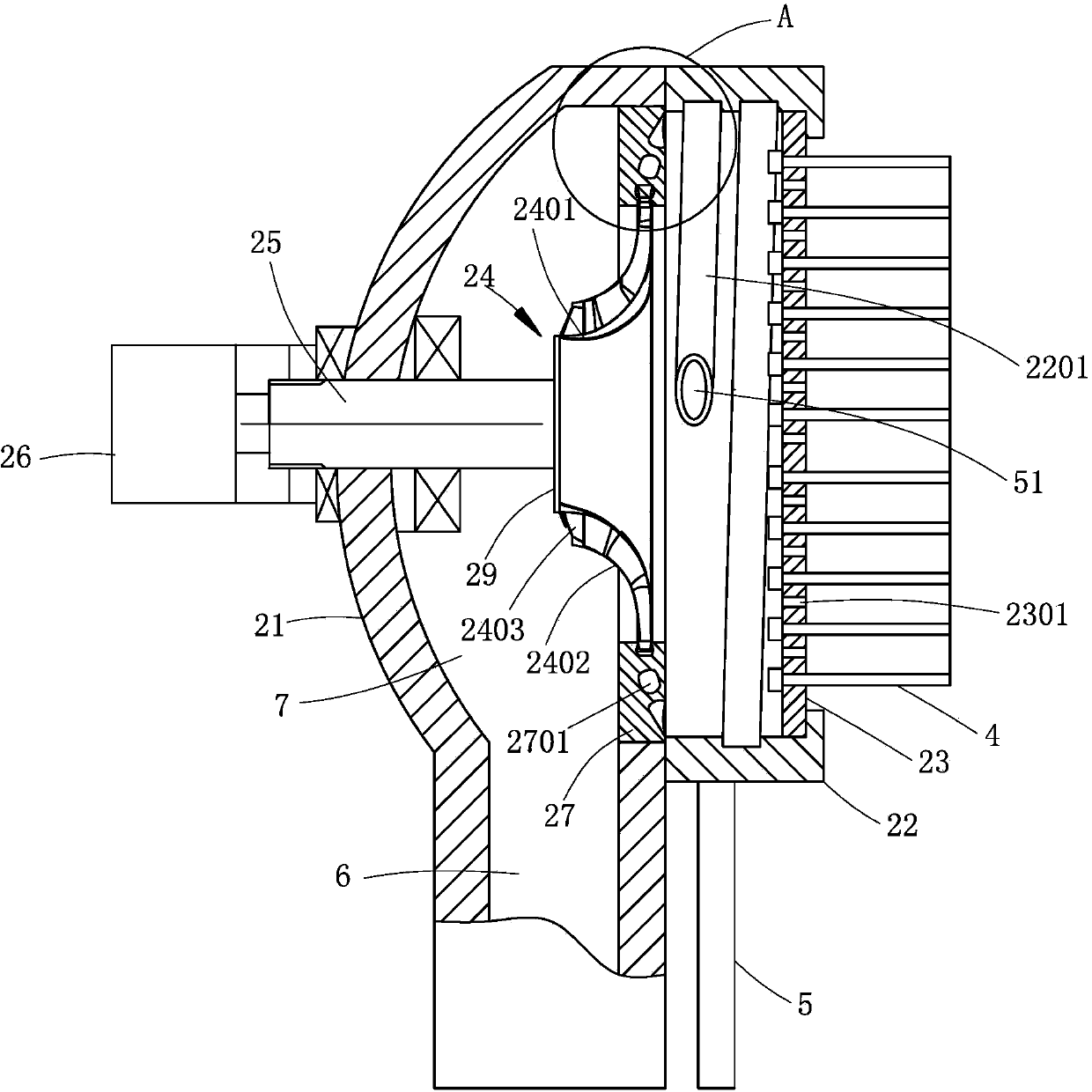

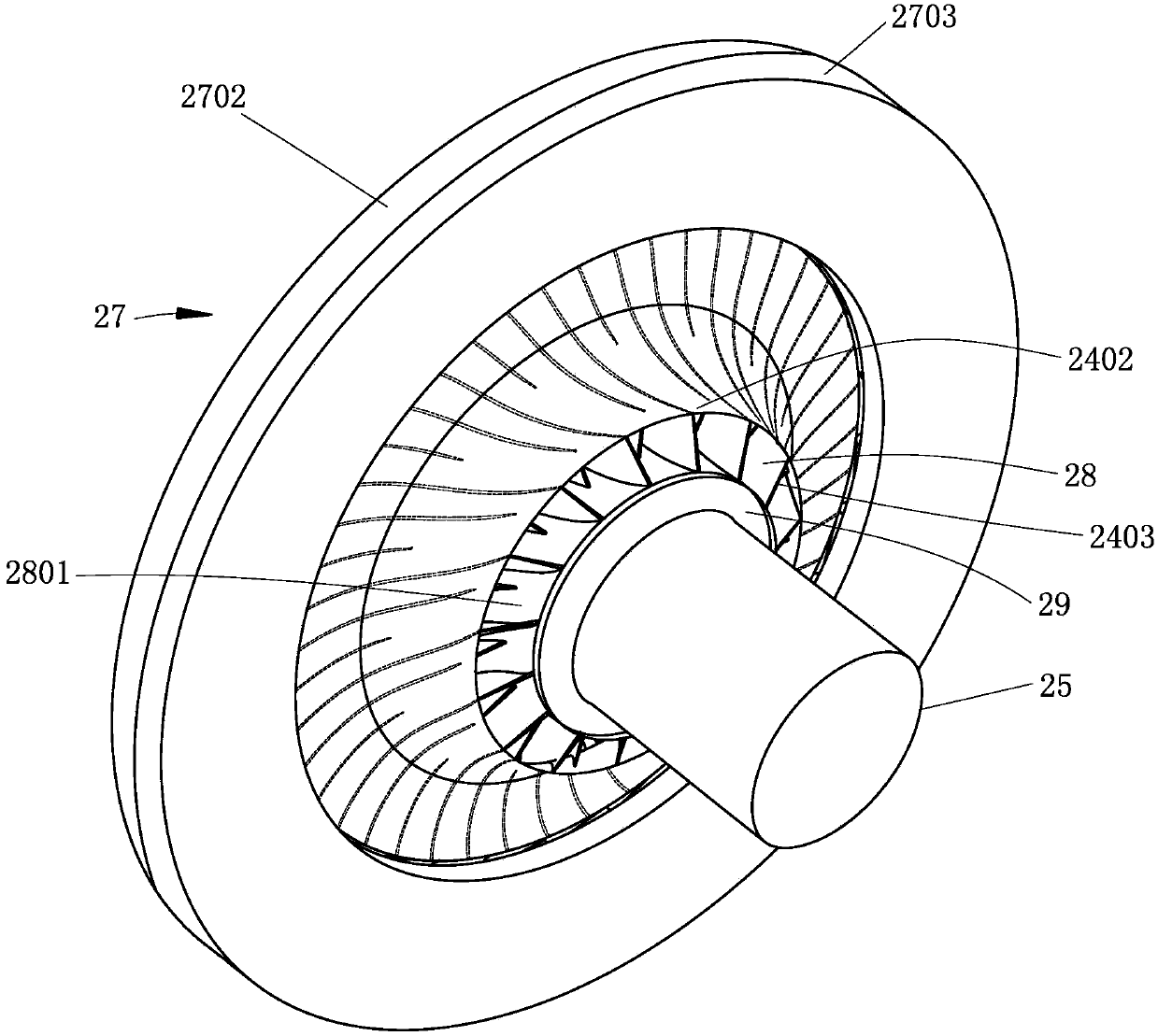

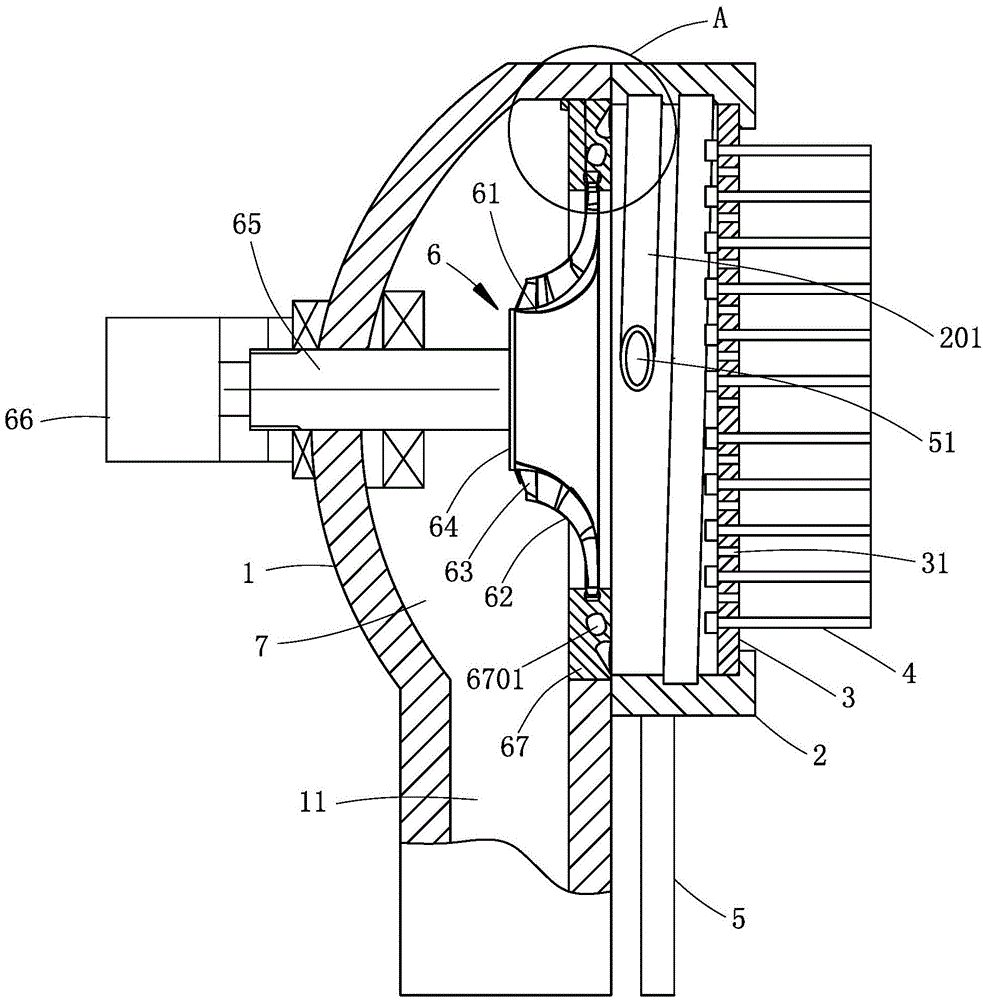

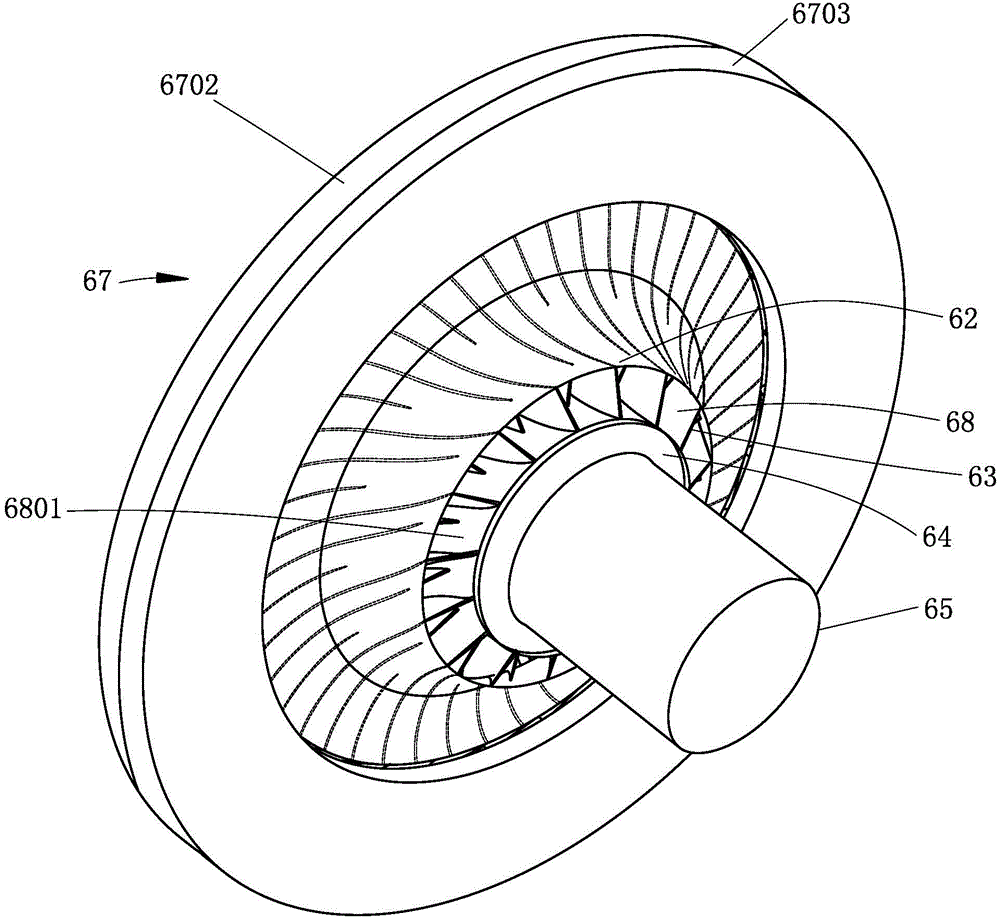

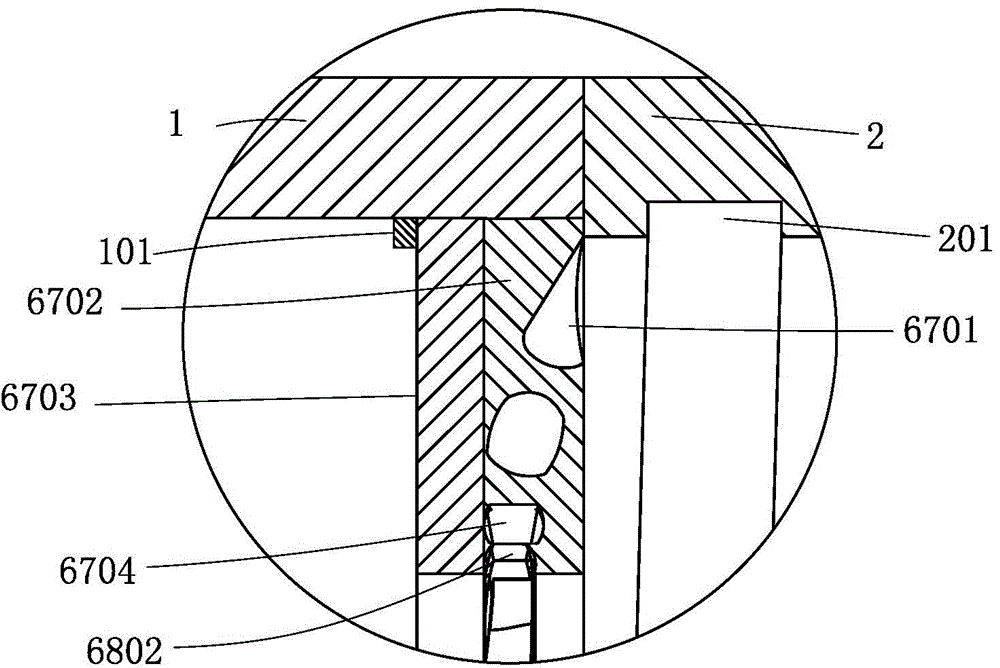

Novel round brush and high pressure cleaning machine with same

ActiveCN104146489ACompensation for pressure lossAvoid water rustBrush bodiesVehicle cleaningWater dischargeEngineering

The invention discloses a novel round brush and a high pressure cleaning machine with the same and belongs the fields of cleaning equipment auxiliary parts and machines. The round brush comprises an upper sprayer and a lower sprayer which are mounted fixedly and integrally and which form a spraying cavity; the lower sprayer is fixedly provided with a brush disc provided with a plurality brush hairs, and the brush disc is provided with a plurality of water discharging holes among the brush hairs; the lower sprayer is connected to a water incoming pipe, and the water outlet of the water incoming plate extends into the spraying cavity; the upper sprayer is provided with an air incoming channel communicating with the spraying cavity, and a pressurizer pressurizing the air flow entering the spraying cavity is arranged between the air incoming channel and the water outlet of the water incoming pipe and is located in the spraying cavity. The round brush has the advantages that energy and water are saved, the brushing effect is fine, a vehicle can be protected and the service life is long, and the round brush is widely applied to vehicle washing.

Owner:NINGBO FUSLE MECHANICAL MFG

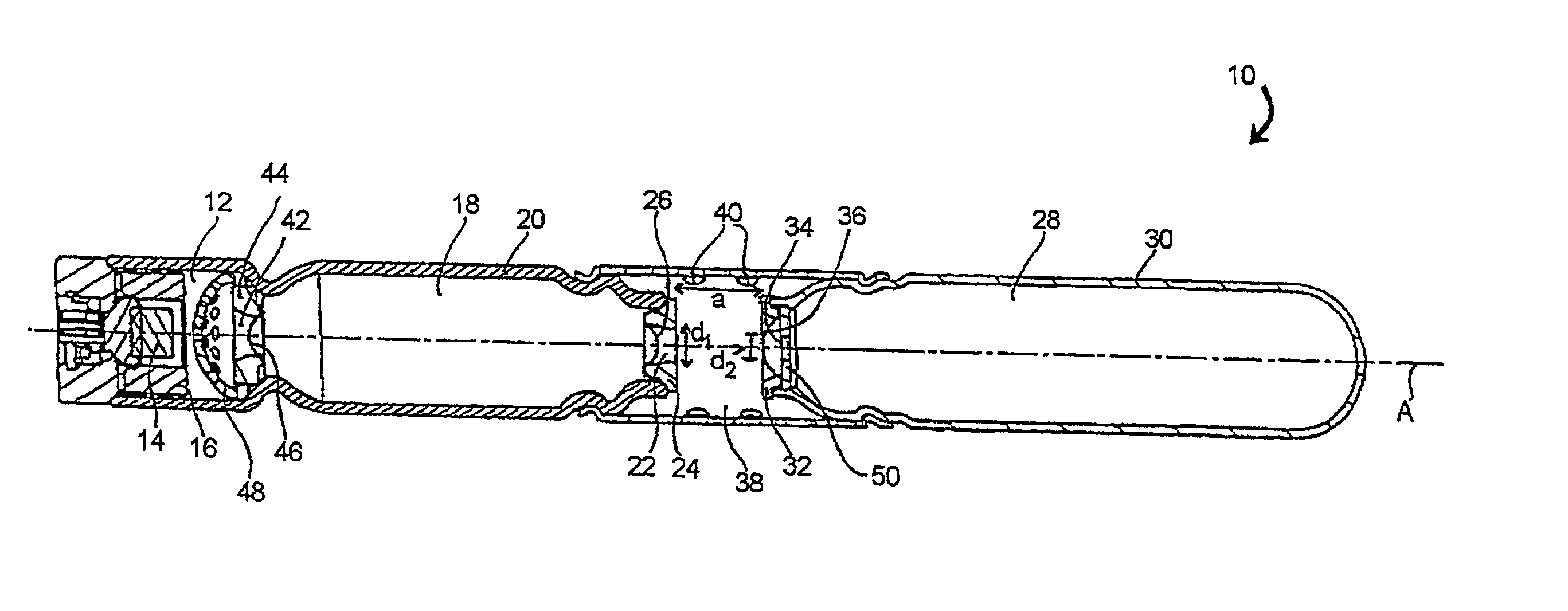

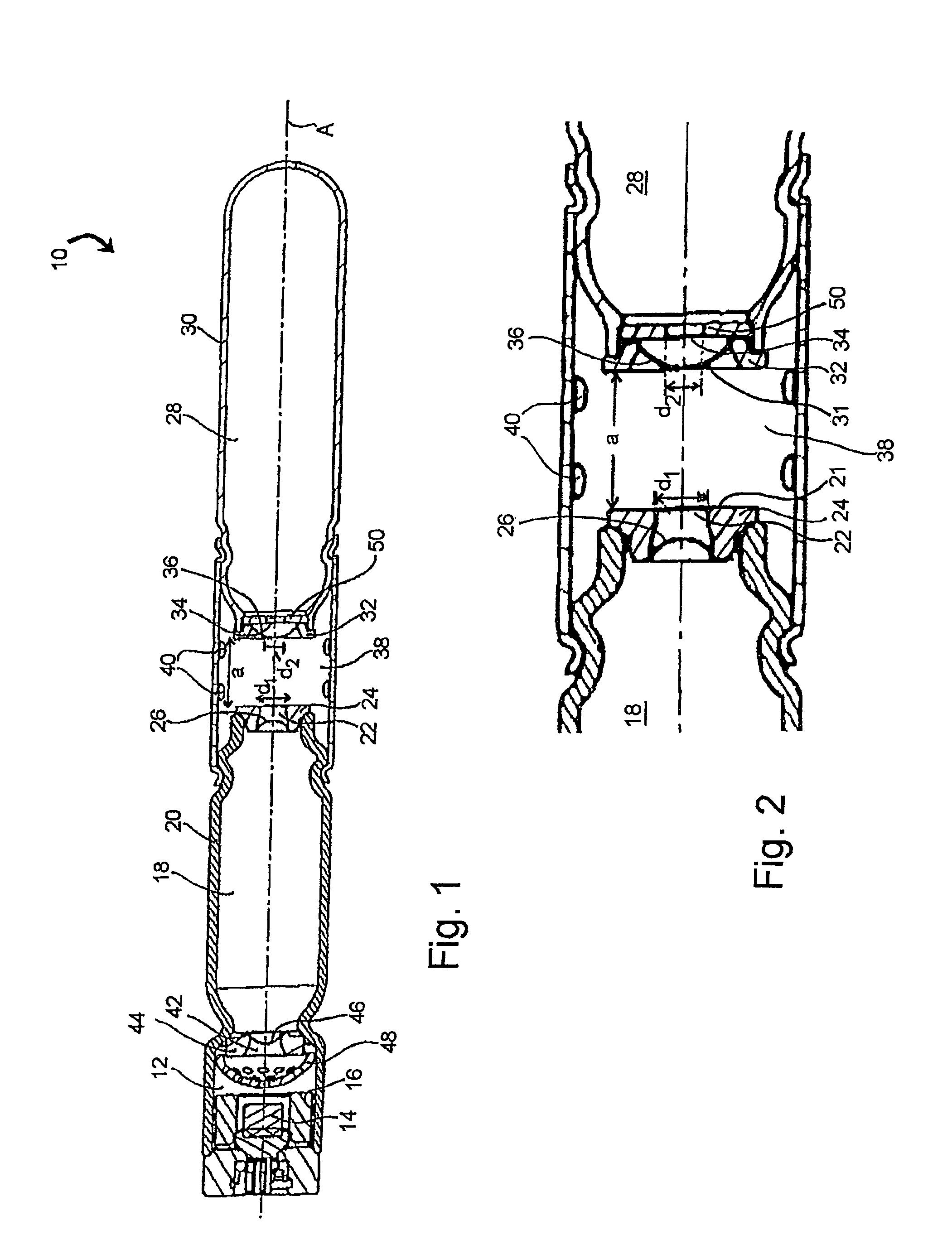

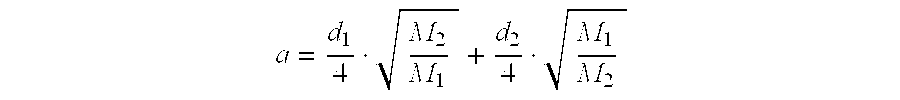

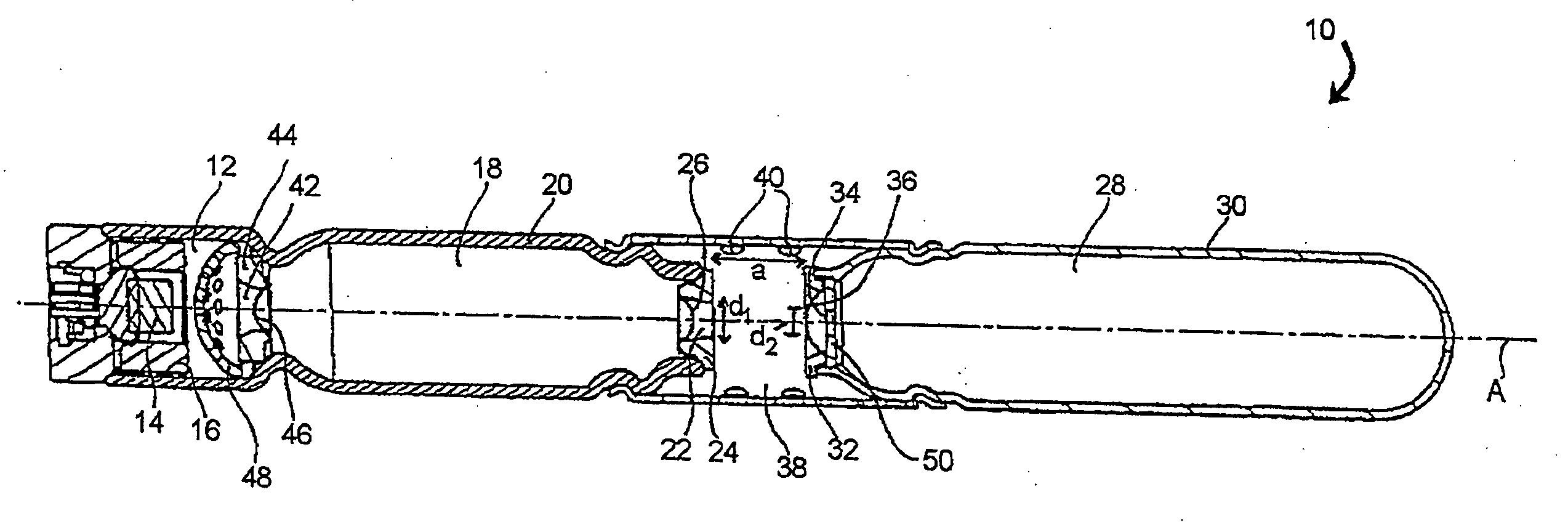

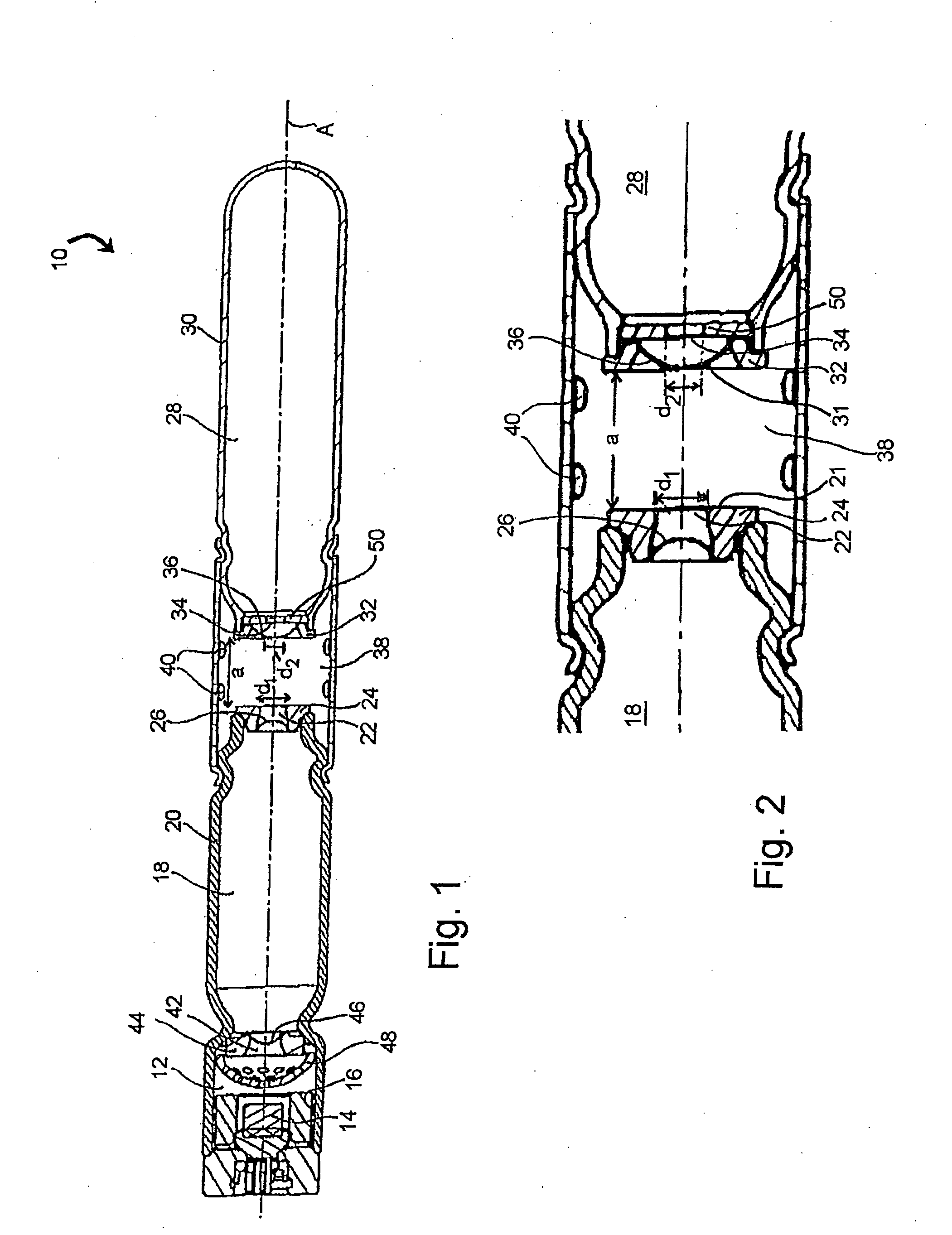

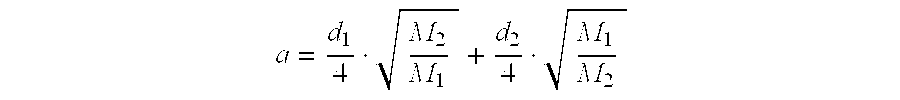

Gas generator, in particular for a vehicle occupant restraint system, and method of activating a vehicle occupant restraint system

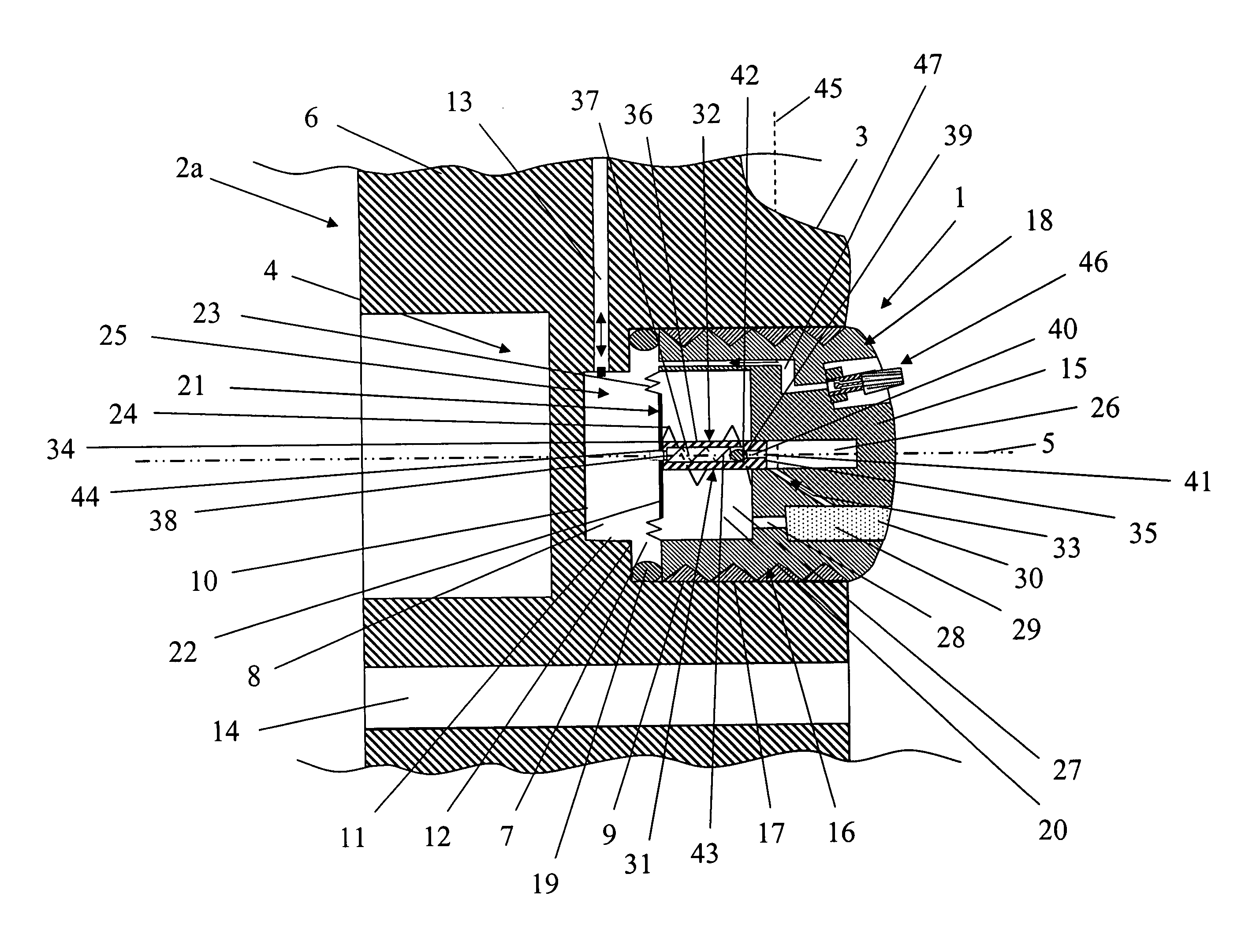

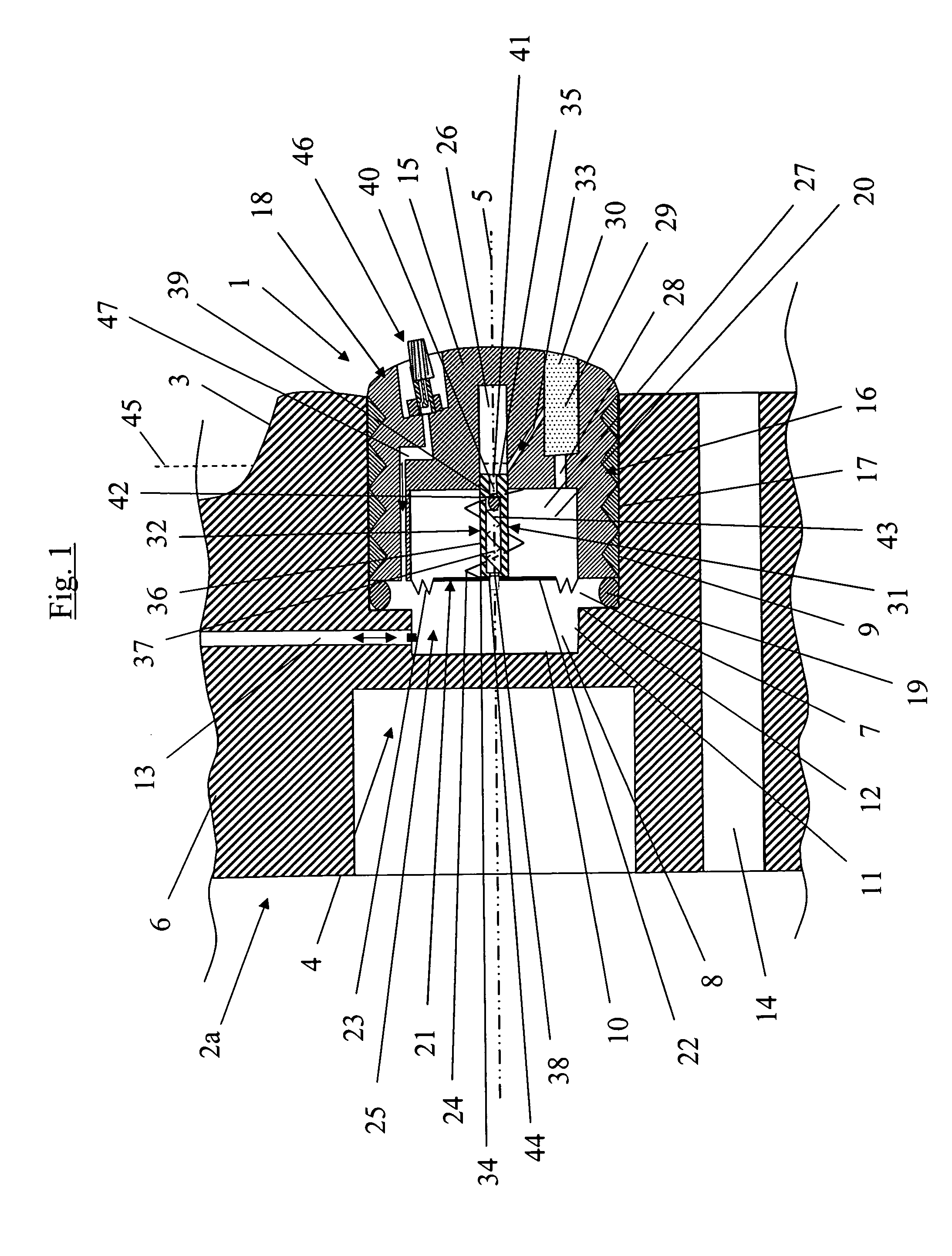

ActiveUS7828324B2Extended supply timeSmall spacingPedestrian/occupant safety arrangementPressure gas generationCombustion chamberBiological activation

A gas generator, in particular for a vehicle occupant restraint system, has a pyrotechnical propellant (16), a combustion chamber (12) filled with the pyrotechnical propellant (16), an igniter (14) associated with the combustion chamber (12), a pressure chamber (18), filled with compressed gas, which is adjacent to the combustion chamber (12) and has a first opening (22) remote from the combustion chamber (12) closed by a first diaphragm (26), the diaphragm (26) being destroyed upon activation of the igniter (14), and a second pressure chamber (28) which is filled with compressed gas and has a second opening (34) closed by a second diaphragm (36). The second diaphragm (36) is likewise destroyed upon activation of the igniter (14), and the openings (22, 34) and the gas volumes of the pressure chambers (18, 28) are adapted so that compressed gas flows out from the second pressure chamber (28) for a longer period than compressed gas from the first pressure chamber (18) to increase a gas supply time of the gas generator (10). Further, a method of activating a vehicle occupant restraint system is described.

Owner:TRW AIRBAG SYST

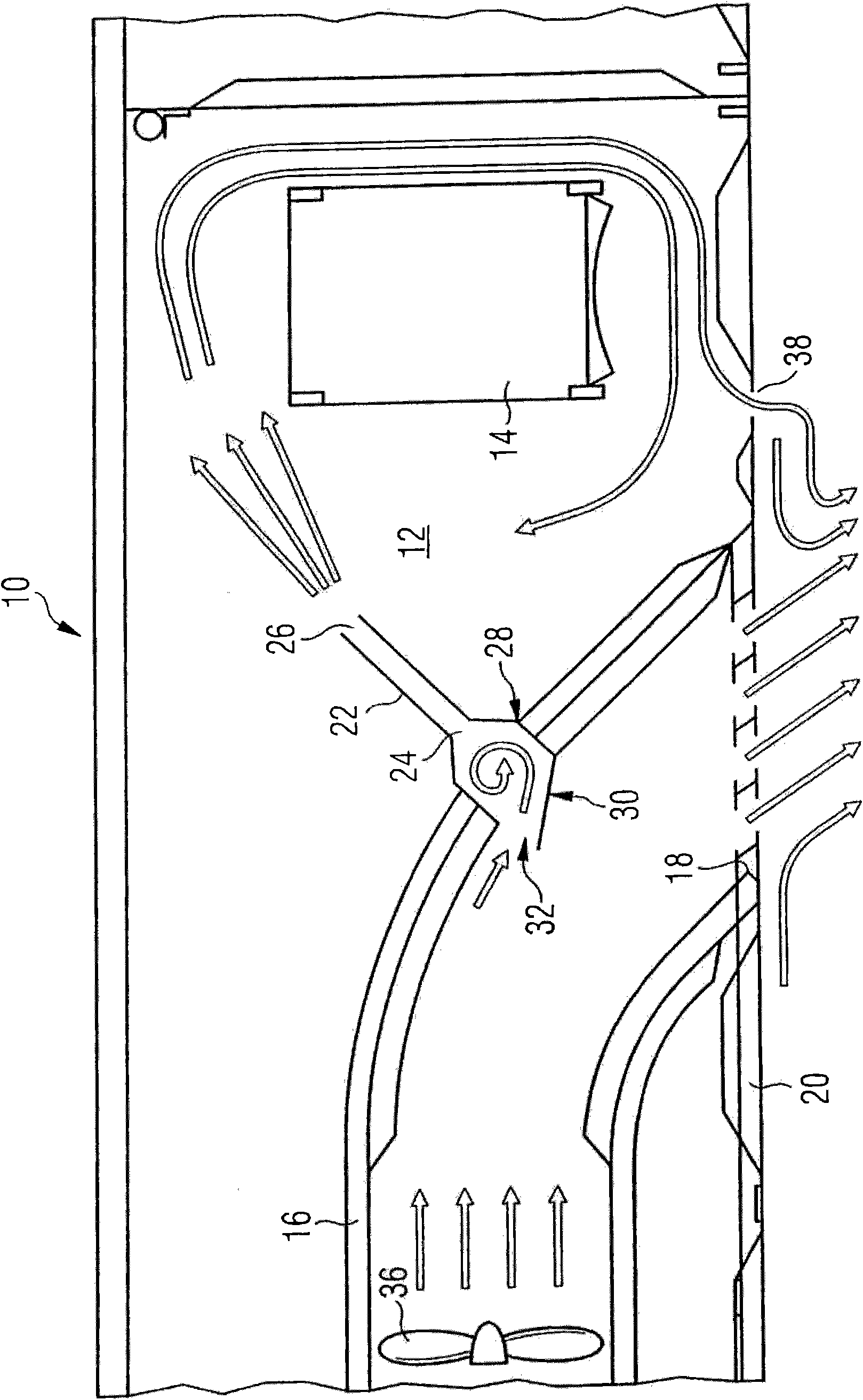

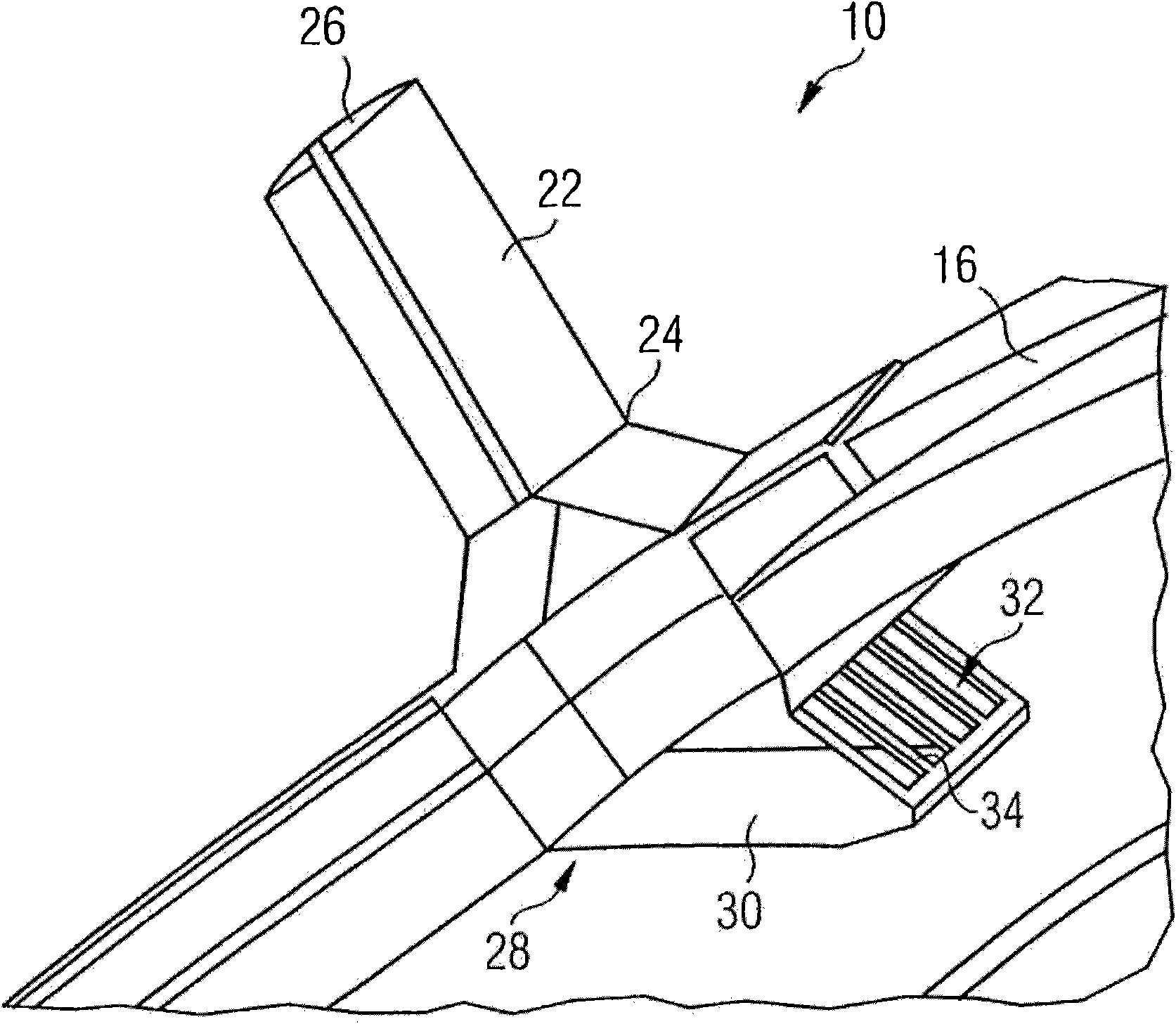

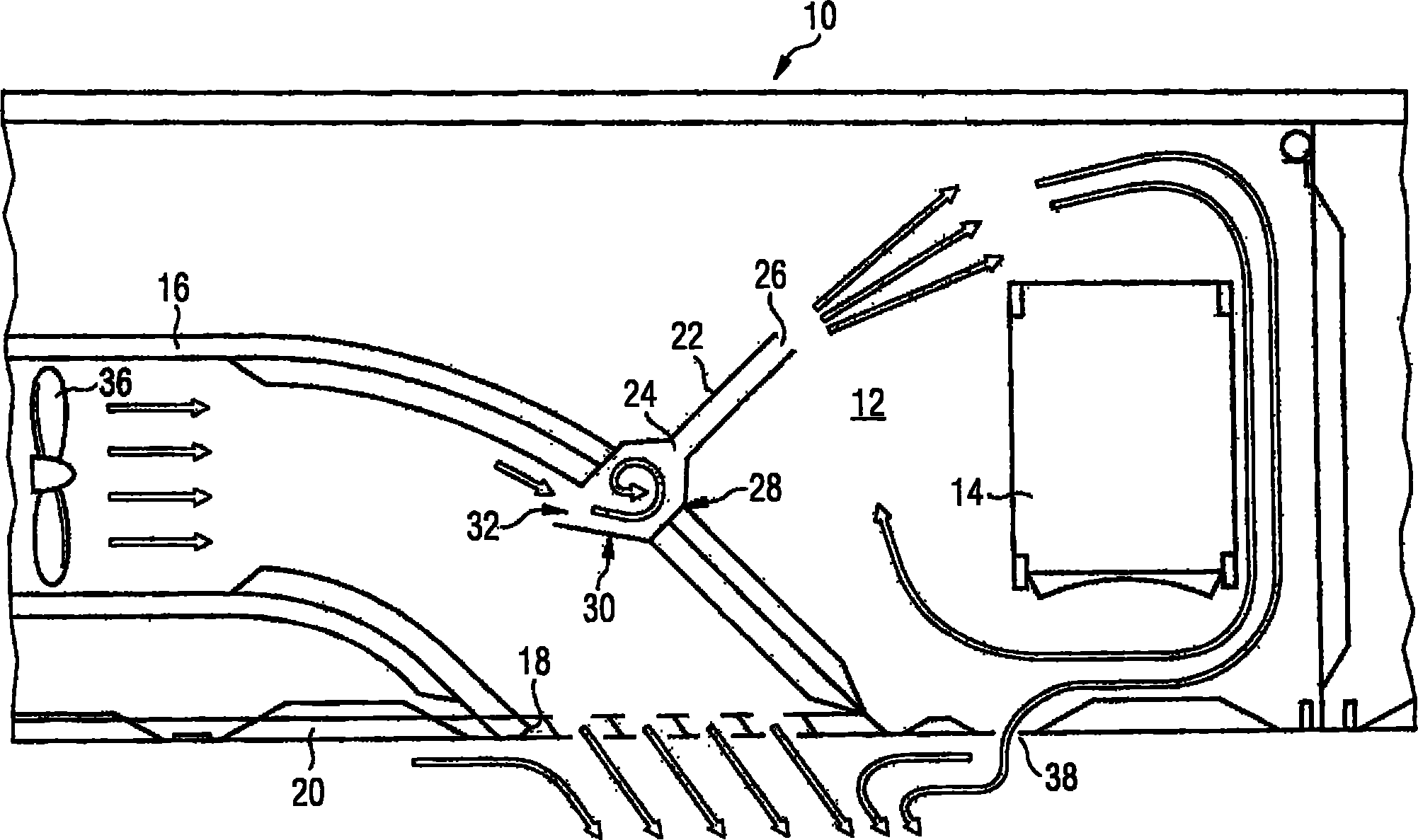

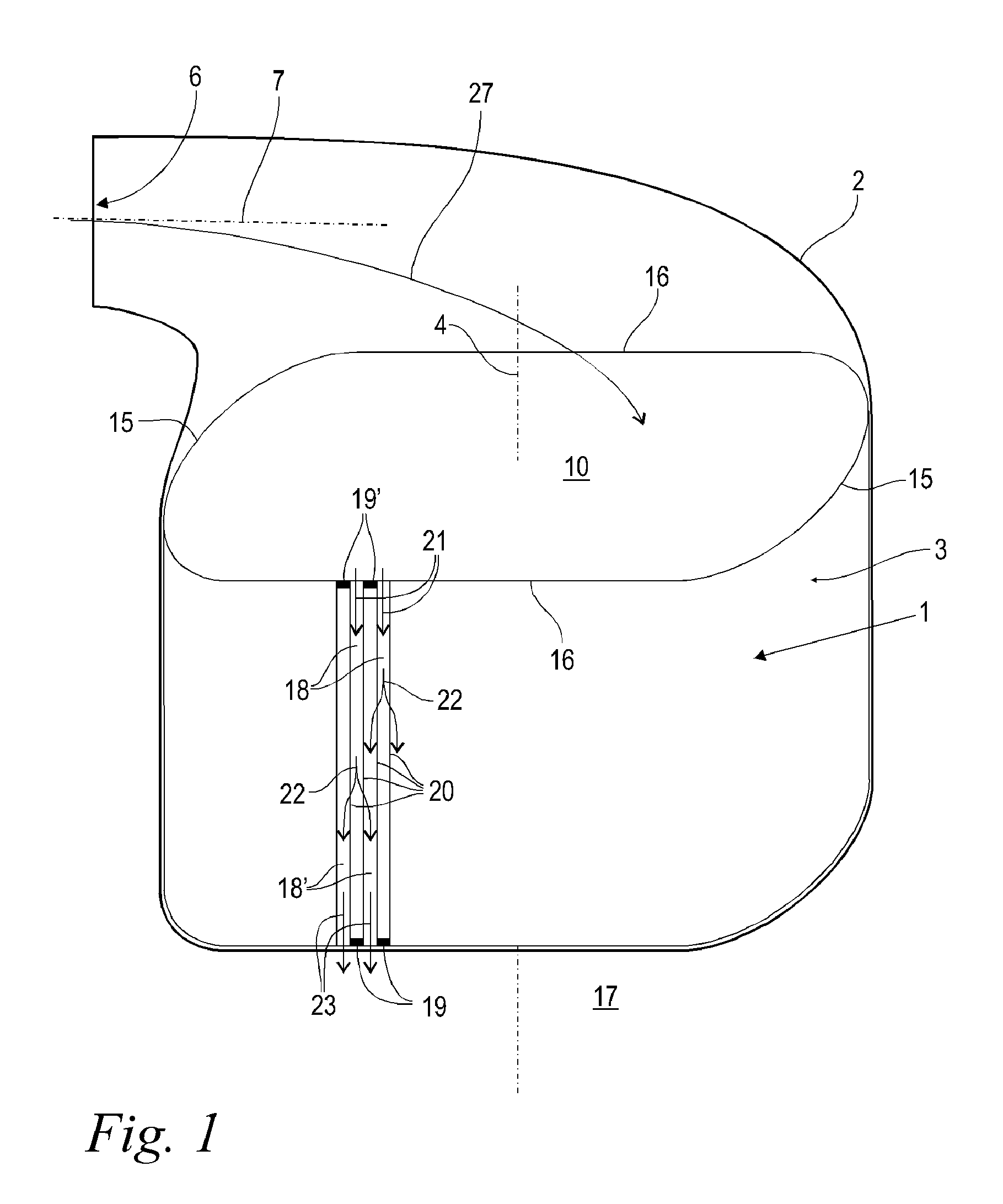

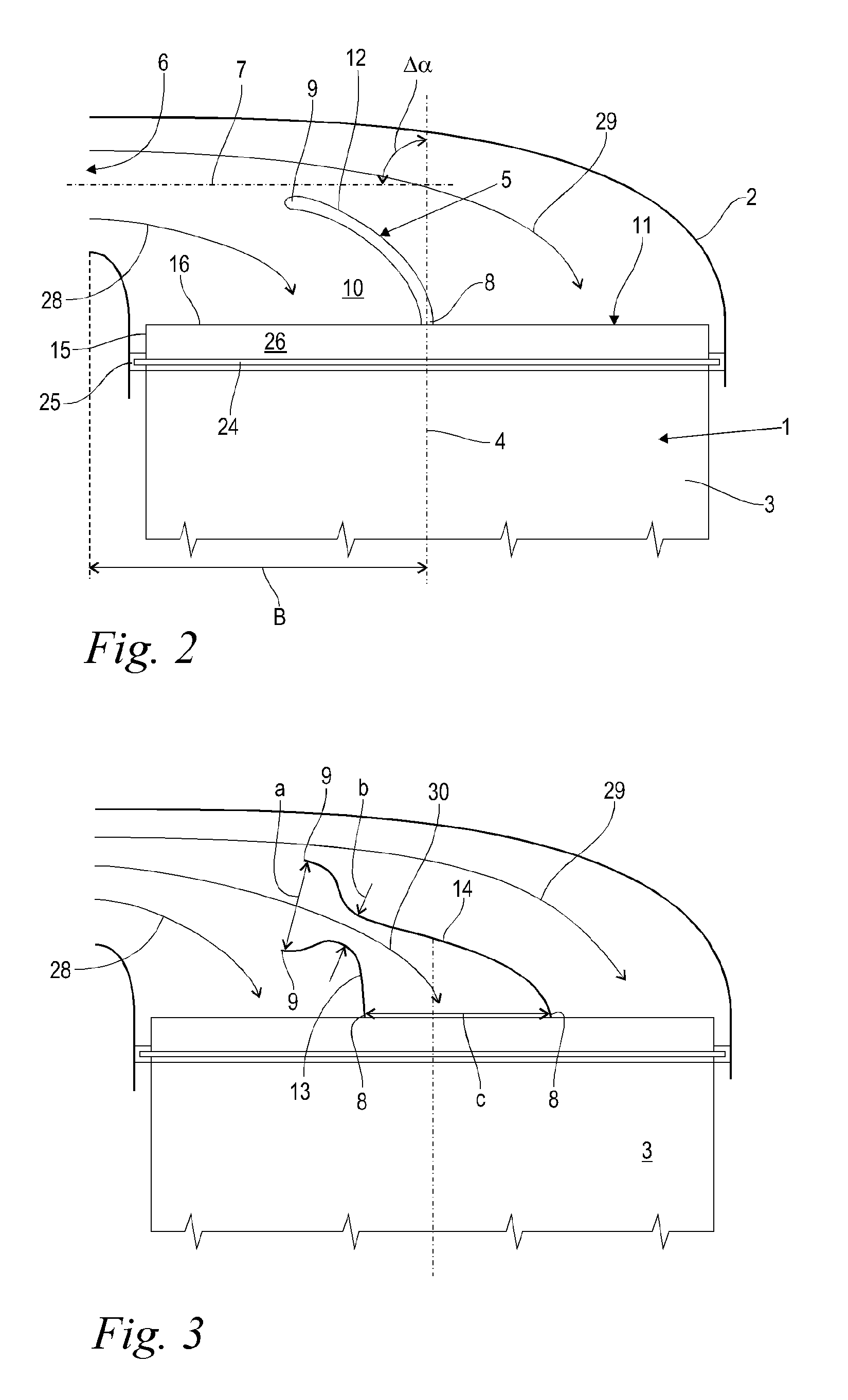

System and method for ventilating explosive regions of an aircraft

InactiveCN101952172AReduce weightReduced space required for installationAir-treatment apparatus arrangementsFuel tank safety measuresOn boardAmbient air

The invention relates to a system (10) for ventilating an explosive region (12) of an aircraft, comprising a ram air channel (16), which has an air inlet for supplying ambient air into the ram air channel (16), and an air outlet (18). The ram air channel (16) is configured to supply air to a device to be cooled on board of the aircraft. A ventilation line (22) has an air inlet (24) for supplying air flowing from the ram air channel (16) into the ventilation line (22), and an air outlet (26). The ventilation line (22) is configured to supply air to a region (12) of the aircraft to be ventilated. A reservoir (28) is disposed between the ram air channel (16) and the air inlet (24) of the ventilation line (22), said reservoir being configured to convert the dynamic pressure of the air flow directed through the ram air channel (16) at least partially into static pressure.

Owner:AIRBUS OPERATIONS GMBH

Pressure balancing tank

InactiveCN1868858AEasy pressure adjustmentLarge adjustment rangeLiquid bottlingEngineeringPressure balance

A pressure balanced tank with stable pouring pressure for the liquid contained in it features that a buffer membrane is used to divide the internal cavity of tank body into an upper gas cavity with gas inlet and outlet having relative gas valves, and a lower liquid cavity with liquid inlet and outlet, and a membrane position indicating column with a lower end in contact with said buffer membrane passes through said gas cavity. It can quickly compensate the pressure loss caused by pouring liquid.

Owner:SHINVA MEDICAL INSTR CO LTD

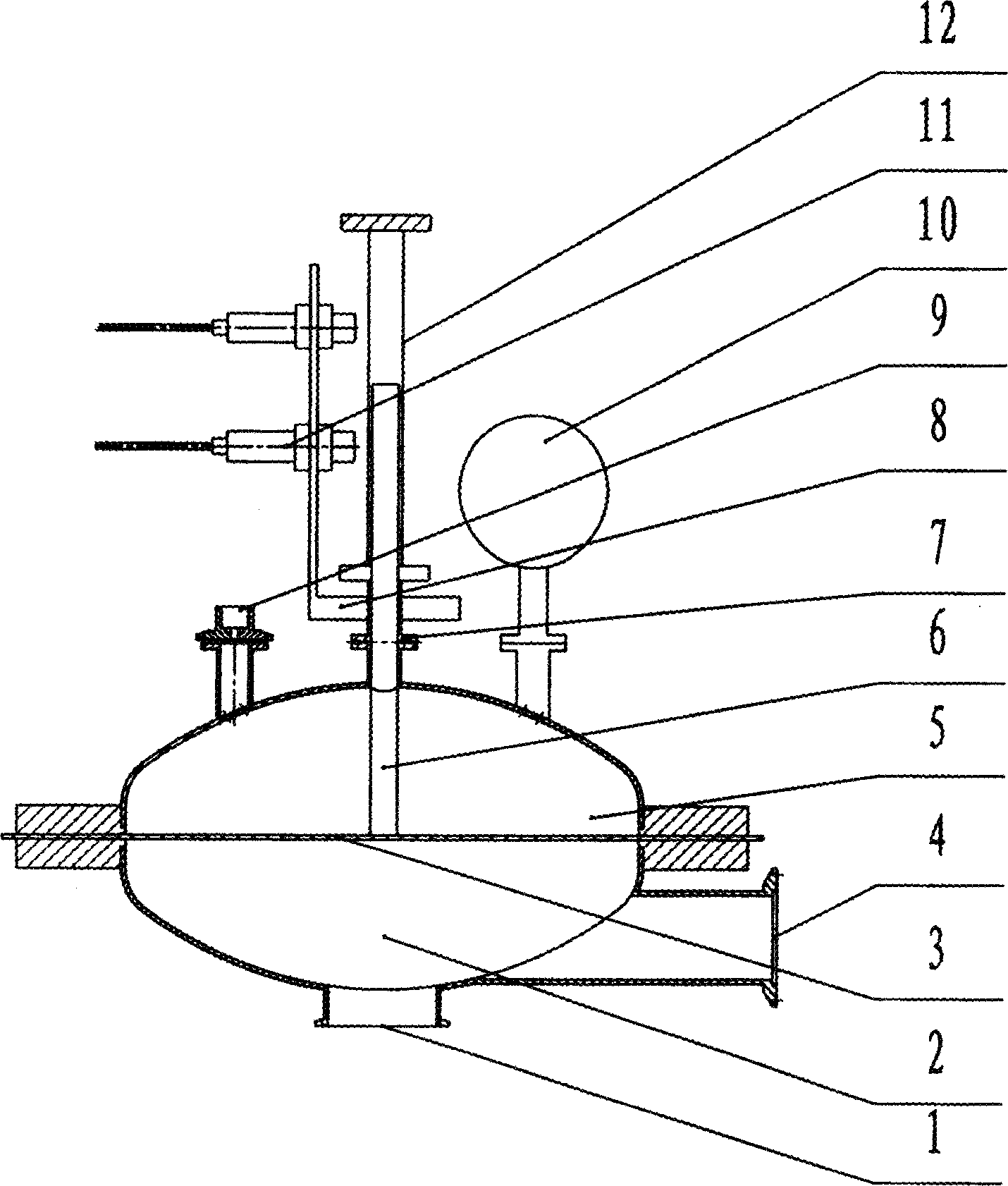

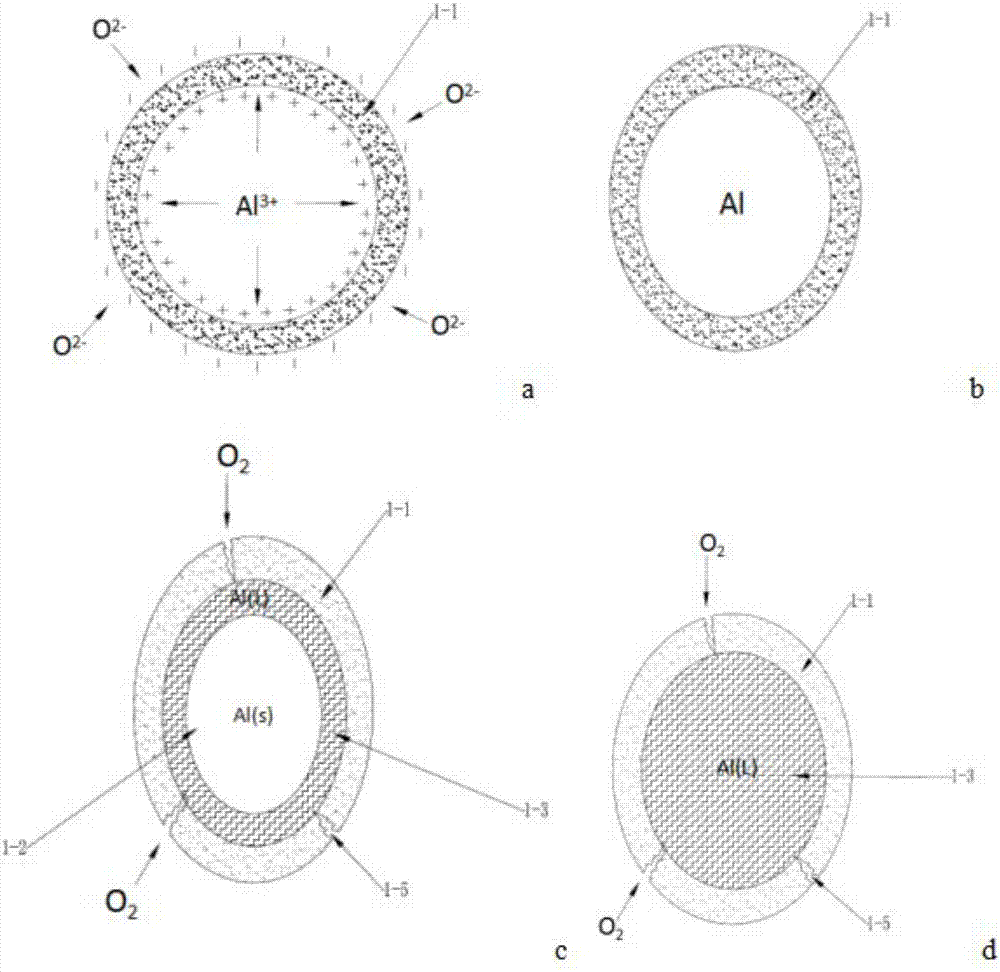

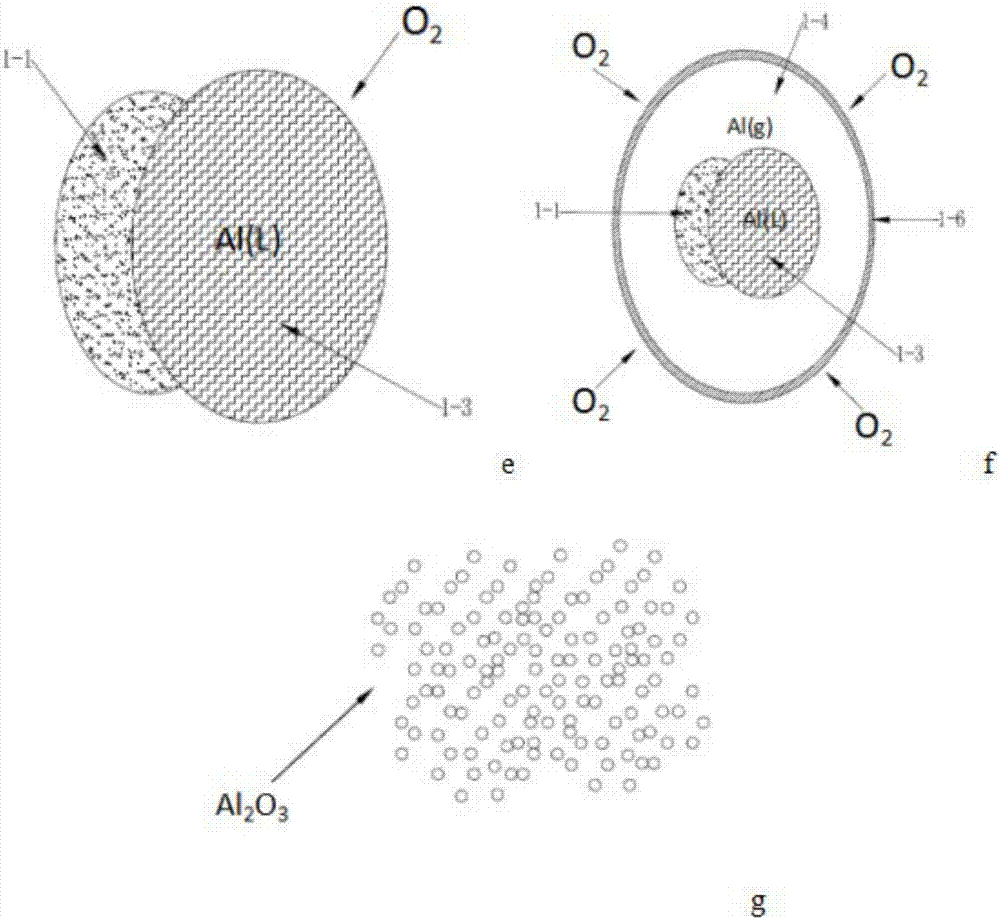

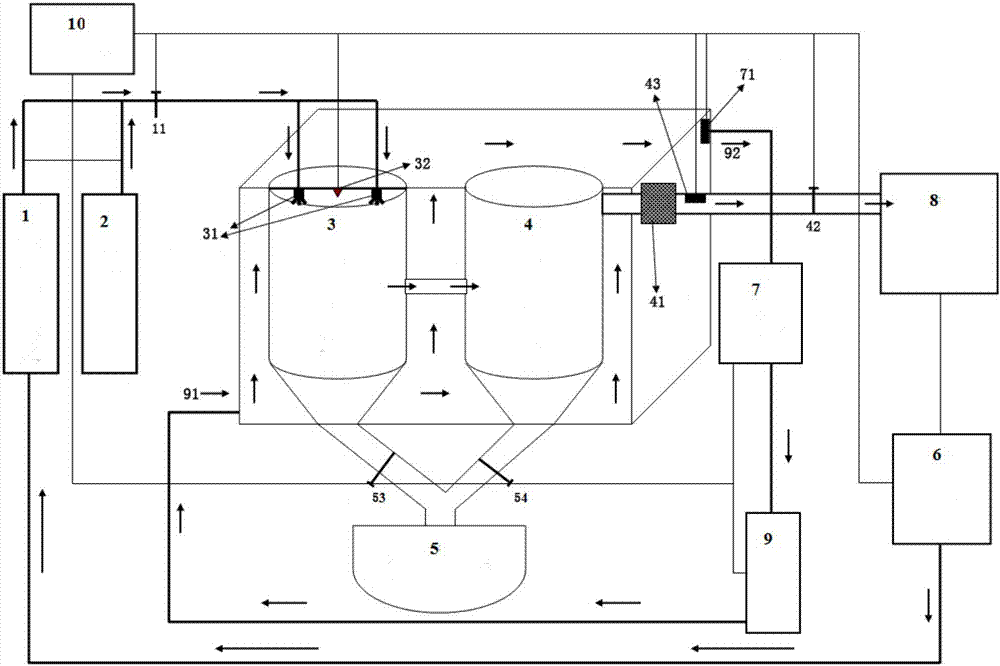

System used for combustion of aluminum powder or magnesium powder and recovery of product generated during combustion

ActiveCN106939829AAvoid emissionsReduce pollution sourcesInternal combustion piston enginesFuel supply apparatusExternal combustion engineFuel tank

The invention provides a system used for combustion of aluminum powder or magnesium powder and recovery of a product generated during combustion. The system comprises a combustion subsystem, a high-pressure fuel gas automatic compensation and storage subsystem, a cooling subsystem, a product recovery subsystem, an external combustion engine and internal combustion engine combined subsystem and an air compression and compensation storage subsystem. The combustion subsystem comprises a compressed air tank, a fuel tank, a combustion tank and a controller. The compressed air tank and the fuel tank are connected to the combustion tank. A fuel gas storage tank of the high-pressure fuel gas automatic compensation and storage subsystem is connected to the fuel tank. A cooling loop of the cooling subsystem is arranged outside the combustion tank and the fuel gas storage tank. A product collection device of the product recovery subsystem is connected to the combustion tank and the fuel gas storage tank. An internal combustion engine of the plasticization is connected to the fuel gas storage tank. The two ends of an air compressor of the air compression and compensation storage subsystem are connected to the internal combustion engine and the compressed air storage tank correspondingly. According to the system, metal powder fuel is adopted, high-pressure gas can be generated in an external combustion engine to drive a machine to act, and energy saving and environmental friendliness are achieved.

Owner:熊朔

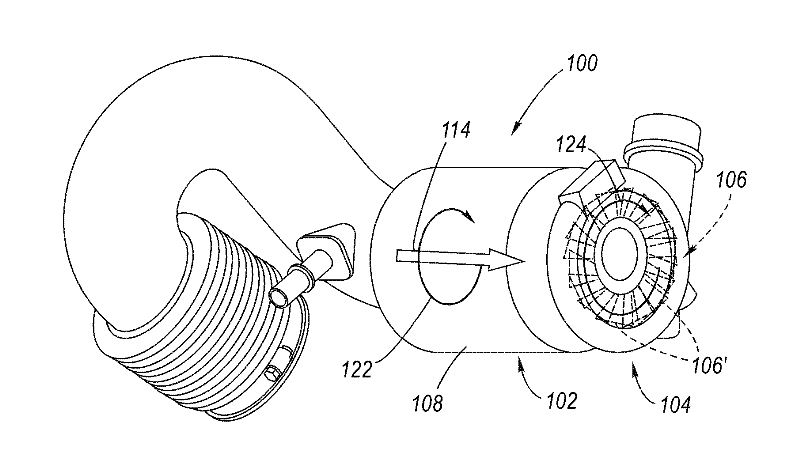

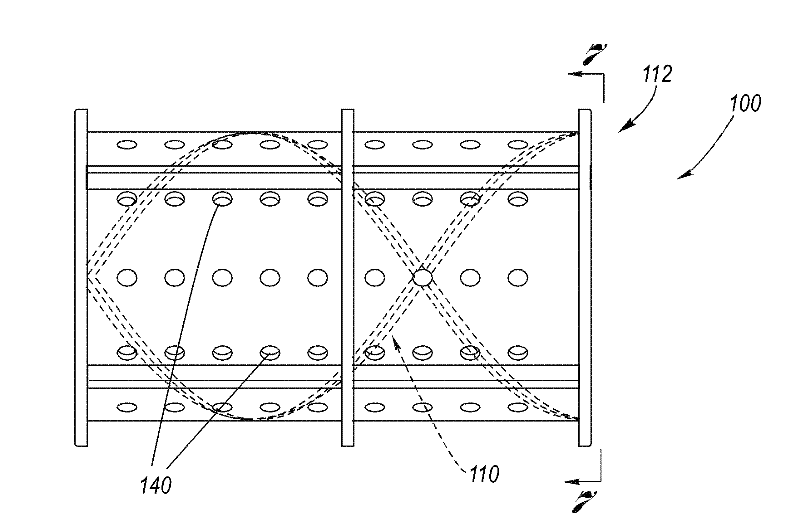

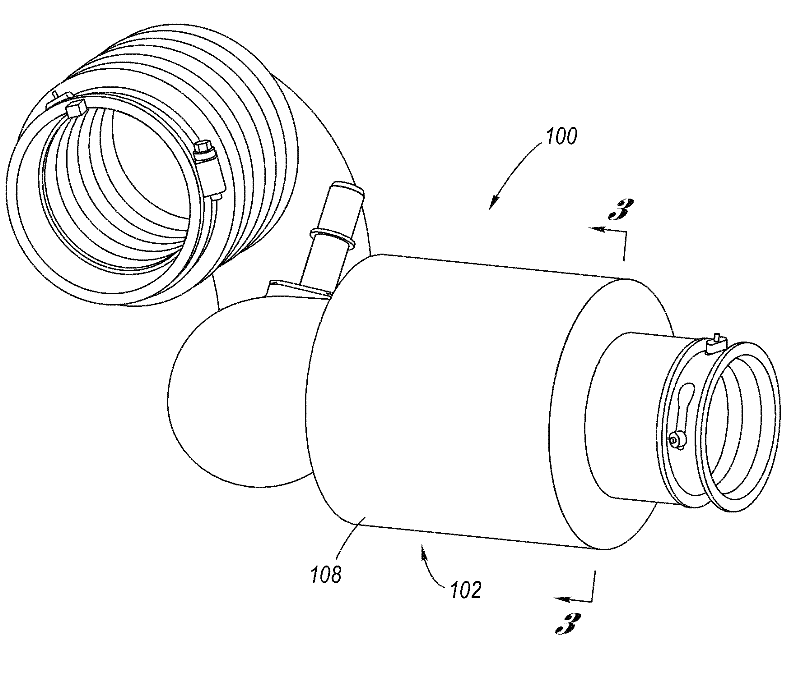

Intake system with airflow rotation and noise absorber for turbine applications

InactiveCN102269088AReduced dynamic pressure loadReduce noiseInternal combustion piston enginesIntake silencers for fuelTurbine wheelEngineering

An air induction system consisting of a cylindrical main flow tube, a helical vane disposed within the main flow tube, and, preferably, a noise absorbing perforated tube disposed within the main flow tube in concentric relation to the helical vane. The twist direction of the helical vane provides air flow rotation in the same direction of rotation as the turbine wheel. The helical vane causes noise reflection and enhancement of noise attenuation by the perorated tube and its adjoining one or more acoustic cavities.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gas generator, in particular for a vehicle occupant restraint system, and method of activating a vehicle occupant restraint system

ActiveUS20080169630A1Extended supply timeSmall spacingPedestrian/occupant safety arrangementPressure gas generationCombustion chamberBiological activation

A gas generator, in particular for a vehicle occupant restraint system, has a pyrotechnical propellant (16), a combustion chamber (12) filled with the pyrotechnical propellant (16), an igniter (14) associated with the combustion chamber (12), a pressure chamber (18), filled with compressed gas, which is adjacent to the combustion chamber (12) and has a first opening (22) remote from the combustion chamber (12) closed by a first diaphragm (26), the diaphragm (26) being destroyed upon activation of the igniter (14), and a second pressure chamber (28) which is filled with compressed gas and has a second opening (34) closed by a second diaphragm (36). The second diaphragm (36) is likewise destroyed upon activation of the igniter (14), and the openings (22, 34) and the gas volumes of the pressure chambers (18, 28) are adapted so that compressed gas flows out from the second pressure chamber (28) for a longer period than compressed gas from the first pressure chamber (18) to increase a gas supply time of the gas generator (10). Further, a method of activating a vehicle occupant restraint system is described.

Owner:TRW AIRBAG SYST

Energy-saving high-pressure cleaning machine

InactiveCN104176012AAvoid wastingAvoid water rustCleaning apparatus for vehicle exteriorsWater savingWater storage

The invention discloses an energy-saving high-pressure cleaning machine, and belongs to the technical field of cleaning equipment. The high-pressure cleaning machine comprises a casing, wherein an air storage cavity and a water storage cavity are vertically formed in the casing, a motor pump is arranged in the water storage cavity and connected with a sprayer through a high-pressure water pipe, the sprayer comprise an upper sprayer body and a lower sprayer body which are fixedly mounted together, the upper sprayer body and the lower sprayer body jointly form a blowing cavity, a brush plate is fixedly mounted on the lower sprayer body and provided with a plurality of bristles, a plurality of water outlet holes are formed in the brush plate and located among the bristles, the lower sprayer body is connected with a water inlet pipe, an air inlet channel communicated with the blowing cavity is formed in the upper sprayer body and communicated with the air storage cavity through an air pipe, and a pressurizer which can increase the pressure of airflow entering the blowing cavity is arranged between the air inlet channel and the end part of the water inlet pipe and located in the blowing cavity. The cleaning machine has the advantages of energy saving, water saving, good washing effect, long service life and the like, and can be widely applied to vehicle cleaning.

Owner:NINGBO FUSLE MECHANICAL MFG

Compact filter

ActiveUS7892307B2Uniform loadExtended service lifeCombination devicesAuxillary pretreatmentEngineeringMechanical engineering

A compact filter has a filter housing and a compact filter element that is arranged in the filter housing, wherein the filter element is exchangeable. The compact filter element has a filter body having a longitudinal axis. The compact filter element has an unfiltered air side and a filtered air side. A baffle element is arranged at the unfiltered air side of the compact filter element. The baffle element is removable together with the filter element from the filter housing and has at least one baffle surface that is slanted relative to the longitudinal axis.

Owner:MANN HUMMEL GMBH

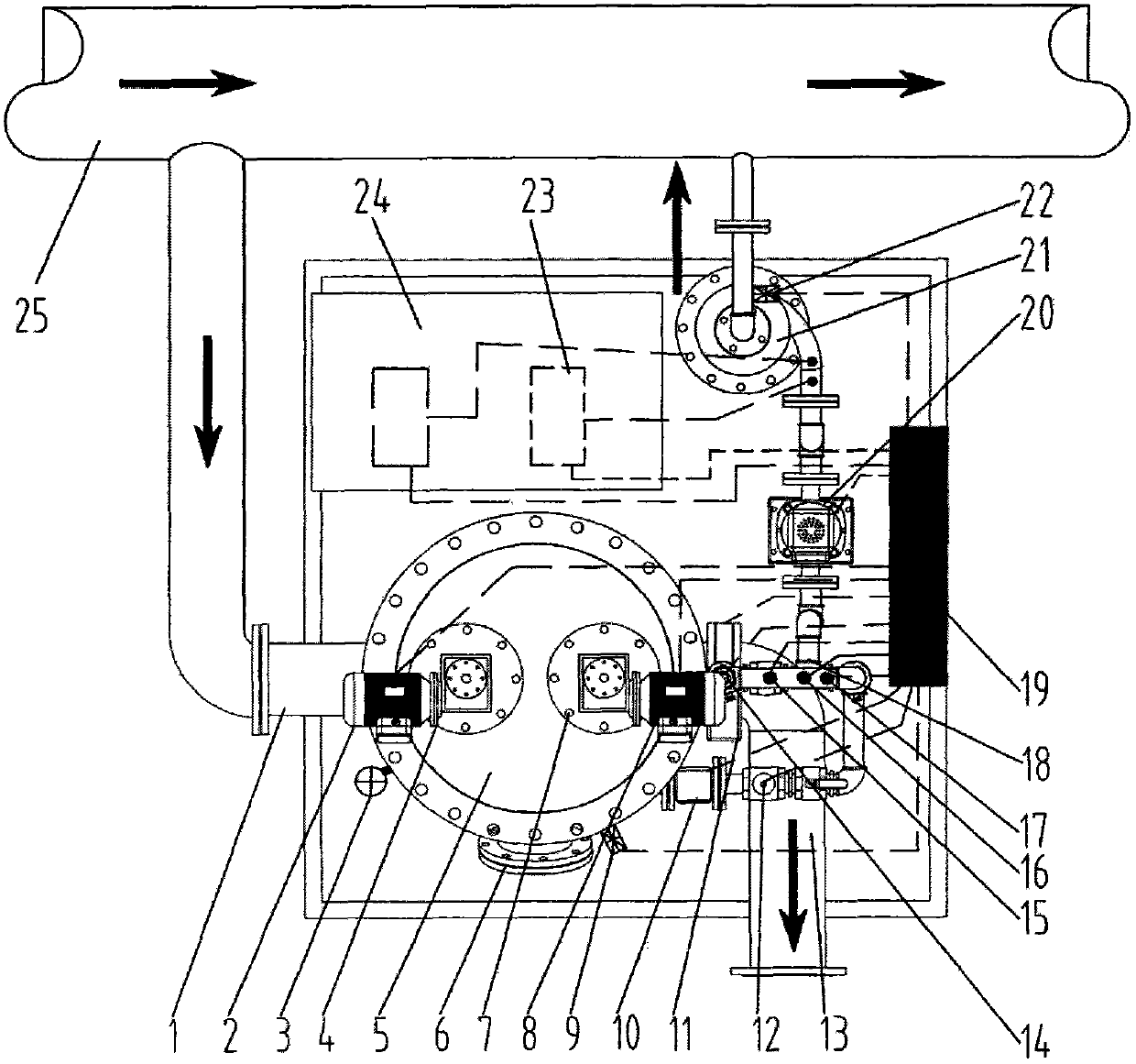

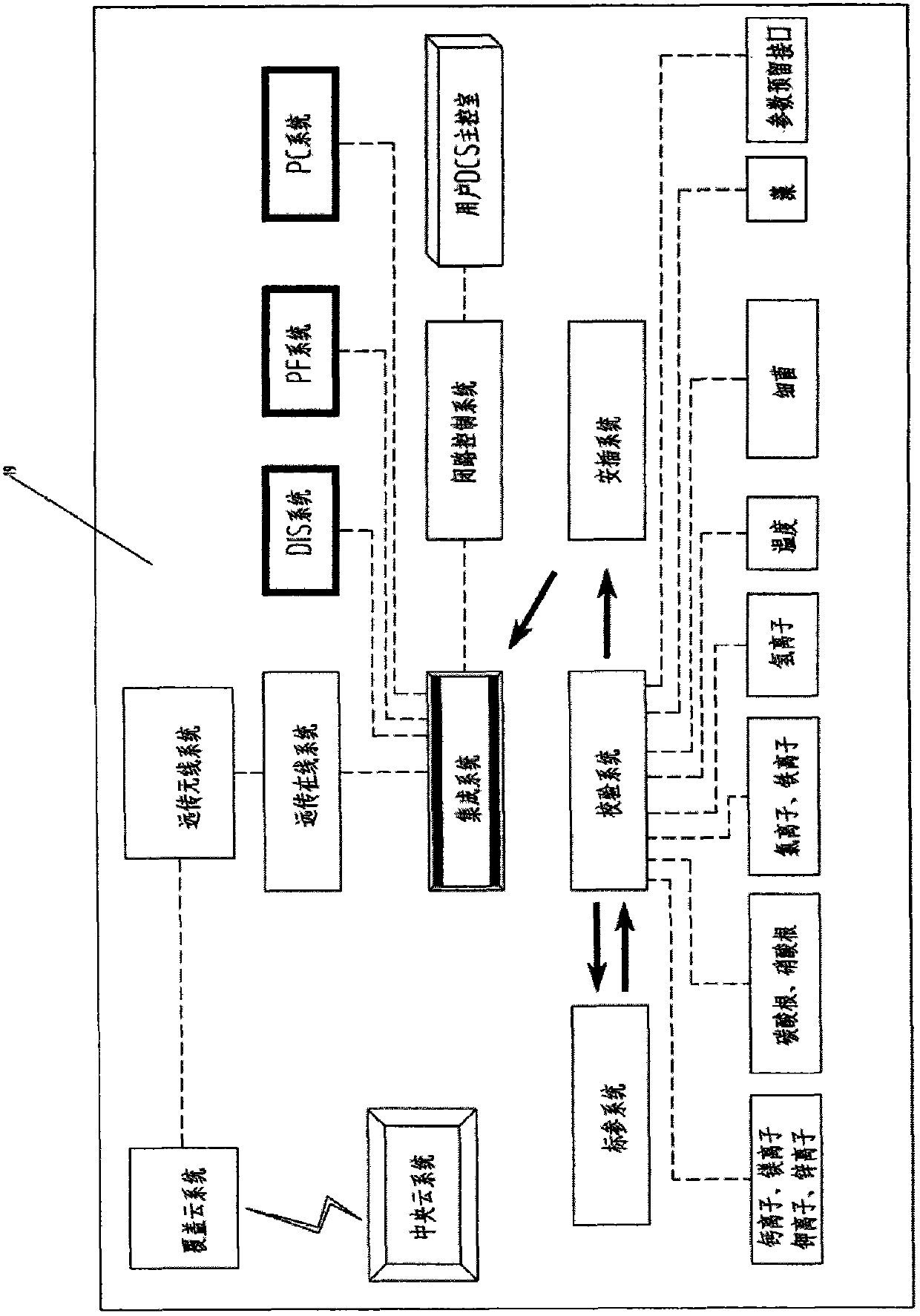

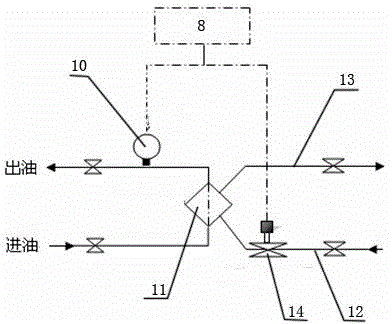

Water containing machine set of circulating water system

ActiveCN103121765AFast fusionEffective protectionMultistage water/sewage treatmentControl systemFiltration

The invention relates to a water containing machine set of a circulating water system. The water containing machine set comprises a DIS system for performing an accurate solid-liquid separation on water in a pipeline, a PF system for adding an additive capable of improving water quality into the water and promoting the full combination of the additive and the water, a PC system for compensating the pressure loss of an outlet pipe of the DIS system as well as the pressure loss of the PF system, a control system for monitoring the water treated by the DIS system and controlling the DIS system, the PF system and the PC system, wherein the DIS system is connected to a main pipeline of the system in a side filtration manner, is positioned in front of a filter of the main pipeline of the system and is also connected with the PC system through the pipeline; the PC system is connected with the PF system through the pipeline; the PF system is connected with the main pipeline of the system through the pipeline; and the DIS system, the PC system and the PF system are connected with the control system through data lines. The water containing machine set provided by the invention has the effects of low carbon, energy conservation and emission reduction.

Owner:北京天御太和环境技术有限公司

Heat exchanger plate and an evaporator with such a plate

InactiveUS8793987B2Compensation for pressure lossEqually distributedExhaust apparatusSilencing apparatusTransverse axisEngineering

Owner:STEAMDRIVE

Gas spring for a revolver cannon or breech cannon

InactiveUS7938054B2Lower energy requirementsReduce MechanismsFiring/trigger mechanismsGun mountingsGas springProcess engineering

The characteristic of one or more of the gas springs themselves used in a revolver cannon or breech cannon is adjusted while the system is in operation. This is done by a separate, self-contained system, which can adjust the gas spring from hard to soft, for example, and back to harder / hard and can thus adjust the characteristic of the gas spring without the loss of gas. In the simplest embodiment, this system has two additional elements, preferably a reserve tank and a connecting line that connects the reserve tank to the gas spring via a valve.

Owner:OERLIKON CONTRAVES BESCHRAENKTER HAFTUNG

Heat pump type clothes dryer with secondary blowing mechanism

InactiveUS9139948B2Increase flow rateReduce capacityDrying solid materials with heatDrying gas arrangementsReducerEngineering

A heat pump type clothes dryer compensates for pressure loss caused by a radiator to increase the flow rate of air passing around the radiator, and suppressing introduction of ambient air through gaps formed in air flow lines to avoid degradation in drying capacity, while avoiding an increase in the power consumption or noise of a fan. The clothes dryer includes a drum to accommodate clothes, an air suction or intake line to suck air into the drum, an air exhaust line to exhaust air from the drum, a heat pump circuit including a compressor, a radiator, a pressure reducer, and a heat absorber, where the heat absorber is provided in the air exhaust line, and the radiator is provided in the air suction or intake line, a first blowing mechanism provided in the air exhaust line, and a second blowing mechanism provided in the air suction or intake line.

Owner:SAMSUNG ELECTRONICS CO LTD

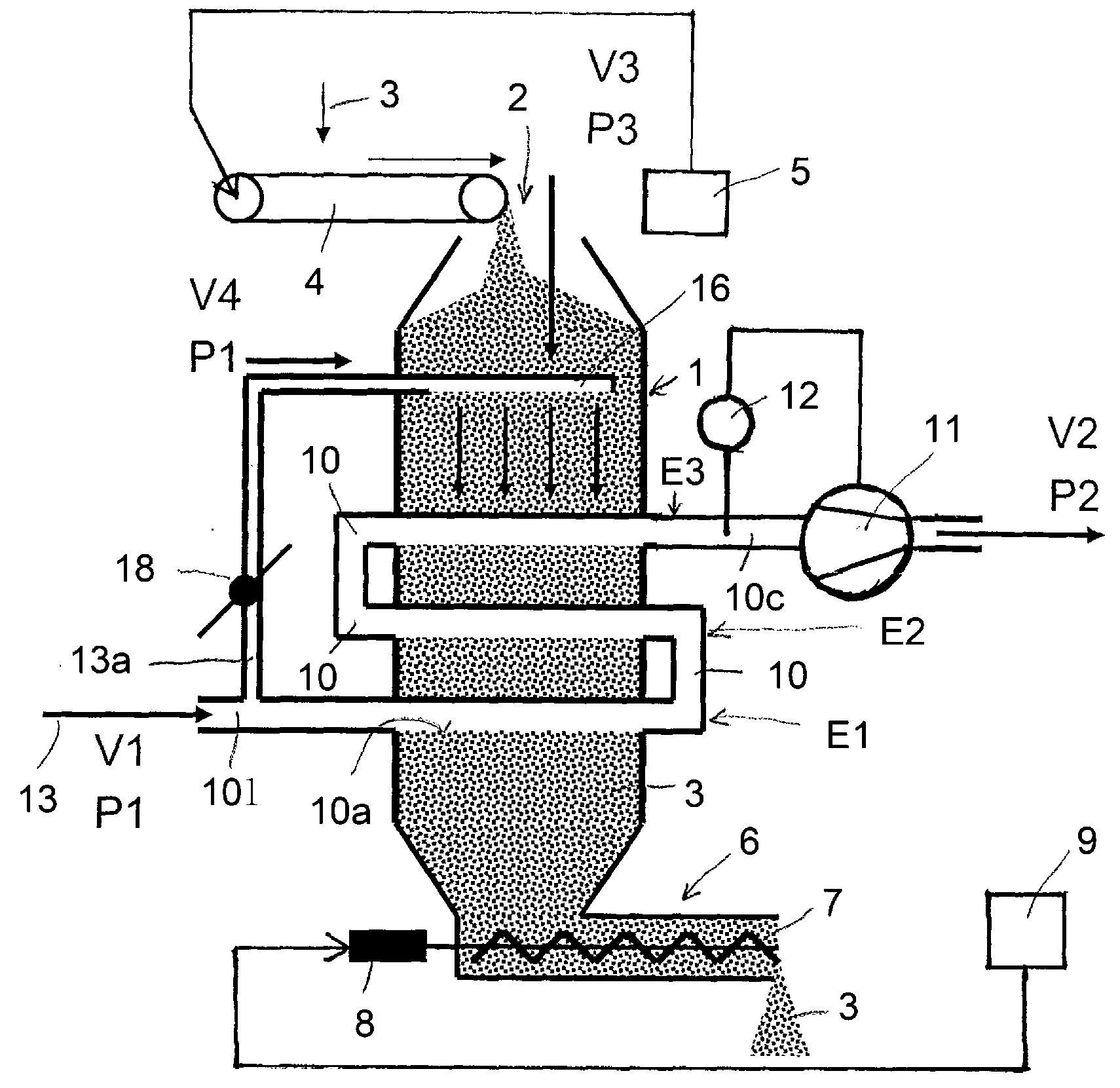

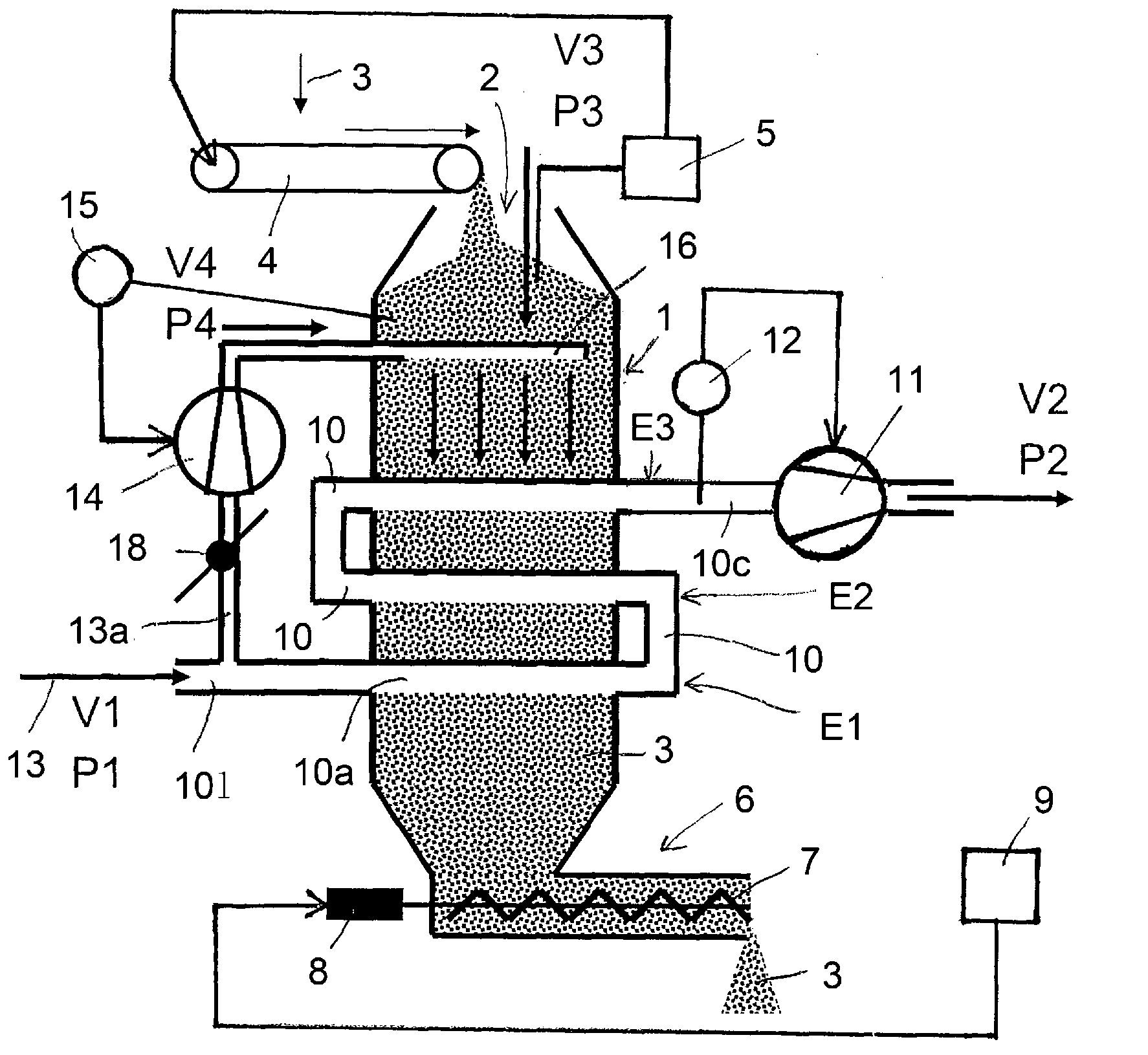

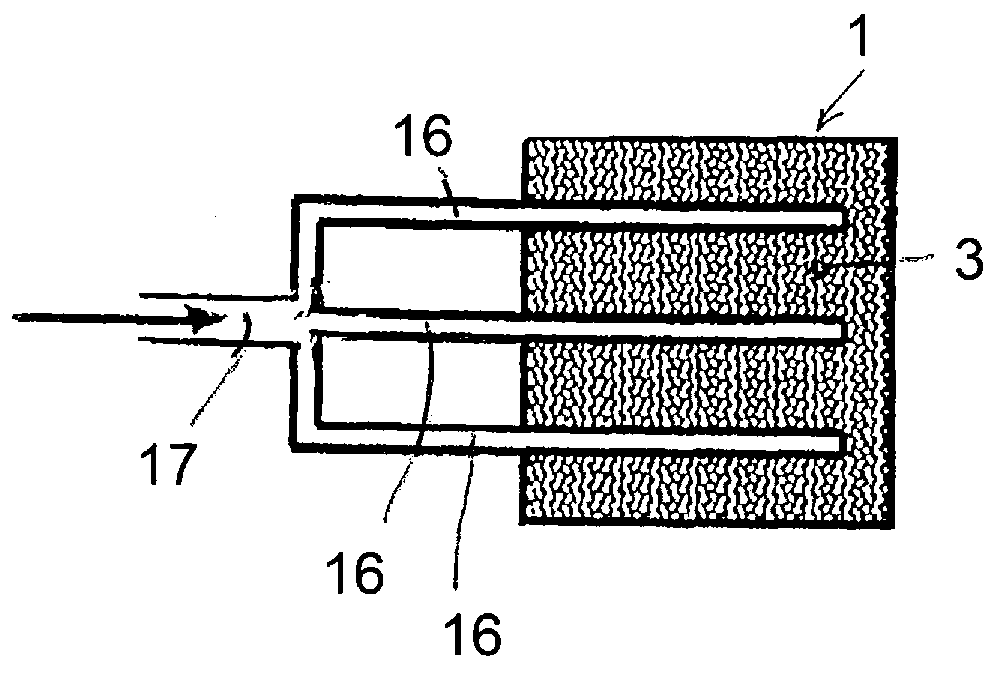

Device for preheating charging materials for glass melting facilities

InactiveCN103269985AAvoid inhalationCompensation for pressure lossCharging furnaceMaintainance of heating chambersEngineeringProduct gas

The invention relates to a device for preheating charging materials (3) for glass melting facilities by means of exhaust gases thereof, having a vertical preheating shaft (1) through which a heat exchanger (10) extends, through which the exhaust gases are directed, wherein the upper end of the preheating shaft (1) has a charging opening (2) for the charging materials (3) and the lower end has a discharge device (6) for the preheated charging materials (3), and wherein the inlet of the heat exchanger is connected to a supply line and the outlet is connected to an outlet line for the exhaust gases. In order that a higher portion of the heat is recovered from the exhaust gases at a lower installation height and lower volume and the suctioning in of ambient air as false air and environmental contamination can be reduced to a minimum degree in such a device, the supply line (10b) for the exhaust gases has at least one branch in the form of an outlet line (13a) for the outlet of a partial volume of the hot gases (13) and the outlet line (13a) is connected to at least one sealing gas line (16) which is open to the bottom and which is arranged in the region of the charging materials (3) above the at least one exhaust gas lead-through (10) of the heat exchanger for releasing the hot gases into the charging materials (3).

Owner:索尔格投资有限及两合公司

Thermal management system for an electric drive system, preferably for a vehicle

ActiveUS11186164B2Improve efficiencyEnhanced short-term performanceElectric propulsion mountingVehicle sub-unit featuresThermal management systemElectric drive

A thermal management system for an electric drive system, preferably for a vehicle, includes an electric drive including an electric motor and power electronics. The electric motor and the power electronics are integrated in a cooling circuit and are cooled by a coolant circulating in the cooling circuit. The coolant is circulated by a coolant pump. In the case of a variable thermal management system, the electric motor and the power electronics are in spatial contact with respective cooling units. The cooling units of the electric motor and of the power electronics are arranged parallel to each other and an electrically controlled coolant distributor is positioned between the coolant pump and the cooling units which coolant distributor has two outlets. One outlet leads to the cooling unit of the electric motor and one outlet leads to the cooling unit of the power electronics and the outlets of the cooling units are merged into a channel and led back to the coolant pump.

Owner:SCHAEFFLER TECH AG & CO KG

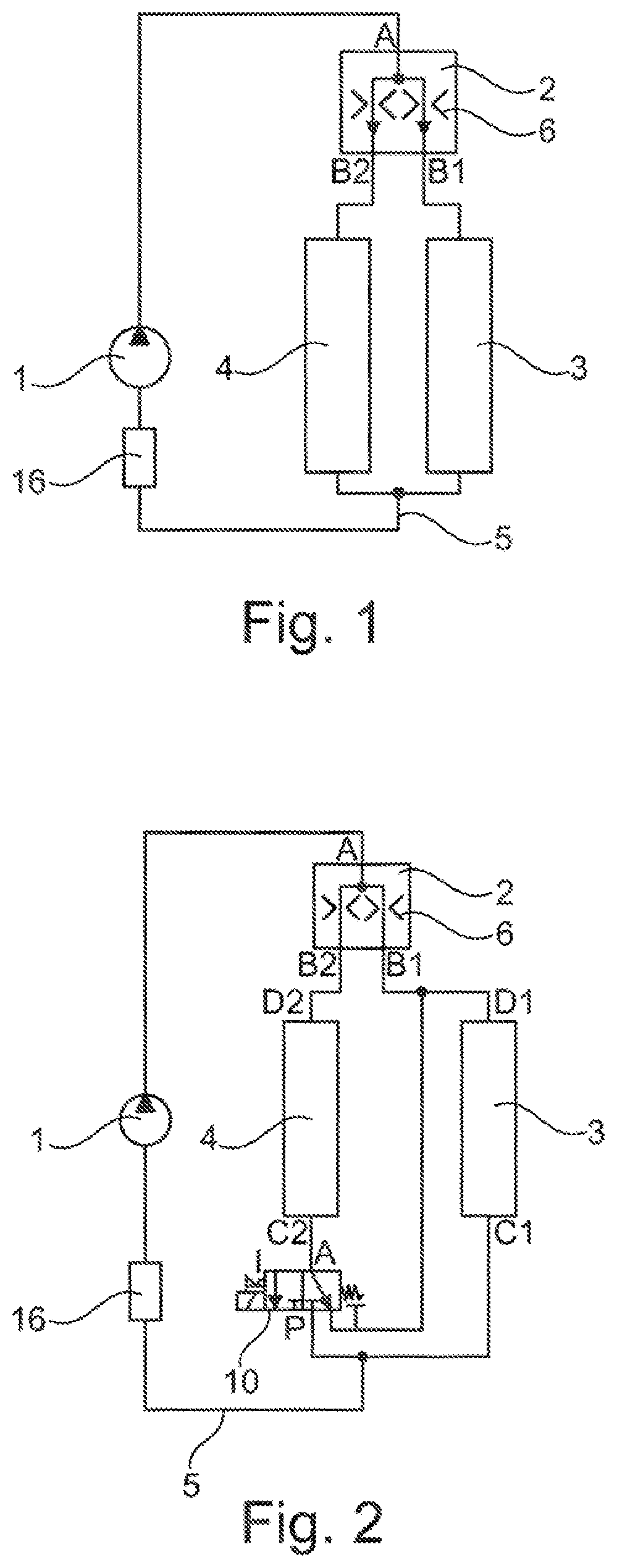

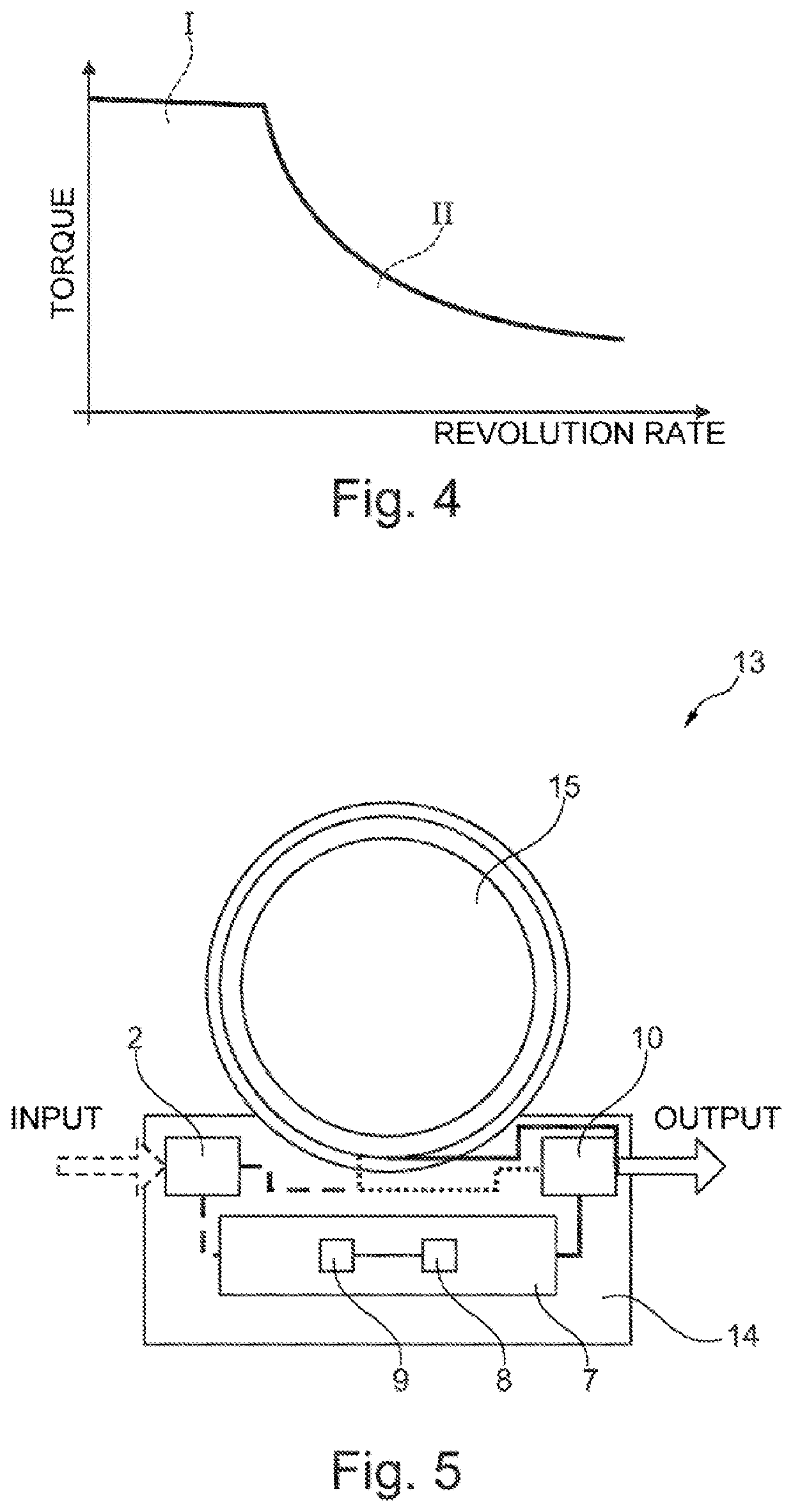

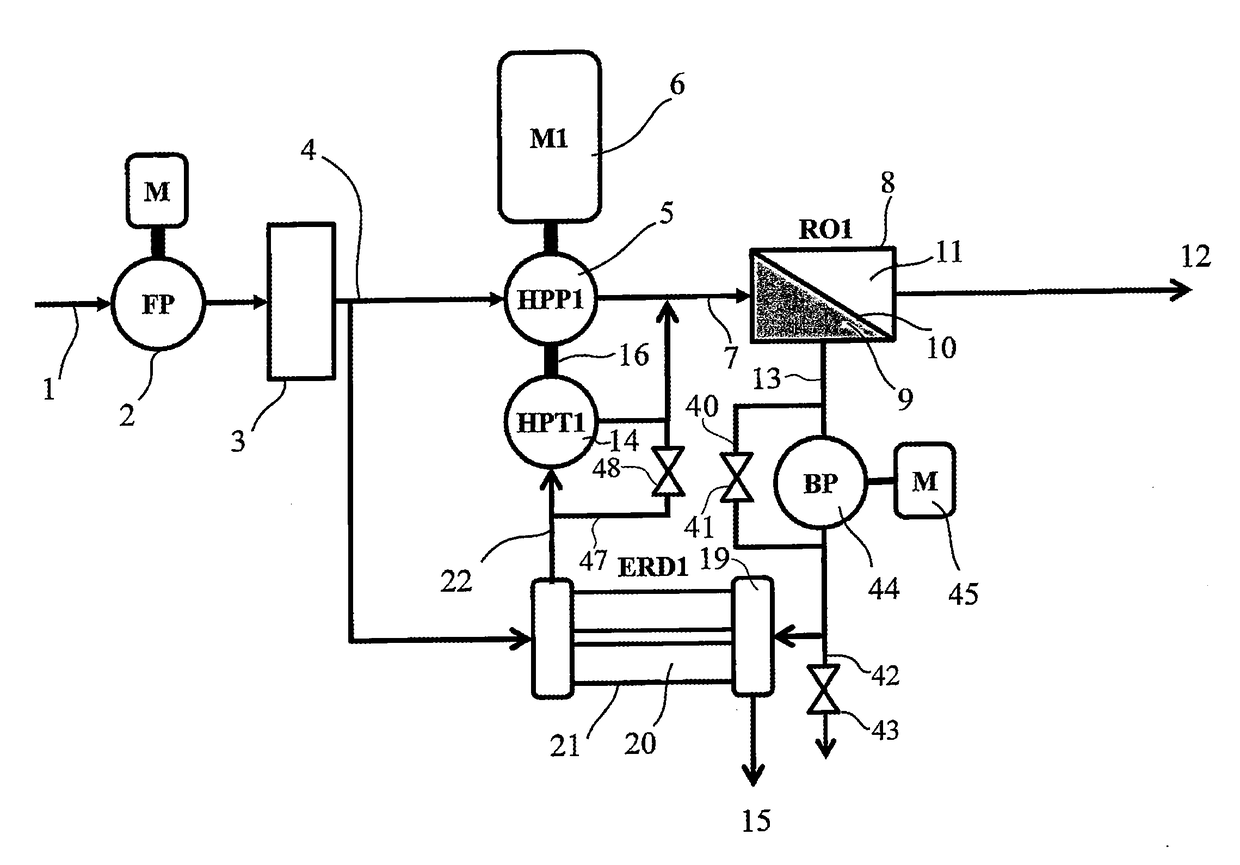

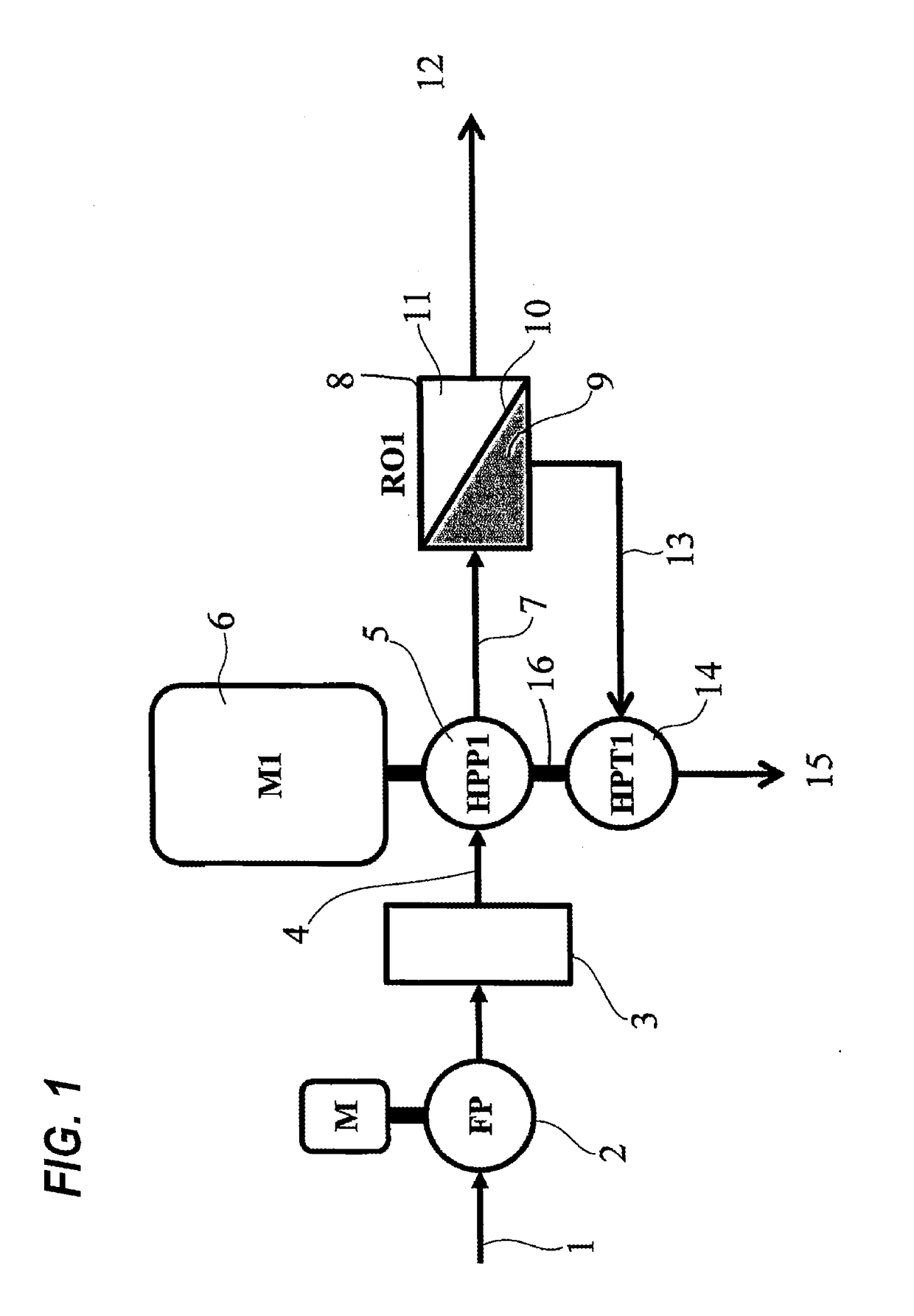

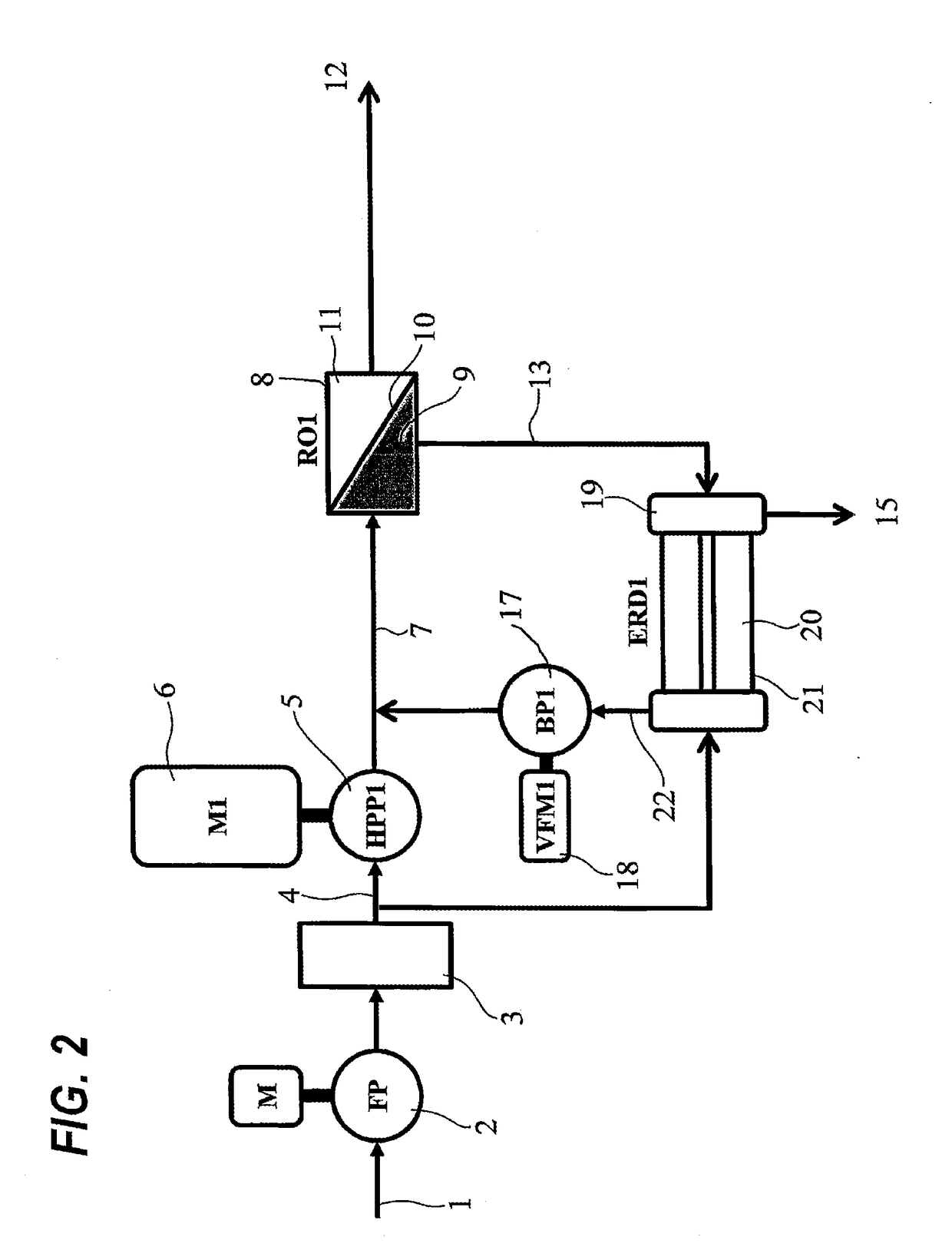

Energy recovery system

ActiveUS20170120194A1Compensation for pressure lossValve arrangementsGeneral water supply conservationSeawaterRaw water

An energy recovery system in a seawater desalination plant uses a reverse-osmosis membrane method for removing salinity from seawater. The system is configured to supply high-pressure water produced by pressurizing raw water with a high-pressure pump to a reverse-osmosis membrane cartridge, and to supply concentrated water discharged from the cartridge to an isobaric energy recovery device to recover pressure energy of the concentrated water whereby part of the raw water supplied to the isobaric energy recovery device is pressurized, and then to allow the pressurized raw water to merge into the high-pressure water pressurized by the high-pressure pump. The system includes a booster pump for boosting a pressure of the concentrated water discharged from the cartridge, and an energy recovery turbine for recovering energy by using the pressure head difference between the pressurized raw water from the isobaric energy recovery device and the high-pressure water discharged from the pump.

Owner:EBARA CORP

A round brush and a high-pressure cleaning machine including it

ActiveCN104146489BCompensation for pressure lossAvoid water rustBrush bodiesVehicle cleaningSprayerEngineering

The invention discloses a novel round brush and a high pressure cleaning machine with the same and belongs the fields of cleaning equipment auxiliary parts and machines. The round brush comprises an upper sprayer and a lower sprayer which are mounted fixedly and integrally and which form a spraying cavity; the lower sprayer is fixedly provided with a brush disc provided with a plurality brush hairs, and the brush disc is provided with a plurality of water discharging holes among the brush hairs; the lower sprayer is connected to a water incoming pipe, and the water outlet of the water incoming plate extends into the spraying cavity; the upper sprayer is provided with an air incoming channel communicating with the spraying cavity, and a pressurizer pressurizing the air flow entering the spraying cavity is arranged between the air incoming channel and the water outlet of the water incoming pipe and is located in the spraying cavity. The round brush has the advantages that energy and water are saved, the brushing effect is fine, a vehicle can be protected and the service life is long, and the round brush is widely applied to vehicle washing.

Owner:NINGBO FUSLE MECHANICAL MFG

Oil well cement gas expander

ActiveCN104818007BPromote expansionAchieve swelling effectDrilling compositionCalcium silicateNitrogen

The invention discloses an oil well cement gas expansion agent, which consists of 30-40 parts by weight of a gas generating agent and 60-70 parts by weight of a stabilizer. The gas generating agent is a sulfohydrazide compound, and the stabilizer is at least one of silicon dioxide and calcium silicate. The oil well cement gas expansion agent can be used for daily dry blending work, and also can be used for on-the-spot wet blending work. When the oil well cement gas expansion agent acts on cement paste, the temperature reaches 35DEG C under an alkaline condition, nitrogen release starts. By means of the effect of the stabilizer in the components, small bubbles can be evenly distributed in the cement paste, and the only generated gas is nitrogen, which has no corrosion to pipes. In addition, the oil well cement gas expansion agent has good compatibility and compatibleness with other cement additives, also can effectively compensate the pressure loss and volume shrinkage when the cement paste solidifies, and prevents well cementing oil gas and water channeling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

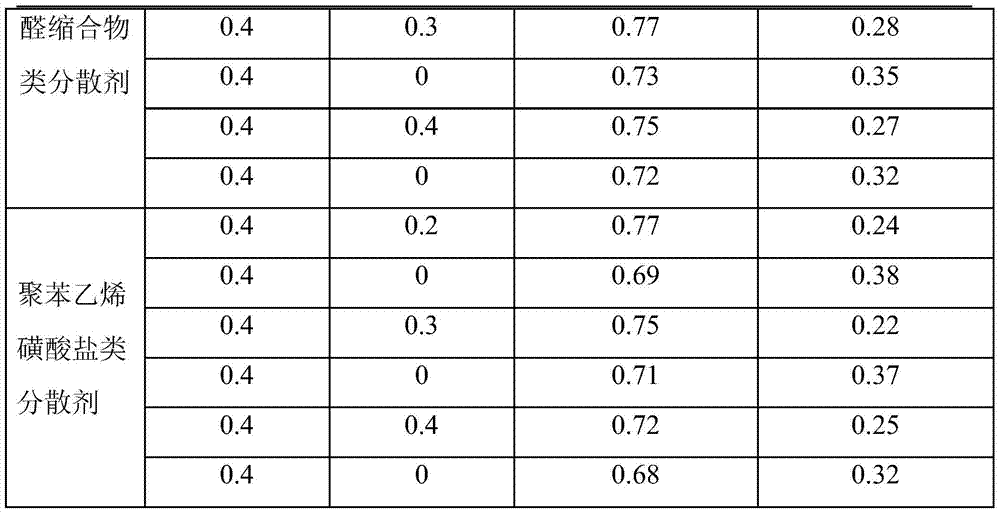

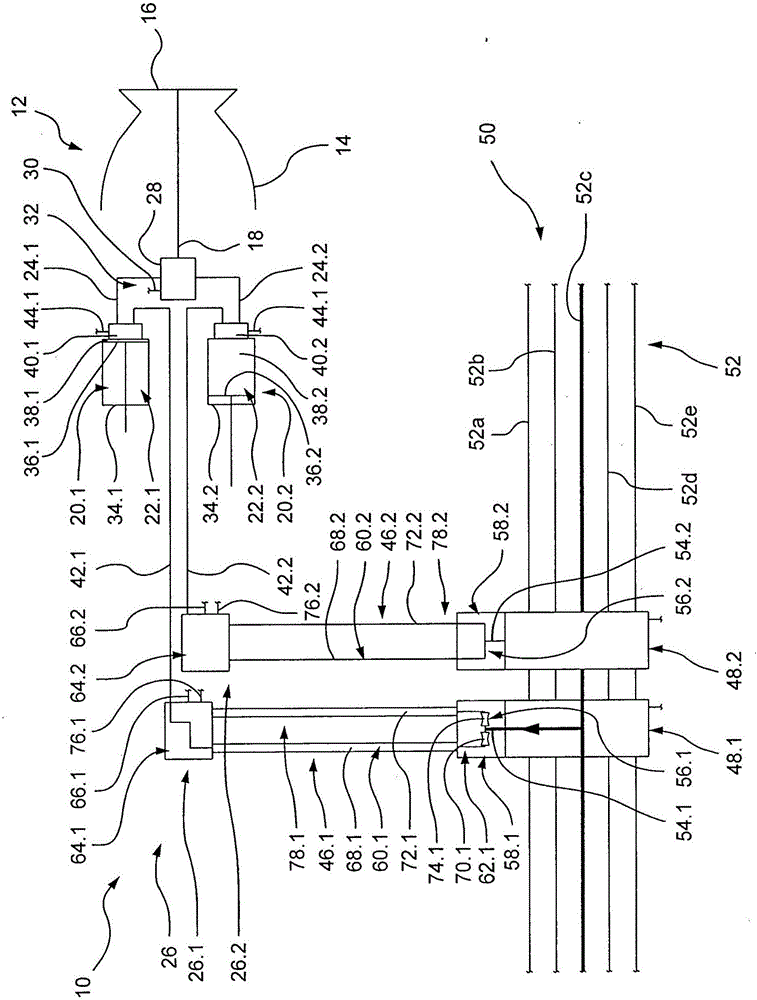

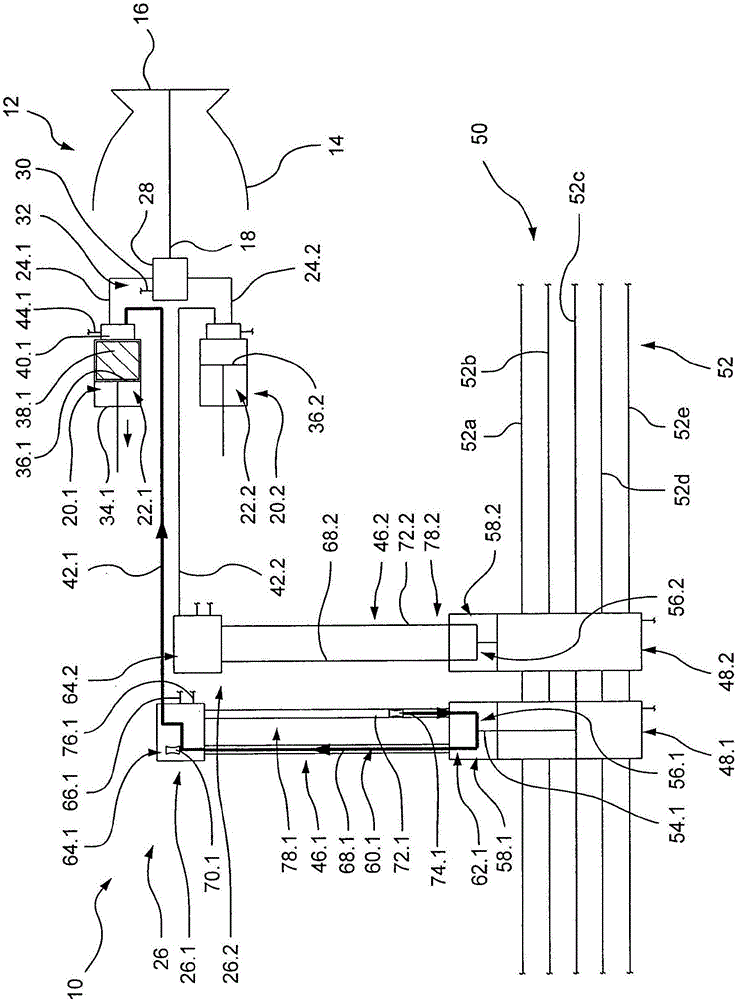

Coating system for coating objects

InactiveCN106470766AIncrease in sizeCompensation for pressure lossSpray nozzlesElectrostatic spraying apparatusCoating systemPigging

The invention relates to a coating system for coating objects, comprising an application device (12) and a supply system (26), by means of which the application device (12) can be supplied with a liquid material. The supply system comprises at least one base supply device (46.1) with a piggable supply line (60.1) which extends between a first pigging station (58.1) and a second pigging station (64.1) and can be connected to one of multiple material sources (52) by means of a supply unit (48.1). The piggable supply line (60.1) is a piggable primary supply line (68.1) which can be connected to a discharge line (54.1) of the supply unit (48.1) by means of a valve unit (56.1). A piggable secondary supply line (72.1) is provided which is connected to the valve unit (56.1) and is connected to a secondary pigging station (64.1; 80.1) at the end remote from the valve unit (56.1). The valve unit (56.1) is designed as a multi-way valve such that the discharge line (54.1) of the supply unit (48.1) can be at least selectively connected to the primary supply line (68.1); or the discharge line (54.1) of the supply unit (48.1) can be at least selectively connected to the primary supply line (68.1) and the secondary supply line (72.1); or the primary supply line (68.1) can be at least selectively connected to the secondary supply line (72.1).

Owner:EISENMANN SE

Engine oil outer cooling and circulating system of engine

InactiveCN103195536BImprove cooling effectImprove performanceMachines/enginesLubrication temperature controlTemperature controlControl signal

The invention relates to an engine oil outer cooling and circulating system of an engine. The engine oil outer cooling and circulating system comprises a constant-temperature control mechanism for performing constant-temperature control on engine oil, wherein an oil inlet of the constant-temperature control mechanism is communicated with an oil outlet of a filter base of the engine through an oil inlet tube, and the oil outlet is communicated with an oil return port of the filter base of the engine through an oil outlet tube. The constant-temperature control mechanism comprises a temperature master control unit, a temperature detection mechanism and a cooling mechanism, wherein standard values of the temperature of the engine oil of the engine are stored in the temperature master control unit; the temperature detection mechanism is used for detecting the temperature of the engine oil in real time, is arranged in the oil outlet tube and can instantly transmit the detected engine oil temperature to the temperature master control unit connected with a signal output end of the temperature detection mechanism; the cooling mechanism is used for cooling the engine oil and receives control signals emitted by the temperature master control unit to cool the engine oil under different engine operation conditions by adjusting the flow and speed of self cooling liquid. The engine oil outer cooling and circulating system is simple in structure, can effectively ensure the temperature of the engine oil flowing into the engine, simultaneously ensures the pressure of the engine oil flowing into the engine, provides good operation environments for the engine and is suitable of engines of various vehicles.

Owner:GREAT WALL MOTOR CO LTD

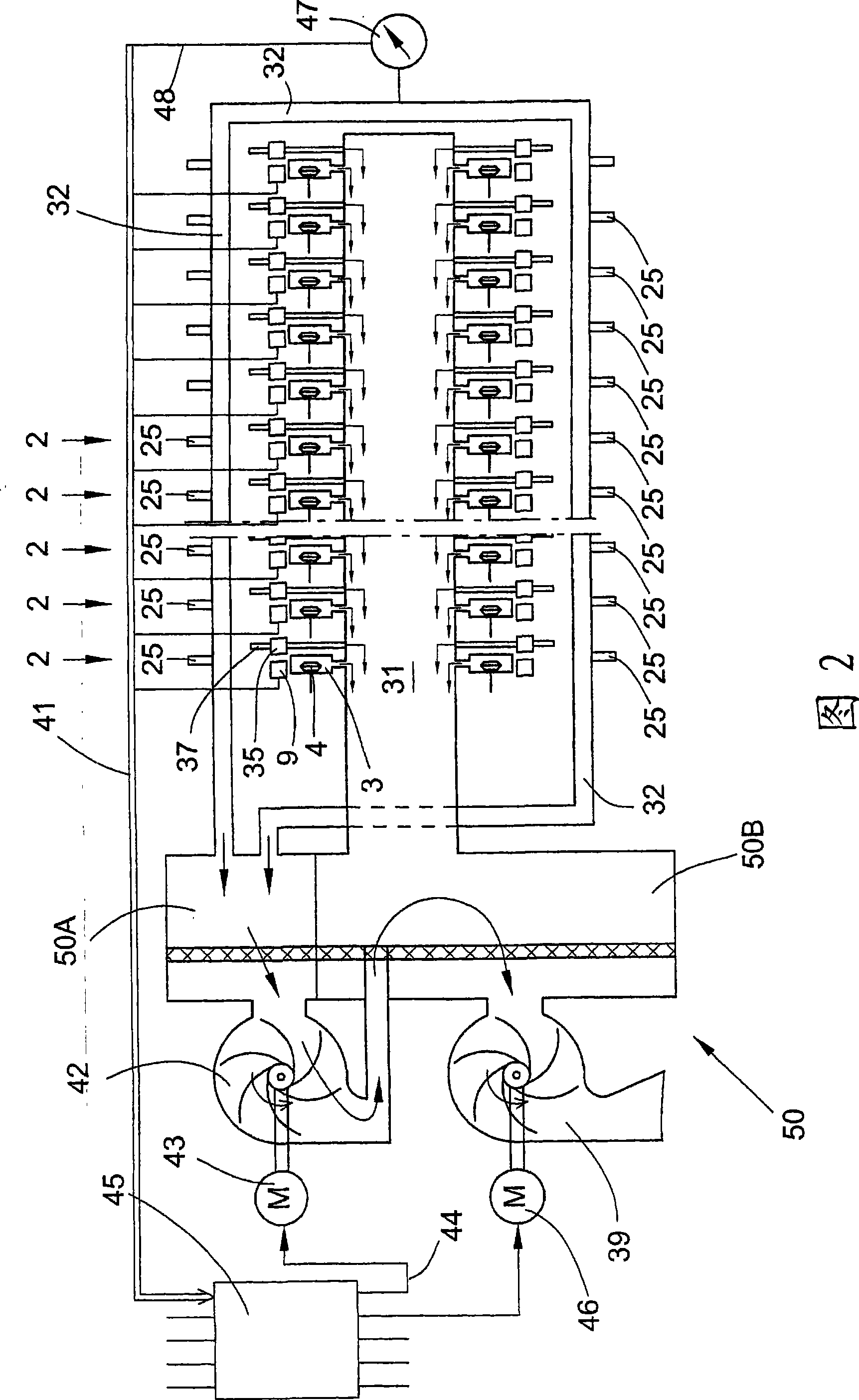

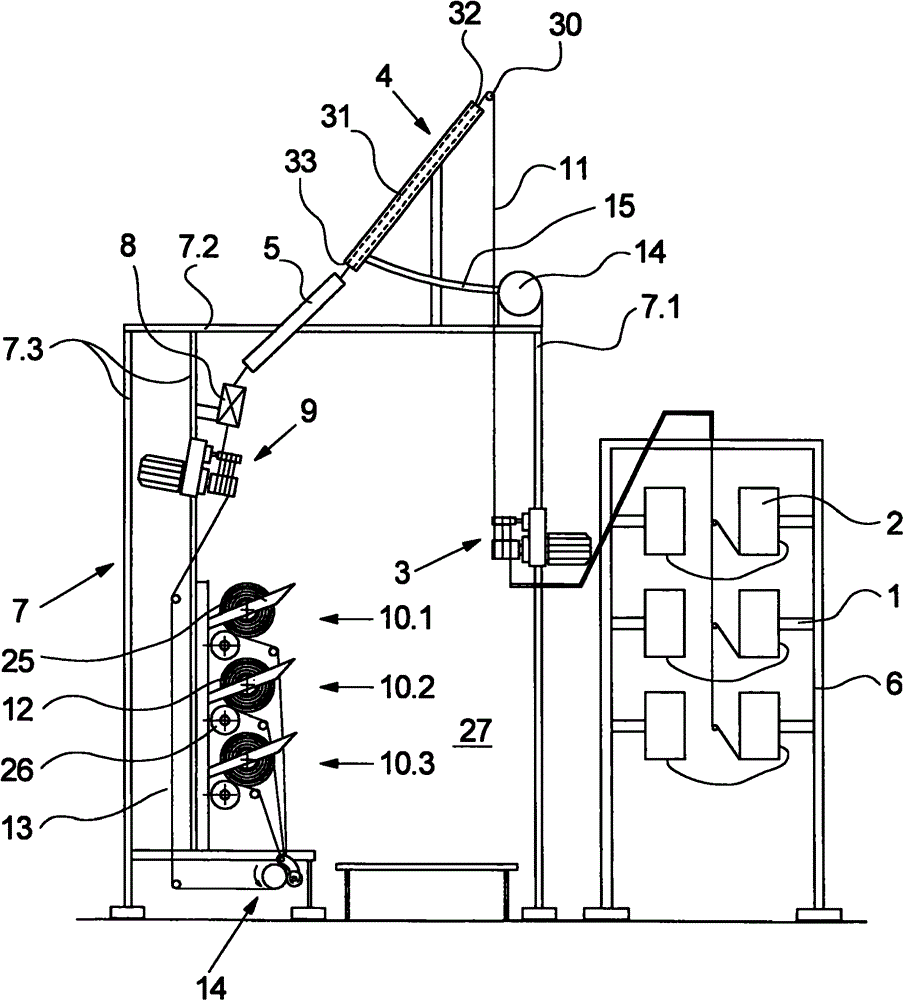

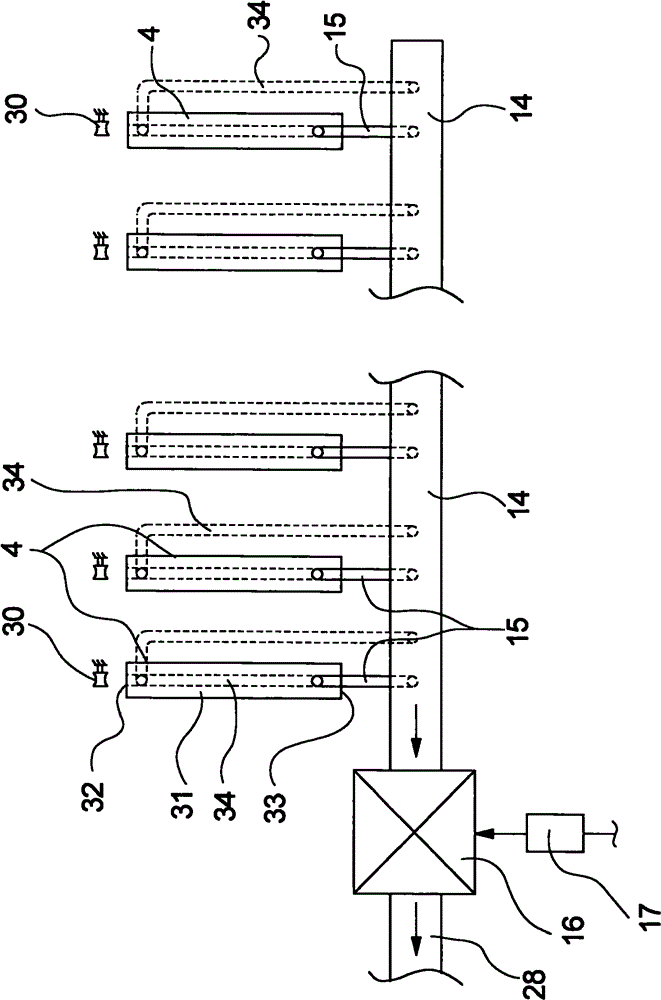

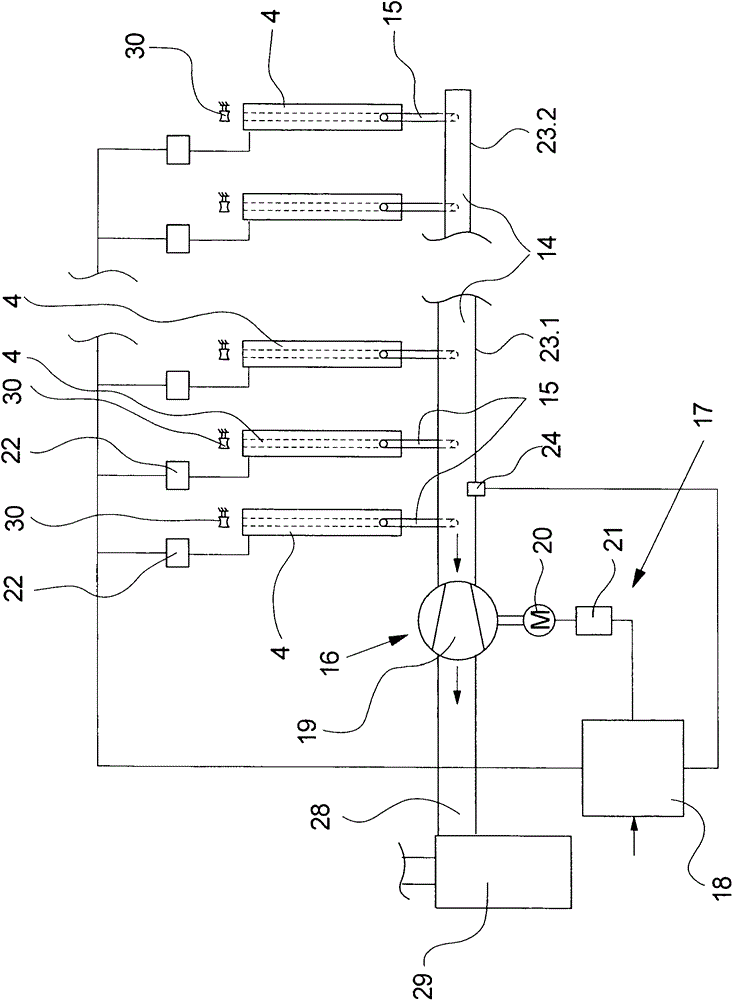

Textile machine

The invention relates to a textile machine, which comprises a plurality of yarn processing stations for processing yarn. In order to heat yarn, a plurality of heating devices are arranged for each of the yarn processing stations. The heating devices are connected with suction pipes respectively via their respective inhale pipes so as to suck out the steam. The suction pipeline is connected with a negative pressure source, wherein a control instrument is arranged for adjusting the suction strength. The control instrument directly applies on the negative pressure source so as to realize the stepless adjustment of the suction strength of the steam.

Owner:OERLIKON TEXTILE GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com