Device for preheating charging materials for glass melting facilities

A glass and equipment technology, applied in the field of material preheating equipment for glass melting systems, can solve problems such as affecting heat balance, interference, process interference, etc., and achieve the effect of compensating for pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

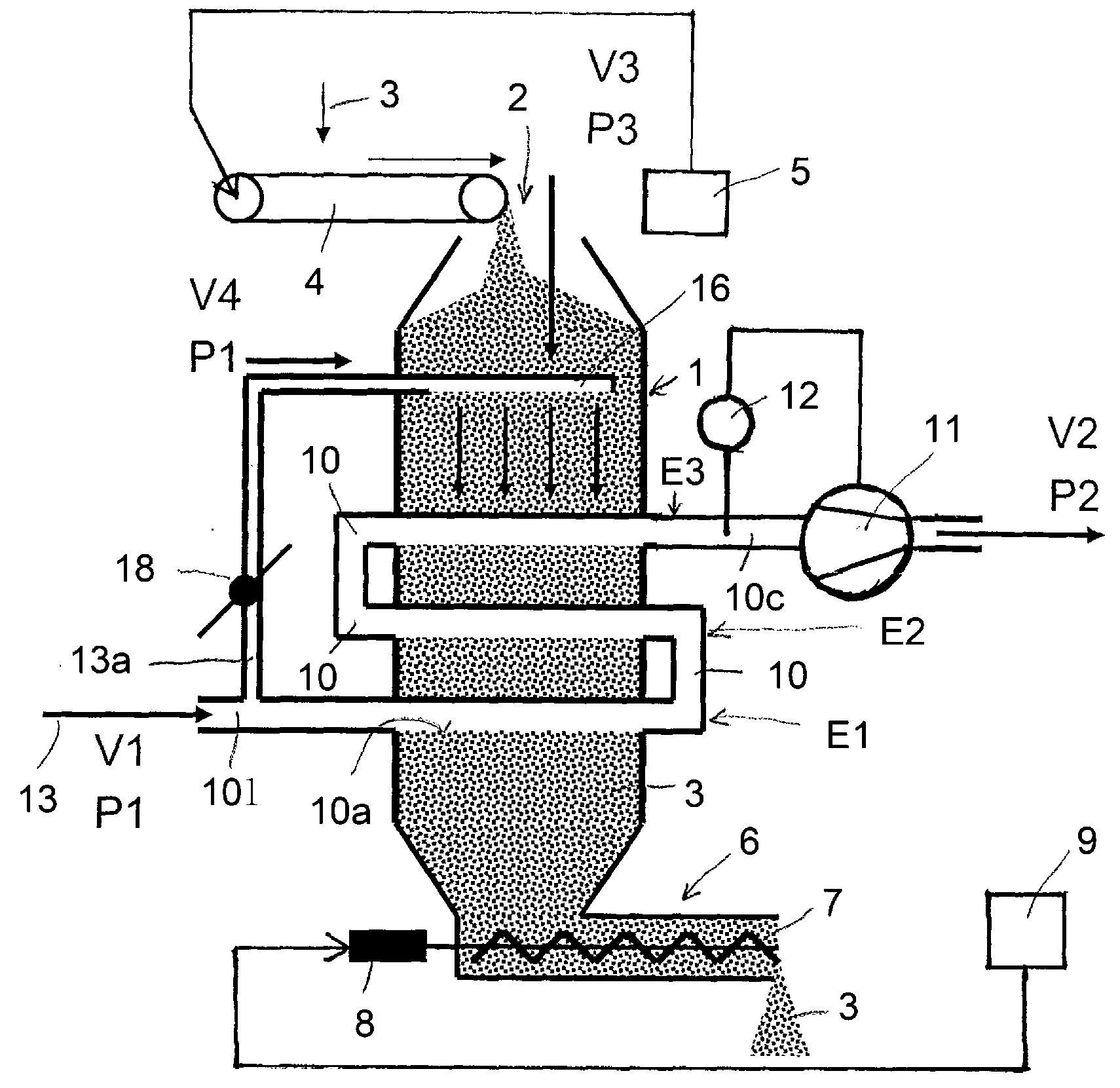

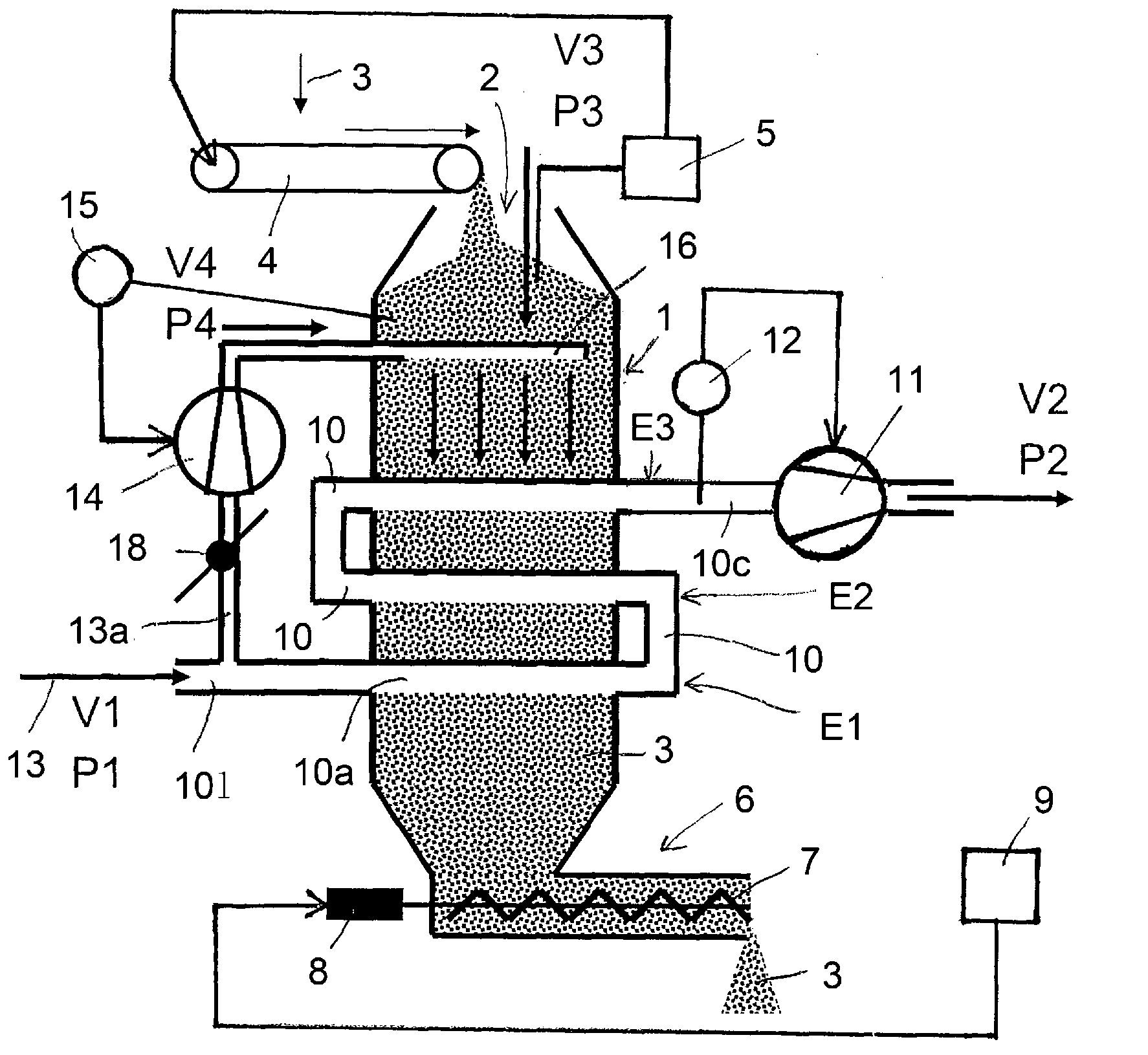

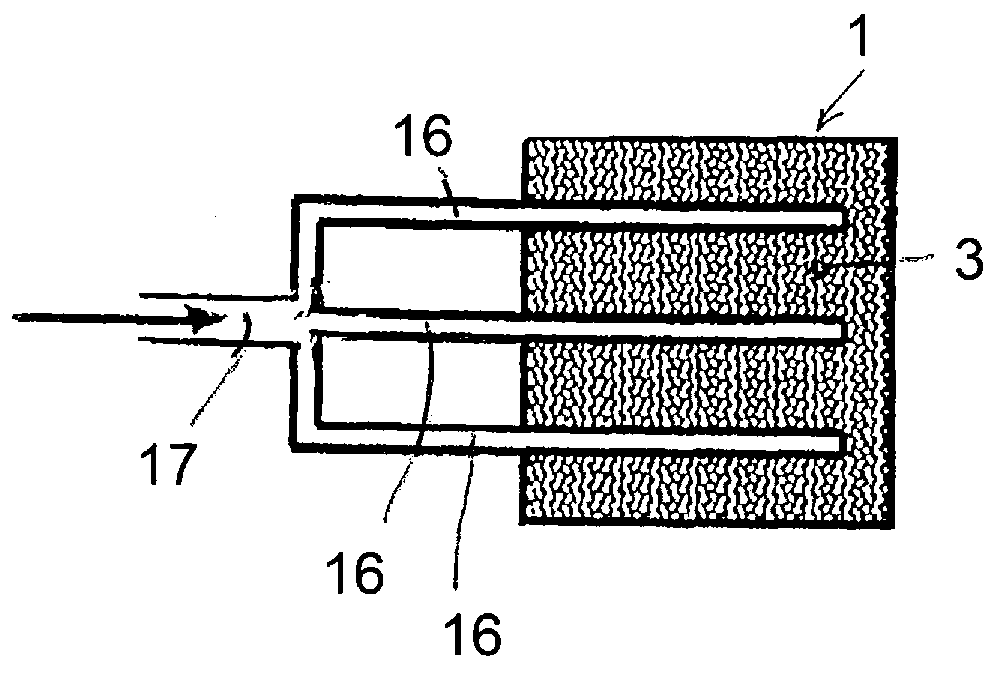

[0018] exist figure 1 A preheating well 1 is shown in , which has a feed opening 2 at the upper end for the material 3 , which forms a descending / settling column in the preheating well 1 . The feed of the material takes place via a belt conveyor 4 whose conveying power is adjusted via a level sensor 5 such that the feed opening 2 is not closed. The removal device 6 for the preheated material 3 is located at the lower end. The removal device 6 has a conveyor screw 7 driven by an electric motor 8 . The rotational speed of the conveying screw, and thus the conveyed quantity per unit of time, is controlled via a sensor 9 which is connected to a level gauge (not shown) on the bath for the glass melt. The preheating well 1 is insulated from the external heat so that the vast majority of the heat input is transferred to the material 3 . The movement of the material in the preheating well 1 is effected by gravity.

[0019] The preheating of the material 3 takes place by means of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com