System and method for ventilating explosive regions of an aircraft

A technology of ventilation system and ventilation method, applied in the direction of containers, large containers, transportation and packaging, etc., can solve problems such as cost increase and weight, and achieve the effect of avoiding disorder and uniform flow profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

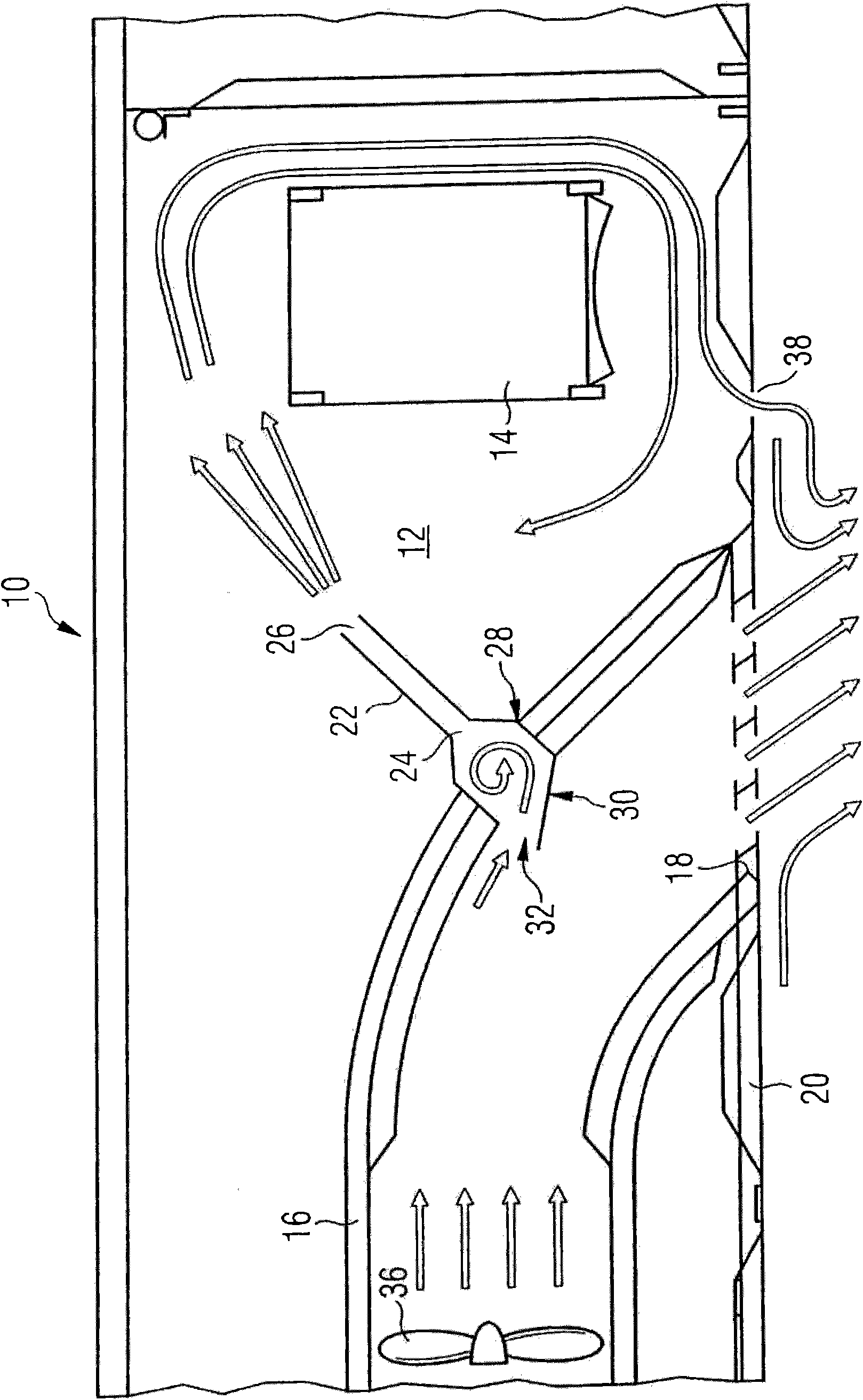

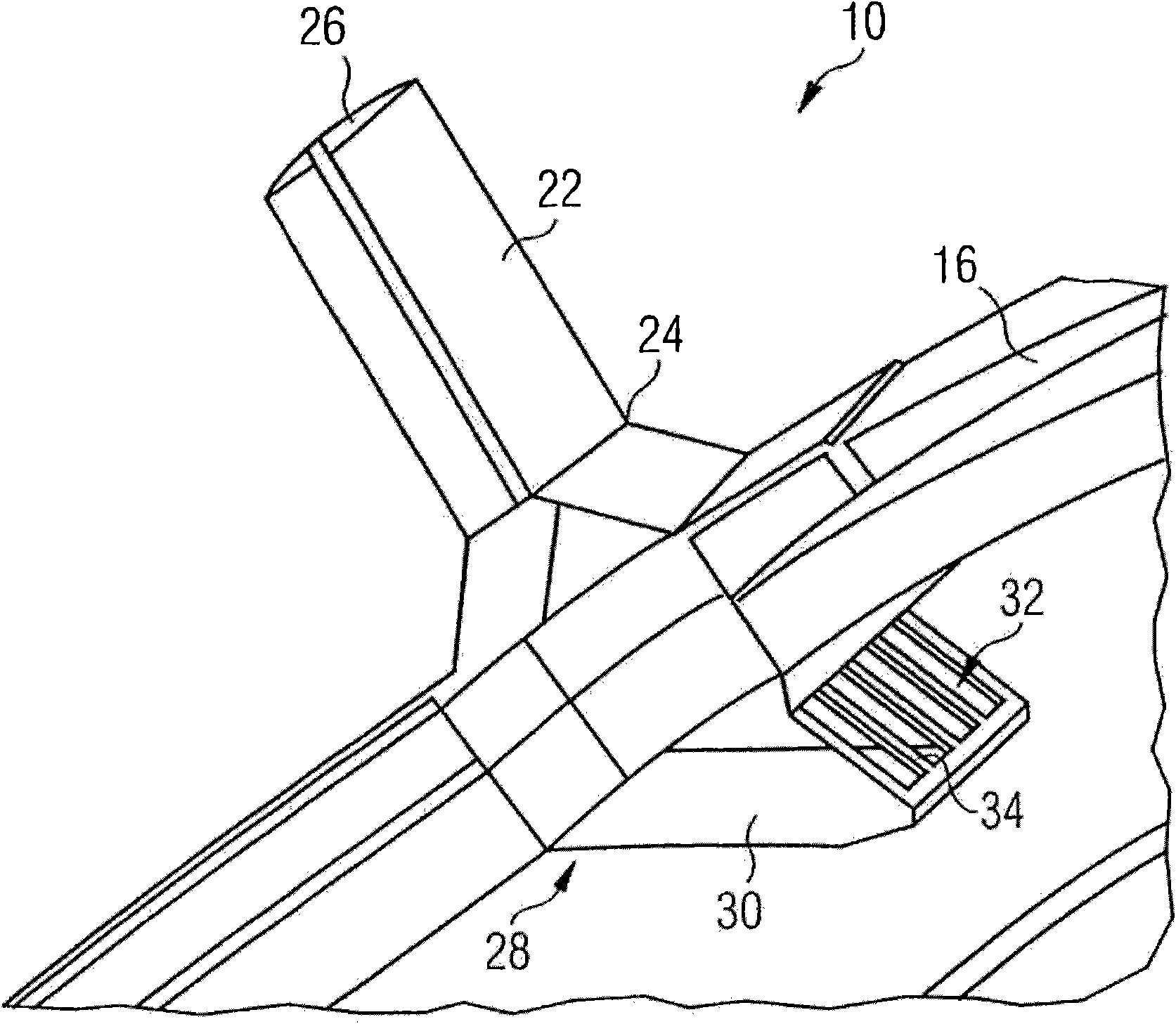

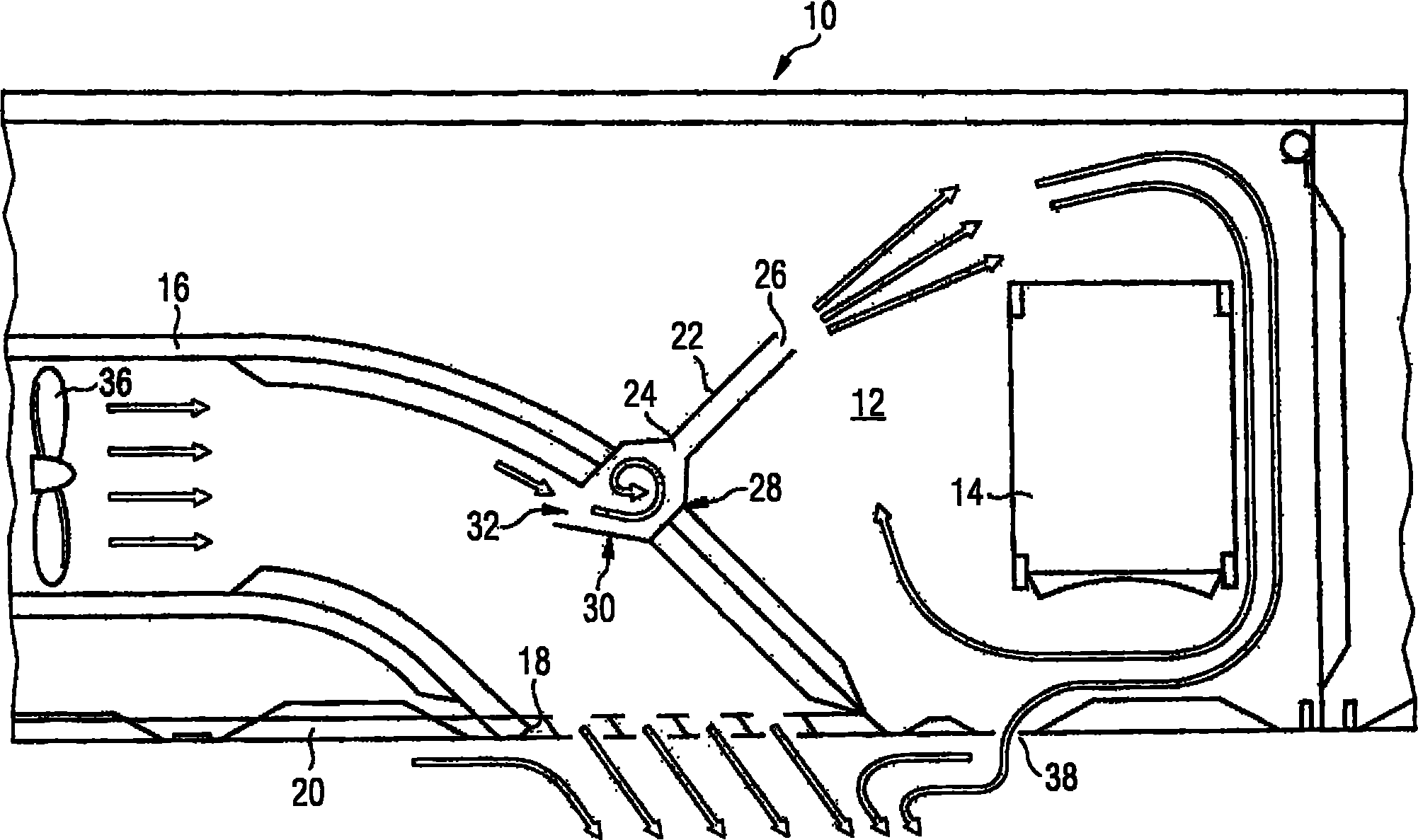

[0022] exist figure 1 A system 10 for ventilating an explosion-hazardous area 12 of a spacecraft is shown in FIG. This explosion-hazardous spacecraft area 12 is adjacent to the spacecraft's fuel tanks (which are not in figure 1 shown in ). For this reason, it is possible for kerosene vapors to seep into zone 12 . A thermal load component 14 in the form of a control unit is arranged in the spacecraft region 12 . In order to prevent the formation of explosive gas mixtures in the area 12 and thereby minimize the risk of fuel explosions, the explosively hazardous spacecraft area 12 must be adequately ventilated. Furthermore, thermally loaded components 14 generate high thermal loads that must be removed from spacecraft region 12 .

[0023] The ventilation system 10 includes a ram air passage 16 having an air inlet that is not in the figure 1is shown in and is designed in the form of a NACA inlet for supplying ambient air to the ram air channel 16 . The air inlets of the ram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com