Centrifugal separator

A centrifugal separator and liquid technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that the efficiency and dehumidification effect need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

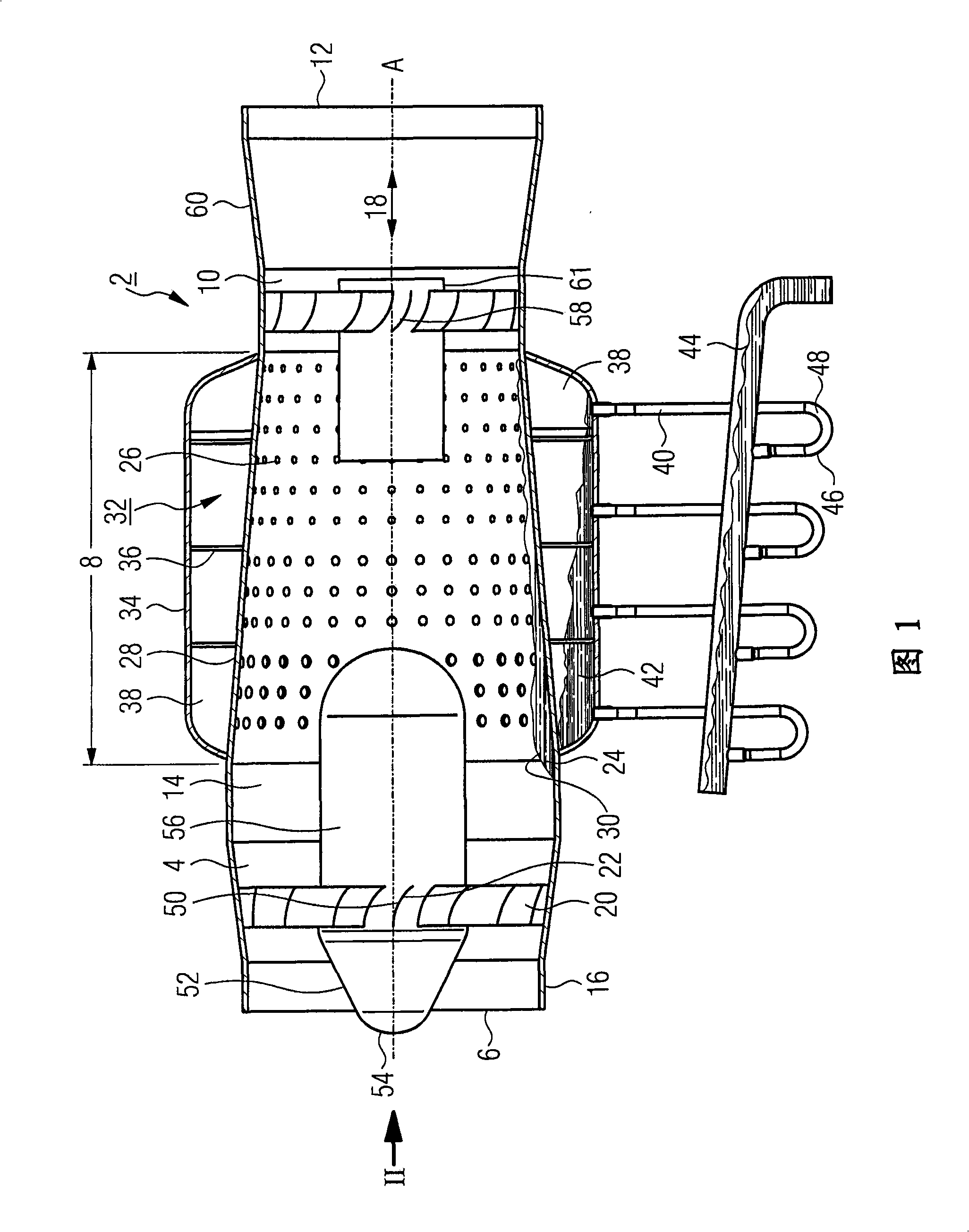

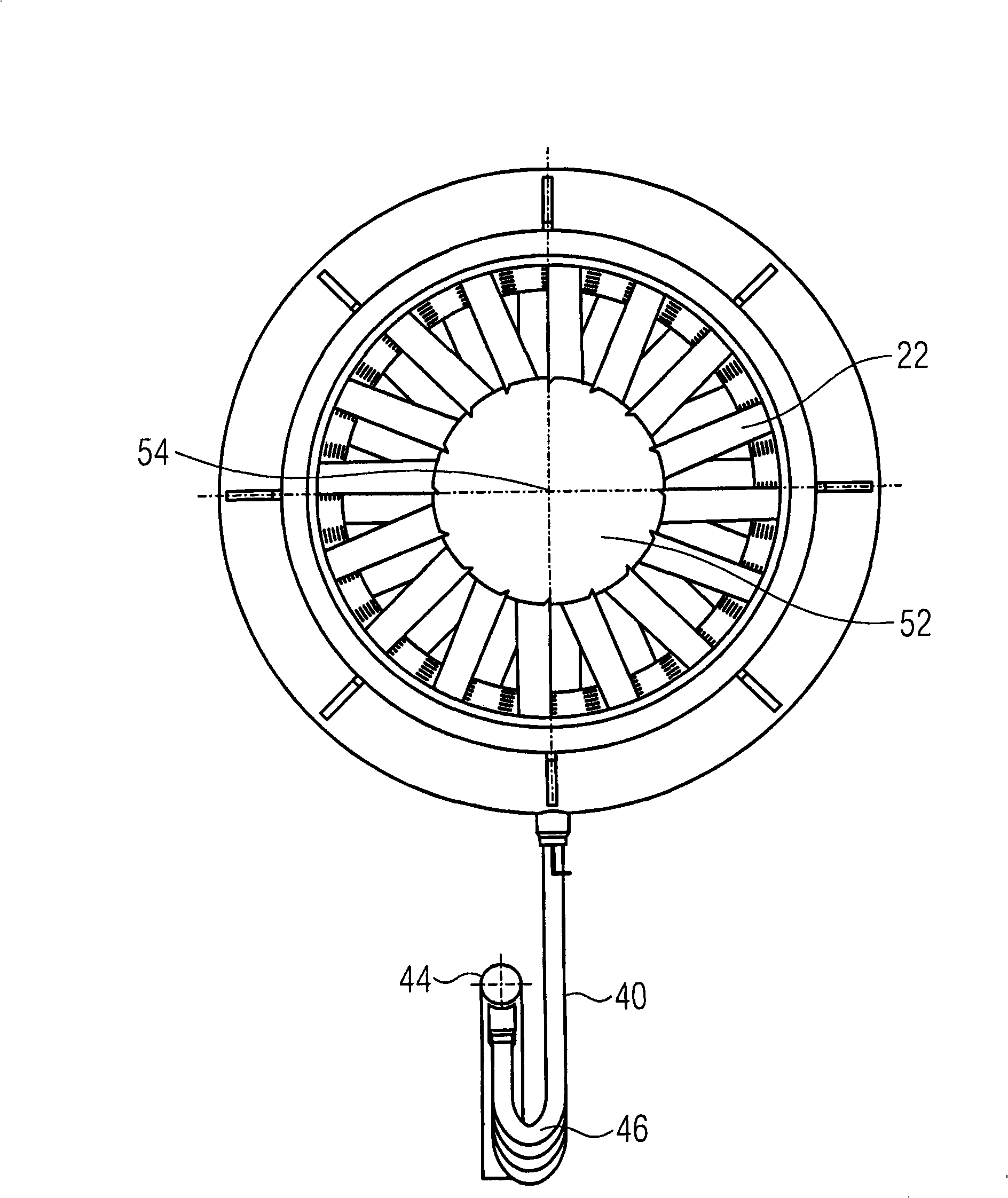

[0019] In Figure 1 and figure 2 The centrifugal separator 2 shown in is used to remove water droplets from the water-steam cycle of a power station, in particular from the high-pressure turbine to the reheater line (not shown here) before the low-pressure turbine ) pre-separated or coarsely separated from the wet vapor stream in the overflow tube. A water separator can be connected here between the centrifugal separator 2 and the reheater tube, the latter being unloaded by the centrifugal separator 2 .

[0020] The centrifugal separator 2 comprises an inlet area 4 with inlet openings 6 for the gas or vapor flow to be dehumidified, a separation section 8 in which the liquid is separated, and an outlet area 10 with outlet openings 12 . Between the inlet opening 6 and the outlet opening 12 a gas or vapor flow is guided in a flow channel 14 which is delimited to the outside by an inner housing 16 with a suitably defined contour.

[0021] The flow channel 14 is aligned along an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com