Textile machine

A technology of textile machines and blowers, which is applied in the direction of textiles and papermaking, can solve problems such as energy loss, and achieve the effect of avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

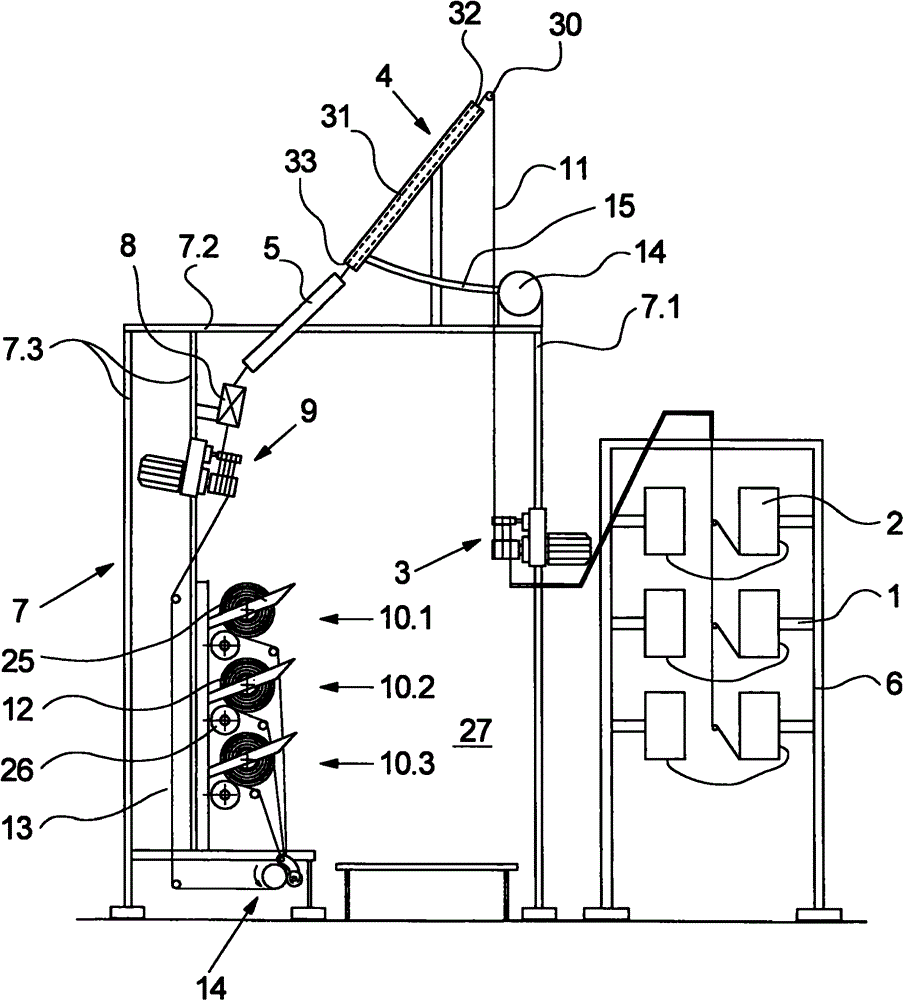

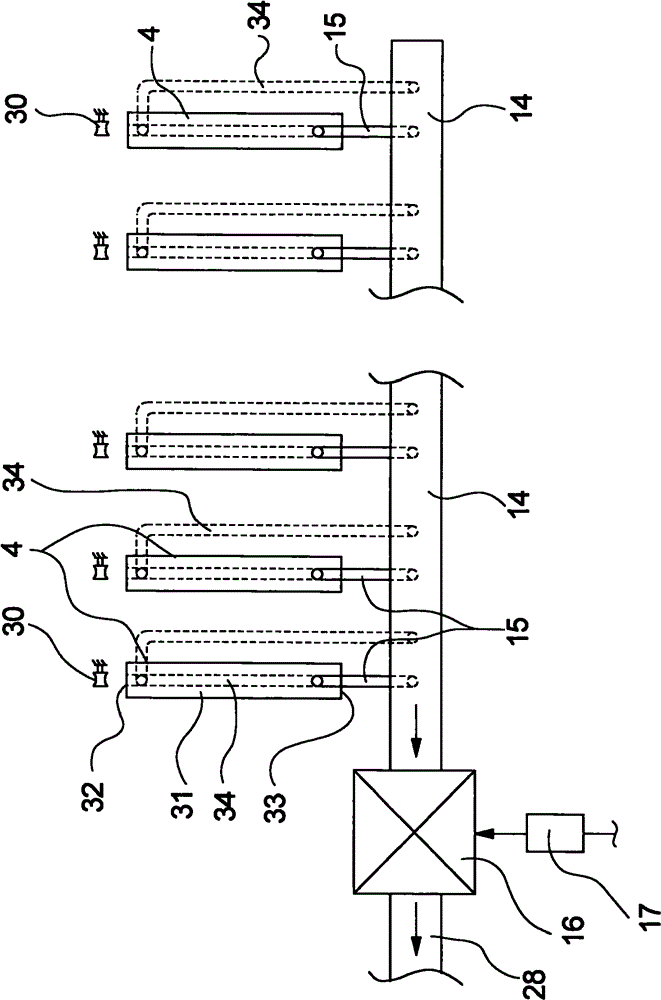

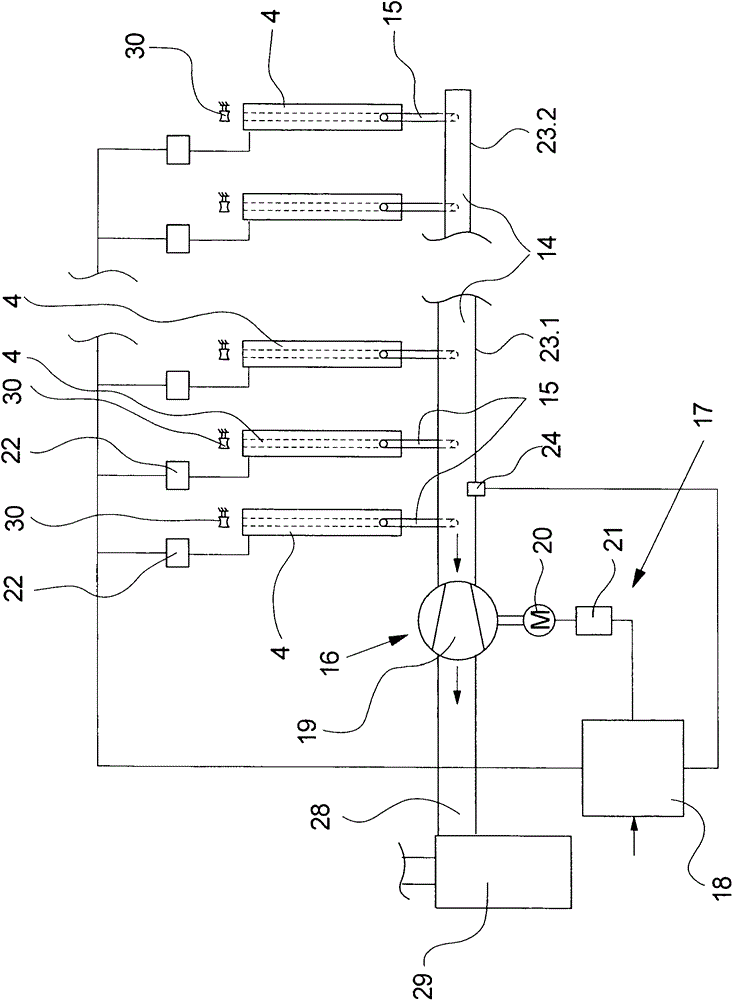

[0023] figure 1 and 2 A first embodiment of a textile machine according to the invention is shown in . figure 1 shows a cross-section of a textile machine, while in figure 2 shows a partial view from above of several heating devices arranged side by side in a machine. The following description applies to both figures unless otherwise stated with respect to one figure.

[0024] figure 1 The cross-sectional view shown in shows the spinning process (Fadenlauf) in a processing station in which the yarn is withdrawn from the yarn supply bobbin, guided, crimped, stretched and wound into a bobbin. The process devices required for this purpose are arranged in a multi-part frame 7 for the spinning process which partly surrounds a process walkway 27 . Textile machine along the longitudinal direction (in figure 1 , where the drawing plane is equal to the transverse plane) has multiple processing stations in order to simultaneously texturize and draw large numbers of yarns side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com