Oil well cement gas expander

A gas expansion, oil well cement technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as unfavorable slurry construction, pipe corrosion, hydrogen embrittlement accidents, etc., and achieve compensation for pressure loss and volume shrinkage. Compatibility, the effect of preventing water channeling

Active Publication Date: 2017-11-14

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

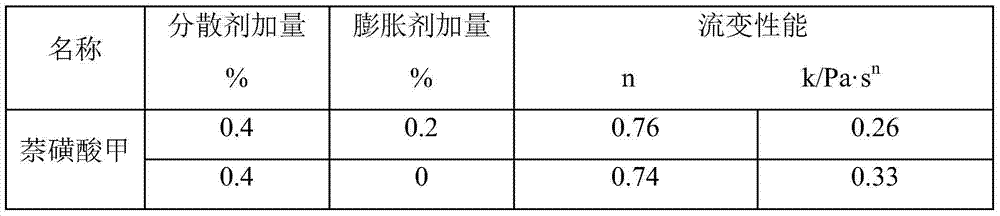

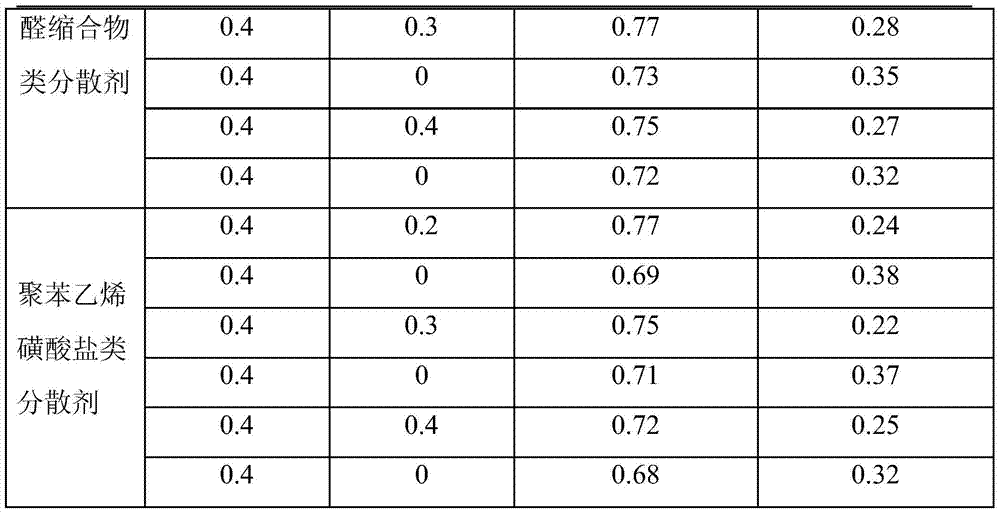

The gas expansion agent reacts quickly under alkaline conditions to produce a large amount of hydrogen, which is not conducive to the on-site slurry mixing construction, and hydrogen corrodes the casing, which is likely to cause hydrogen embrittlement accidents; currently, the nitrogen expansion agent mainly uses azo compounds as gas Source, through the addition of gas aids to make it react under a certain temperature of alkaline conditions to release nitrogen to produce expansion effects, can be dry mixed or wet mixed, and the on-site slurry is convenient, but the accompanying gas CO, NH 3 And some products will cause different degrees of corrosion to the pipe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Prepared by mixing 30 parts of benzenesulfonyl hydrazide and 70 parts of silica mill powder.

Embodiment 2

[0019] Prepared by mixing 30 parts of benzenesulfonyl hydrazide, 30 parts of silicon dioxide and 40 parts of calcium silicate powder.

Embodiment 3

[0021] Prepared by mixing 20 parts of benzenesulfonyl hydrazide, 15 parts of p-(N-methoxyformylamino)benzenesulfonyl hydrazide, 30 parts of silicon dioxide and 40 parts of calcium silicate powder.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an oil well cement gas expansion agent, which consists of 30-40 parts by weight of a gas generating agent and 60-70 parts by weight of a stabilizer. The gas generating agent is a sulfohydrazide compound, and the stabilizer is at least one of silicon dioxide and calcium silicate. The oil well cement gas expansion agent can be used for daily dry blending work, and also can be used for on-the-spot wet blending work. When the oil well cement gas expansion agent acts on cement paste, the temperature reaches 35DEG C under an alkaline condition, nitrogen release starts. By means of the effect of the stabilizer in the components, small bubbles can be evenly distributed in the cement paste, and the only generated gas is nitrogen, which has no corrosion to pipes. In addition, the oil well cement gas expansion agent has good compatibility and compatibleness with other cement additives, also can effectively compensate the pressure loss and volume shrinkage when the cement paste solidifies, and prevents well cementing oil gas and water channeling.

Description

technical field [0001] The invention relates to the technical field of oil and gas well cementing engineering operations, in particular to an oil well cement gas expansion agent. Background technique [0002] The channeling of oil, water and gas in the annular space of oil and gas wells has always been a prominent problem in the oil industry at home and abroad. It has not been fundamentally solved so far, and has caused great economic losses to the oil industries of various countries. Annulus channeling after cementing and poor cement sheath cementation have always been prominent problems that affect productivity evaluation, water injection effect, and oil and gas well production. If interlayer sealing is poor, fluid from the high-pressure layer will inevitably flow into the low-pressure layer, resulting in the loss of oil and gas resources or Reservoir damage is also a huge threat to environmental protection. In recent years, various oilfields at home and abroad have adopt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/473

CPCC09K8/473

Inventor 王野任强任路赵德喜彭松王红科赵秋羽曹洪昌刘景丽罗文丽侯士东

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com