Single-phase winding coiling method used for p axial magnetic field motors and winding structures thereof, printed circuit board and motor

A single-phase winding, axial magnetic field technology, applied to the shape/style/structure of winding conductors, synchronous motors with stationary armatures and rotating magnets, windings, etc., can solve the problem of affecting motor performance, unreasonable winding shape, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

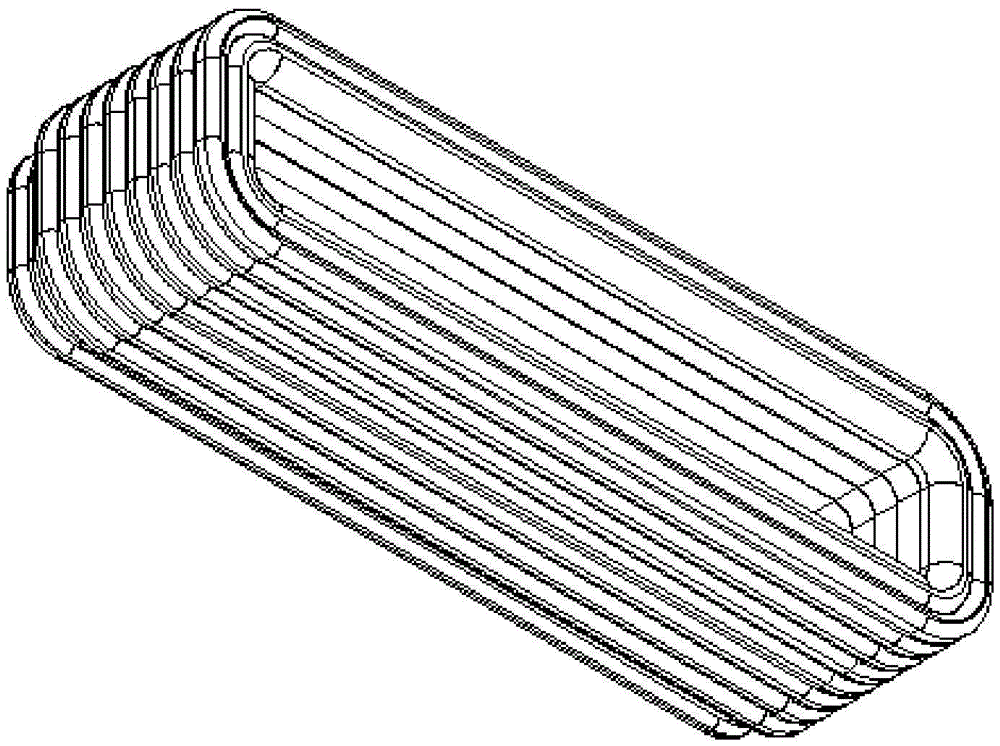

[0072] like Figure 4 and Figure 5 As shown, a winding method for a single-phase winding structure of an axial field motor with poles, the number of layers of the PCB board is 2N, including Figure 4 structure with a first layer winding period p-1 as shown, or Figure 5 The structure of p-2 is shown, or a similar p-n structure (n=1, 2, . . . , p-1). The selection of the period number of the first layer winding is determined by the position of the electronic device and the space required by the drive circuit. The two terminal lines of the winding are located on the first layer of the PCB. The winding adopts a centralized structure with a maximum span of 180° electrical angle; the number of winding layers is even; except for the first layer, the windings on each layer are composed of winding periodic rings with the same number of motor poles p; adjacent The winding layers are connected in series through connection holes. Since the number of cycles of the first-layer windin...

Embodiment 2

[0074] A winding method for a single-phase winding structure of an axial field motor with poles, the number of layers of the PCB board is 2N, including Image 6 The winding structure shown. For a PCB with 2N layers, every two layers constitute a PCB component, forming N components in total. The winding tail of each component is connected to the head of the next component with vias. The tail end of the last component is connected to the first layer of the first component by vias, and is connected to the port of the driver chip. The presence of vias does not affect the layout of the PCB windings. Obviously, this winding arrangement can further increase the number of turns of the winding and simplify the production conditions of the PCB.

Embodiment 3

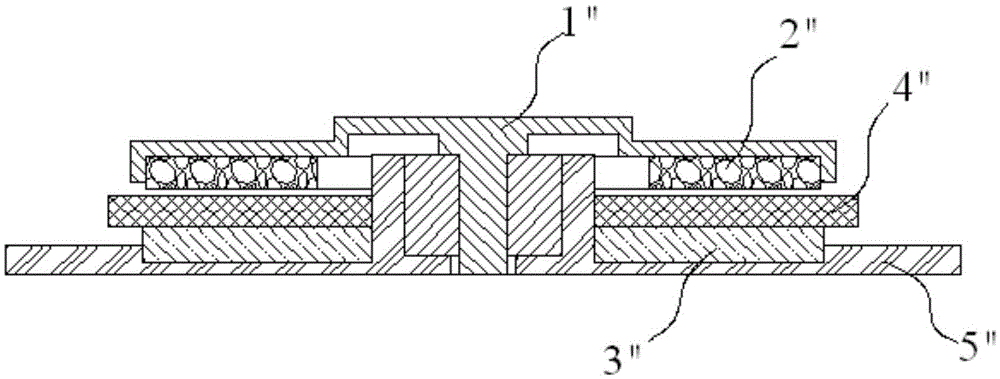

[0076] like Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a printed circuit board using the above-mentioned single-phase winding structure, each single-phase winding structure is a PCB group, the printed circuit board includes N PCB groups, the winding end of the first group of PCBs is located outside the winding cycle The vias are connected to the winding ends of the connected PCB.

[0077] Wherein, the side of the PCB set away from the magnetic steel is provided with a driving device.

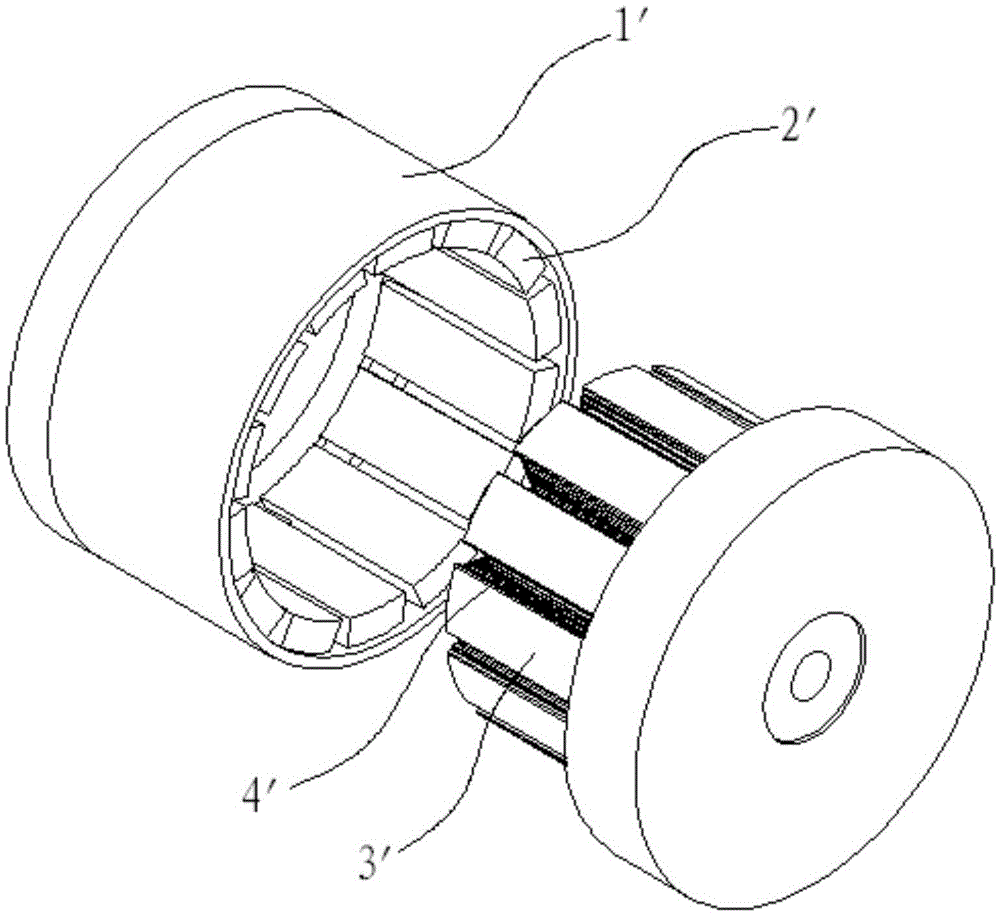

[0078] A motor, comprising a motor base, a PCB group and a rotor housing, the motor base is provided with a bearing, one end of the motor shaft of the rotor housing passes through the PCB group and is arranged in the bearing, the rotor housing is provided with a rotor magnetic steel, The side of the PCB set away from the rotor magnetic steel is provided with a positioning piece, and the magnetic permeability of the material is greater than 1.

[0079] In order to make the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com