Transparent laminate

A technology of transparent laminates and transparency, applied in the direction of coating, layered products, synthetic resin layered products, etc., to achieve the effect of excellent ease of manufacture and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

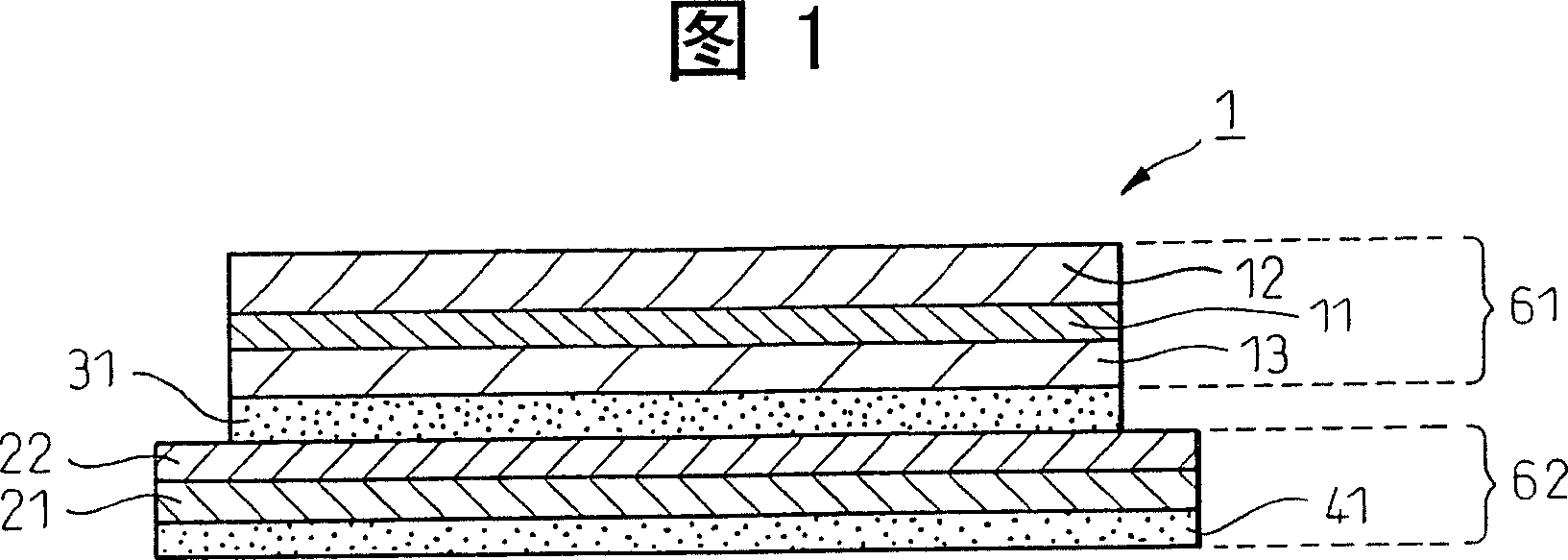

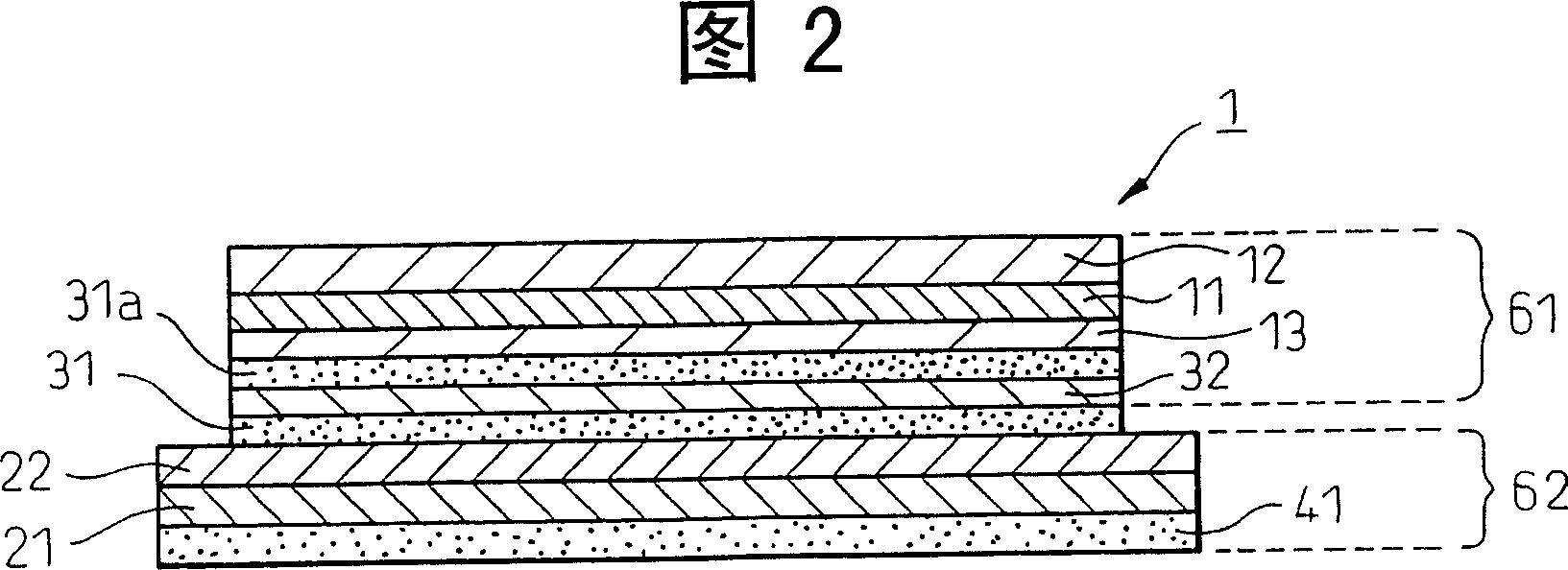

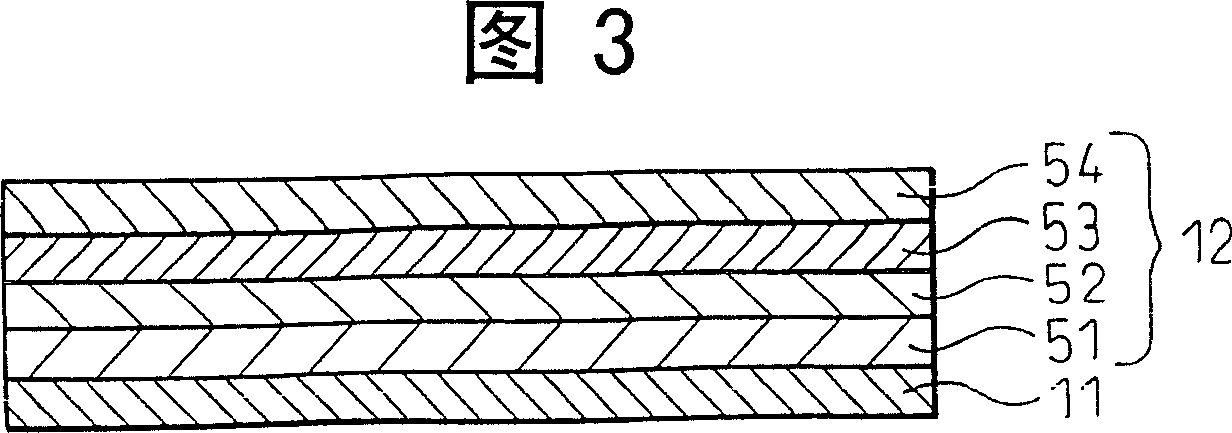

Embodiment 1

[0177] Use a PET film with a thickness of 100 μm as the first transparent substrate, and form an anti-reflection layer consisting of a hard coat layer, a conductive medium refractive index layer, a high refractive index layer, and a low refractive index layer on one surface, and form an antireflection layer on the opposite surface. A near-infrared shielding layer containing a transparent resin is formed by making a diiminium-based compound having an opposite anion represented by chemical formula (1), that is, a diiminium-based dye, thereby forming a first laminated portion. And phthalocyanine pigments (manufactured by Nippon Shokubai, trademark: イクスカカラ-IR-10A), and containing in the general formula (2) X is the monomer component polymerization of 50 parts by weight of the monomer of isobornyl group and form get. The diiminium-based dye and the phthalocyanine-based dye were mixed in a weight ratio of 2:1.

[0178]Next, a paste containing palladium colloid was printed on a PET ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com