Electroplating apparatus

A kind of electroplating equipment and plating technology, applied in the direction of plating tank, electrolytic process, electrolytic components, etc., can solve problems such as corrosion and not yet achieved remarkable results, achieve good plating and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

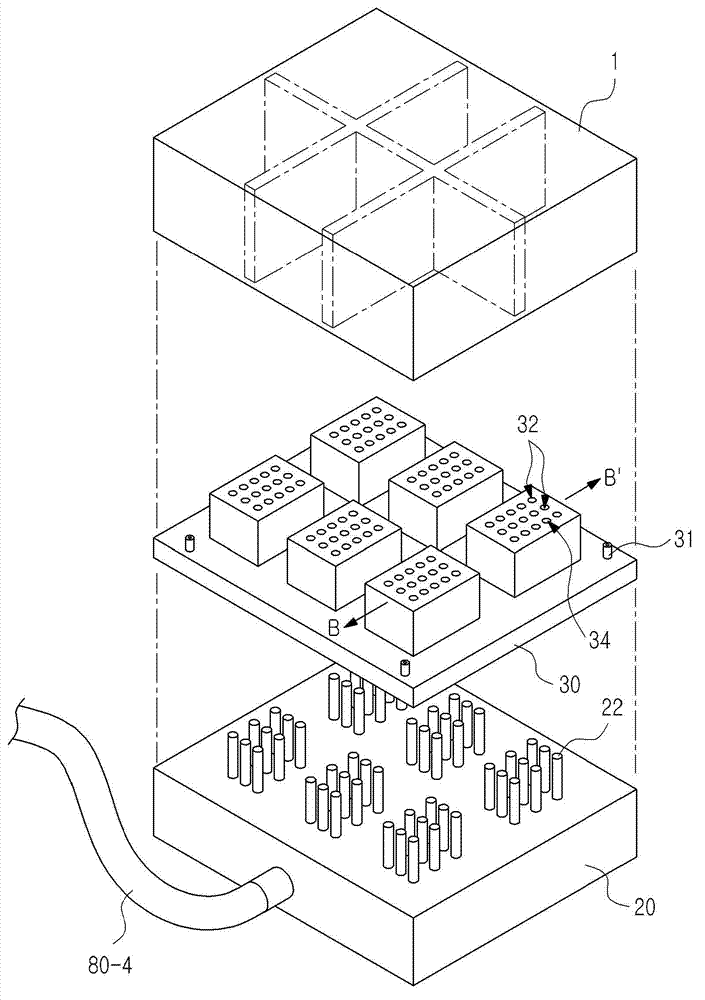

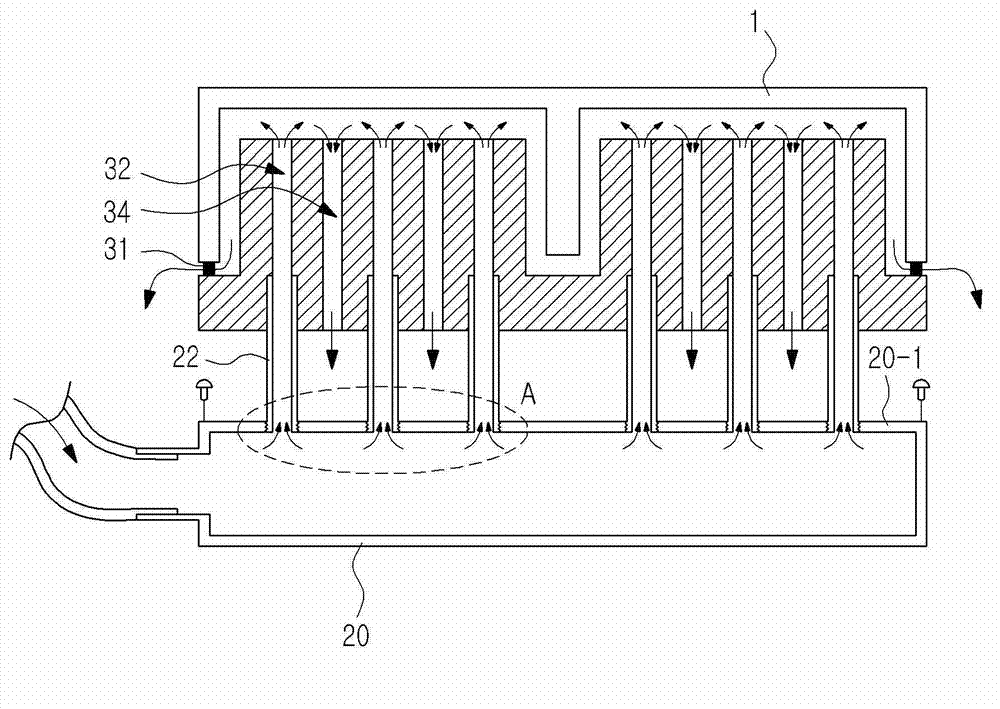

[0020] The following will be combined with Figures 1 to 4 , to describe exemplary embodiments of the present invention in detail. In the following drawings, the same components are denoted by the same reference numerals as much as possible.

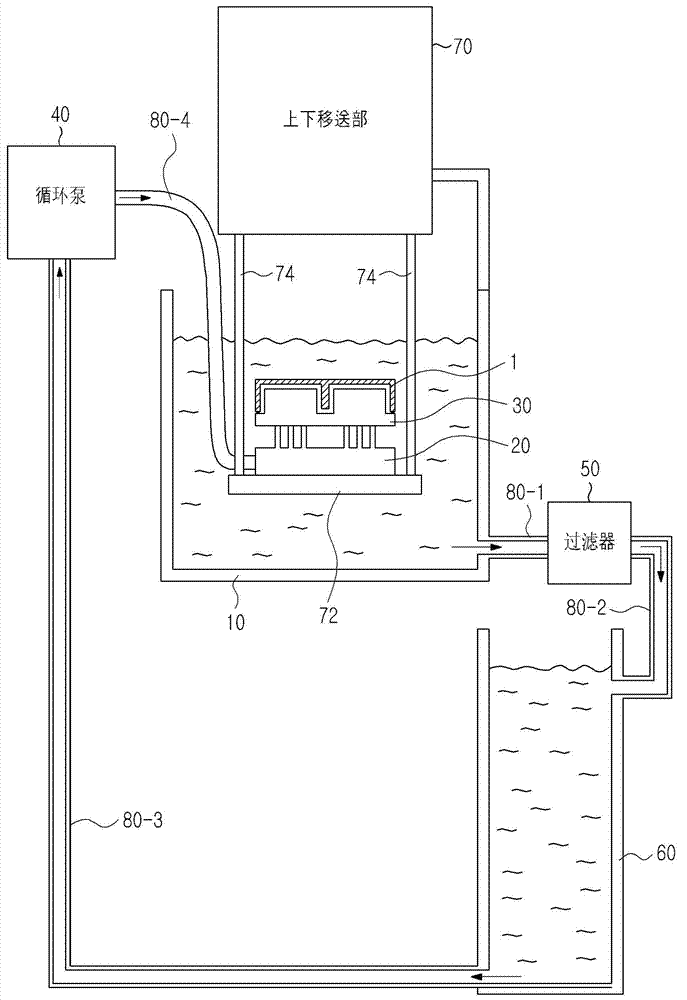

[0021] Such as figure 1 As shown, the electroplating device of the present invention, especially the object to be plated (1) of magnesium material (or magnesium alloy material), basically has a plating container containing an electrolyte containing metals such as copper or silver for plating (10). At this time, according to the characteristics of the present invention, there is an electrolyte injection part (20), which, after obtaining the electrolyte supply of the plating container (10), passes through multiple nozzles ( figure 2 22) to spray the electrolyte. In addition, there is also a circulation pump (40) for supplying electrolyte to the electrolyte injection part (20). ), the circulating pump (40) supplies the pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com