Method for making flexible, transparent and conductive film made of metal nanowires

A transparent conductive film, metal nanowire technology, applied in nanotechnology, cable/conductor manufacturing, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor environmental stability, large surface roughness, limited application, etc., to solve the adhesion force Poor, high surface flatness, solve the effect of large surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

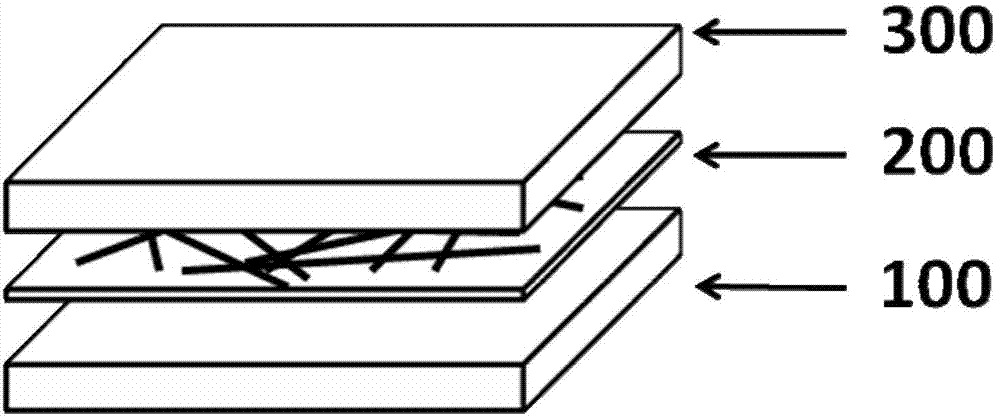

[0029] Specifically, the preparation method of the metal nanowire flexible transparent conductive film of the present invention comprises the following steps:

[0030] First, metal nanowire solutions with different concentrations are prepared, and a metal nanowire layer 200 with a thickness of 30-300 nm is prepared on a planar substrate 100 by a solution processing method; 500 μm transparent flexible base layer 300; finally, the transparent flexible base layer 300 with the metal nanowire layer 200 on the surface is peeled off from the planar substrate 100 to form a metal nanowire flexible transparent conductive film.

[0031] The above-mentioned planar substrate 100 is rigid material such as glass, quartz or semiconductor.

[0032] The above-mentioned metal nanowire solution is a nanowire dispersion liquid of metal materials such as Ag, Au or Cu, the diameter of the metal nanowire is 30-200nm, the length is 5-30μm, and the solution concentration is 0.1-6mg / ml.

[0033] The ab...

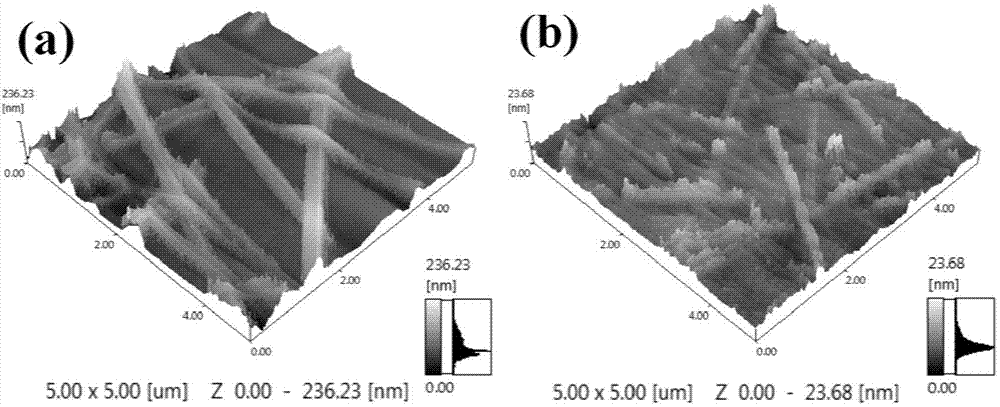

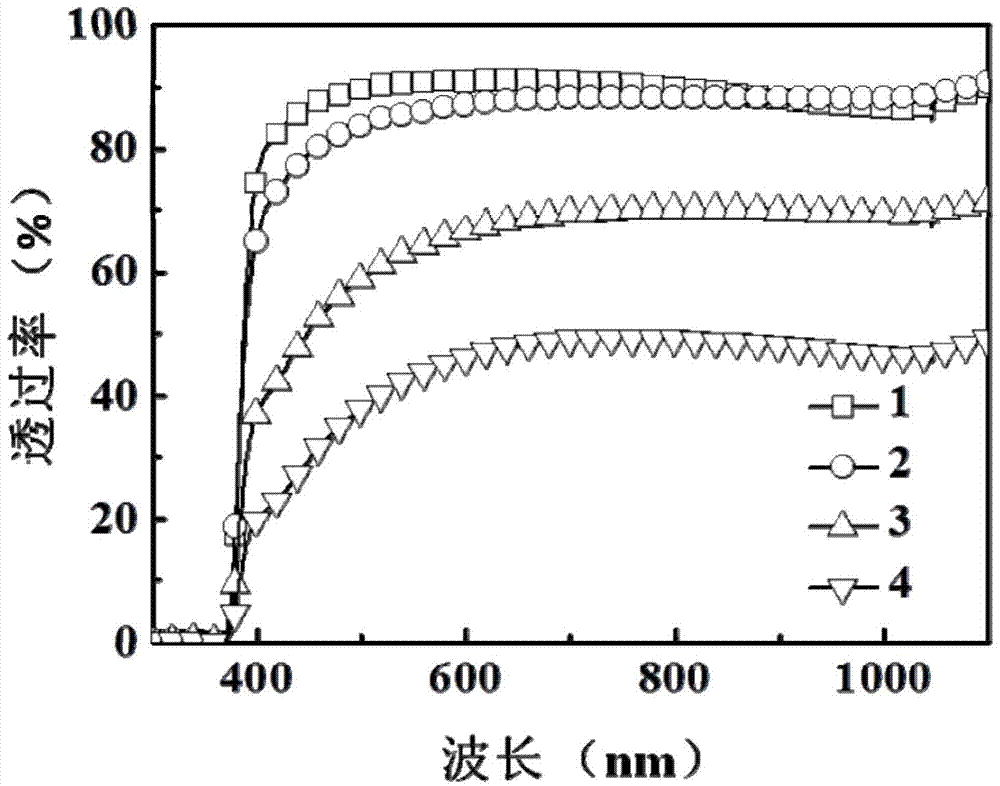

Embodiment 1

[0038] A metal nanowire layer 200 with a thickness of 60 nm is prepared on a flat substrate 100 by a drop coating method, and a transparent flexible base layer 300 with a thickness of 25 μm is prepared on the metal nanowire layer 200 by a drop coating method, and finally the surface is covered with metal nanowires. The transparent and flexible base layer 300 of the wire layer 200 is peeled off from the planar substrate 100 to form a flexible transparent conductive film of metal nanowires. The planar substrate 100 is a glass substrate; the metal nanowire layer 200 is prepared from a silver nanowire solution with a concentration of 1 mg / ml, the diameter of the metal silver nanowire is 50 nm, and the length is 15 μm; the transparent flexible base layer 300 is a PI substrate.

Embodiment 2

[0040] A metal nanowire layer 200 with a thickness of 100 nm is prepared on a flat substrate 100 by a drop coating method, and a transparent flexible base layer 300 with a thickness of 25 μm is prepared on the metal nanowire layer 200 by a drop coating method, and finally the surface is coated with metal nanowires. The transparent and flexible base layer 300 of the wire layer 200 is peeled off from the planar substrate 100 to form a flexible transparent conductive film of metal nanowires. The planar substrate 100 is a glass substrate; the metal nanowire layer 200 is prepared from a silver nanowire solution with a concentration of 2 mg / ml, and the diameter of the metal silver nanowire is 50 nm, and the length is 15 μm; the transparent flexible base layer 300 is a PI substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com