Ultraviolet-cured high-adhesion scraping-resistant agent for heat insulating film

A technology with high adhesion and ultraviolet light, applied in the direction of coating, etc., can solve the problems of high cost and poor adhesion, and achieve the effect of high cost performance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

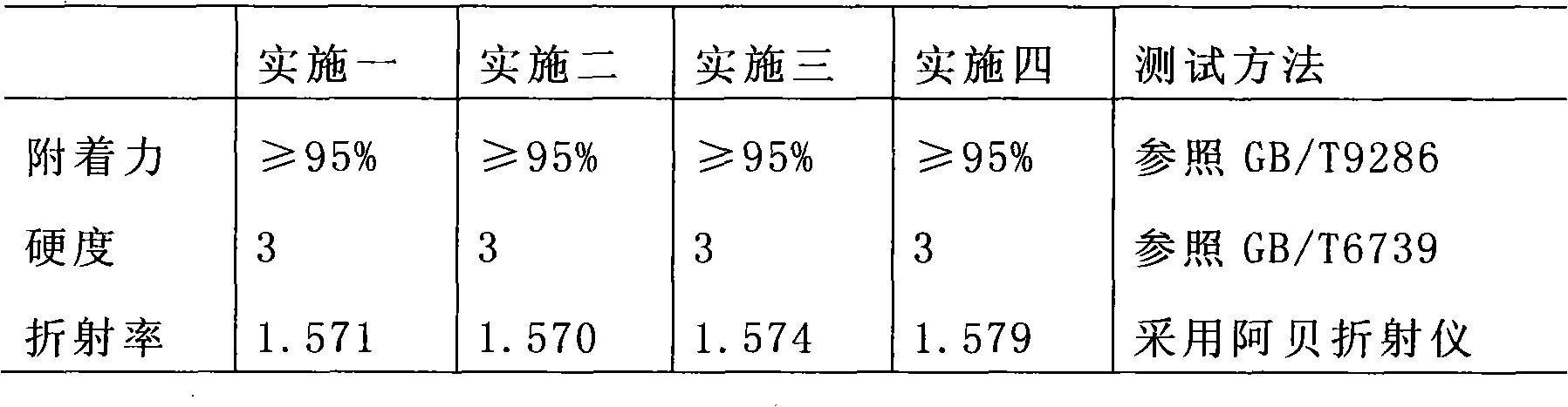

Examples

Embodiment 1

[0022] Set the mass parts of each component of the acrylate scratch-resistant agent as:

[0023] Polyurethane acrylate oligomer PRO30053 15.5 parts

[0024] 5 parts of hydroxyethyl acrylate

[0025] Dipentaerythritol hexaacrylate 4 parts

[0026] Trimethylolpropane Triacrylate 8 parts

[0027] 35 parts isopropanol

[0028] 15 parts of toluene

[0029] Aliphatic urethane acrylate adhesion promoter 12 parts

[0030] Leveling agent BYK-332 0.5 parts

[0031] Irgacure 184 5.5 parts.

Embodiment 2

[0033] Set the mass parts of each component of the acrylate scratch-resistant agent as:

[0034] Polyurethane acrylate oligomer CN9010 22 parts

[0035] Vinyl acetate 3.1 parts

[0036] Ethoxylated dipentaerythritol hexaacrylate 3 parts

[0037] Ethoxylated trimethylolpropane triacrylate 8 parts

[0038] 30 parts of ethyl acetate

[0039] 20 parts of toluene

[0040] Chlorinated polyester resin adhesion promoter 8 parts

[0041] Leveling agent BYK-333 0.6 parts

[0042] Irgacure 907 0.3 parts

[0043] Darocur 1173 5 servings.

Embodiment 3

[0045] Set the mass parts of each component of the acrylate scratch-resistant agent as:

[0046] Polyurethane acrylate oligomer PRO30053 12 parts

[0047] Polyurethane acrylate oligomer CN9010 13 parts

[0048] 4 parts vinyl acetate

[0049] Ethoxylated dipentaerythritol pentaacrylate 4 parts

[0050] Ethoxylated trimethylolpropane triacrylate 7.5 parts

[0051] Butanone 32 parts

[0052] 10 parts of toluene

[0053] Organic-inorganic hybrid material accelerator 3.5 parts

[0054] Aliphatic urethane acrylate accelerator 8 parts

[0055] Leveling agent BYK-323 0.5 parts

[0056] Irgacure 500 1 serving

[0057] Irgacure 184 4.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com