Finish paint for plastic

A topcoat and plastic technology, applied in the field of coatings, can solve the problems of long production cycle, labor-intensive, high energy consumption, etc., and achieve the effect of solving high energy consumption, saving electricity, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

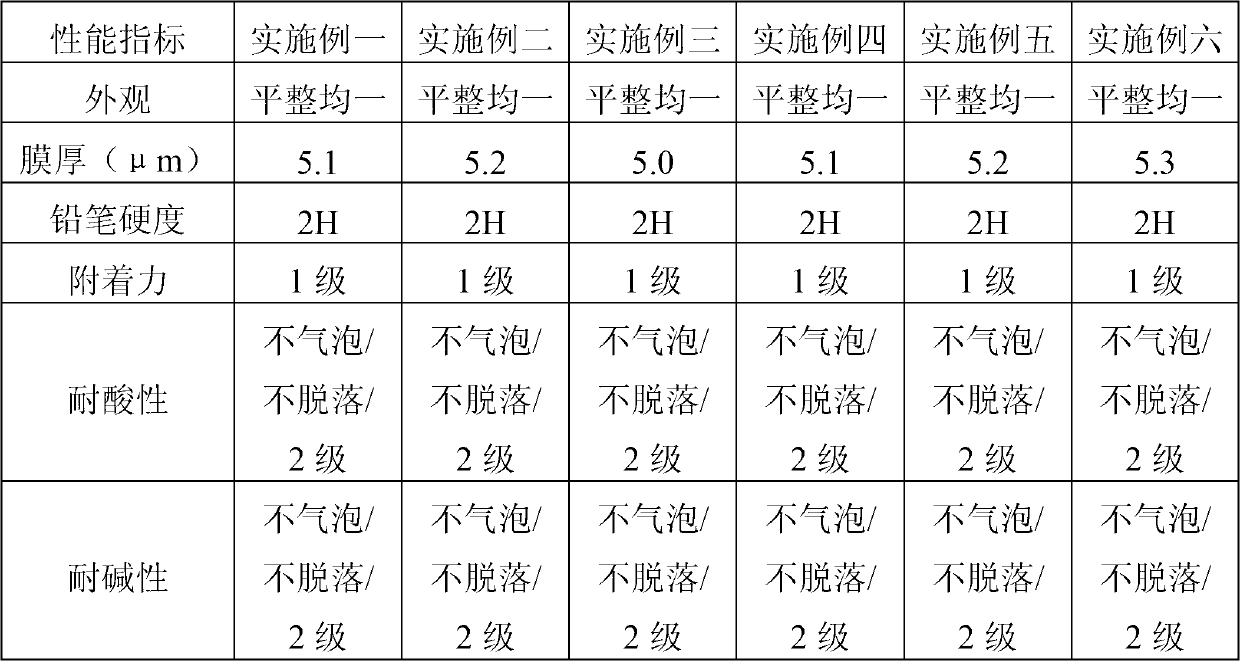

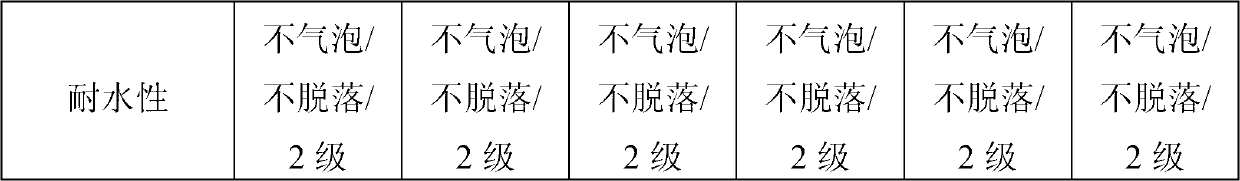

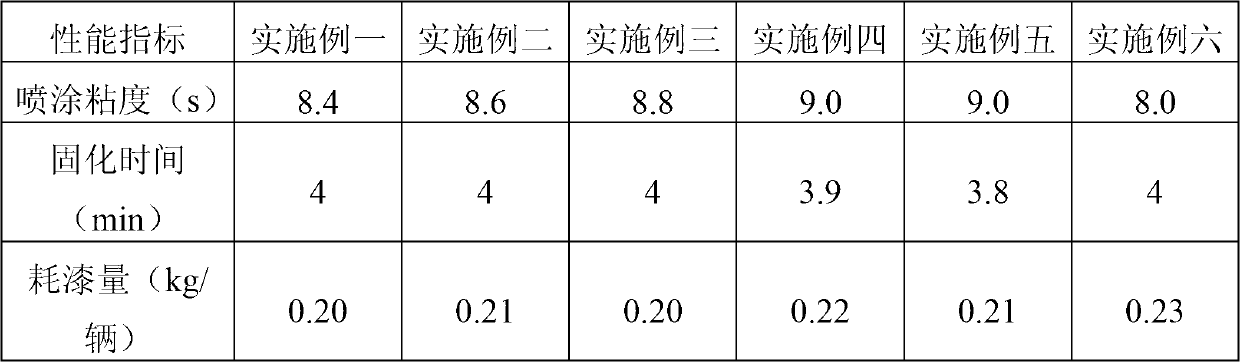

Examples

preparation example Construction

[0094] The preparation method (each component is added in proportion in the following steps) of the plastic topcoat of the present invention is given below:

[0095] Step 1: Add aliphatic urethane acrylate, aromatic urethane acrylate, polymer copolymer containing pigment affinity groups, unsaturated polyamic acid homopolymer, silicone, and cellulose ester in sequence, then stir and mix at 800RPM 5 minutes;

[0096] Step 2. Add pearlescent powder, aluminum silver powder, a mixture of pigments and nano-scale fillers to the solution obtained in step 1, and stir evenly at 2000-3000 RPM;

[0097] Step 3. Add hydroxyl acrylic resin, styrene maleic anhydride modified vinyl acetate resin, multifunctional reactive diluent, difunctional reactive diluent and trifunctional reactive diluent to the solution obtained in step 2, and stir evenly at 800 RPM;

[0098] Step 4: Mix the cleavage-type photoinitiator and the acylphosphine oxide photoinitiator until it becomes clear and transparent, ...

Embodiment 1

[0101] Aliphatic urethane acrylate 5%;

[0102] Aromatic polyurethane acrylate 15%;

[0103] 1.5% polymer interpolymer with pigment affinity group;

[0104] Unsaturated polyamic acid homopolymer 0.3%;

[0105] Aralkyl modified silicone 0.2%;

[0106] Nitrocellulose ester 30%;

[0107] 5% mixture of pearlescent powder, aluminum silver powder and titanium dioxide;

[0108] Nanoscale silicon oxide filler 3%, wherein the particle size is 5nm;

[0109] Hydroxy acrylic resin 10%;

[0110] Styrene maleic anhydride modified vinyl acetate resin 8%;

[0111] Dipentaerythritol pentaacrylate 9%;

[0112] Dipropylene glycol diacrylate 4%;

[0113] Dipentaerythritol triacrylate 5%;

[0114] 1-Hydroxy-cyclohexylbenzophenone 3%;

[0115] 2,4,6-Trimethylbenzoyl-diphenylphosphine oxide 1%.

Embodiment 2

[0117] Aliphatic urethane acrylate 10%;

[0118] Aromatic polyurethane acrylate 10%;

[0119] Unsaturated polyamic acid homopolymer 0.1%;

[0120] Polyether modified silicone 0.1%;

[0121] Cellulose acetate butyrate 35%;

[0122] 2% mixture of pearl powder, aluminum silver powder and bright red;

[0123] Nanoscale zirconia filler 3%, particle size 10nm;

[0124] Hydroxy acrylic resin 13%;

[0125] Styrene maleic anhydride modified vinyl resin 7%;

[0126] Dipentaerythritol Pentaacrylate 10%;

[0127] Dipropylene glycol diacrylate 5%;

[0128] Dipentaerythritol triacrylate 3%;

[0129] 1-Hydroxy-cyclohexylbenzophenone 1%;

[0130] 2,4,6-Trimethylbenzoyl-diphenylphosphine oxide 0.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com