Surface flame retardant coating of rubber as well as preparation method of coating

A technology for flame-retardant coatings and rubber surfaces, applied in fire-retardant coatings, polyurea/polyurethane coatings, coatings, etc., to achieve the effects of easy large-scale production, increased production costs, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of rubber surface flame retardant coating of the present invention, this flame retardant coating is formulated according to the weight ratio of 2:1 by A component and B component, the solid content of A component is 70wt%, the solid content of B component 75wt%;

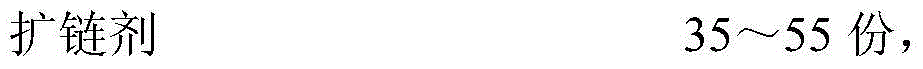

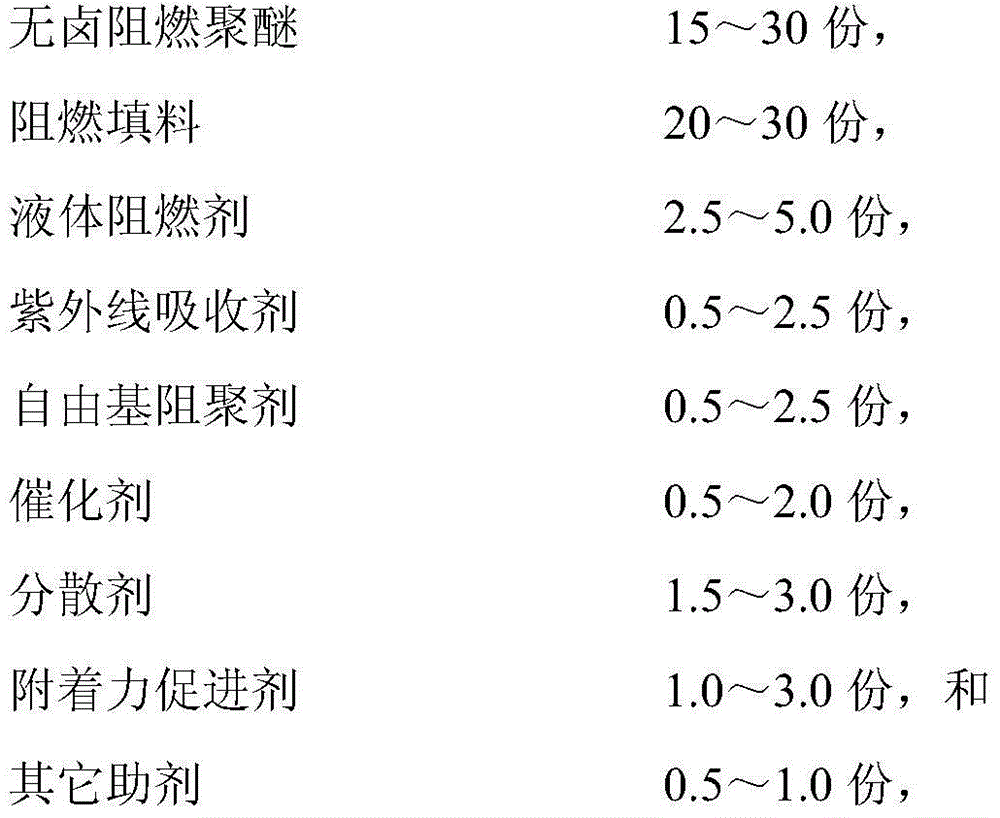

[0039] Component A is prepared from the following raw materials in parts by weight:

[0040]

[0041]

[0042] Above-mentioned 20 parts of flame retardant fillers include 10.5 parts of ammonium polyphosphate, 5.0 parts of pentaerythritol, 2.0 parts of titanium dioxide and 2.5 parts of carbon black,

[0043] The diluent of component A is composed of 150# solvent oil, propylene glycol methyl ether acetate and butyl acetate with a mass ratio of 1:1:1;

[0044] Component B is prepared from the following raw materials by weight (the sum of other raw materials except diluent is 100 parts):

[0045]

[0046] Above-mentioned 99.6 parts of isocyanate curing agents include 49.8 parts of hexamethylene d...

Embodiment 2

[0058] A kind of rubber surface flame retardant coating of the present invention, this flame retardant coating is formulated according to the weight ratio of 2:1 by A component and B component, the solid content of A component is 70wt%, the solid content of B component 85wt%;

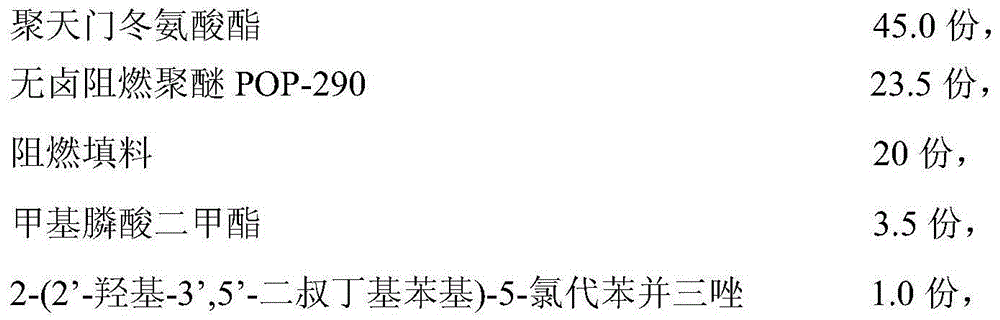

[0059] Component A is prepared from the following raw materials in parts by weight:

[0060]

[0061] Above-mentioned 20 parts of flame retardant fillers include 10.5 parts of ammonium polyphosphate, 5.0 parts of pentaerythritol, 2.0 parts of titanium dioxide and 2.5 parts of carbon black,

[0062] Above-mentioned diluent is made up of 150# solvent naphtha, propylene glycol methyl ether acetate and butyl acetate that mass ratio is 1: 1: 1;

[0063] Component B is prepared from the following raw materials in parts by weight:

[0064]

[0065] The above-mentioned isocyanate curing agent is composed of 33.2 parts of diphenylmethane diisocyanate and 66.4 parts of xylylene diisocyanate-polycaprolacto...

Embodiment 3

[0077] A kind of rubber surface flame retardant coating of the present invention, this flame retardant coating is formulated according to the weight ratio of 3:1 by A component and B component, the solid content of A component is 80wt%, the solid content of B component 75wt%;

[0078] Component A is prepared from the following raw materials in parts by weight:

[0079]

[0080] Above-mentioned 30 parts of flame retardant fillers include 16.5 parts of ammonium polyphosphate, 7.5 parts of pentaerythritol, 2.5 parts of titanium dioxide and 3.5 parts of carbon black,

[0081] Above-mentioned diluent is made up of 150# solvent naphtha, propylene glycol methyl ether acetate and butyl acetate that mass ratio is 1: 1: 1;

[0082] Component B is prepared from the following raw materials in parts by weight:

[0083]

[0084] Above-mentioned 99.6 parts of isocyanate curing agents include 49.8 parts of hexamethylene diisocyanate trimer and 49.8 parts of isophorone diisocyanate-pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com