Epoxy resin pouring sealant and preparation method thereof

A technology of epoxy resin and potting glue, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of operators feeling uncomfortable, poor compatibility of epoxy resin, high viscosity of nitrile rubber, etc. Achieve the effects of reducing CTE, avoiding cracking, and improving aging hard and brittle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of preparation method of epoxy resin encapsulant that another embodiment of the present invention proposes, it comprises:

[0049]1) Mix 40-70 parts of bisphenol F epoxy resin, 20-50 parts of active polyurethane toughening agent, 10-20 parts of reactive diluent, 30-50 parts of inorganic filler, 0.1-0.5 parts of defoamer, thixotropic agent 1-3 parts, mixed with 0.5-1 coupling agent, stirred under 800-1500rpm high-speed disperser for 0.5-1.5h to disperse the glue evenly, vacuum stirred in the stirring tank for 1-2 hours to discharge air bubbles, and obtained A component;

[0050] 2) Heat 50 parts of isophorone diamine to 60-65°C under nitrogen atmosphere, slowly add 20 to 40 parts of 1,4-butanediol diglycidyl ether under low-speed stirring condition, heat to 85-95°C, Stir and react under nitrogen for 2-2.5 hours, take samples and titrate the amine value according to QB / T2853-2007, the range of amine value is 300-350mgKOH, the modified alicyclic amine can be obtaine...

Embodiment

[0053] A kind of preparation method of epoxy resin encapsulant that one embodiment of the present invention proposes, it comprises:

[0054] 1) Mix 50 parts of bisphenol F epoxy resin, 40 parts of active polyurethane toughening agent, 10 parts of triglycidyl ether, 30 parts of inorganic filler, 0.3 parts of defoamer, 2 parts of thixotropic agent, and 1 part of coupling agent , Stir for 1 hour under the 800-1500rpm high-speed disperser to disperse the glue evenly, and vacuum stir in the stirring tank for 1-2 hours to discharge the air bubbles, and obtain A component;

[0055] 2) 70 parts of modified alicyclic amine, 30 parts of polyether amine, 10 parts of DMP-30 accelerator are added dropwise, and vacuum stirring is performed to remove air bubbles to obtain component B;

[0056] 3) Mix the A component and the B component in a weight ratio of 3:1 to obtain an epoxy resin potting compound.

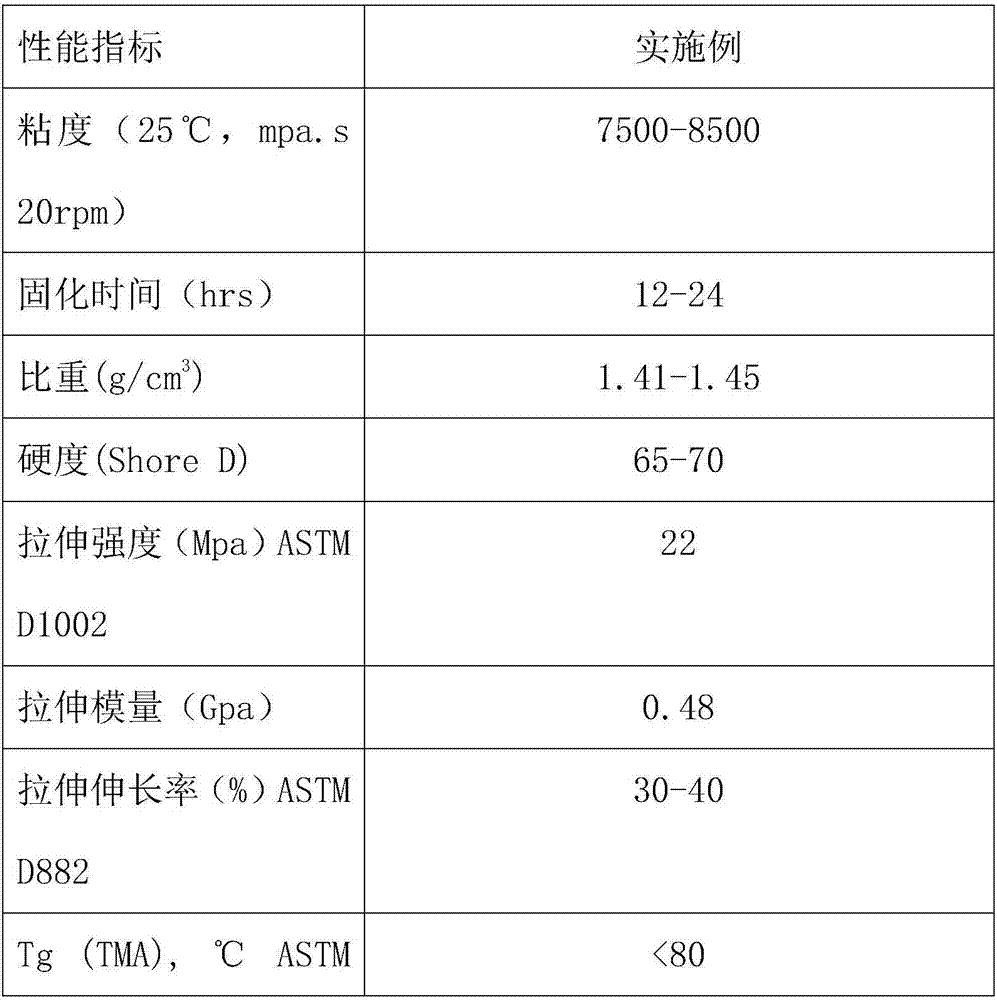

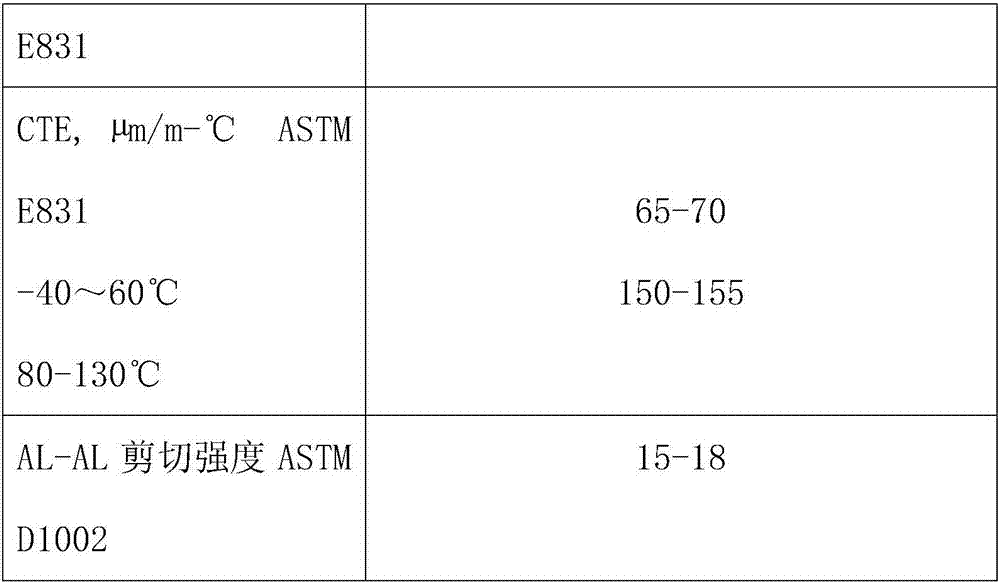

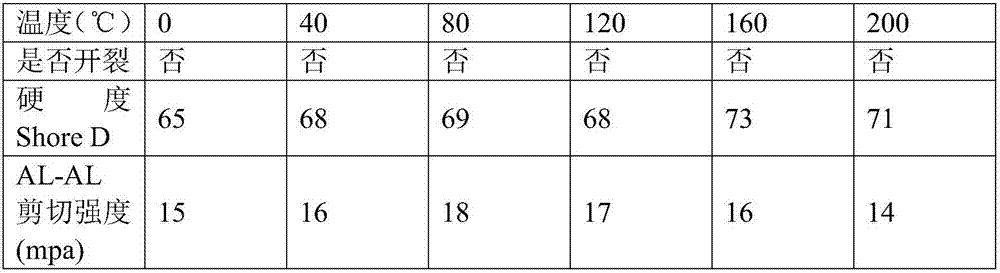

[0057] An epoxy resin potting compound proposed by an embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com