UV curing packaging adhesive for liquid crystal display

A liquid crystal display and adhesive technology, applied in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve unreacted groups' aging resistance, unfavorable anti-yellowing performance, and UV curing adhesive performance can not be fully satisfied , The problem of less charged ions in the adhesive, etc., to achieve the effect of excellent solvent resistance, low curing shrinkage rate, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

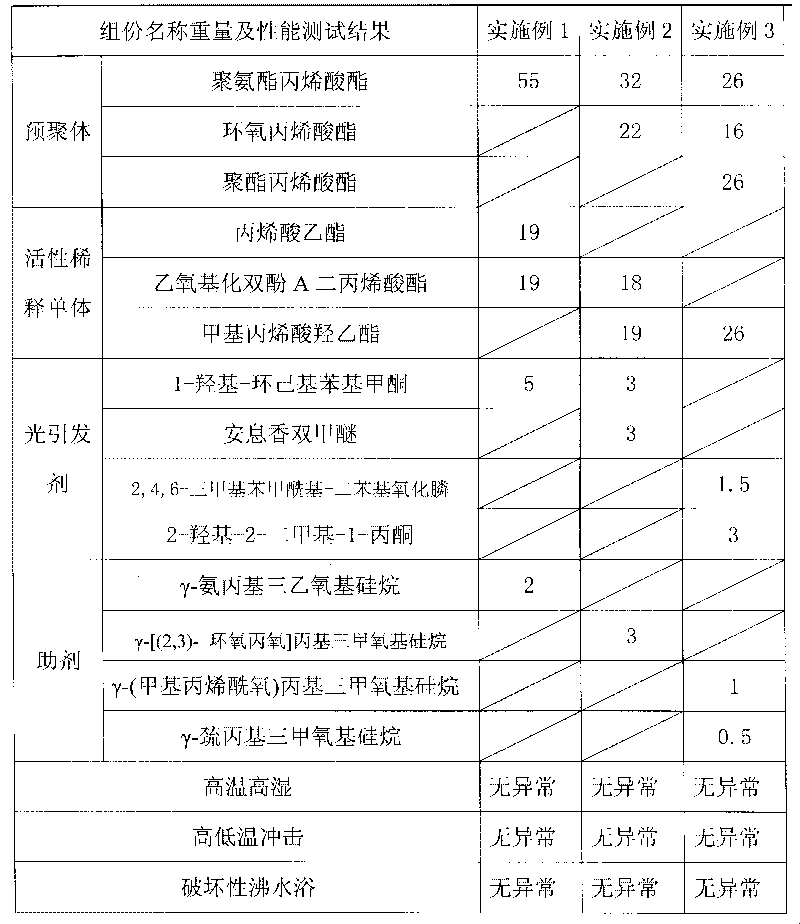

[0027] Under normal temperature and pressure, according to the content of each component specified in the following Table 1, the prepolymer is selected from polyurethane acrylate, and the reactive diluent monomer is selected from a mixture of ethyl acrylate and ethoxylated bisphenol A diacrylate. The initiator is selected from 1-hydroxy-cyclohexyl phenyl ketone, and the auxiliary agent is selected from gamma-aminopropyl triethoxysilane. Add the above materials into the reaction vessel, and disperse evenly with a planetary mixer at a temperature of 20-40°C. The UV curing light source can be a 1000W medium pressure mercury lamp with a light intensity of 80mW / cm 2 , the effective optical radiation center wavelength is 365nm. Dispensing glue at the position where the liquid crystal display is dispensing, at 200mj / cm 2 Solidify under the accumulated energy, cool for 5 minutes, conduct high temperature and high humidity 85℃×85%RH×1500h, high and low temperature impact -40~80℃×1500...

Embodiment 2

[0029] Repeat the method of Example 1 according to the content of each component specified in the following table 1, the prepolymer is selected from polyurethane acrylate and epoxy acrylate, and the reactive diluent monomer is selected from hydroxyethyl methacrylate and ethoxylated bisphenol A diacrylate mixture, the photoinitiator is a mixture of 1-hydroxy-cyclohexyl phenyl ketone and benzoin dimethyl ether, and the auxiliary agent is γ-[(2,3)-glycidyloxy]propyltrimethoxysilane . The preparation and test environment are the same as those in Example 1, and the test results are listed in Table 1.

Embodiment 3

[0031] Repeat the method of Example 1 according to the content specified in the following table 1, the prepolymer is selected from urethane acrylate, epoxy acrylate and polyester acrylate to mix, the reactive diluent monomer is selected from hydroxyethyl methacrylate, and the photoinitiator is selected from 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 2-hydroxy-2-dimethyl-1-propanone are mixed, and the auxiliary agent is γ-(methacryloyloxy)propyl trimethoxy silane and γ-mercaptopropyltrimethoxysilane mixed. The preparation and test environment are the same as those in Example 1, and the test results are listed in Table 1.

[0032] The examples listed in Table 1 and the test results of high temperature and high humidity, high and low temperature impact, destructive boiling water bath, etc. show that: the ultraviolet curable adhesive of the present invention has fast curing speed, low curing shrinkage rate, high bonding strength with glass and metal, and is durable. It ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com