Liquid optical adhesive and preparation method thereof

An adhesive and optical technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve problems such as high refraction and atomization, poor adhesive tape adhesion, and insufficient flexibility, and achieve low refractive index and production The effect of high efficiency and high light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

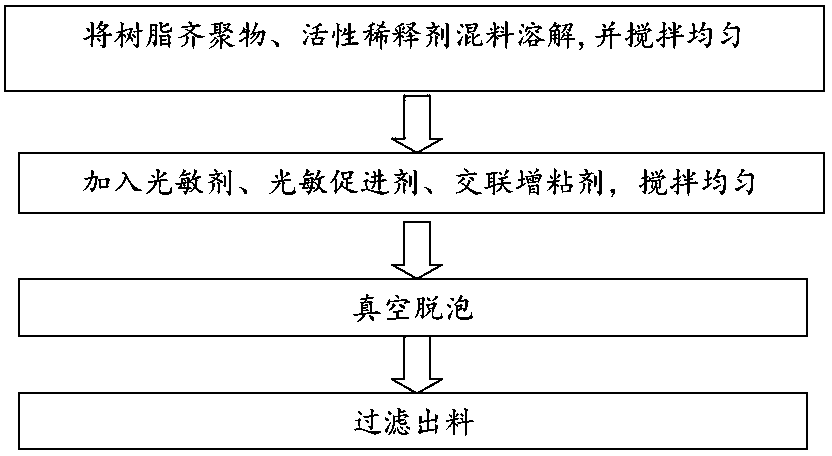

Method used

Image

Examples

Embodiment 1

[0015] A raw material for making a liquid optically transparent adhesive according to the present invention includes the following ingredients in proportion by weight:

[0016] Resin oligomer for binder: polyurethane acrylate PUA 22%

[0018] Reactive diluent: HDDA 24.5%

[0019] TPGDA 30%

[0020] Photosensitizer: HMPF 1.5%

[0021] Photosensitization Accelerator: EDAB 1.3%

[0022] Crosslinking tackifier: KH-170 1.7%

[0023] Add the resin oligomer and reactive diluent weighed according to the above weight percentage ratio into the reaction kettle, stir at room temperature (25°C) for 1.5 hours, and then add photosensitizer, photosensitization accelerator, and crosslinking tackifier according to the proportion of ingredients , stirred for 3.5 hours, until the mixture was uniform; then, conventional vacuum defoaming was carried out on the obtained product of the preceding steps, and after filtering and discharging, in the finished product, s...

Embodiment 2

[0026] The raw materials for making the liquid optically transparent adhesive of embodiment 2 include the following ingredients in proportion by weight:

[0027] Binder resin oligomer: polyurethane acrylate PUA 35%

[0028] Reactive diluent: TPGDA 63%

[0029] Photosensitizer: HMPF 0.8%

[0030] Photosensitization Accelerator: EDAB 0.6%

[0031] Crosslinking tackifier: KH-550 0.7%

[0032] Similarly, weigh the binder resin oligomer and active diluent into the reaction kettle according to the above weight percentage ratio, stir at 40°C for 0.5 hours, then add photosensitizer, photosensitization accelerator, crosslinking enhancer according to the above ratio of ingredients. Viscosity, stirring for 4 hours, until the mixture is uniform; then carry out conventional vacuum degassing on the obtained product of the previous steps, and after filtering and discharging, in the finished product, samples are compared with the technical indicators, and the quality parameters are checked...

Embodiment 3

[0035] The liquid optical adhesive of embodiment 3 comprises the following raw material formula feeding and making by weight ratio:

[0036] Binder resin oligomer: epoxy acrylate EA 45%

[0037] Reactive diluent: HDDA 29%

[0038] TPGDA 23%

[0039] Photosensitizer: HMPF 1.2%

[0040] Photosensitizer: EDAB 0.8%

[0041] Crosslinking tackifier: KH550 1.0%

[0042] Add the resin oligomer and active diluent weighed according to the above weight percentage ratio into the reaction kettle, stir at 30°C for 2.5 hours, then add photosensitizer, photosensitization accelerator, and crosslinking tackifier according to the proportion of ingredients, and stir for 2.5 hours. Hours, until the mixture is uniform, take its clear sample, and carry out quality inspection against the technical indicators. The measured viscosity of the product is 2530 mPa·s, the liquid light transmittance is 99.2%, and the refractive index is 1.48.

[0043] The liquid optical adhesive for the UV curing capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com