Method for synthesizing unsaturated polyester resin

A synthetic method and technology of polyester resin, which is applied in the field of synthesizing unsaturated polyester resin from renewable vegetable oil, can solve the problems of high cost and waste of resources, and achieve the effect of reducing production cost, low curing shrinkage rate and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

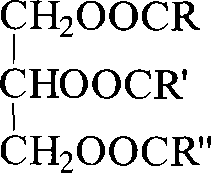

[0014] The synthetic method of unsaturated polyester resin provided by the invention can adopt the method comprising the following steps:

[0015] (1) Ingredients: weigh renewable vegetable oil, organic polyol, organic unsaturated acid or anhydride, organic saturated acid or anhydride, catalyst, polymerization inhibitor and crosslinking agent according to the formula;

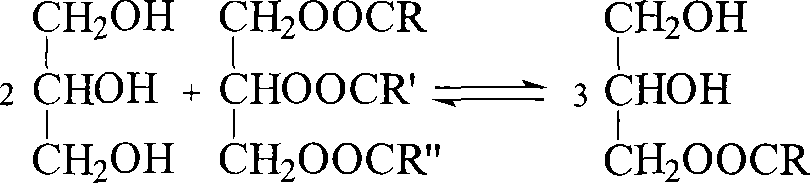

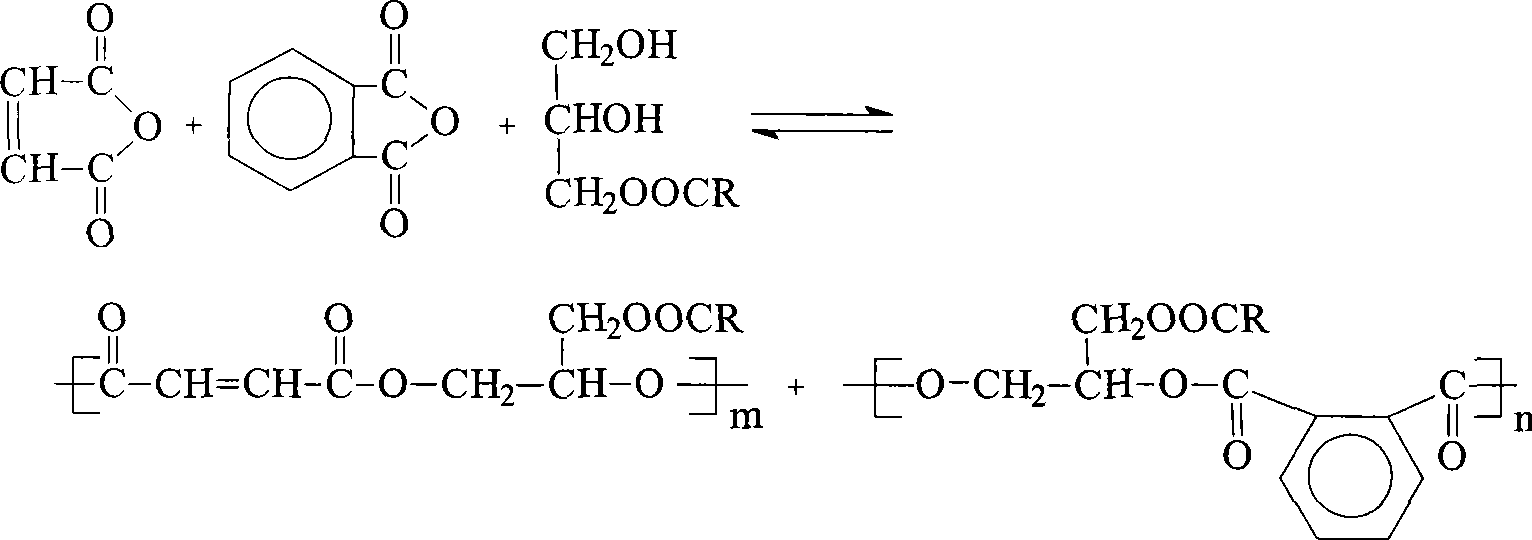

[0016] (2) Alcoholysis, polycondensation reaction: put into the reactor renewable vegetable oil, organic polyol and catalyst, after charging N 2 Stir under protection, and carry out alcoholysis reaction at 200~240℃ for 0.5~1.5h, then gradually reduce the alcoholysis reaction temperature to 160~200℃, then add organic unsaturated acid or acid anhydride, organic saturated acid or acid anhydride , keep the temperature for 3.5 ~ 5h for polycondensation reaction, when the acid value reaches 40 ~ 60mgNaOH / g, it is the end point of polycondensation reaction, and finally add the polymerization inhibitor;

[0017] (3) D...

Embodiment 1

[0034] Embodiment 1: in parts by mass, linseed oil 60%, glycerol 17% and calcium hydroxide 0.05% are dropped in the reactor, after charging into N 2 Stir vigorously under the condition of 220°C for 0.5~1.5h, gradually reduce the reaction temperature to 160°C~200°C, then add 10% maleic anhydride and 12.95% phthalic anhydride, and keep the temperature After 3.5-5 hours, the acid value of the system reaches about 50mgNaOH / g, which is the end of the reaction; when the temperature is lowered to 120°C-130°C, it is blended with an appropriate amount of styrene, stirred evenly and cooled to room temperature, and the unsaturated polyester resin is obtained.

Embodiment 2

[0035] Embodiment 2: by mass parts, castor oil 50%, glycerol 15% and Lithium Hydroxide 0.1% drop in the reaction kettle, after filling N 2 Under the condition of strong stirring, react at 210°C for 1-1.5h, then add 15% of maleic anhydride and 19.9% of phthalic anhydride, and the rest are basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com