Product prepared by light-curing rapid prototyping process and preparation method thereof

A molding process and light-curing technology, applied in the field of 3D printing materials, can solve the problems that the performance cannot meet the development and demand of the market, the types of photosensitive resins are few, and the corrosion is strong, etc., to achieve good printability, small curing shrinkage, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

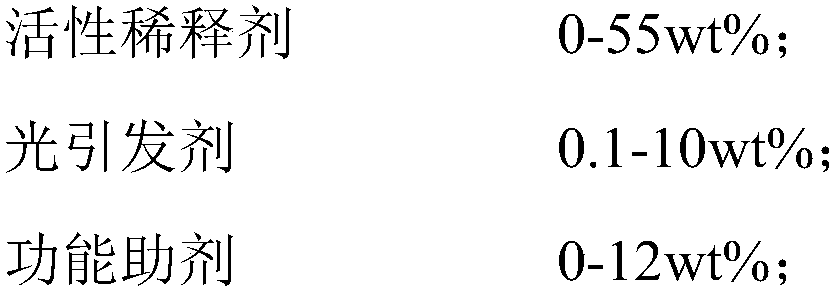

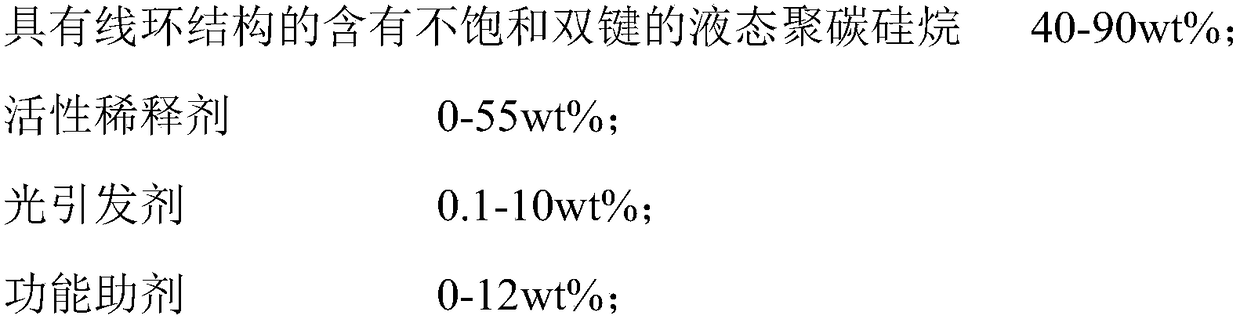

Method used

Image

Examples

Embodiment 1

[0056] Preparation of vinyl-containing polycarbosilane: Add dropwise a mixed solution of 5.67 g of chloromethyltriethoxysilane and 8 mL of tetrahydrofuran to 8.0 g of magnesium chips and 20 mL of tetrahydrofuran, and continue to drop 80.28 g of methyl chloride after triggering the Grignard reaction A mixed solution of triethoxysilane and 450mL tetrahydrofuran was incubated at 30°C for 6h. Continue to drop 98.58g of vinylmagnesium bromide in methyl tetrahydrofuran solution, keep the reaction at 30°C for 2h, then add 10.8g of lithium aluminum hydride, and continue to react at 30°C for 10h. After the reaction, the reaction solution was gradually added to a 3.0mol / L hydrochloric acid solution, stirred for 0.5 to 2 hours, then extracted with 200mL of hexane, the organic phase was separated and dried by adding anhydrous magnesium sulfate, filtered and rotary evaporated to obtain polycarbosilane. The polycarbosilane has a number average molecular weight of 670 g / mol, a weight averag...

Embodiment 2

[0060] Preparation of allyl-containing polycarbosilane: Add dropwise a mixed solution of 7.35 g of chloromethyltrimethoxysilane and 11 mL of tetrahydrofuran to 10.2 g of magnesium chips and 24 mL of tetrahydrofuran, and continue to drop 97.0 g of methyl chloride after triggering the Grignard reaction A mixed solution of trimethoxysilane and 500mL tetrahydrofuran was incubated at 45°C for 8h. Continue to add 135.87g of allylmagnesium bromide in methyl tetrahydrofuran solution dropwise, keep the reaction at 45°C for 6h, then add 19.5g of lithium aluminum hydride, and continue to react at 45°C for 10h. After the reaction, the reaction solution was gradually added to a 3.0mol / L hydrochloric acid solution, stirred for 0.5 to 2 hours, then extracted with 240mL of hexane, the organic phase was separated and dried by adding anhydrous magnesium sulfate, filtered and rotary evaporated to obtain based polycarbosilane. The polycarbosilane has a number average molecular weight of 490 g / mo...

Embodiment 3

[0064] Preparation of isopropenyl-containing polycarbosilane: Add dropwise a mixed solution of 12.66 g of chloromethyltriethoxysilane and 20 mL of tetrahydrofuran to 17.5 g of magnesium chips and 42 mL of tetrahydrofuran, and continue to drop 186.0 g of chlorine after the Grignard reaction is initiated. A mixed solution of methyltriethoxysilane and 700mL tetrahydrofuran was incubated at 45°C for 9h. Continue to add 256.0g of isopropenylmagnesium bromide in methyl tetrahydrofuran solution dropwise, keep the reaction at 45°C for 6.5h, then add 35.8g of lithium aluminum hydride, and continue to react at 45°C for 13h. After the reaction, the reaction solution was gradually added to a 3.0mol / L hydrochloric acid solution, stirred for 0.5 to 2 hours, then extracted by adding 430mL of hexane, the organic phase was separated and dried by adding anhydrous magnesium sulfate, filtered and rotary evaporated to obtain based polycarbosilane. The polycarbosilane has a number average molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com