Epoxy resin modified silica sol based high-temperature-resistant hydrophobic coating and preparation method thereof

A technology of epoxy resin and hydrophobic coating, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of weak bond instability, easy decomposition of organic phase, phase separation, etc., and achieve improvement of construction process and change of curing shrinkage rate Small, the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

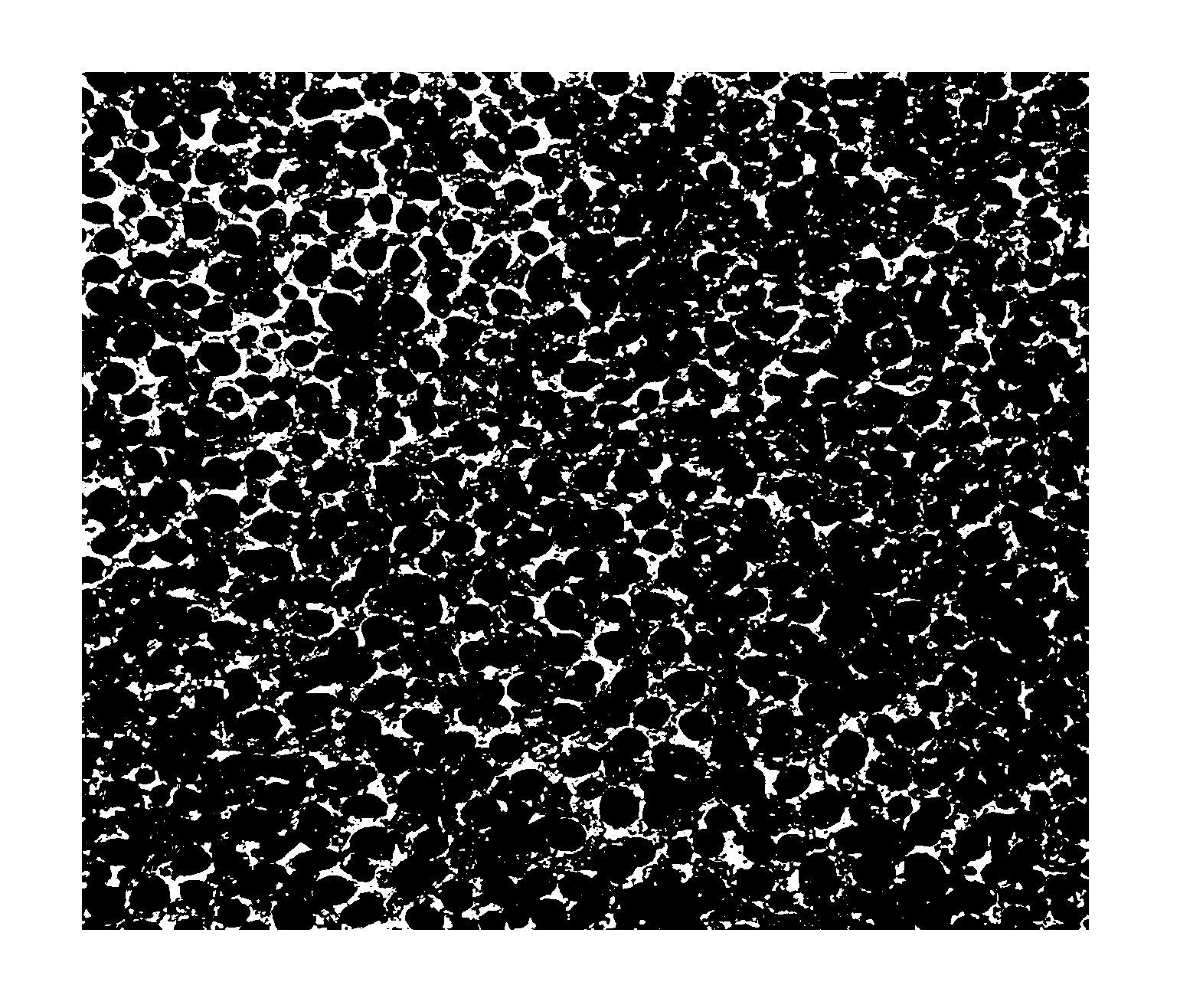

Image

Examples

Embodiment 1

[0039] 1. The formula and preparation method of epoxy resin modified silica sol:

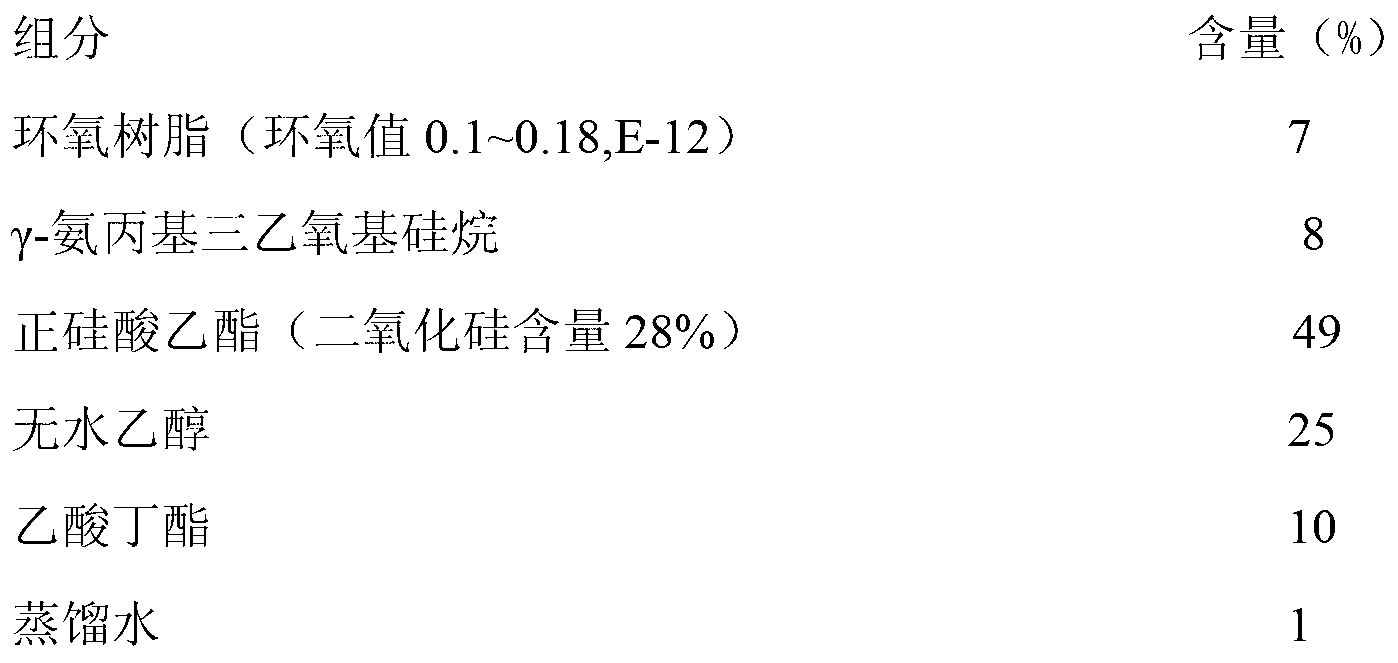

[0040] 1. Formula:

[0041]

[0042] 2. Preparation method: Stir and soften all the epoxy resin at 110°C for 30 minutes, then add the weighed butyl acetate into the reaction vessel and stir for 30 minutes until it is dispersed and dissolved, then quantitatively add γ-aminopropyl tris Ethoxysilane was added into the reaction vessel, the reaction system was stirred and reacted at 60°C for 3 hours, the temperature was set at 80°C, all the ethyl orthosilicate was mixed with ethanol and then added into the reaction vessel, distilled water was added dropwise, The addition time was 1 hour. After the dropwise addition was completed, the reaction was kept at 80° C. for 6 hours, and the mixture was discharged at room temperature.

[0043] 2. Formula and preparation of high temperature resistant hydrophobic coating based on epoxy resin modified silica sol:

[0044] 1. Formula

[0045]

[0046] ...

Embodiment 2

[0049] 1. The formula and preparation method of epoxy resin modified silica sol:

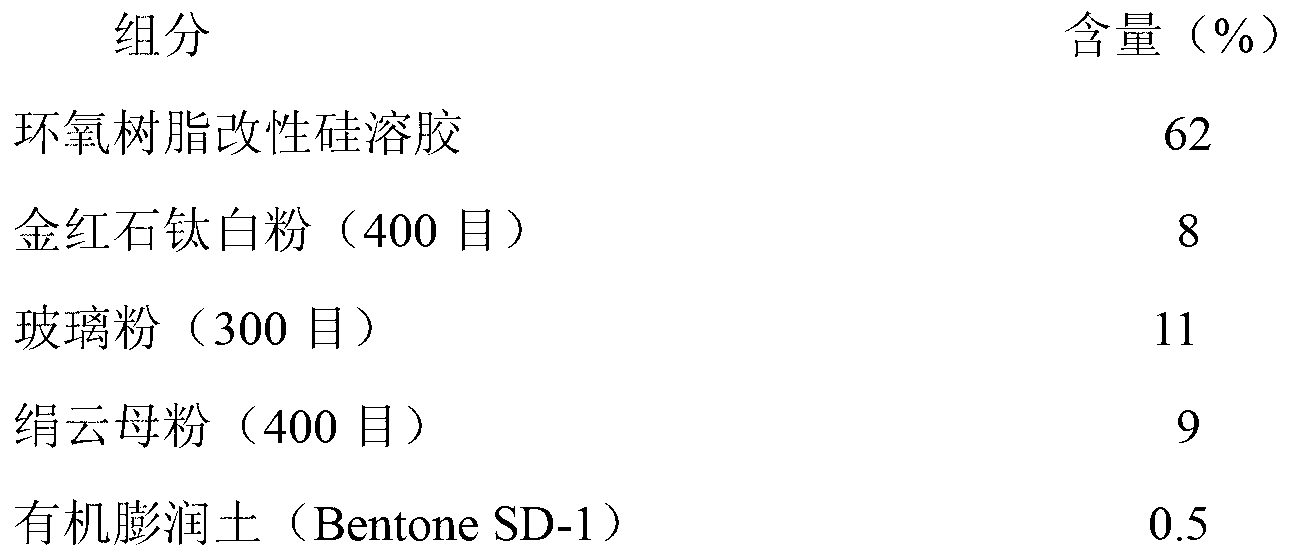

[0050] 1. Formula:

[0051]

[0052]2. Preparation method: Stir and soften all the above-mentioned epoxy resins at 60°C for 10 minutes, then add the weighed butyl acetate into the reaction vessel and stir for 15 minutes until dispersed and dissolved, then quantitatively add γ-aminopropyl Add triethoxysilane into the reaction vessel, stir the reaction system at 45°C for 4 hours, set the temperature at 50°C, mix all the ethyl orthosilicate and ethanol into the reaction vessel, add distilled water dropwise, The dropwise addition time was 4 hours. After the dropwise addition was completed, the reaction was kept at 40°C for 5 hours, and the mixture was discharged at room temperature.

[0053] 2. Formula and preparation of high temperature resistant hydrophobic coating based on epoxy resin modified silica sol:

[0054] 1. Formula:

[0055]

[0056] 2. Preparation method: According to the abov...

Embodiment 3

[0058] 1. The formula and preparation method of epoxy resin modified silica sol:

[0059] 1. Formula:

[0060]

[0061] 2. Preparation method: Stir and soften all the epoxy resin at 90°C for 20 minutes, then add the weighed butyl acetate into the reaction vessel and stir for 25 minutes until it is dispersed and dissolved, then quantitatively add γ-aminopropyl tris Ethoxysilane was added to the reaction vessel, the reaction system was stirred and reacted at 50°C for 7 hours, the temperature was set at 70°C, all the ethyl orthosilicate was mixed with ethanol and added to the reaction vessel, distilled water was added dropwise, The addition time was 5 hours. After the dropwise addition was completed, the reaction was kept at 70°C for 8 hours, and the mixture was discharged at room temperature.

[0062] 2. Formula and preparation of high temperature resistant hydrophobic coating based on epoxy resin modified silica sol:

[0063] 1. Formula:

[0064]

[0065] 2. Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com