A kind of anti-stripping composite modified asphalt and its preparation method

A composite modified asphalt and anti-stripping technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of insufficient asphalt adhesion and compatibility of modifiers, and achieve anti-stripping performance and adhesion improvement , Improve the adhesion performance and peeling resistance, and improve the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

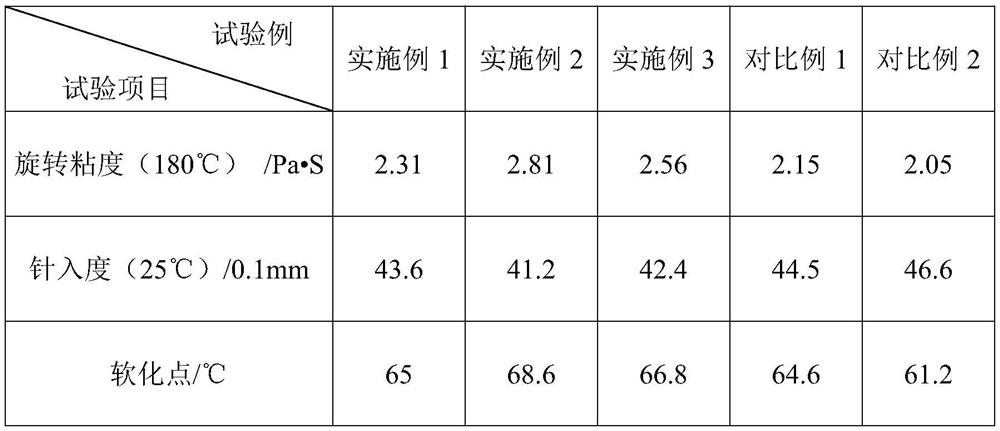

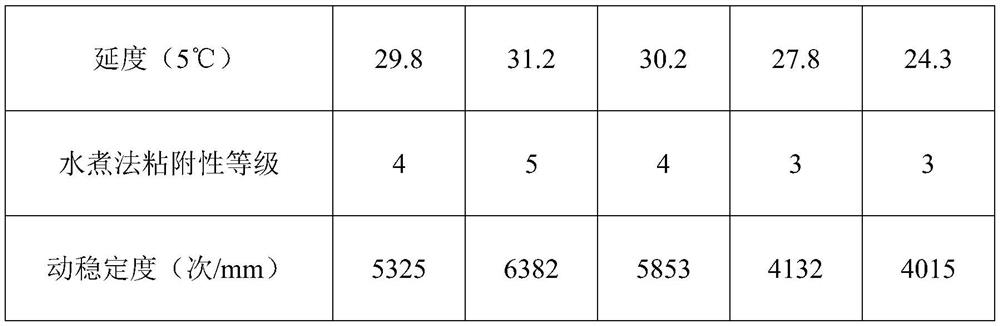

[0027] Embodiment 1, anti-stripping composite modified asphalt

[0028] The anti-stripping composite modified asphalt is prepared from the following raw materials in parts by weight:

[0029] 1 part of lignocellulose, 10 parts of aloe clay, 60 parts of petroleum pitch, 1 part of ethyl-4-methylimidazole, 1 part of vinyl trifluoroborate potassium, trimethylolpropane-tris(3-ethyleneimine) propionate) 0.1 part.

[0030] Prepare anti-stripping composite modified asphalt as follows:

[0031] a. place lignocellulose and halloy clay in the reaction kettle, and mechanically stir for 60 minutes to obtain the lignocellulose-allloy clay composite;

[0032] b. Add the lignocellulose-alloy clay composite obtained in step a to petroleum pitch, and stir and fully react for 45 minutes under the condition of 210° C. to obtain the mixture of lignocellulose-alloy clay composite and petroleum pitch mixture;

[0033] c. Add 2-ethyl-4-methylimidazole, potassium vinyl trifluoroborate, and trimeth...

Embodiment 2

[0035] Embodiment 2, anti-stripping composite modified asphalt

[0036] The anti-stripping composite modified asphalt is made of the following raw materials in parts by weight:

[0037] 4 parts of lignocellulose, 15 parts of aloe clay, 70 parts of petroleum pitch, 4 parts of ethyl-4-methylimidazole, 4 parts of vinyl potassium trifluoroborate, trimethylolpropane-tris(3-ethyleneimine) propionate) 0.4 parts.

[0038] The preparation method is similar to Example 1.

Embodiment 3

[0039] Embodiment 3, anti-stripping composite modified asphalt

[0040] Prepared from the following raw materials in parts by weight:

[0041]10 parts of lignocellulose, 20 parts of halloy soil, 80 parts of petroleum pitch, 10 parts of ethyl-4-methylimidazole, 10 parts of vinyl trifluoroborate potassium, trimethylolpropane-tris(3-ethyleneimine) propionate) 1.0 parts.

[0042] The preparation method is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com