A kind of environment-friendly water-based interface agent and preparation method thereof

A kind of interface agent, water-based technology, applied in the direction of epoxy resin coating, coating, etc., to achieve the effect of excellent mechanical properties, stable performance, and increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

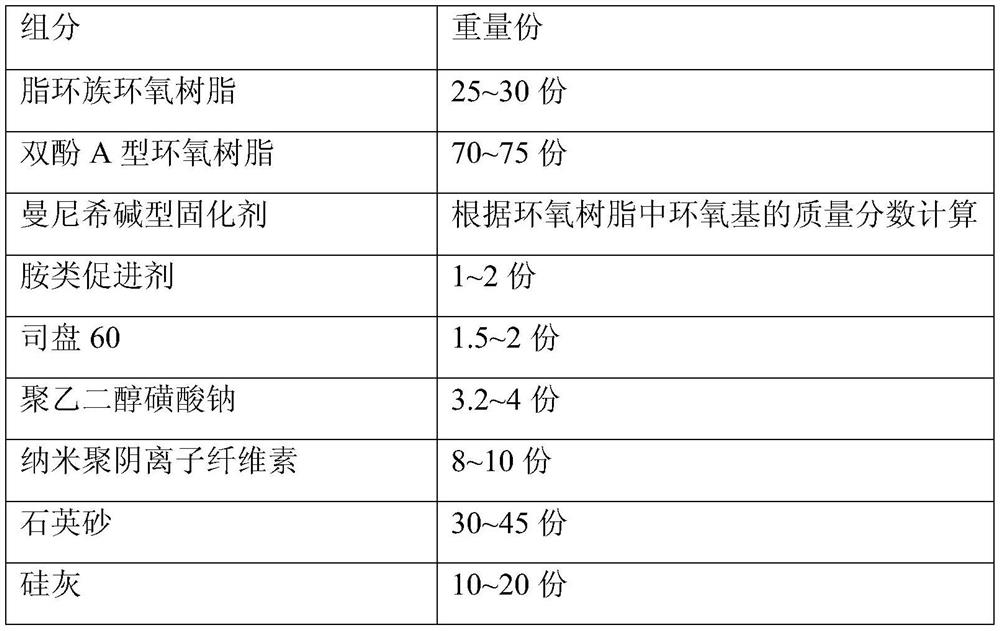

[0046] The interface agent was prepared according to the following components and methods.

[0047] components parts by weight Cycloaliphatic epoxy resin ERL4221 30 copies Bisphenol A type epoxy resin E-44 70 copies Mannich base curing agent Calculated based on the mass fraction of epoxy groups in epoxy resin Amine Accelerator DMP-10 2 copies Span 60 1.5 servings Sodium Polyethylene Glycol Sulfonate 3.2 parts Low viscosity nano polyanionic cellulose (80nm) 10 copies Quartz sand (50μm) 30 copies Silica fume (40μm) 20 copies Cellulose ether 10 copies

[0048] Preparation method: mix bisphenol A epoxy resin and cycloaliphatic epoxy resin evenly, add nano polyanion cellulose, stir at 35°C for 45min, then add Mannich base curing agent and amine accelerator, mix evenly , add Span 60, sodium polyethylene glycol sulfonate and appropriate amount of water to emulsify for 1-2 hours, then add quartz sand, ...

Embodiment 2

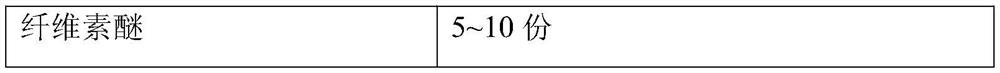

[0050] The interface agent was prepared according to the following components and methods.

[0051]

[0052]

[0053] Preparation method: mix bisphenol A epoxy resin and cycloaliphatic epoxy resin evenly, add nano polyanion cellulose, stir at 35°C for 45min, then add Mannich base curing agent and amine accelerator, mix evenly , add Span 60, sodium polyethylene glycol sulfonate and appropriate amount of water to emulsify for 1-2 hours, then add quartz sand, silica fume, cellulose ether and appropriate amount of water, and stir for 2-3 hours to obtain the product.

Embodiment 3

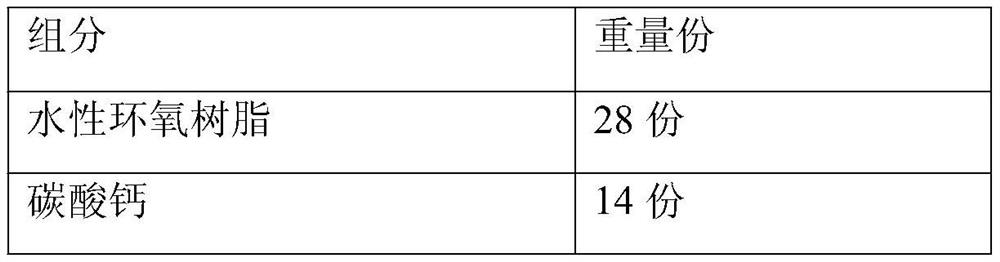

[0055] The interface agent was prepared according to the following components and methods.

[0056] components parts by weight Cycloaliphatic epoxy resin 2021P 28 copies Bisphenol A type epoxy resin E-51 73 copies Mannich base curing agent Calculated based on the mass fraction of epoxy groups in epoxy resin Amine Accelerator DMP-30 1.8 servings Span 60 1.6 servings Sodium Polyethylene Glycol Sulfonate 3.7 servings High viscosity nano polyanionic cellulose (40nm) 8.6 servings Quartz sand (60μm) 40 copies Silica fume (10μm) 12 copies Cellulose ether 8 servings

[0057] Preparation method: mix bisphenol A epoxy resin and cycloaliphatic epoxy resin evenly, add nano polyanion cellulose, stir at 35°C for 45min, then add Mannich base curing agent and amine accelerator, mix evenly , add Span 60, sodium polyethylene glycol sulfonate and appropriate amount of water to emulsify for 1-2 hours, then add qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com