A kind of preparation method of powder particle transmission electron microscope sample

An electron microscope, powder particle technology, applied in the preparation of test samples, material analysis using wave/particle radiation, sampling, etc. Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

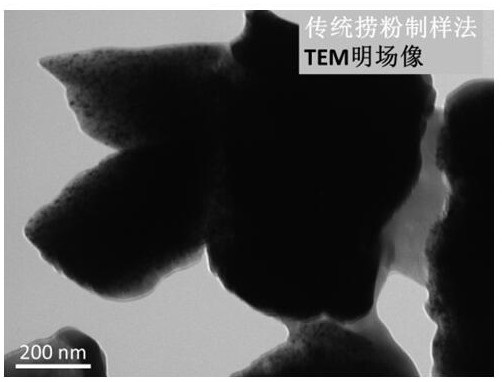

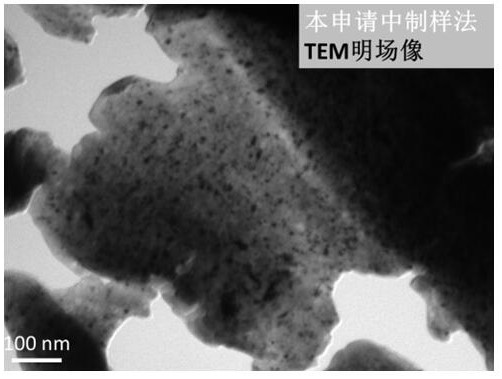

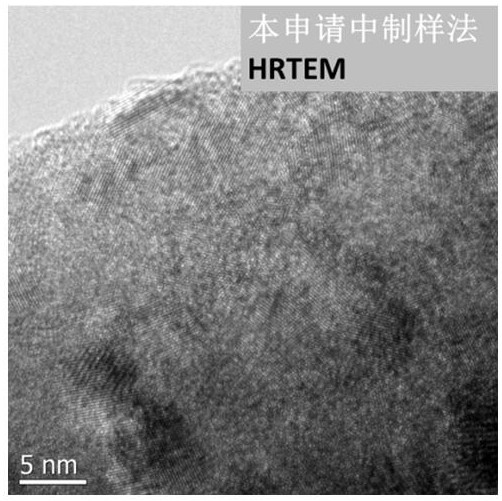

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a powder particle transmission electron microscope sample, comprising the following specific steps:

[0028] 1) According to the particle size of the powder particles, select a copper foam structure with an average pore size slightly larger than the average particle size (Note: During TEM observation, magnetic samples will cause electron beam scattering, which will make the clarity of TEM photos worse ), the thickness of the foam net is 1mm, and the foam net with an area of 5×5mm (at least one TEM sample of φ3mm can be obtained after post-processing) is used for later use;

[0029] 2) Use a cotton swab to stick a small amount of sample powder and sprinkle it evenly on the foam net. The thickness of the powder layer is 1 / 4 of the thickness of the foam net;

[0030] 3) Put the foam net containing a small amount of sample powder on the platform, tap the platform, and master the tapping force so that the powder particles gradually leak into the hole...

Embodiment 2

[0036] A method for preparing a powder particle transmission electron microscope sample, comprising the following specific steps:

[0037] 1) According to the particle size of the powder particles, select a copper foam structure with an average pore size slightly larger than the average particle size (Note: During TEM observation, magnetic samples will cause electron beam scattering, which will make the clarity of TEM photos worse ), the thickness of the foam net is 0.5mm, and the foam net with an area of 5×5mm is cut for use;

[0038] 2) Use a cotton swab to stick a small amount of sample powder and sprinkle it evenly on the foam net. The thickness of the powder layer is 1 / 4 of the thickness of the foam net;

[0039] 3) Put the foam net containing a small amount of sample powder on the platform, tap the platform, and master the tapping force so that the powder particles gradually leak into the holes of the foam net, and prevent the powder from spilling out of the foam net. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com