Patents

Literature

37results about How to "Improve mechanical properties such as strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

B1-grade special high-flame-retardant low-smoke halogen-free cable material and preparation method thereof

InactiveCN111621085AImprove mechanical properties such as strengthImprove heat resistancePlastic/resin/waxes insulatorsLinear low-density polyethyleneLow smoke zero halogen

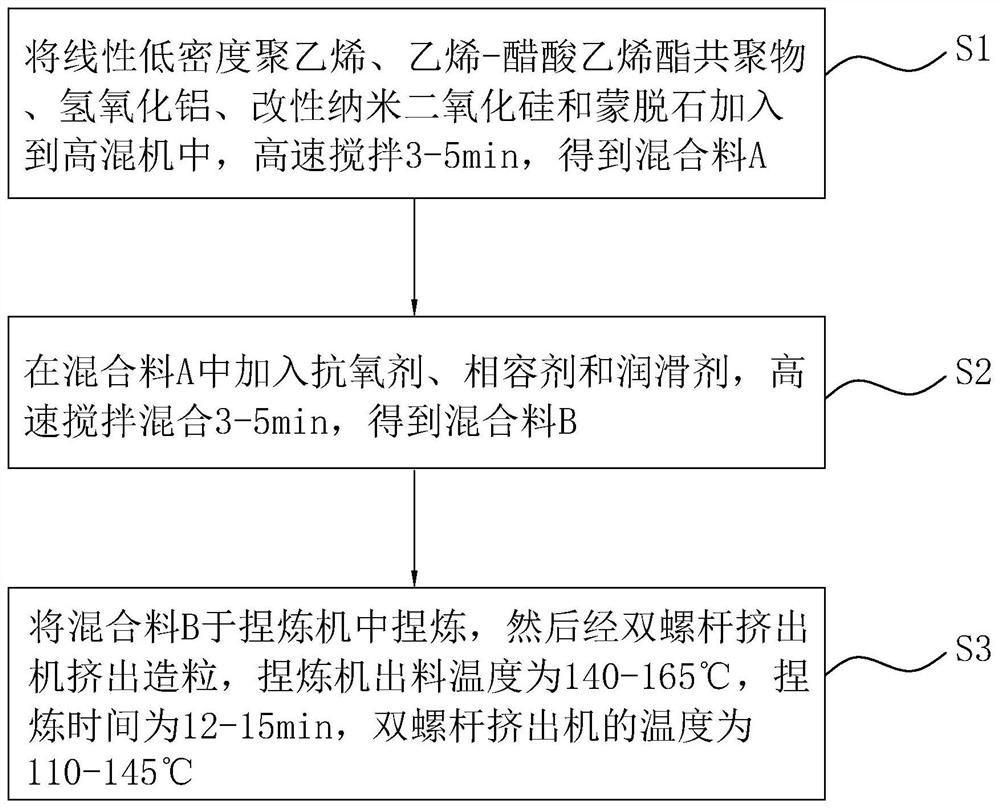

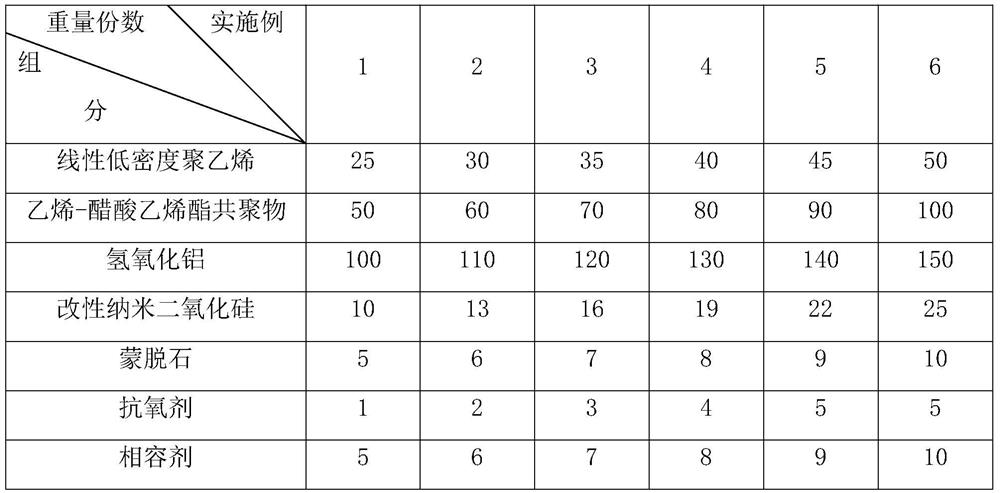

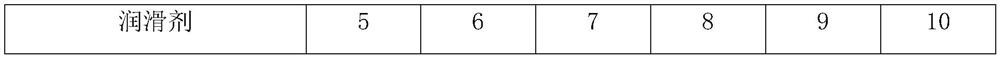

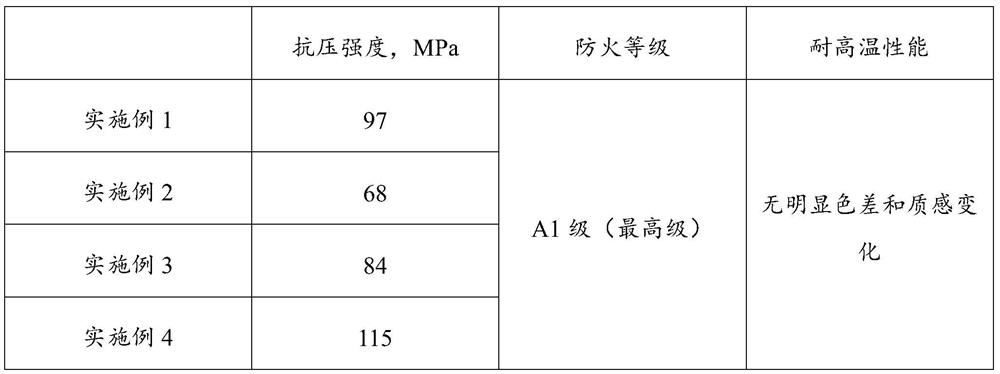

The invention discloses a B1-grade special high-flame-retardant low-smoke halogen-free cable material and a preparation method thereof, and relates to the technical field of wires and cables. The technical key point is that the B1-grade special high-flame-retardant low-smoke halogen-free cable material comprises the following components in parts by weight: 25 to 50 parts of linear low-density polyethylene; 50 to 100 parts of an ethylene-vinyl acetate copolymer; 100 to 150 parts of aluminum hydroxide; 10 to 25 parts of modified nano silicon dioxide; 5 to 10 parts of montmorillonite; 1 to 5 parts of an antioxidant; 5 to 10 parts of a compatilizer; 5 to 10 parts of a lubricant; the preparation method of the modified nano silicon dioxide comprises the following steps: adding nano silicon dioxide into absolute ethyl alcohol, uniformly stirring and dispersing, then adding a silane coupling agent, heating to react for 3-4 hours, and drying and grinding the nano silicon dioxide after the reaction is finished so as to obtain the modified nano silicon dioxide. The obtained low-smoke halogen-free cable material has the advantages that the B1-grade flame-retardant standard is met, the mechanical property is high, and the processability is excellent.

Owner:上海方之德新材料有限公司

Solid waste-based inorganic artificial stone plate and preparation method thereof

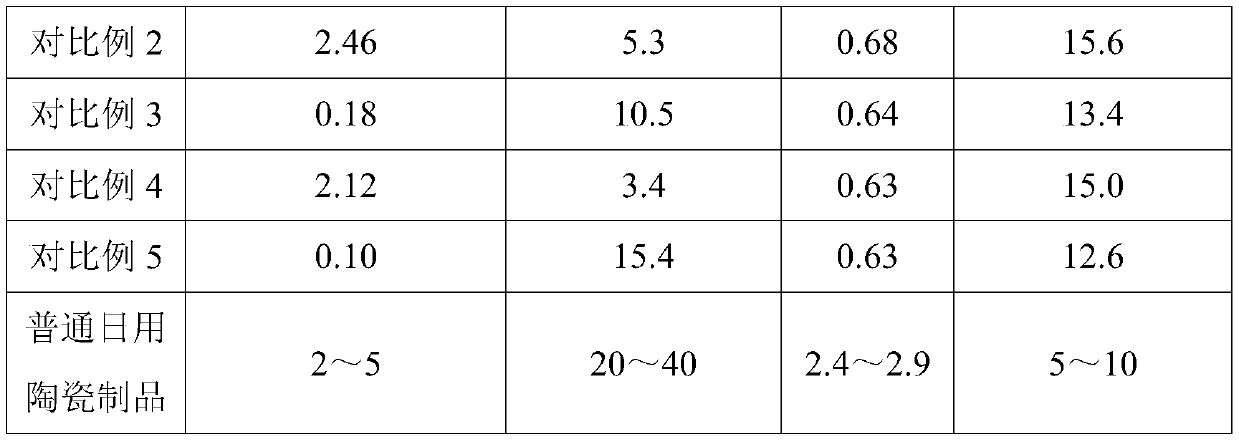

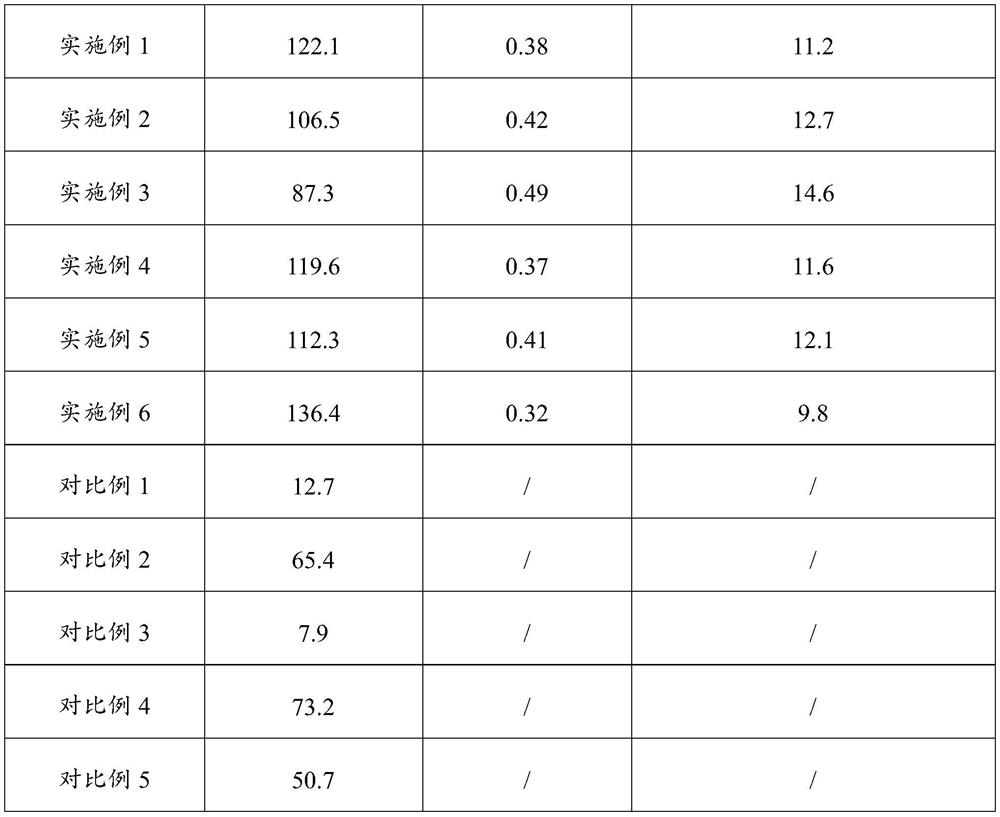

The invention belongs to the technical field of building materials, and particularly relates to a solid waste-based inorganic artificial stone plate and a preparation method thereof. The solid waste-based inorganic artificial stone plate comprises, by weight, 46-66 parts of a solid waste-based material, 90-165 parts of quartz sand, 4-12 parts of an excitant, 7-16 parts of water, 0-2 parts of a water reducing agent and 0-10 parts of an inorganic pigment. The water consumption is low, generation of pores in the product due to excessive moisture is avoided, and the strength and other mechanical properties of the plate are improved; reinforcing materials such as fibers, resin and polyvinyl alcohol do not need to be additionally added, the chemical activity of solid waste is fully utilized, allthe raw materials are matched and used in proportion, that is, the solid waste-based inorganic artificial stone plate with high polymerization degree, high compactness and high strength can be generated in situ through the coordination effect of all the components, the mechanical property requirement of the artificial stone plate is met, the economic cost is effectively reduced, no free formaldehyde is released, and the solid waste-based inorganic artificial stone plate is more environmentally friendly, better in fireproof and high-temperature-resistant performance and wide in application prospect.

Owner:UNIV OF JINAN

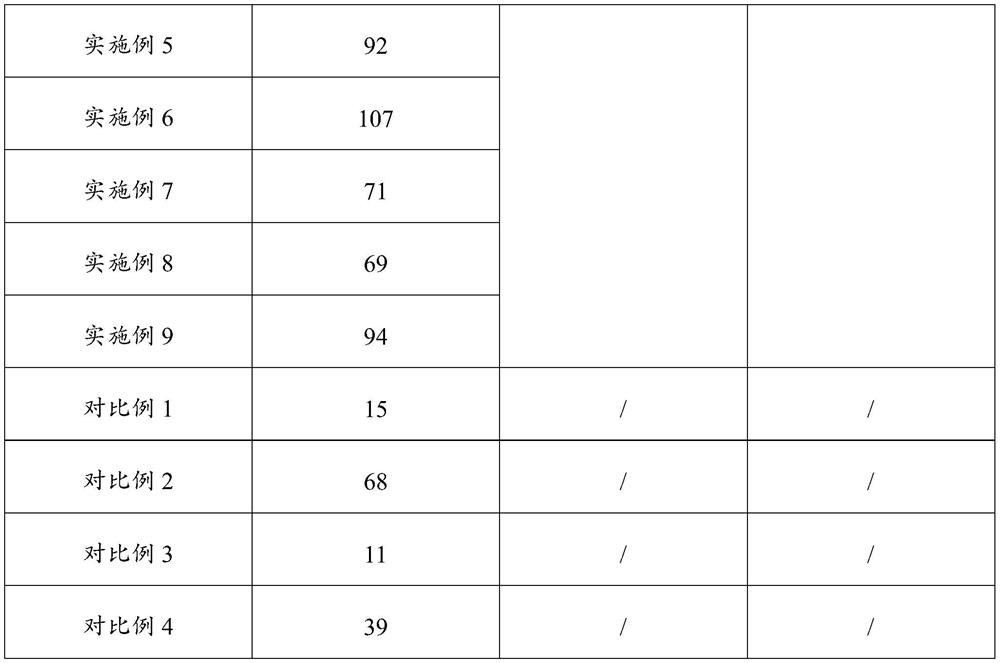

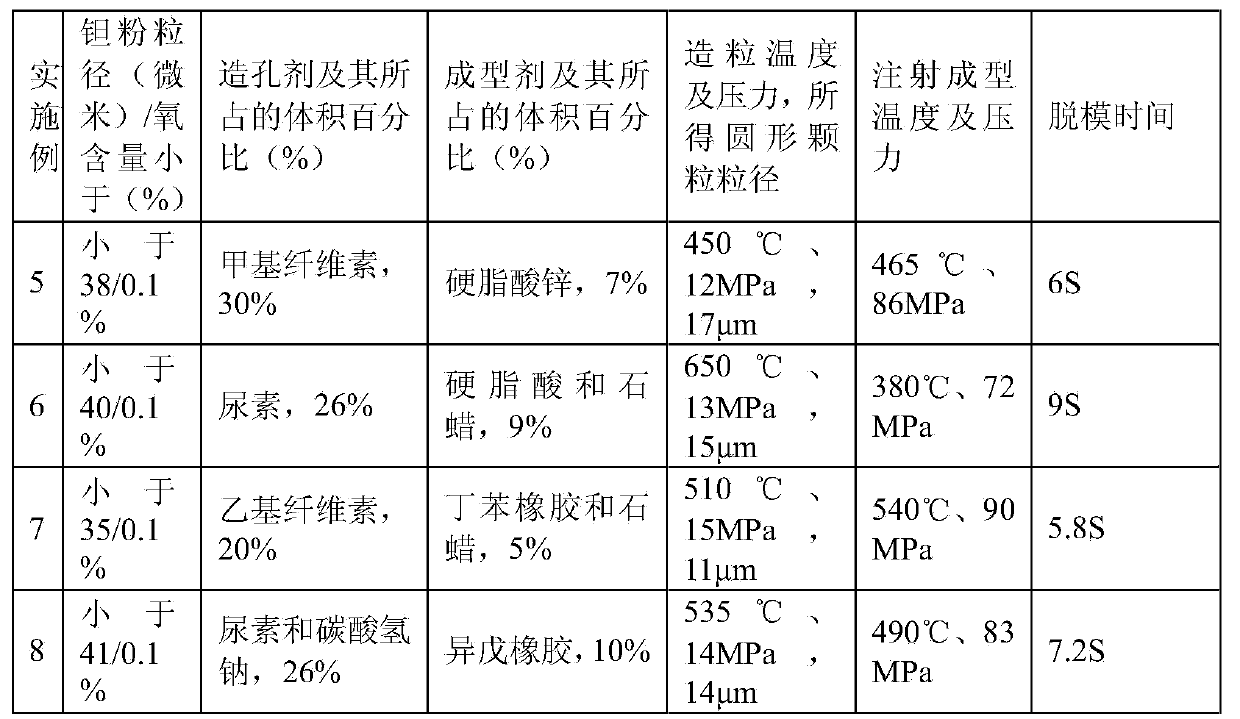

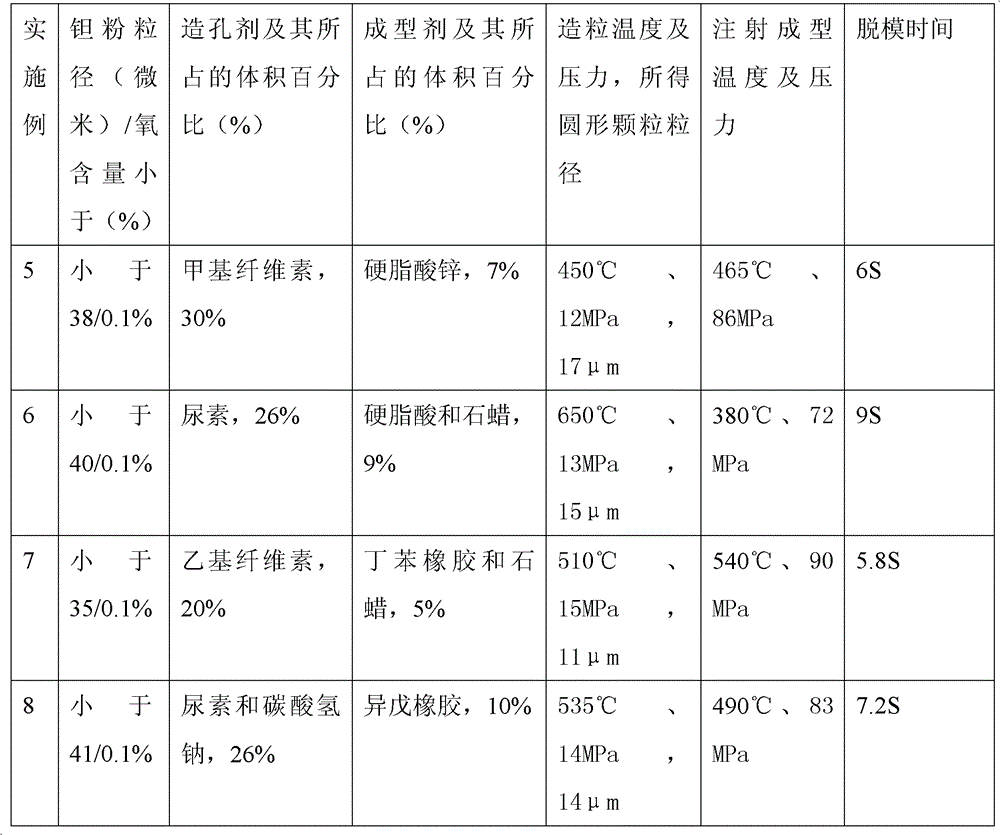

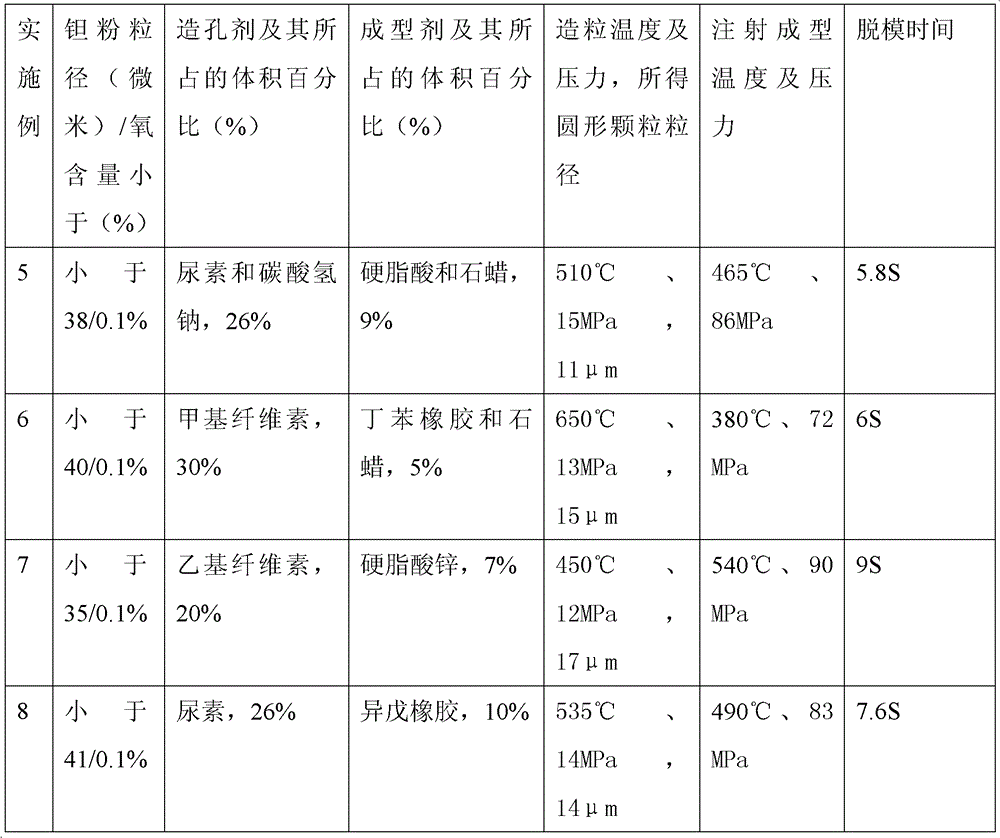

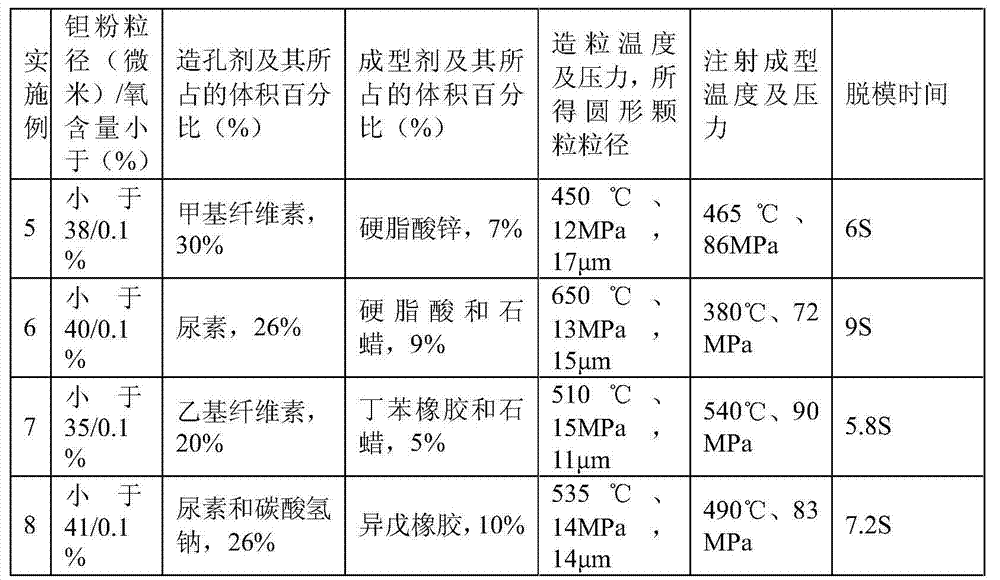

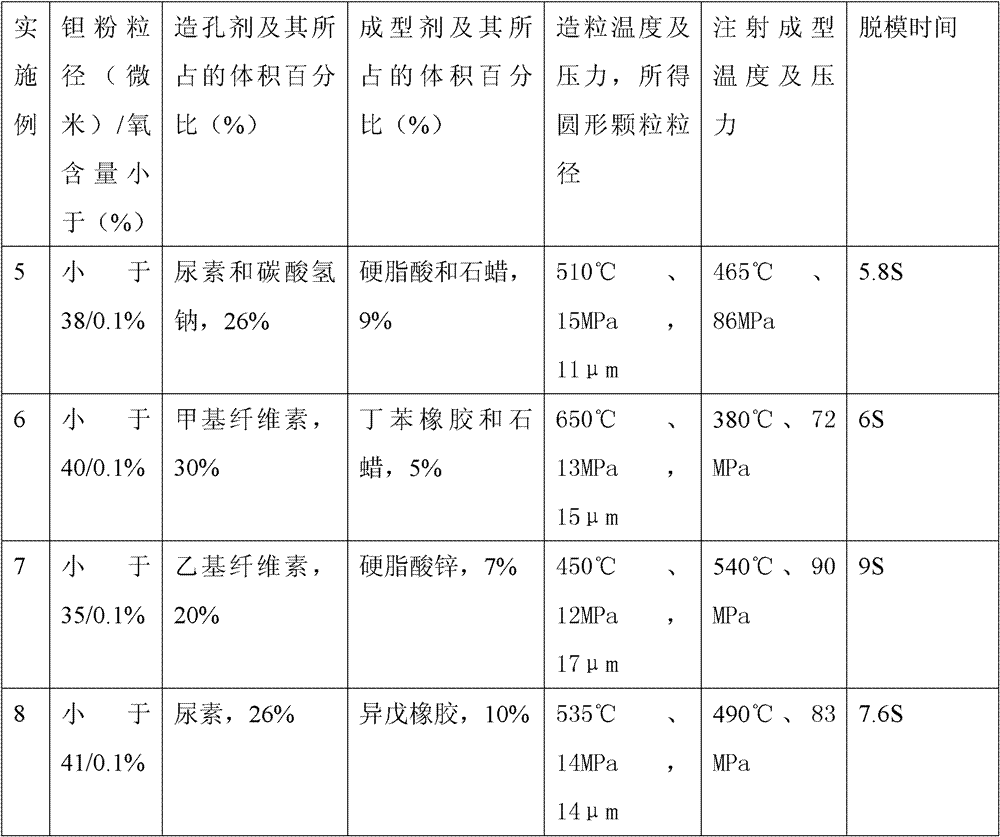

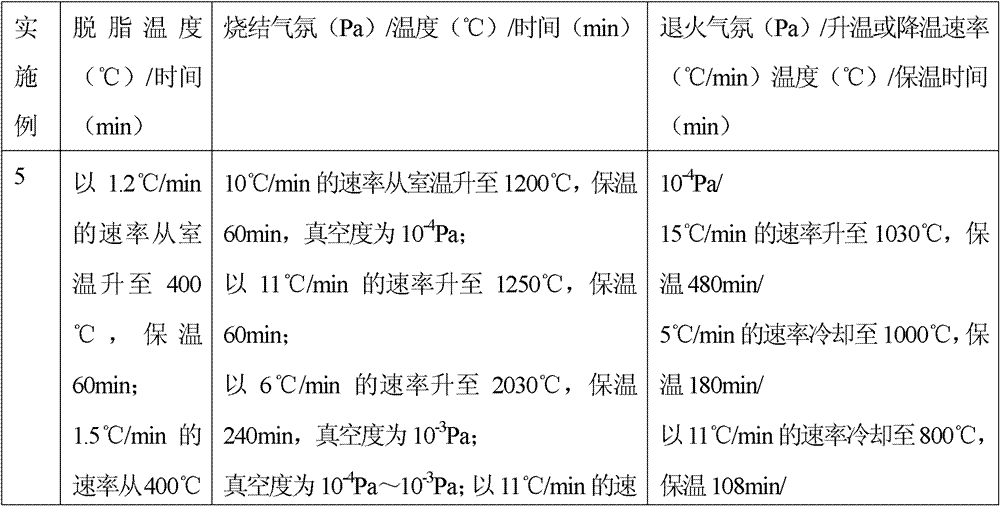

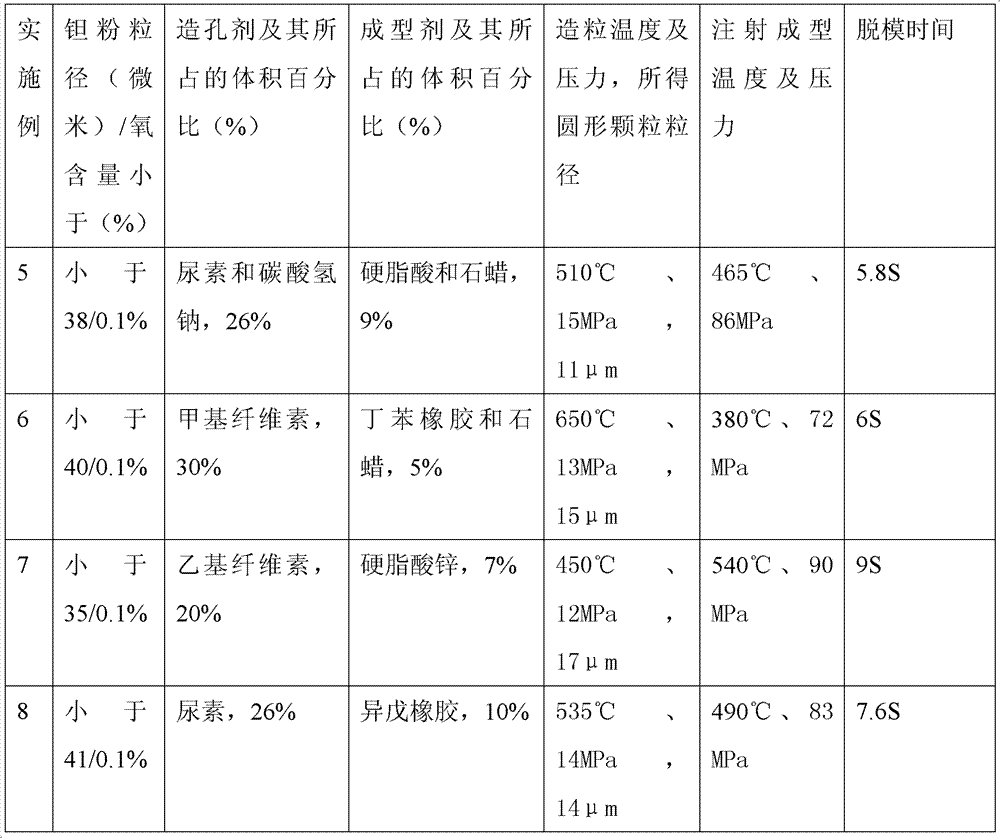

Preparation method of medical porous metal implant material

ActiveCN103740964AImproved biosafety and biocompatibilityOptimizing Process ConditionsProsthesisUreaImplant material

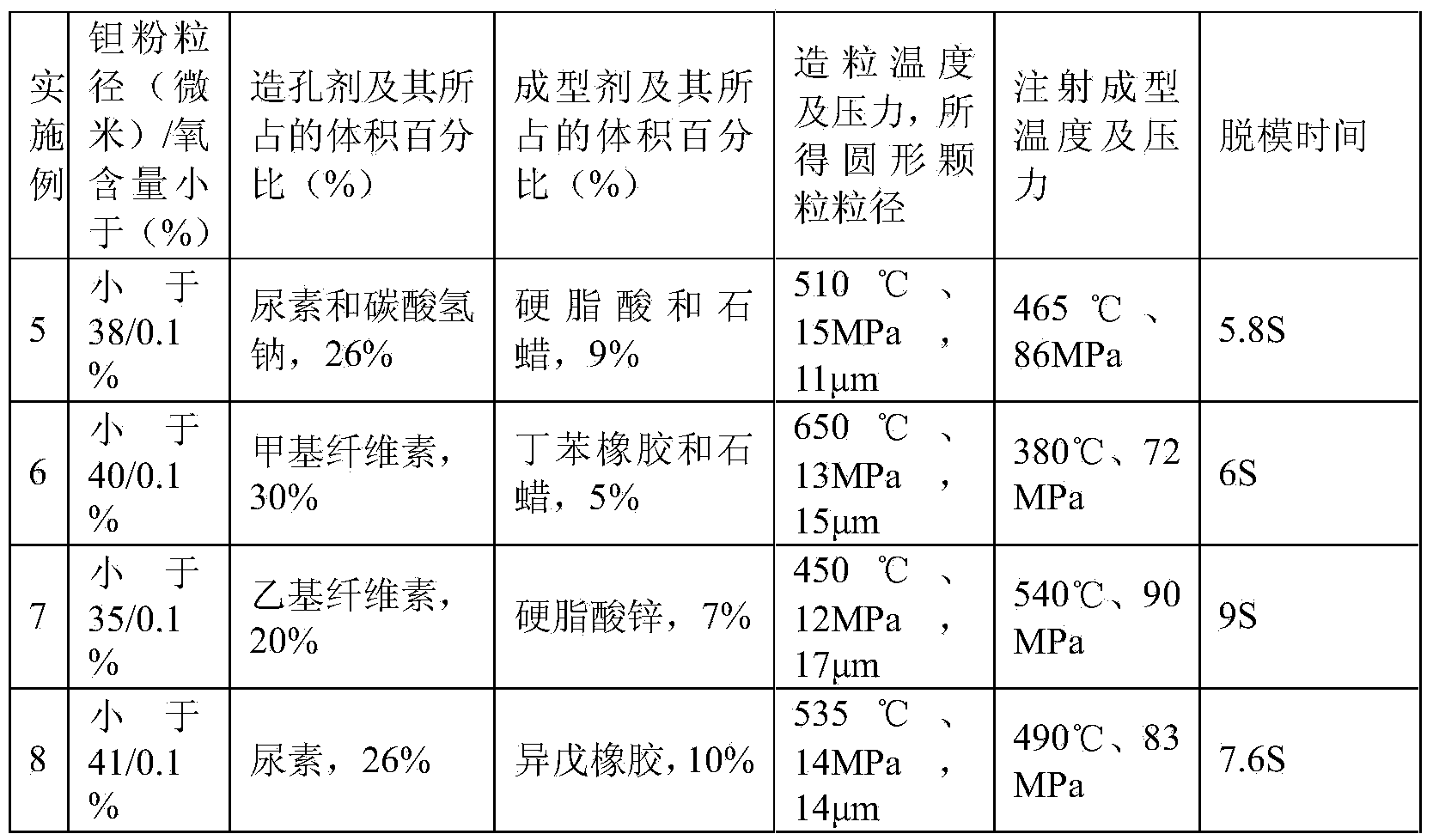

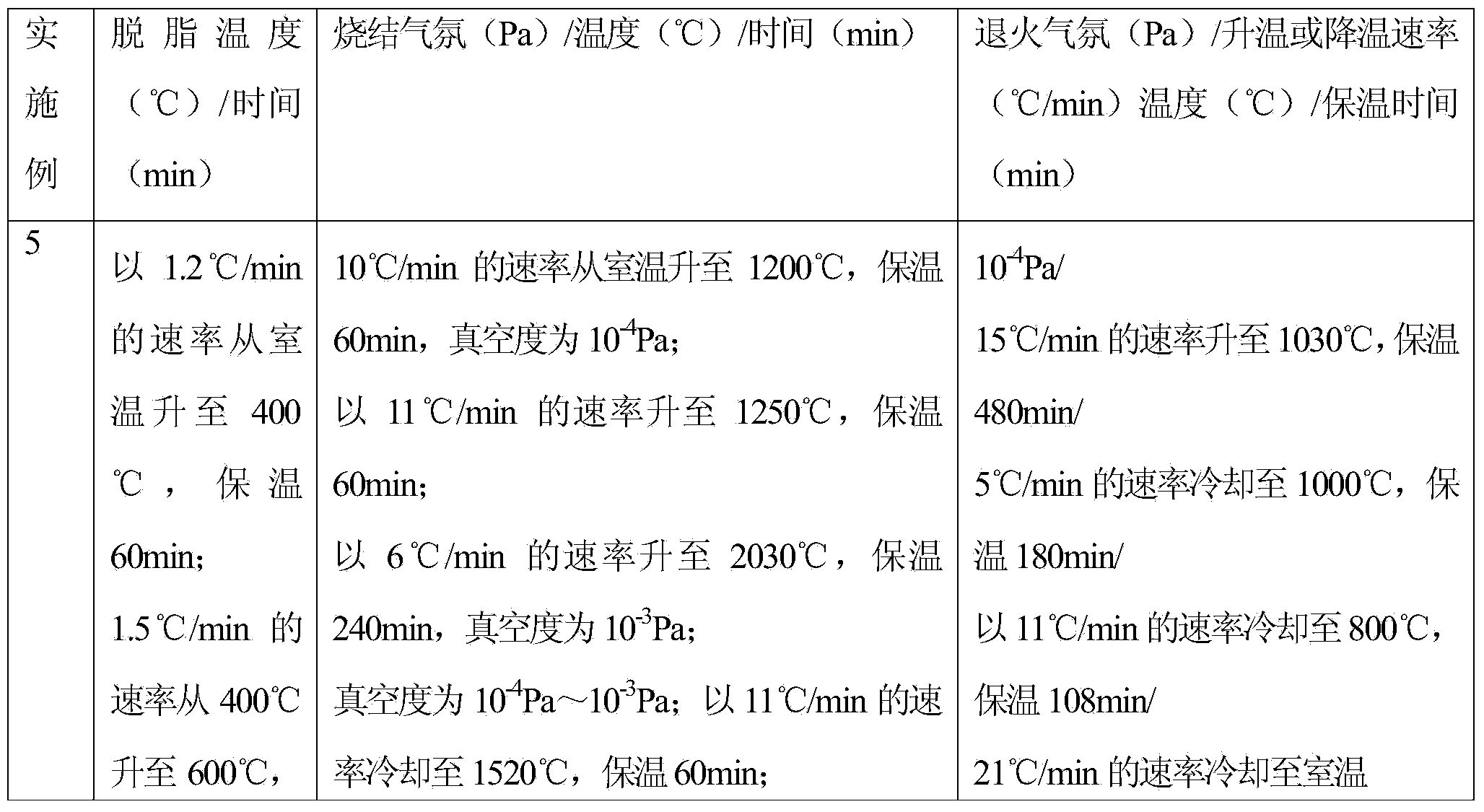

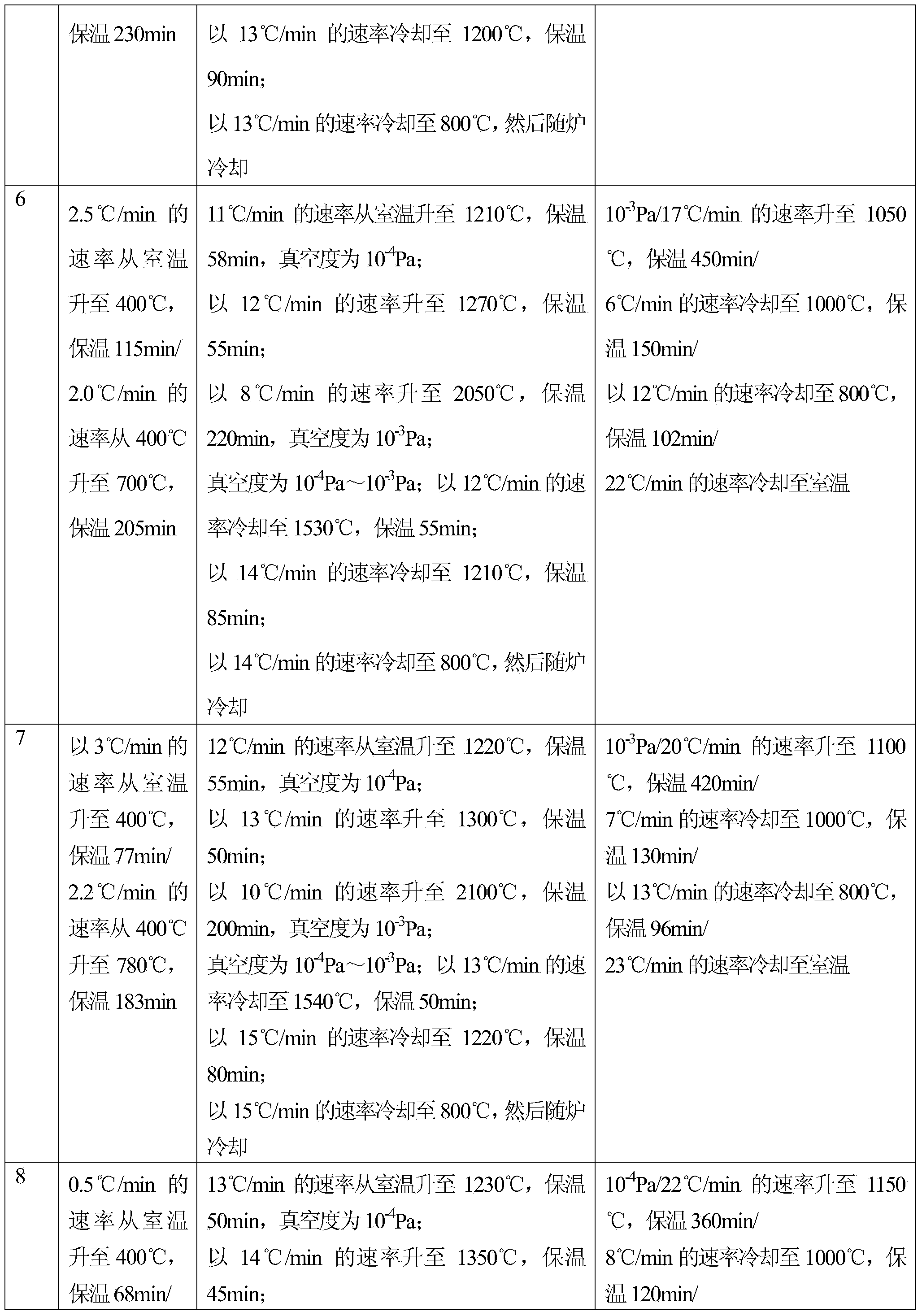

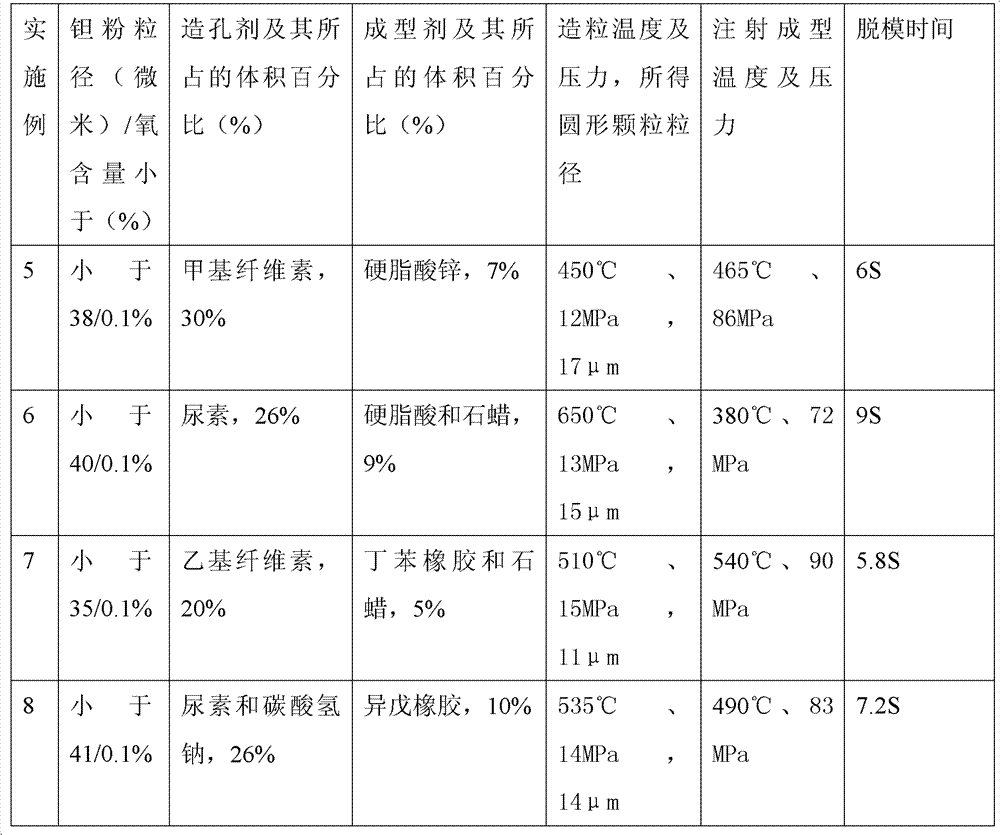

The invention relates to a preparation method of a medical porous metal implant material. The method comprises the following steps: mixing tantalum powder with a pore former and a forming agent so as to form mixed powder; and performing granulation, injection mould forming, demoulding, degreasing, sintering and heat treatment on the mixed powder so as to prepare the medical porous metal implant material capable of replacing a dentale tissue, wherein the pore former is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyecellulose; the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; the degreasing process is performed under the conditions of gradually heating to 400 DEG C to 800 DEG C according to the speed rate of 0.5 DEG C / minute to 3 DEG C / minute, forming a protective atmosphere in an argon leading-in mode and carrying out heat preservation for 60 to 240 minutes; the sintering process and the heat treatment process are effectively improved. Thus, the mechanical property of the prepared medical porous metal implant material is greatly improved. As a result, the prepared medical porous metal implant material is very suitable for replacement of the dentale tissue.

Owner:CHONGQING RUNZE PHARM CO LTD

Aluminum alloy suitable for cold forming and preparation method thereof

The invention discloses an aluminum alloy suitable for cold forming and a preparation method thereof. The aluminum alloy comprises, by mass, 2-6 wt.% of Zn, 0.2-6 wt.% of Mg, 0.2-3 wt.% of Mn, 0.2-3 wt.% of Cu, 0.1-2 wt.% of Sc, 0.1-2 wt.% of Yb, 0.1-1 wt.% of Tb, 0.2-2 wt.% of Zr, and the balance Al. The preparation method of the aluminum alloy comprises the four steps of smelting, homogenizationtreatment, cold forming and aging treatment. According to the aluminum alloy suitable for cold forming and the preparation method thereof, Zn, Mg, Mn, Cu, Yb and Tb elements are added to the aluminumalloy, a ZnYb strengthening phase, and a ZnTb strengthening phase and a MgZn strengthening phase are introduced to the aluminum alloy structure; grain refinement is conducted through Sc and Zr; through subsequent homogenization treatment, more than 60% of deformation of the homogenized aluminum alloy is realized without cracking; and finally, the homogenized aluminum alloy is subjected to cold plasticity deformation and aging treatment, and the high-performance aluminum alloy suitable for cold forming is prepared.

Owner:上海纳特汽车标准件有限公司 +1

Preparation method of medical porous metal implanting material

ActiveCN102796899AUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePolyvinyl alcohol

The invention discloses a preparation method of a medical porous metal implanting material. The preparation method comprises the steps of: mixing tantalum powder, pore-forming agent and forming agent to mixed powder; and carrying out granulation, mould-injection forming, demoulding, degreasing, sintering and heat treatment to obtain the medical porous metal implanting material which is used for replacing tooth bone tissues, wherein the pore-forming agent comprises one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyl cellulose; the forming agent comprises one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; and the degreasing process comprises the steps of: gradually raising the temperature to 400-800 DEG C at a speed of 0.5-3 DEG C / min, introducing in argon to form protection atmosphere and holding the temperature for 60-240min. According to the preparation method provided by the invention, the sintering and heat treatment steps are effectively improved, so that the mechanical property of a prepared porous tantalum material is greatly improved and the porous tantalum material is particularly suitable for serving as a medical implanting material for replacing the tooth bone tissues of human body.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

ActiveCN102796898AUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusParaffin waxSodium bicarbonate

The invention discloses a method for preparing a medical porous metal implant material. The method comprises the following steps of: mixing tantalum powder, a pore forming agent and a forming agent to obtain mixed power, wherein the pore forming agent is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethylcellulose, and the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin wax and synthetic rubber; pelletizing; injecting into a mould and forming; demoulding; degreasing, namely gradually raising temperature to 400 to 800 DEG C at the speed of 0.5 to 3 DEG C / min, introducing argon to form protective atmosphere and preserving heat for 60 to 240 minutes; sintering; and performing thermal treatment, namely raising temperature to 800 to 900 DGE C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DEG C at the speed of 2 to 5 DEG C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with a furnace, and finally, the medical porous metal implant material for replacing dentale tissues can be obtained. Through tests, the prepared porous tantalum material is very suitable to be used as the medical implant material for replacing dentale tissues.

Owner:CHONGQING RUNZE PHARM CO LTD

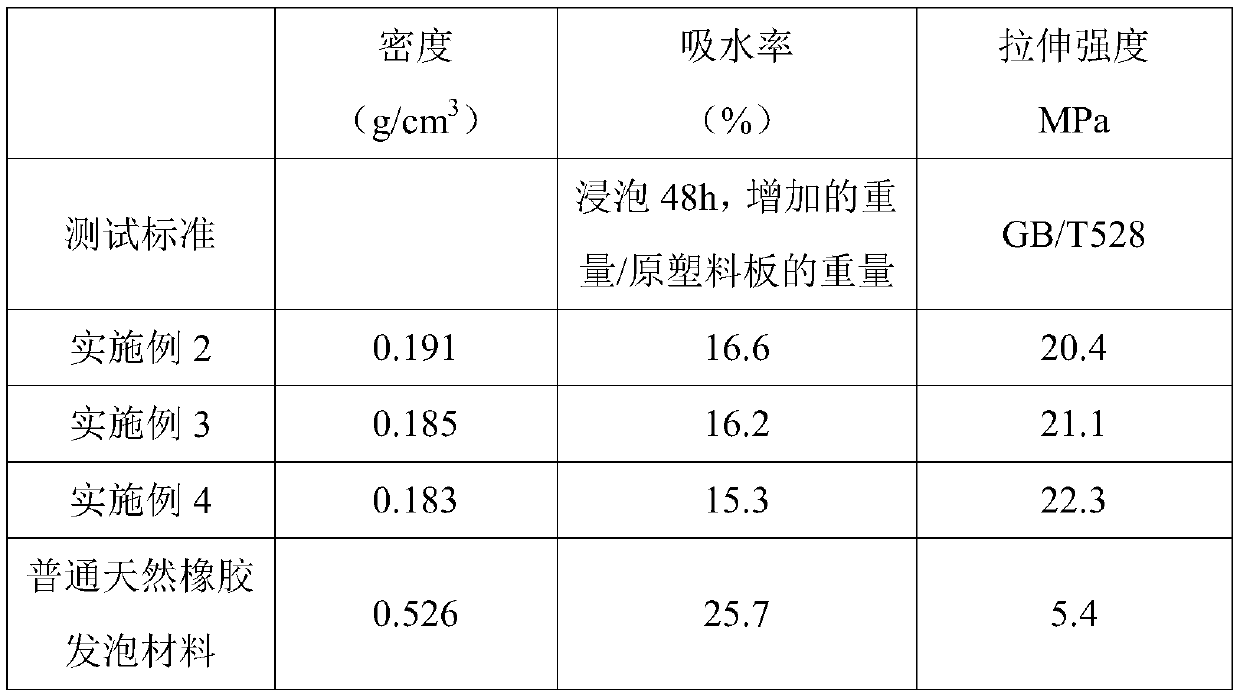

Graphene natural rubber oil-resistant mixed foaming material and preparation method thereof

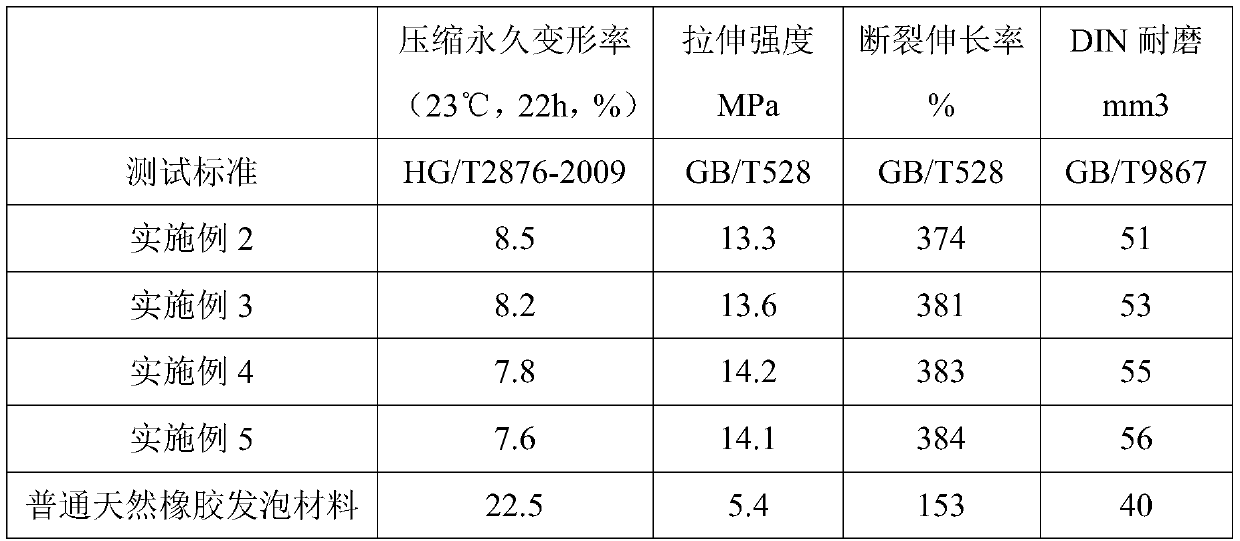

The invention discloses a graphene natural rubber oil-resistant mixed foaming material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 36-44 parts of natural rubber, 28-33 parts of nitrile butadiene rubber, 8.5-11.5 parts of cis-1,4-polybutadiene rubber, 14-16 parts of polyvinyl chloride resin, 4-6 parts of white carbon black, 1.2-1.5parts of silicone oil, 1.7 to 2.1 parts of zinc oxide, 1.4 to 1.8 parts of zinc stearate, 1.3 to 1.6 parts of stearic acid, 2.3 to 2.9 parts of a cross-linking agent, 2.5 to 3.5 parts of graphene, 1.9 to 2.5 parts of a foaming agent and 1.8 to 2.4 parts of a flow aid. After being soaked in a hydrocarbon oil solvent (such as butyl acrylate), the product still maintains high tensile strength and high elongation at break, is not easy to react with the hydrocarbon oil solvent, and has good oil resistance and good mechanical properties; the compression set rate, the rebound resilience and the mechanical property are good; and wear resistance is good.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Bio-based polyester non-woven fabric and preparation method thereof

InactiveCN111979645ABig bursting strengthHigh breaking strengthConjugated synthetic polymer artificial filamentsNon-woven fabricsMaleic anhydrideDiamine

The invention discloses a bio-based polyester non-woven fabric and a preparation method thereof. The bio-based polyester non-woven fabric is prepared from bio-based polyester filaments through a spunlace process. The bio-based polyester filament is prepared from the following raw material of, in parts by weight, 80-88 parts of bio-based succinic acid-pentanediol ester copolyester, 12-16 parts of bio-based polypentamethylene adipate diamine, 6-9 parts of a thermoplastic elastomer, 1.5-2.5 parts of carboxylated carbon nanotubes, 2-3.5 parts of quartz fibers, 3-5 parts of calcium carbonate, 0.8 to 1.2 parts of cerium dioxide and 5 to 7 parts of maleic anhydride grafted polypropylene. The bio-based polyester non-woven fabric is high in bursting strength and breaking strength which are very close to those of common PET non-woven fabric, good in mechanical property, durable, good in biodegradability, environmentally friendly, healthy and high in use comfort; and the comprehensive mechanicalperformance is good, the comprehensive use performance is good, and the market application prospect is wide.

Owner:福建尚龙新材料科技有限公司

Casting method for sink roll shaft sleeve

The invention provides a casting method for a sink roll shaft sleeve. The casting method includes the steps of drying and preheating, raw material smelting, casting parameter setting, casting, and discharging from a furnace. Variable-pressure centrifugal casting is adopted. According to the casting method, the sink roll shaft sleeve is manufactured from creative raw material ingredients through the method combining non-equal-pressure casting and centrifugal casting, so that the microstructure of the sink roll shaft sleeve is made more compact, the dynamic properties, such as strength, of the sink roll shaft sleeve are effectively improved, the sink roll shaft sleeve is durable, and long-time stable operation of a sink roll is guaranteed.

Owner:江苏优泽科技有限公司

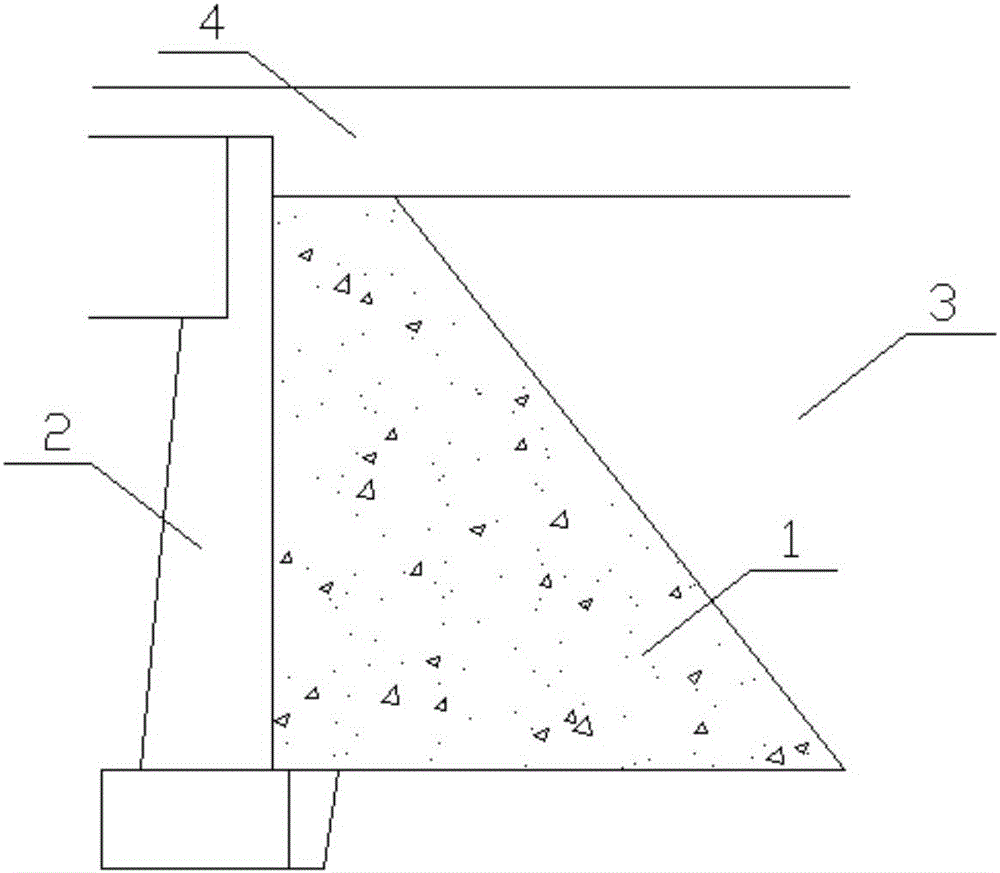

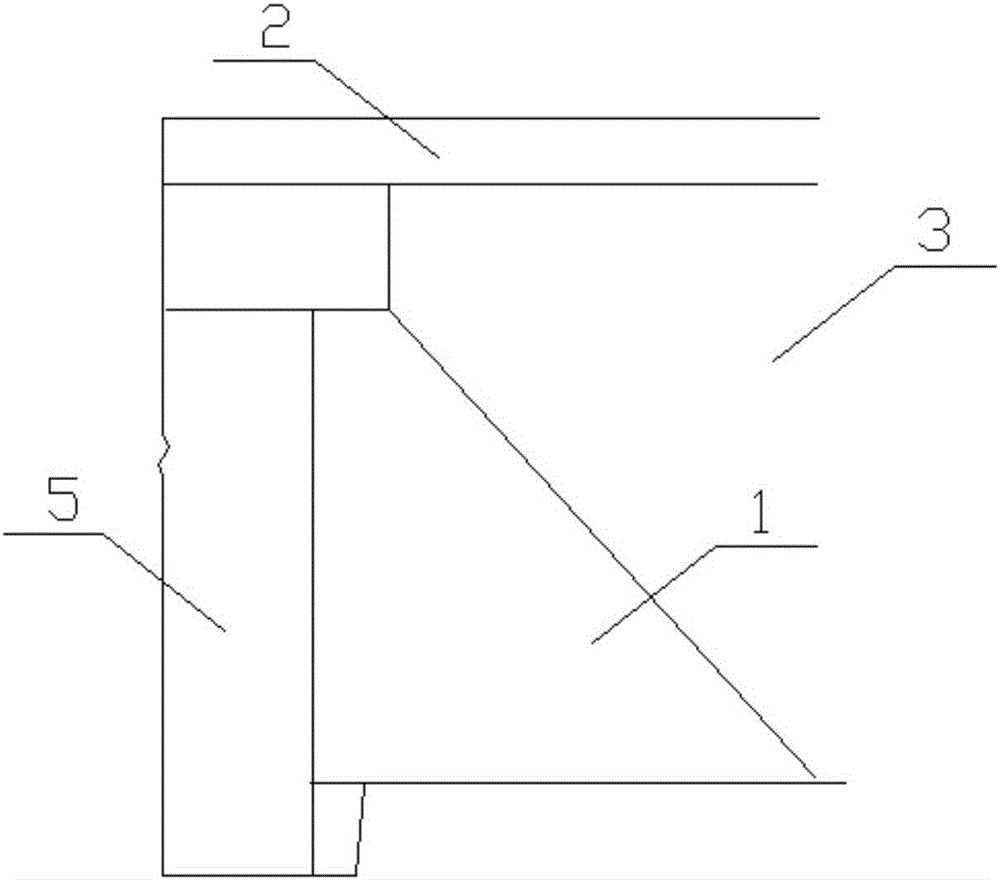

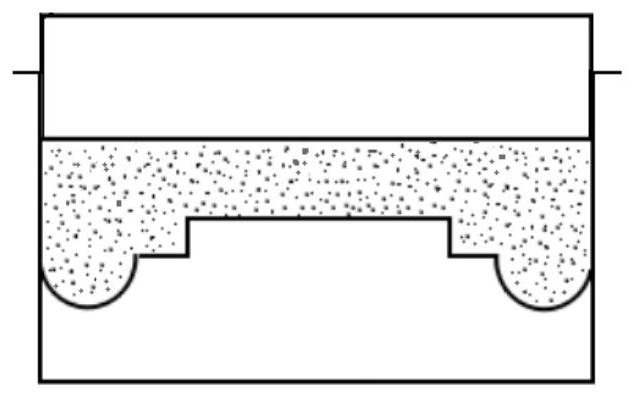

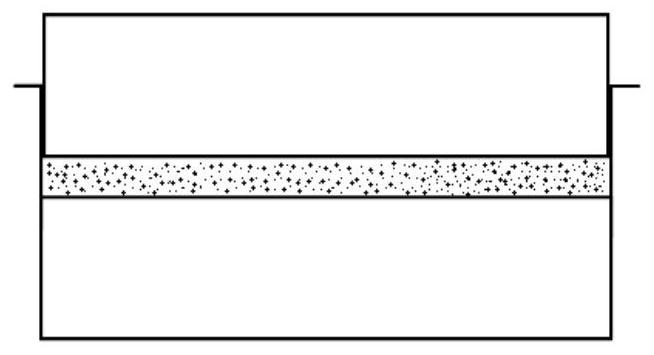

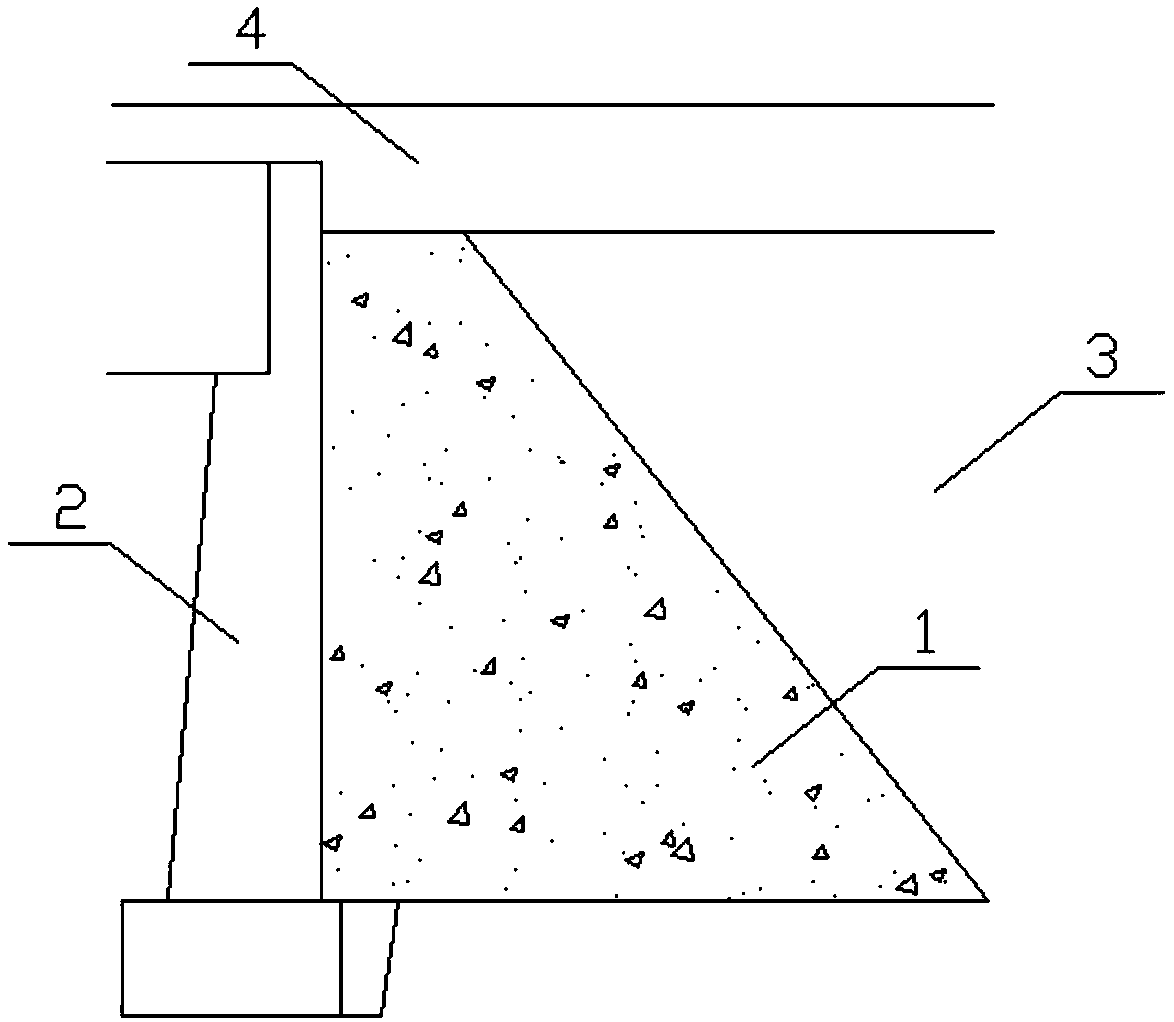

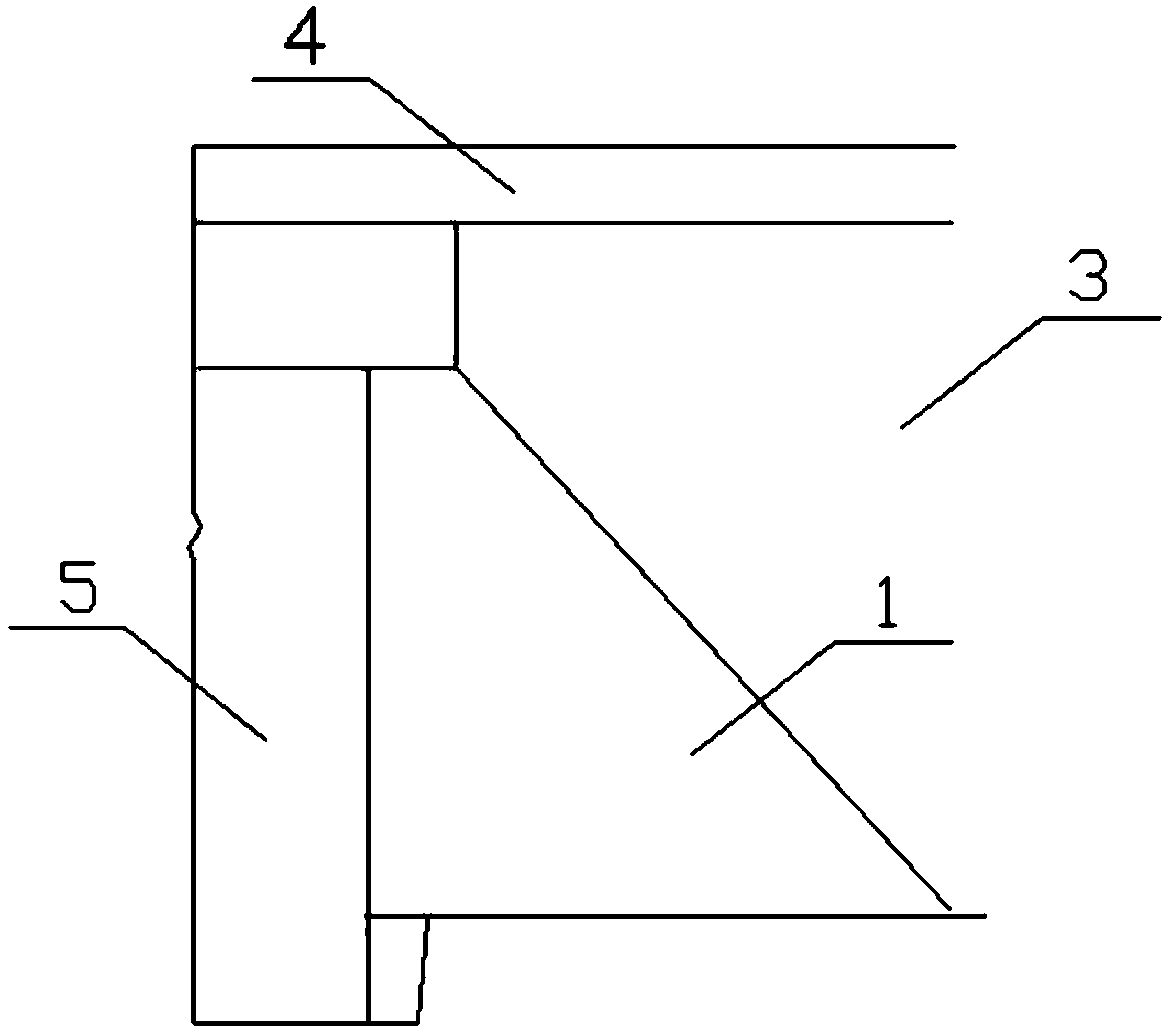

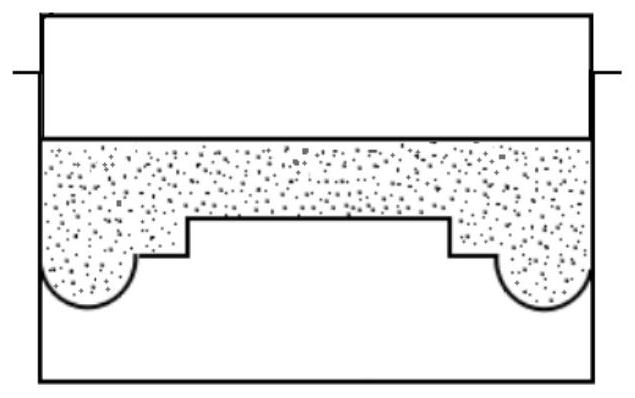

Bridge and culvert structure transition section anti-frost-heaving structure in cold region

The invention relates to a bridge and culvert structure transition section anti-frost-heaving structure in a cold region. The portion between the connecting portions of a side wall of a transverse building and a roadbed is filled with an anti-frost structural layer in a built manner. The longitudinal profile of the anti-frost structural layer is almost in a right trapezoid shape with the upper portion narrower than the lower portion. The longitudinal right-angle side of the trapezoid of the anti-frost structural layer faces the side wall of the transverse building. The longitudinal profile of the anti-frost structural layer is designed in the trapezoid with the upper portion narrower than the lower portion, the anti-frost-heaving effect can be guaranteed, meanwhile, materials are saved to the maximum extent, and the structure is low in construction cost, scientific and reasonable.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Preparation method of epoxidized crosslinked polypropylene powder coating

InactiveCN107201092AImprove aging resistance and storage stabilityReduce reunionPowdery paintsPolypropyleneAcetylacetone

The invention discloses a preparation method of an epoxidized crosslinked polypropylene powder coating. According to the preparation method, diatomite is subjected to epoxidation treatment, then polypropylene powder is dispersed into acetic ether, mixing treatment is performed with 8-hydroxyquinoline and calcium acetylacetonate to improve anti-aging resistance and storage stability of the polypropylene powder, then the polypropylene powder is reacted with a saponification solution of triethylamine to obtain a mixture of aminated polypropylene and epoxidized diatomite, and crosslinking is formed under the action of diisocyanate, so that agglomeration is reduced, the compatibility between the diatomite and polypropylene is improved, and the stability and strength of a finished product are improved.

Owner:谢泳江

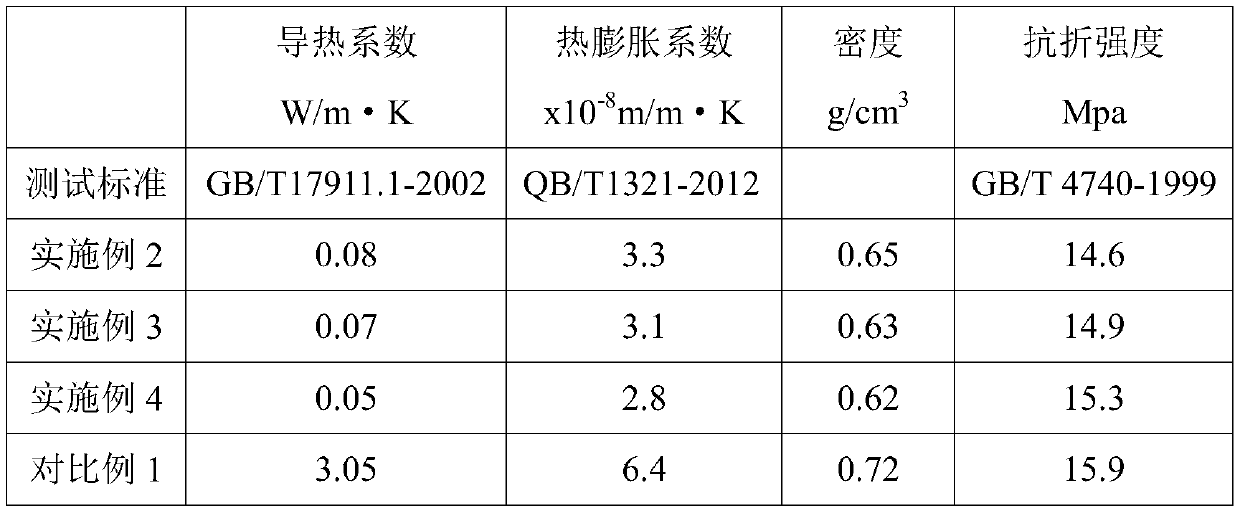

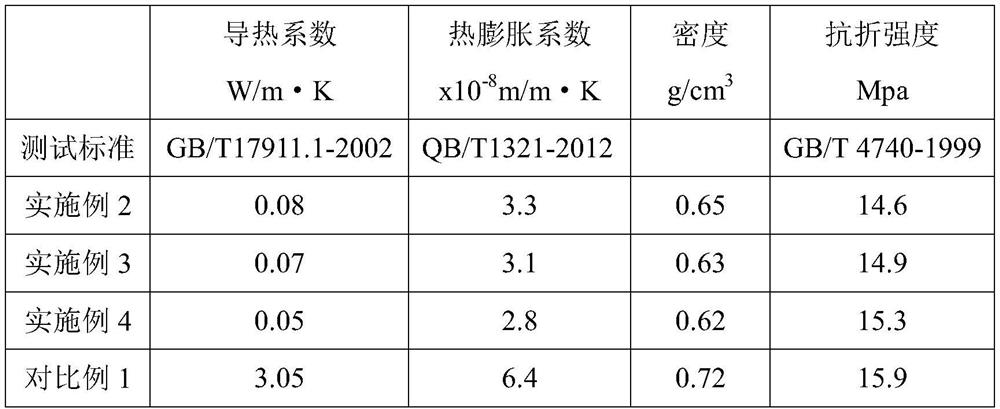

Domestic ceramic product with good thermal insulation property and preparation method thereof

ActiveCN111548126ALow thermal conductivityGood insulation performanceClaywaresSodium silicateAluminum silicate

The invention discloses a domestic ceramic product with a good thermal insulation property and a preparation method thereof. The domestic ceramic product with a good thermal insulation property is prepared from the following raw materials in parts by weight: 20 to 26 parts of albite, 15 to 19 parts of anorthite, 30-40 parts of calcite, 25-32 parts of attapulgite clay, 10-14 parts of sodium bentonite, 5-7 parts of painite, 10-14 parts of quartz, 8-11 parts of an aluminum silicate fiber tube, 4-5.5 parts of sodium silicate, 2.2-3 parts of a foaming agent, 0.9-1.3 parts of a foam stabilizer and 0.8-1.1 parts of a water reducing agent. The domestic ceramic product has the advantages of low heat conductivity coefficient, good thermal insulation property, low coefficient of thermal expansion, low thermal expansion, strong high temperature resistant property, high rupture strength, good mechanical properties, low density, lightness, and good comprehensive performance.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

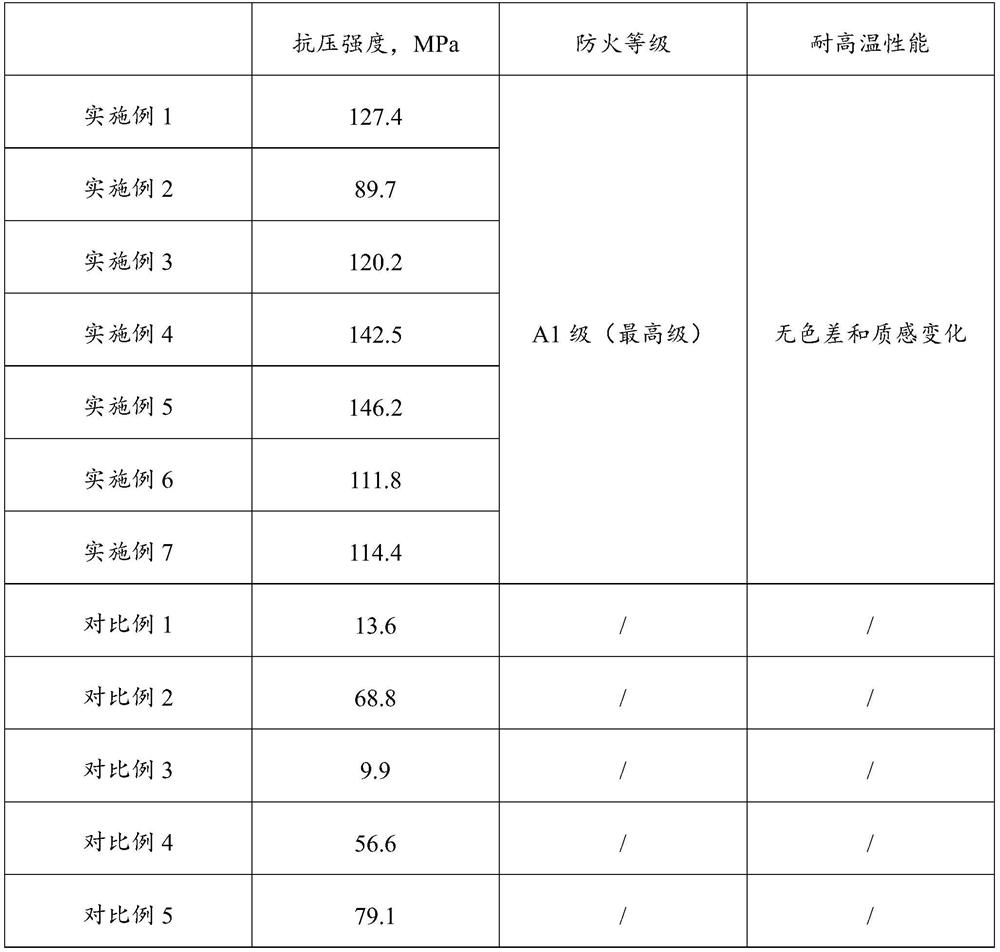

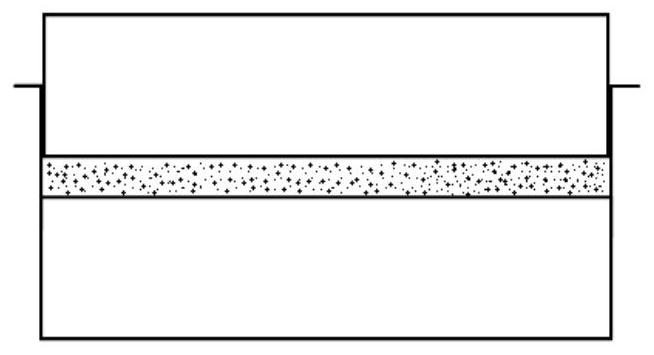

Geopolymer member and preparation method thereof

ActiveCN111732378AHigh strengthImprove mechanical properties such as strengthCeramic shaping apparatusCement productionFiberPolyvinyl alcohol

The invention belongs to the technical field of building materials, and particularly relates to a geopolymer component and a preparation method thereof. The component is composed of 58-74 parts of a silicon-aluminum raw material, 4-12 parts of an excitant, 3-7 parts of an inorganic curing agent, 0.2-0.5 part of an additive, and 7-20 parts of water. According to the technical scheme, the water consumption is low, generation of pores in the product due to existence of excessive moisture is avoided, and the strength and other mechanical properties of the geopolymer are improved; reinforcing materials such as fibers, resin and polyvinyl alcohol do not need to be additionally added; the chemical activity of the raw materials is fully utilized; especially, an inorganic curing agent is used; allthe raw materials are matched and used in proportion; the geopolymer component with high polymerization degree, high compactness and high strength can be rapidly generated in situ through the coordination effect of all the components, the economic cost is effectively reduced, the delivery time is greatly shortened, no free formaldehyde is released, and the geopolymer component is more environmentally friendly, better in fireproof and high-temperature-resistant performance and wide in application prospect.

Owner:UNIV OF JINAN

A kind of aluminum alloy suitable for cold forming and its preparation method

Owner:上海纳特汽车标准件有限公司 +1

A kind of daily-use ceramic product with good thermal insulation performance and preparation method thereof

ActiveCN111548126BImprove high temperature resistanceImprove mechanical propertiesClaywaresThermal dilatationFiber

The invention discloses a daily-use ceramic product with good thermal insulation performance and a preparation method thereof. The daily-use ceramic product with good thermal insulation performance is made from the following raw materials by weight: 20-26 parts of albite, anorthite 15-19 parts, 30-40 parts of calcite, 25-32 parts of attapulgite, 10-14 parts of sodium bentonite, 5-7 parts of monetite, 10-14 parts of quartz, 8-8 parts of aluminum silicate fiber tube 11 parts, 4-5.5 parts of sodium silicate, 2.2-3 parts of foaming agent, 0.9-1.3 parts of foam stabilizer, and 0.8-1.1 parts of water reducing agent. The daily-use ceramic product with good thermal insulation performance of the invention has low thermal conductivity and good thermal insulation performance; small thermal expansion coefficient, small thermal expansion, good high temperature resistance; , the overall performance is good.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

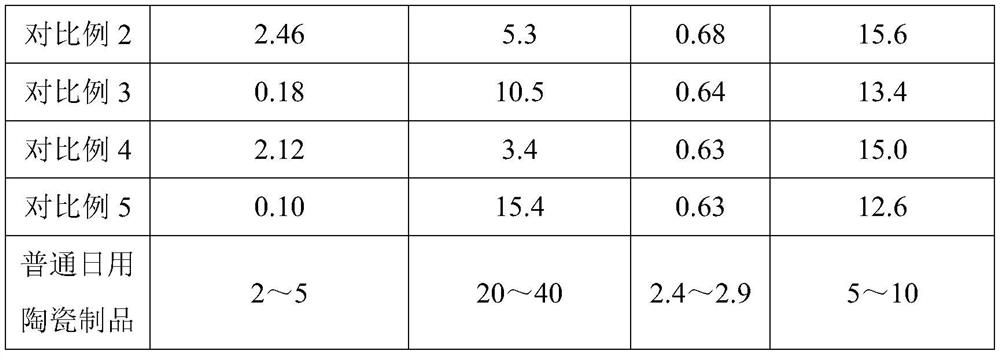

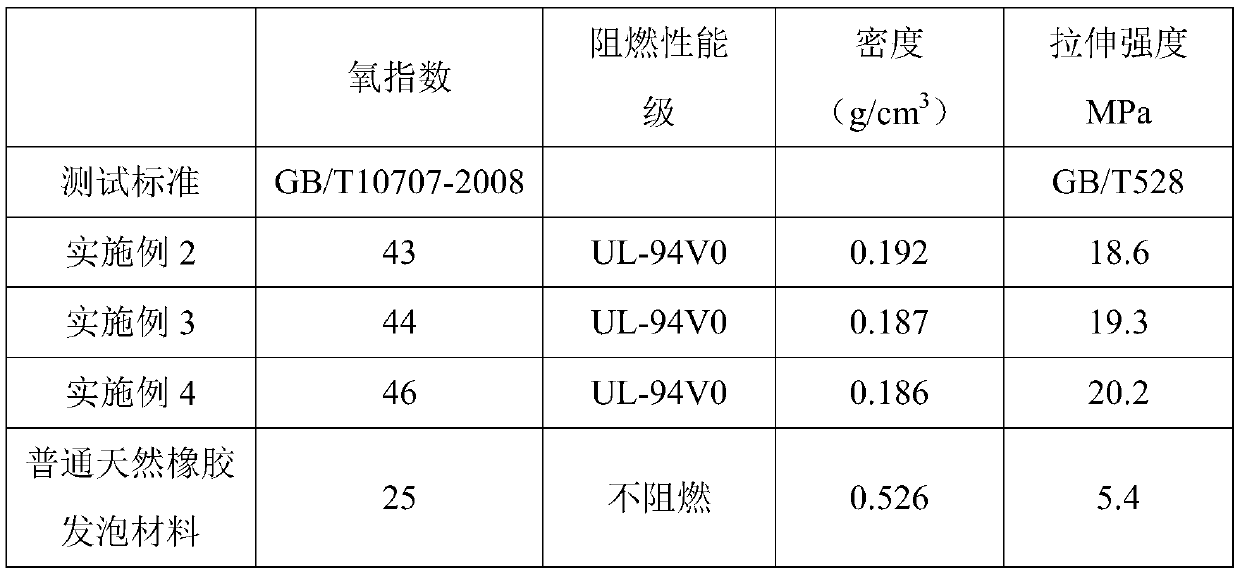

High-performance thermoplastic elastomer for cable of charging pile and preparation method of high-performance thermoplastic elastomer

The invention relates to a high-performance thermoplastic elastomer for a cable of a charging pile and a preparation method of the high-performance thermoplastic elastomer, and belongs to the technical field of polymer materials. The thermoplastic elastomer is prepared from components in parts by weight as follows: 30-40 parts of a styrene elastomer, 30-39 parts of polyformaldehyde, 18-26 parts ofmodified porous CaCO3, 8-15 parts of cellulose fiber, 29-42 parts of a flame retardant, 3-8 parts of an oil resistant agent and 6-10 parts of a softening agent. The prepared thermoplastic elastomer has the characteristics of being high in strength, resistant to tear, heat and wear and good in flame retardance.

Owner:宁波聚泰新材料科技有限公司

Filling master batch for plastics and preparation method of filling master batch

The invention discloses a filling master batch for plastics and a preparation method of the filling master batch. The filling master batch is prepared from the following raw materials in parts by weight: 14 to 20 parts of polypropylene resin, 80 to 90 parts of modified bentonite, 4 to 8 parts of polypropylene wax, 3 to 5 parts of stearic acid and 2 to 2.4 parts of a silane coupling agent. The preparation method comprises the following steps: (1), raising the temperature of a high-speed mixer to 180 to 200 DEG C and then keeping constant temperature for 5 to 10 minutes; (2), pouring the modified bentonite and the silane coupling agent, stirring for 15 to 20 minutes, continuously stirring and then reducing the temperature to 110 to 120 DEG C; (3), pouring the polypropylene wax and stearic acid, continuously stirring for 1 to 2 minutes, then putting the polypropylene resin, carrying out mixed stirring for 4 to 5 minutes, discharging and cooling; (4), extruding the cooled materials and then granulating, thus obtaining the filling master batch for the plastics. According to the filling master batch for the plastics, disclosed by the invention, by adopting the dodecyl trimethyl ammonium chloride modified bentonite, the compatibility of the modified bentonite and carrier resin is improved; the prepared filling master batch is easily dispersed in matrix resin; besides, mechanical properties such as the strength of plastic products are improved.

Owner:贵州通汇塑料科技有限公司

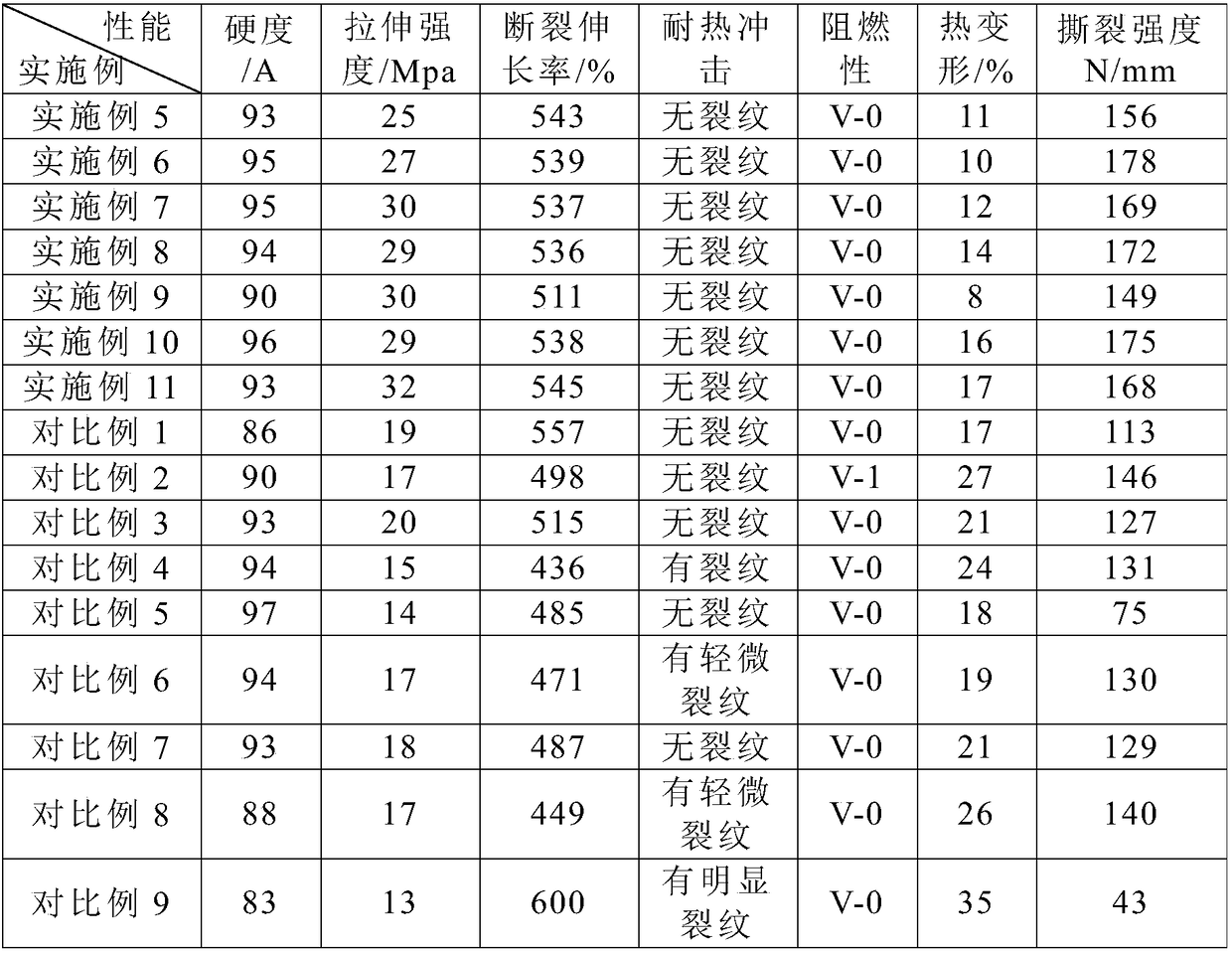

Graphene rubber macromolecular flame-retardant composite foaming material and preparation method thereof

The invention discloses a graphene rubber macromolecular flame-retardant composite foaming material and a preparation method thereof. The graphene rubber macromolecular flame-retardant composite foaming material comprises the following raw materials in parts by weight: 50-60 parts of natural rubber, 13-17 parts of butadiene rubber, 4-6 parts of ethylene propylene diene monomer, 4-6 parts of whitecarbon black, 14-17 parts of a flame retardant, 1.8-2.4 parts of graphene, 4-6 parts of a nano medium, 2-3 parts of zinc oxide, 2.5-4 parts of a heat stabilizer, 2-2.4 parts of a cross-linking agent,3-4 parts of a flow aid and 2-2.4 parts of a foaming agent, wherein the flame retardant is a mixture of zinc diethylphosphinate and triphenyl phosphate. The flame-retardant test of the graphene rubbermacromolecular flame-retardant composite foaming material reaches a UL-94V0 level, and the oxygen index of the graphene rubber macromolecular flame-retardant composite foaming material is far higherthan that of a common natural rubber foam material; the density of the graphene rubber macromolecular flame-retardant composite foaming material is lower than that of a common natural rubber foaming material, and the graphene rubber macromolecular flame-retardant composite foaming material is ultra-light; and moreover, the tensile strength of the graphene rubber macromolecular flame-retardant composite foaming material is greatly superior to that of a common natural rubber foaming material, the mechanical property is good, and the ultra-light property and the excellent mechanical property arewell considered.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Graphene natural rubber polymer surfboard composite foamed material and preparation method thereof

The invention discloses a graphene natural rubber polymer surfboard composite foamed material and a preparation method thereof. The graphene natural rubber polymer surfboard composite foamed materialis prepared from the following raw materials in parts by weight: 47-53 parts of natural rubber, 32-36 parts of butyl rubber, 8.5-11.5 parts of isoprene rubber, 5-7 parts of a nano medium, 2-2.5 partsof graphene, 3.5-4.5 parts of fumed silica, 1.5-2 parts of zinc oxide, 3-4 parts of a heat stabilizer, 2-2.5 parts of a cross-linking agent, 3-4 parts of a flow aid and 2-2.2 parts of a foaming agent.The density of the graphene natural rubber polymer surfboard composite foamed material is far lower than that of a common natural rubber foamed material, and the graphene natural rubber polymer surfboard composite foamed material has ultralight weight; the water absorption rate is far lower than that of the common natural rubber foamed material, the tensile strength is far higher than that of thecommon natural rubber foamed material, the mechanical property is good, and the graphene natural rubber polymer surfboard composite foamed material is very suitable to be taken as a surfboard material and has a wide market application prospect.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Method for preparing novel bamboo fiber composite materials

InactiveCN109082098AImprove mechanical properties such as strengthGood compatibilityPotassium persulfateDibutyl sebacate

The invention provides a method for preparing novel bamboo fiber composite materials. The method includes shearing bamboo fibers, washing the bamboo fibers by ethyl alcohol and distilled water, then placing the bamboo fibers in drying ovens at the temperatures of 90-105 DEG C and drying the bamboo fibers until the bamboo fibers are absolutely dry; mixing polyethylene glycol, polyether and polyimide with one another, stirring the polyethylene glycol, the polyether and the polyimide at the temperature of 60-80 DEG C for 20-40 min to obtain mixed liquid and uniformly stirring the mixed liquid; adding dibutyl sebacate into the mixed liquid, and stirring the dibutyl sebacate and the mixed liquid at the temperature of 100-120 DEG C for 10-30 min; adding the dried bamboo fibers and potassium persulfate into the mixed liquid; carrying out ultrasonic treatment at the power of 1000-1500 W for 8-15 min; increasing the temperatures until the temperatures reach 130-150 DEG C and carrying out hot-pressing under the pressure of 2-5 MPa for 20-40 min; carrying out natural cooling until the temperatures reach the room temperature so as to obtain the novel bamboo fiber composite materials.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Preparation method of medical porous metal implant material

ActiveCN103740964BUniform tissueOrganizational stabilityProsthesisSodium bicarbonatePolyvinyl alcohol

The invention relates to a preparation method of a medical porous metal implant material. The method comprises the following steps: mixing tantalum powder with a pore former and a forming agent so as to form mixed powder; and performing granulation, injection mould forming, demoulding, degreasing, sintering and heat treatment on the mixed powder so as to prepare the medical porous metal implant material capable of replacing a dentale tissue, wherein the pore former is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyecellulose; the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; the degreasing process is performed under the conditions of gradually heating to 400 DEG C to 800 DEG C according to the speed rate of 0.5 DEG C / minute to 3 DEG C / minute, forming a protective atmosphere in an argon leading-in mode and carrying out heat preservation for 60 to 240 minutes; the sintering process and the heat treatment process are effectively improved. Thus, the mechanical property of the prepared medical porous metal implant material is greatly improved. As a result, the prepared medical porous metal implant material is very suitable for replacement of the dentale tissue.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

A preparation method for a medical porous metal implant material comprising mixing tantalum powder, a pore-forming agent, and a forming agent into a powder mixture, then granulating, injecting into a mold for forming, demolding, degreasing, sintering, and performing a heating process to produce the medical porous metal implant material for dental bone tissue replacement; the pore-forming agent is one or multiple of sodium bicarbonate, urea, sodium chloride, methyl cellulose, and ethyl cellulose, and the forming agent is one or multiple of polyvinyl alcohol, stearic acid, zinc stearate, paraffin, and synthetic rubber; the degreasing process comprises: gradually increasing the temperature to 400 to 800°C at a speed of 0.5 to 3°C / min, introducing argon gas to form a protective atmosphere, and maintaining the temperature for 60 to 240 minutes. Measurements show that the porous tantalum material prepared using the method has an impurity concentration lower than 0.2%. The density reaches 11.67 to 13.34 g / cm3, the porosity reaches 20% to 30%, and the pore diameter reaches 12 to 25 mum. The elastic modulus reaches 4.5 to 6.0 Gpa, the elongation rate reaches 12.0% to 13.8%, the bending strength reaches 120 to 150 Mpa, and the compressive strength reaches 90 to 110 Mpa.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

ActiveCN103691004BUniform tissueOrganizational stabilityProsthesisSodium bicarbonatePolyvinyl alcohol

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implanting material

ActiveCN102796899BUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePowder mixture

A preparation method for a medical porous metal implant material comprising mixing tantalum powder, a pore-forming agent, and a forming agent into a powder mixture, then granulating, injecting into a mold for forming, demolding, degreasing, sintering, and performing a heating process to produce the medical porous metal implant material for dental bone tissue replacement; the pore-forming agent is one or multiple of sodium bicarbonate, urea, sodium chloride, methyl cellulose, and ethyl cellulose, and the forming agent is one or multiple of polyvinyl alcohol, stearic acid, zinc stearate, paraffin, and synthetic rubber; the degreasing process comprises: gradually increasing the temperature to 400 to 800°C at a speed of 0.5 to 3°C / min, introducing argon gas to form a protective atmosphere, and maintaining the temperature for 60 to 240 minutes; Effective improvements to the sintering and heating process steps substantially enhance the mechanic properties of the produced porous tantalum material, thereby enabling the material to be very suitable as a medical implant material for human dental bone tissue replacement.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

ActiveCN102796898BUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePowder mixture

A preparation method for a medical porous metal implant material comprising mixing tantalum powder, a pore-forming agent, and a forming agent into a powder mixture, then granulating, injecting into a mold for forming, demolding, degreasing, sintering, and performing a heating process to produce the medical porous metal implant material for dental bone tissue replacement; the pore-forming agent is one or multiple of sodium bicarbonate, urea, sodium chloride, methyl cellulose, and ethyl cellulose, and the forming agent is one or multiple of polyvinyl alcohol, stearic acid, zinc stearate, paraffin, and synthetic rubber; the degreasing process comprises: gradually increasing the temperature to 400 to 800°C at a speed of 0.5 to 3°C / min, introducing argon gas to form a protective atmosphere, and maintaining the temperature for 60 to 240 minutes; the heating process step comprises: within a vacuum degree of 10-4 to 10-3 Pa, increasing the temperature to 800 to 900°C at a speed of 10 to 20°C / min, maintaining the temperature for 240 to 480 minutes, cooling to 400°C at a speed of 2 to 5°C / min, maintaining the temperature for 120 to 300 minutes, and cooling together with the furnace to room temperature. The porous tantalum produced is very suitable as a medical implant material for dental bone tissue replacement.

Owner:CHONGQING RUNZE PHARM CO LTD

A kind of high-strength tear-resistant nonwoven fabric for bag production and preparation method thereof

ActiveCN111270342BGood compatibilityGood synergyConjugated synthetic polymer artificial filamentsNon-woven fabricsBursting strengthPolymer science

The invention discloses a high-strength tear-resistant nonwoven fabric for bag production and a preparation method thereof. The high-strength composite fibers are made from the following raw materials in parts by weight: 30-37 parts of polybutylene adipamide, 45-55 parts of polyhexamethylene adipamide, and 15-55 parts of polysebamide 20 parts, 10-14 parts of poly(p-phenylene terephthalamide), 3.5-5 parts of carboxylated carbon nanotubes, 2.5-3.5 parts of graphene oxide, 1.5-2.2 parts of cerium oxide, 3-5 parts of nano-fillers, 5 to 10 parts of flow aid. Under the condition of the same thickness, the high-strength tear-resistant non-woven fabric for bag production of the present invention has large bursting strength and breaking strength, which are obviously better than ordinary nylon non-woven fabrics, and has high strength and high tear resistance. Excellent performance.

Owner:厦门澳丽妃包袋有限公司

Anti-frost heaving structure of transition section of bridge and culvert structures in cold regions

The invention relates to a bridge and culvert structure transition section anti-frost-heaving structure in a cold region. The portion between the connecting portions of a side wall of a transverse building and a roadbed is filled with an anti-frost structural layer in a built manner. The longitudinal profile of the anti-frost structural layer is almost in a right trapezoid shape with the upper portion narrower than the lower portion. The longitudinal right-angle side of the trapezoid of the anti-frost structural layer faces the side wall of the transverse building. The longitudinal profile of the anti-frost structural layer is designed in the trapezoid with the upper portion narrower than the lower portion, the anti-frost-heaving effect can be guaranteed, meanwhile, materials are saved to the maximum extent, and the structure is low in construction cost, scientific and reasonable.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

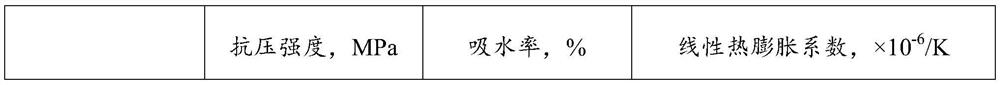

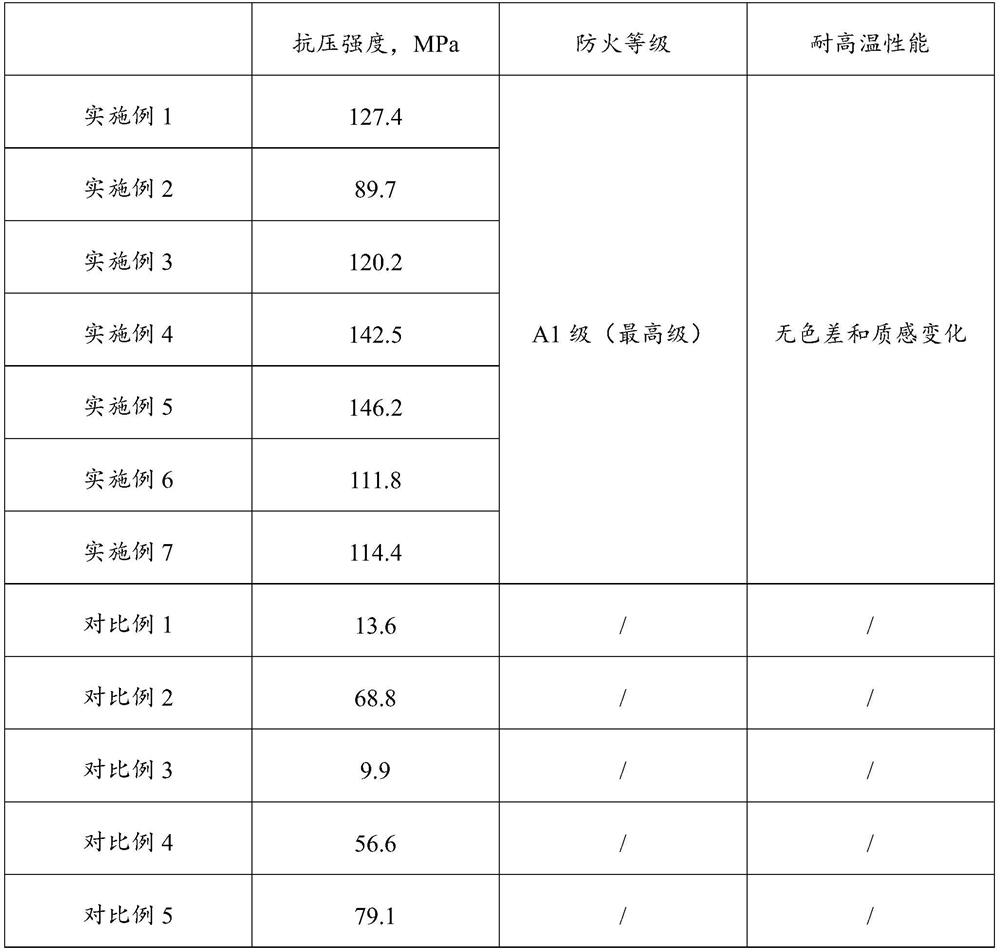

Inorganic ceramic artificial board and preparation method thereof

ActiveCN111732377AHigh strengthImprove interfacial adhesionCement productionChemical activityCeramic

The invention belongs to the technical field of building materials, and particularly relates to an inorganic ceramic artificial board and a preparation method thereof. According to the inorganic ceramic artificial board, the water consumption is low, generation of pores in the product due to excessive moisture is avoided, and the strength and other mechanical properties of the board are improved;reinforcing materials such as fibers, resin and polyvinyl alcohol do not need to be additionally added; the chemical activity of raw materials is fully utilized; the components are reasonably proportioned, relatively low pressure and temperature are adopted, and through the synergistic effect of the components, the material with high polymerization degree and high compactness is generated in situ;the compressive strength of the prepared inorganic ceramic board can be greater than 120 MPa; water absorption can be less than 0.4%, the linear thermal expansion coefficient can be smaller than 12.0*10<-6> / K, various performance requirements on the ceramic board are met, a high-temperature sintering step is not needed, energy is saved, the economic cost is effectively reduced, no free formaldehyde is released, the better environment-friendly effect is achieved, the fireproof and high-temperature-resistant performance is better, the ceramic board can be completely replaced, and the wide application prospect is achieved.

Owner:UNIV OF JINAN

A kind of geopolymer component and its preparation method

ActiveCN111732378BHigh strengthImprove mechanical properties such as strengthCeramic shaping apparatusCement productionFiberPolyvinyl alcohol

The invention belongs to the technical field of building materials, and in particular relates to a geopolymer component and a preparation method thereof. The component is composed of 58-74 parts of silicon-aluminum raw materials; 4-12 parts of activator; 3-7 parts of inorganic curing agent; 0.2-0.5 parts of additives; 7-20 parts of water. The technical solution of the present invention consumes less water, avoids the formation of pores in the product caused by the existence of excess water, and improves the mechanical properties such as the strength of the geopolymer; the present invention does not require additional reinforcing materials such as fibers, resins, and polyvinyl alcohol , making full use of the chemical activity of raw materials, especially the use of inorganic curing agents, only through the coordination of various raw materials and the ratio of dosage, it can be quickly produced in situ through the coordination of various components with high degree of polymerization and high density. , High-strength geopolymer components, effectively reducing economic costs, greatly shortening the delivery time, no release of free formaldehyde, more environmentally friendly, and better fire resistance and high temperature resistance, with broad application prospects.

Owner:UNIV OF JINAN

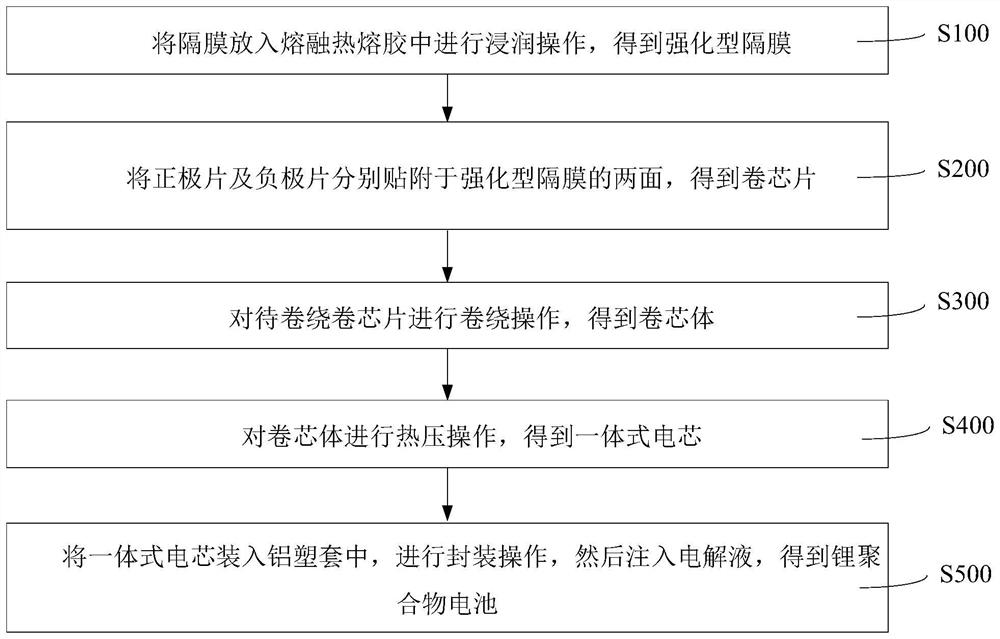

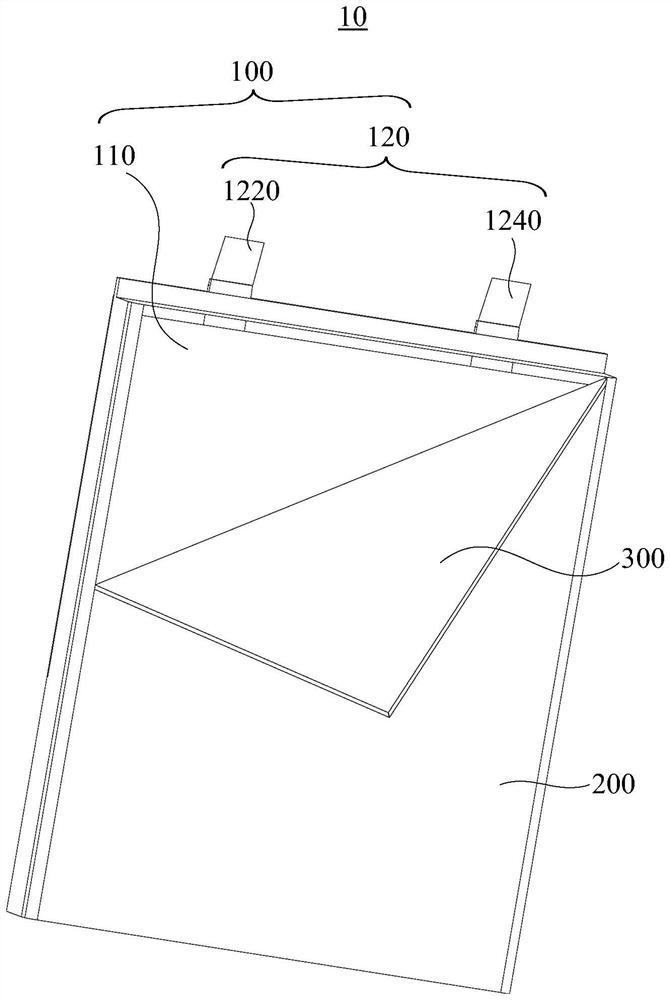

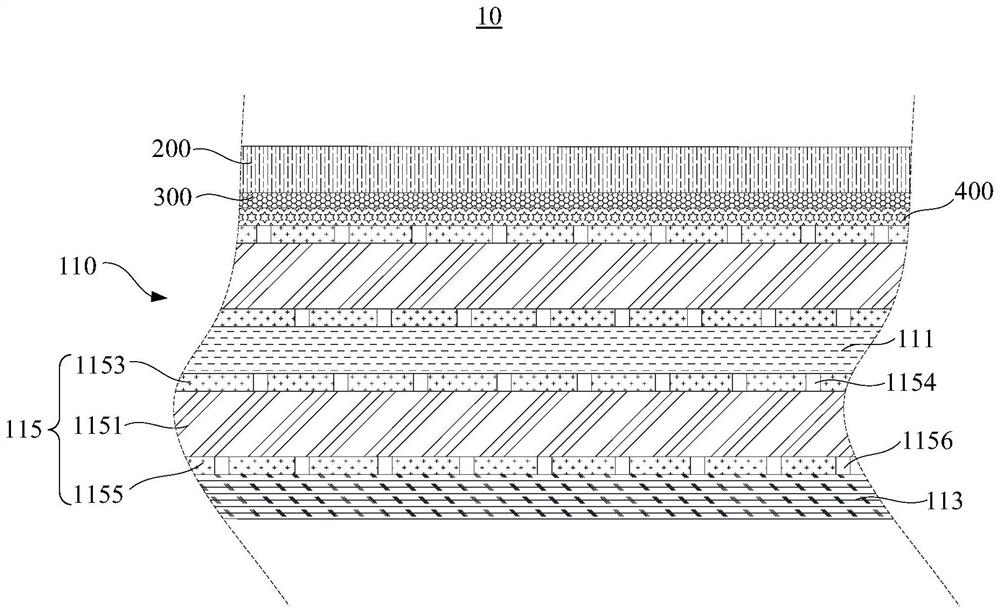

Lithium polymer battery and preparation method thereof

PendingCN114243123AAvoid corrosionInhibit swellingFinal product manufactureSecondary cellsPhysical chemistryEngineering

The invention provides a lithium polymer battery and a preparation method thereof. The preparation method of the lithium polymer battery comprises the following steps: putting the diaphragm into a molten hot melt adhesive for infiltration operation to obtain the reinforced diaphragm, so that the problems of internal corrosion and expansion of the lithium polymer battery are effectively prevented, and the safety performance of the lithium polymer battery is improved; respectively attaching the positive plate and the negative plate to the two surfaces of the reinforced diaphragm to obtain a roll chip; carrying out tab welding operation on the roll chip to obtain a to-be-wound roll chip; winding the to-be-wound roll core sheet to obtain a roll core body; carrying out hot pressing operation on the roll core body to obtain an integrated battery core; and loading the integrated battery cell into an aluminum plastic sleeve, injecting an electrolyte, and then carrying out packaging operation to obtain the lithium polymer battery, so that the structural stability and safety of the lithium polymer battery cell are further improved.

Owner:MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com