Graphene rubber macromolecular flame-retardant composite foaming material and preparation method thereof

A technology of flame-retardant composite and foamed materials, applied in the field of rubber products, can solve the problems of inability to meet the requirements of flame-retardant performance, insufficient light weight, poor mechanical properties such as tensile strength and elongation at break, etc., and save manpower. and equipment cost, improving quality stability, and the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

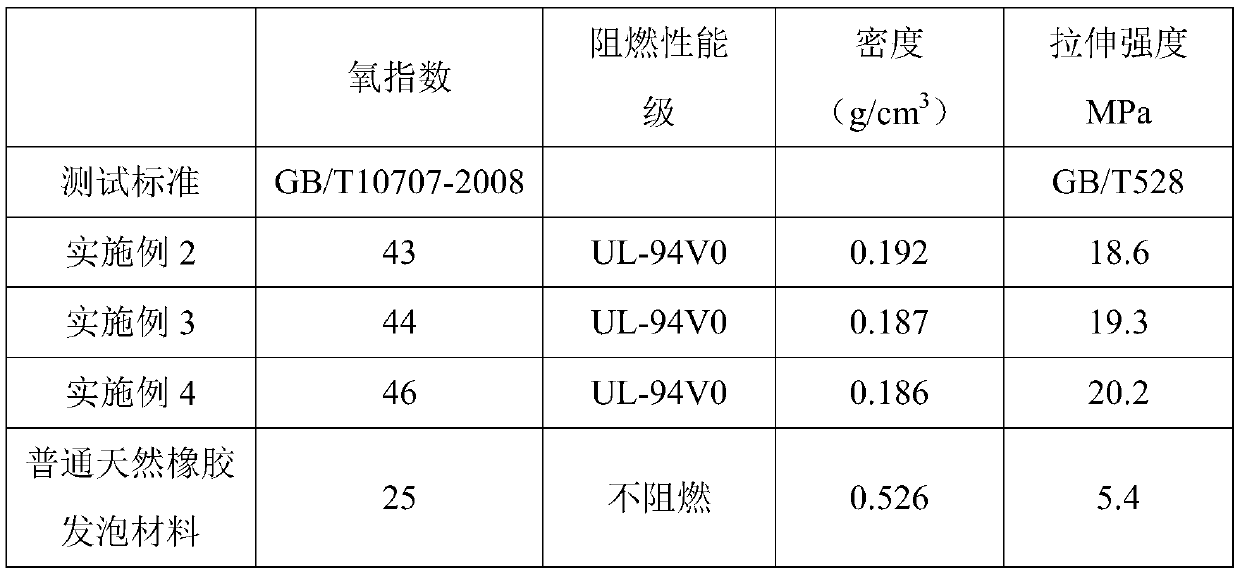

Examples

Embodiment 1

[0043] A kind of graphene rubber macromolecule flame-retardant composite foaming material, is made of the raw material that comprises following parts by weight:

[0044] 50-60 parts of natural rubber, 13-17 parts of butadiene rubber, 4-6 parts of EPDM rubber, 4-6 parts of white carbon black, 14-17 parts of flame retardant, 1.8-2.4 parts of graphene, nano-media 4~6 parts, 2~3 parts of zinc oxide, 2.5~4 parts of heat stabilizer, 2~2.4 parts of crosslinking agent, 3~4 parts of flow aid, 2~2.4 parts of foaming agent;

[0045] The flame retardant is a mixture of zinc diethylphosphinate and triphenyl phosphate.

[0046] In this embodiment, the graphene rubber polymer flame retardant composite foam material is made of raw materials comprising the following parts by weight:

[0047] 55 parts of natural rubber, 15 parts of butadiene rubber, 5 parts of EPDM rubber, 5 parts of white carbon black, 15 parts of flame retardant, 2 parts of graphene, 5 parts of nano medium, 2.5 parts of zinc...

Embodiment 2

[0062] A kind of graphene rubber macromolecule flame-retardant composite foaming material, is made of the raw material that comprises following parts by weight:

[0063] 50 parts of natural rubber, 17 parts of butadiene rubber, 6 parts of EPDM rubber, 4 parts of white carbon black, 14 parts of flame retardant, 1.8 parts of graphene, 4 parts of nano-media, 2 parts of zinc oxide, 2.5 parts of heat stabilizer 2 parts, 2 parts of crosslinking agent, 3 parts of flow aid, 2 parts of foaming agent;

[0064] The flame retardant is a mixture of zinc diethylphosphinate and triphenyl phosphate.

[0065] In this embodiment, the mass ratio of zinc diethylphosphinate and triphenyl phosphate in the mixture of zinc diethylphosphinate and triphenyl phosphate is 10:23.

[0066] In this embodiment, the graphene is reduced graphene oxide.

[0067] In this embodiment, the nano-medium is nano-calcium carbonate.

[0068] In the present embodiment, the thermal stabilizer is a mixture of zinc stear...

Embodiment 3

[0079] A kind of graphene rubber macromolecule flame-retardant composite foaming material, is made of the raw material that comprises following parts by weight:

[0080] 60 parts of natural rubber, 13 parts of butadiene rubber, 4 parts of EPDM rubber, 6 parts of white carbon black, 17 parts of flame retardant, 2.4 parts of graphene, 6 parts of nano-media, 3 parts of zinc oxide, and 4 parts of heat stabilizer Parts, 2.4 parts of crosslinking agent, 4 parts of flow aid, 2.4 parts of blowing agent;

[0081] The flame retardant is a mixture of zinc diethylphosphinate and triphenyl phosphate.

[0082] In this embodiment, the mass ratio of zinc diethylphosphinate and triphenyl phosphate in the mixture of zinc diethylphosphinate and triphenyl phosphate is 10:27.

[0083] In this embodiment, the graphene is reduced graphene oxide.

[0084] In this embodiment, the nano-medium is nano-calcium carbonate.

[0085] In the present embodiment, the thermal stabilizer is a mixture of zinc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com