High-performance thermoplastic elastomer for cable of charging pile and preparation method of high-performance thermoplastic elastomer

A thermoplastic elastomer and charging pile technology, applied in the field of polymer materials, can solve the problems of poor tear resistance and heat resistance, insufficient tear resistance, and difficult processing, and achieve improved tear resistance and excellent grip. The effect of wrapping force and reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

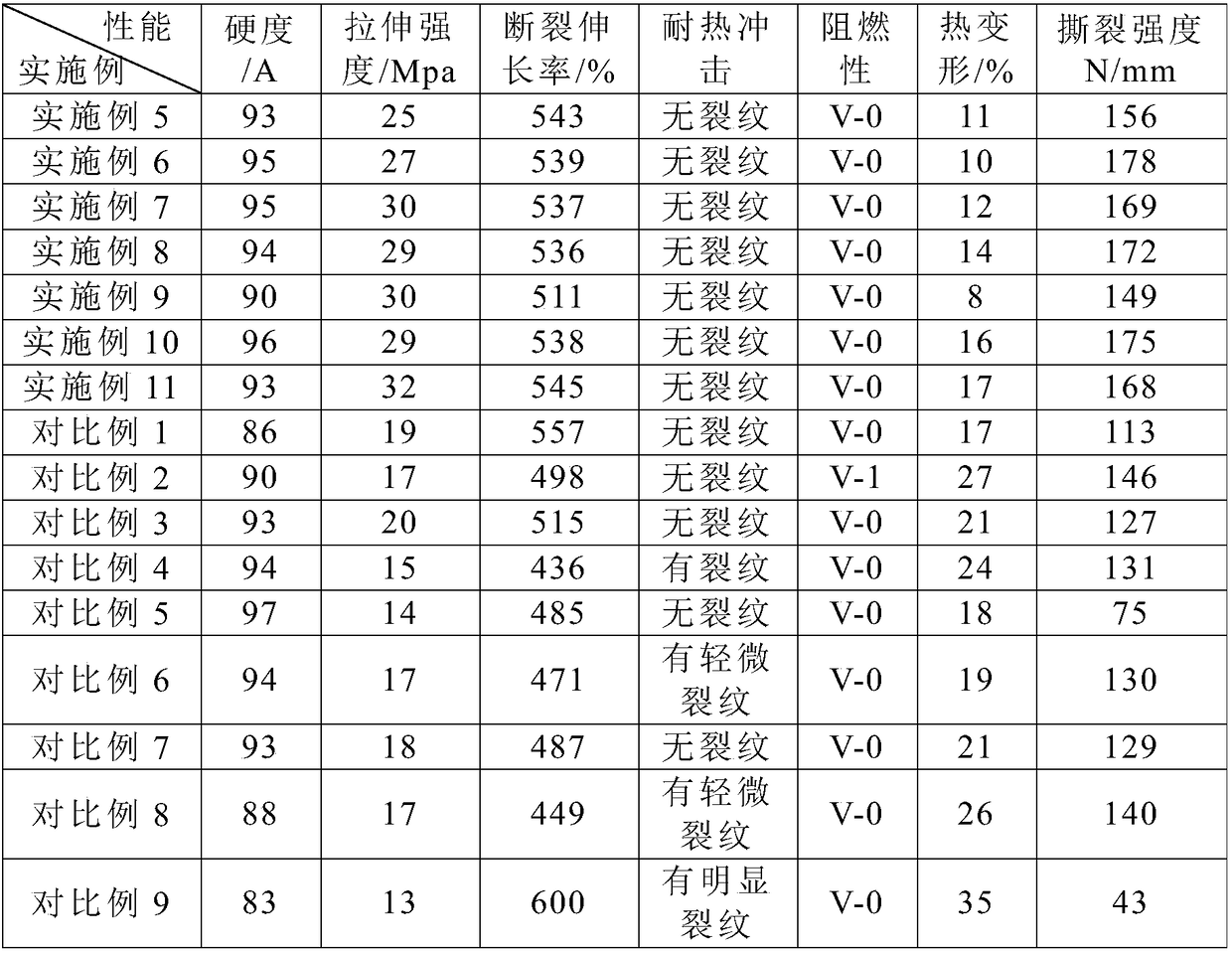

Examples

Embodiment 1

[0040] In this embodiment, the thermoplastic elastomer for the high-performance charging pile cable, the thermoplastic elastomer includes the following components in parts by weight:

[0041] 30 parts of styrenic elastomer,

[0042] 39 parts of polyoxymethylene,

[0043] Modified porous CaCO 3 18 copies,

[0044] Cellulose fiber 15 parts,

[0045] 26 parts of polyphosphazenes,

[0046] 7 parts of zirconium phosphate,

[0047] 2 parts silicone,

[0048] Oil resistance agent hydrogenated styrene block thermoplastic polyurethane copolymer 3 parts,

[0049] Softener industrial white oil 10 parts;

[0050] Styrene-based elastomers are block copolymers containing styrene structural units, the weight percent content of styrene is 15%, and the block copolymers are hydrogenated poly(styrene-b-isoprene) with a weight ratio of 1:2. ene) and hydrogenated poly(styrene-b-butadiene-b-styrene).

Embodiment 2

[0052] In this embodiment, the thermoplastic elastomer for the high-performance charging pile cable, the thermoplastic elastomer includes the following components in parts by weight:

[0053] 35 parts of styrenic elastomer,

[0054] 35 parts of polyoxymethylene,

[0055] Modified porous CaCO 3 22 copies,

[0056] Cellulose fiber 11 parts,

[0057] 22 parts of polyphosphazene,

[0058] 5 parts of zirconium phosphate,

[0059] 2 parts silicone,

[0060] 6 parts of oil resistant hydrogenated styrene block thermoplastic polyurethane copolymer,

[0061] Softener naphthenic oil 8 parts;

[0062] Styrene-based elastomers are block copolymers containing styrene structural units, the weight percent content of styrene is 18%, and the block copolymers are hydrogenated poly(styrene-b-isoamyl) with a weight ratio of 1:2 diene) and hydrogenated poly(styrene-b-butadiene-b-styrene).

Embodiment 3

[0064] In this embodiment, the thermoplastic elastomer for the high-performance charging pile cable, the thermoplastic elastomer includes the following components in parts by weight:

[0065] 35 parts of styrenic elastomer,

[0066] 35 parts of polyoxymethylene,

[0067] Modified porous CaCO 3 22 copies,

[0068] Cellulose fiber 11 parts,

[0069] 30 parts of polyphosphazene,

[0070] 9 parts of zirconium phosphate,

[0071] 3 parts silicone,

[0072] 6 parts of oil resistant hydrogenated styrene block thermoplastic polyurethane copolymer,

[0073] Softener industrial white oil 6 parts;

[0074] Styrene-based elastomers are block copolymers containing styrene structural units, the weight percent content of styrene is 18%, and the block copolymers are hydrogenated poly(styrene-b-isoprene) with a weight ratio of 2:3 ene-b-styrene) and hydrogenated poly(styrene-b-isoprene / butadiene-b-styrene).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com