B1-grade special high-flame-retardant low-smoke halogen-free cable material and preparation method thereof

A high flame retardant and cable material technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., to achieve the effects of enhancing interface interaction, improving strength, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

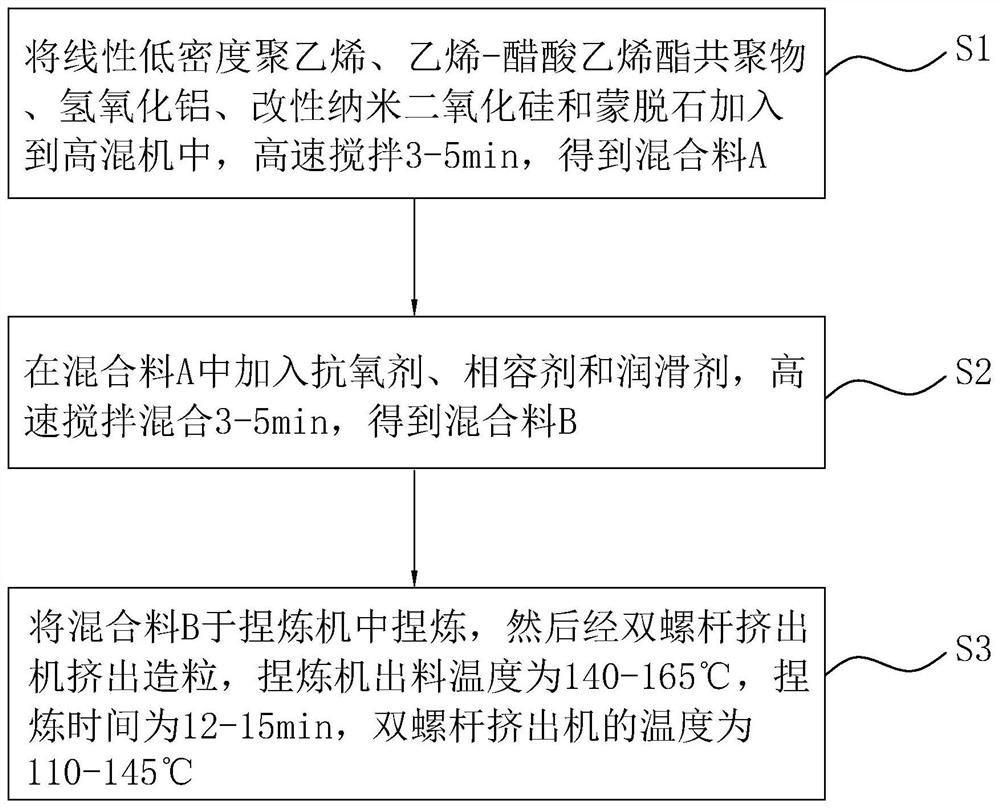

[0045] Example 1: A B1-grade special high flame-retardant low-smoke halogen-free cable material, the components and their corresponding parts by weight are shown in Table 1, as figure 1 , and obtained by the following steps:

[0046] S1, adding linear low density polyethylene, ethylene-vinyl acetate copolymer, aluminum hydroxide, modified nano-silica and montmorillonite into a high mixer, stirring at 600rpm for 5min to obtain a mixture A;

[0047] S2, adding antioxidant, compatibilizer and lubricant to mixture A, stirring at 600rpm for 5min to obtain mixture B;

[0048] S3, knead the compound B in a kneader, and then extrude and granulate through a twin-screw extruder. The output temperature of the kneader is 165°C, and the kneading time is 12min. 110°C, 120°C, 120°C, 120°C, 1350°C, 135°C, 135°C, 145°C, and the screw speed during extrusion is 200rpm.

[0049] In this example, the preparation method of modified nano-silica is as follows: add 10 parts of nano-silica with an av...

Embodiment 2-6

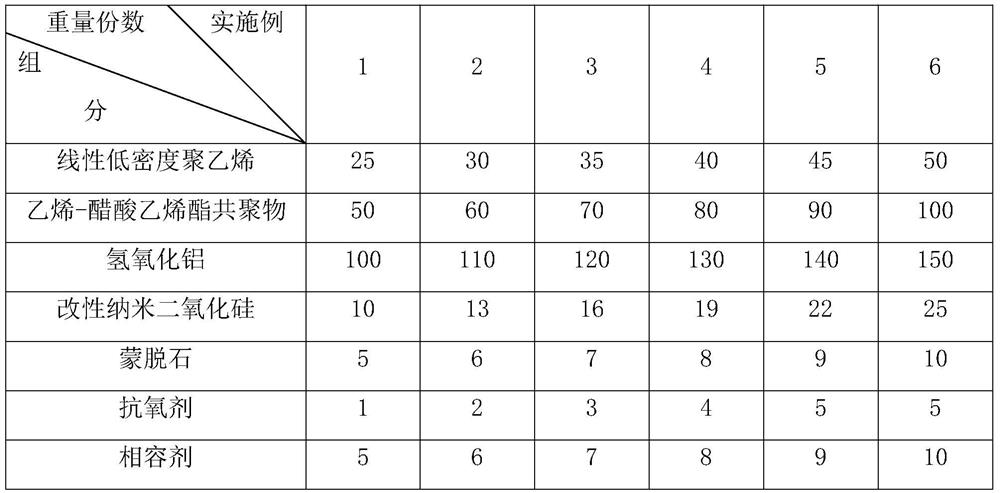

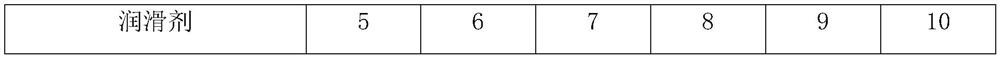

[0053] Example 2-6: A B1 grade dedicated high flame-retardant low-smoke halogen-free cable material. The difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0054] Each component and parts by weight thereof in table 1 embodiment 1-6

[0055]

[0056]

Embodiment 7

[0057] Example 7: A B1-grade special high flame-retardant low-smoke halogen-free cable material, which is different from Example 1 in that it is prepared through the following steps:

[0058] S1, adding linear low-density polyethylene, ethylene-vinyl acetate copolymer, aluminum hydroxide, modified nano-silica and montmorillonite into a high mixer, stirring at 800rpm for 3min, to obtain a mixture A;

[0059] S2, adding antioxidant, compatibilizer and lubricant to the mixture A, stirring at 800rpm for 3min to obtain the mixture B;

[0060] S3, knead the compound B in the kneader, and then extrude and granulate through the twin-screw extruder. 110°C, 120°C, 120°C, 120°C, 1350°C, 135°C, 135°C, 145°C, and the screw speed during extrusion is 200rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com