Anti-frost heaving structure of transition section of bridge and culvert structures in cold regions

A technology for cold areas and structures, applied to buildings, roads, roads, etc., can solve the problems of reduced frost heave performance, low service life, poor integrity, etc., to improve frost heave performance, increase service life, and reduce the amount of filler Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

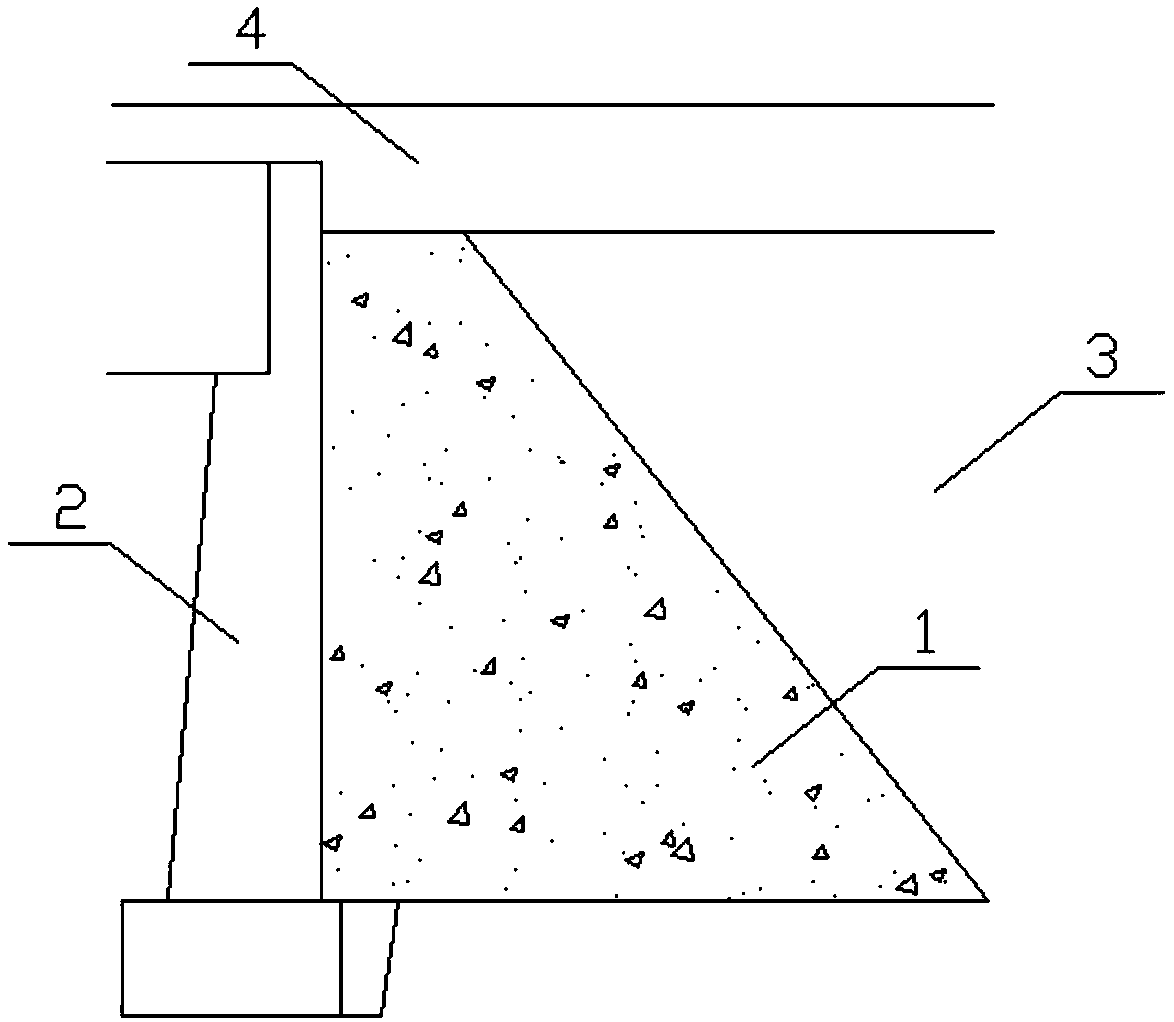

[0035] Such as figure 1 As shown, at the connection between the bridge and the subgrade, an antifreeze structural layer 1 is provided between the side wall 2 of the abutment and the subgrade filler 3. The height is in contact with the abutment side wall 2, the top of the antifreeze structure layer 1 is paved with road filler 4, and the outside of the hypotenuse of the antifreeze structure layer 1 is the roadbed filler 3.

[0036] The antifreeze structure layer adopts foam concrete filler layer, and thickener is added in the foam concrete.

[0037] In order to ensure the quality of on-site construction, a special thickener for cast-in-place foam concrete was specially developed (see Example 3-7 for details of the thickener), which made the on-site foam concrete have uniform pores and a one-time pouring height of more than 1m. The poured foam concrete has good thermal insulation performance, light weight and high strength, and good resistance to dynamic loads.

Embodiment 2

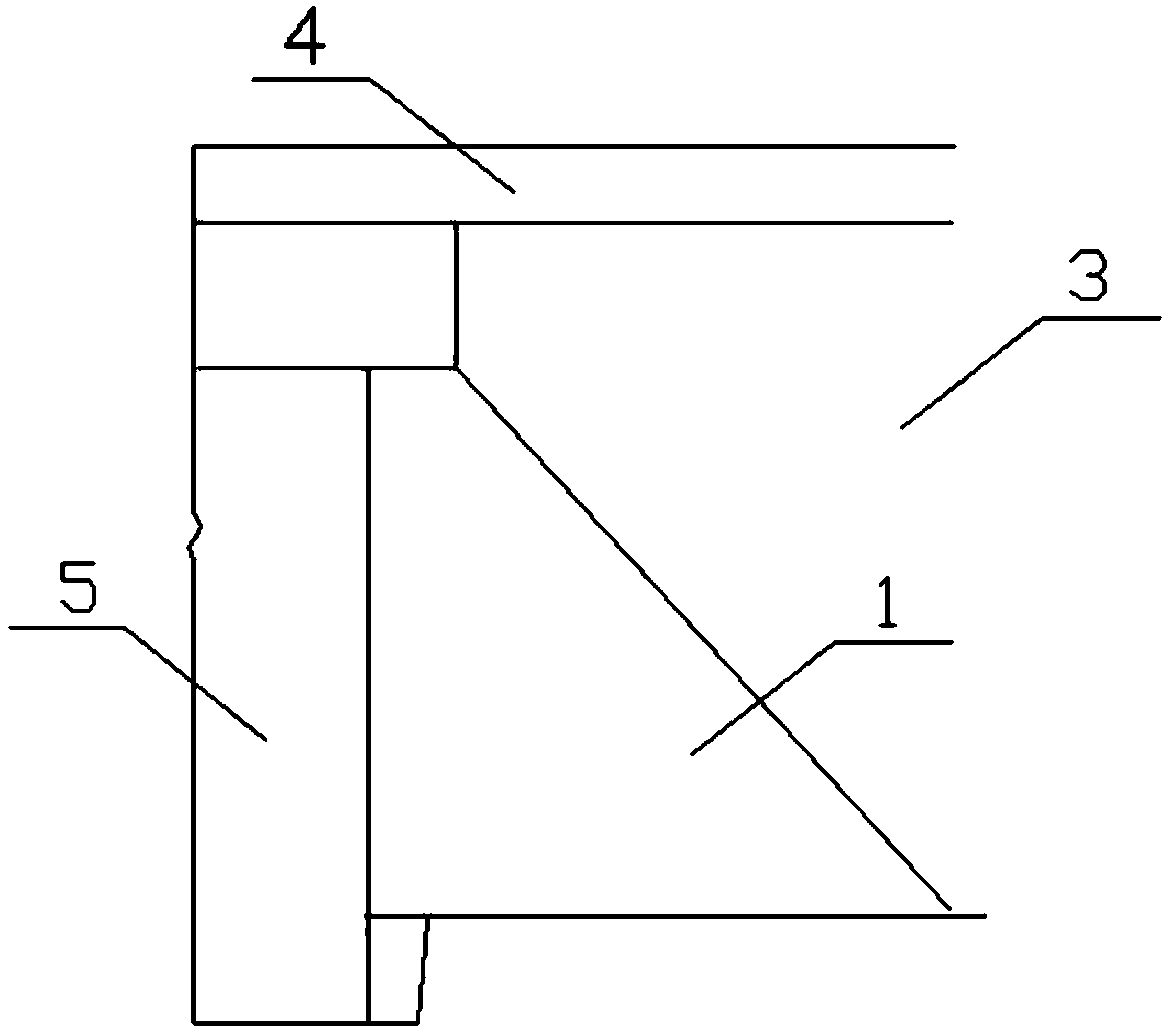

[0039] Such as figure 2 As shown, at the joint between the culvert and the roadbed, an antifreeze structure layer 1 is provided between the side wall of the culvert 5 and the roadbed filler 3, and the longitudinal section shape of the antifreeze structure layer 1 is a right-angled trapezoid with a narrow top and a wide bottom. The height is in contact with the side wall 5 of the culvert, the top of the antifreeze structure layer 1 is paved with road filler 4, and the outside of the hypotenuse of the antifreeze structure layer 1 is the subgrade filler 3.

[0040] It is worth mentioning that the antifreeze structural layer can also extend from the top towards the side of the horizontal building to cover the top of the horizontal building, which is also within the protection scope of the present application.

Embodiment 3

[0042] The formula of the thickener added in the foam concrete is: silica fume: 60 parts; bentonite: 70 parts; xanthan gum: 1 part. Pour into a container and stir until smooth. When the thickener is in use, the weight of the thickener accounts for 8% of the weight of the cement in the foam concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com