Lithium polymer battery and preparation method thereof

A lithium polymer battery and cell technology, applied in secondary batteries, battery components, circuits, etc., can solve problems such as aluminum-plastic film corrosion, potential safety hazards, battery inflation, etc., to improve tightness and prevent gaps Or poor contact, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

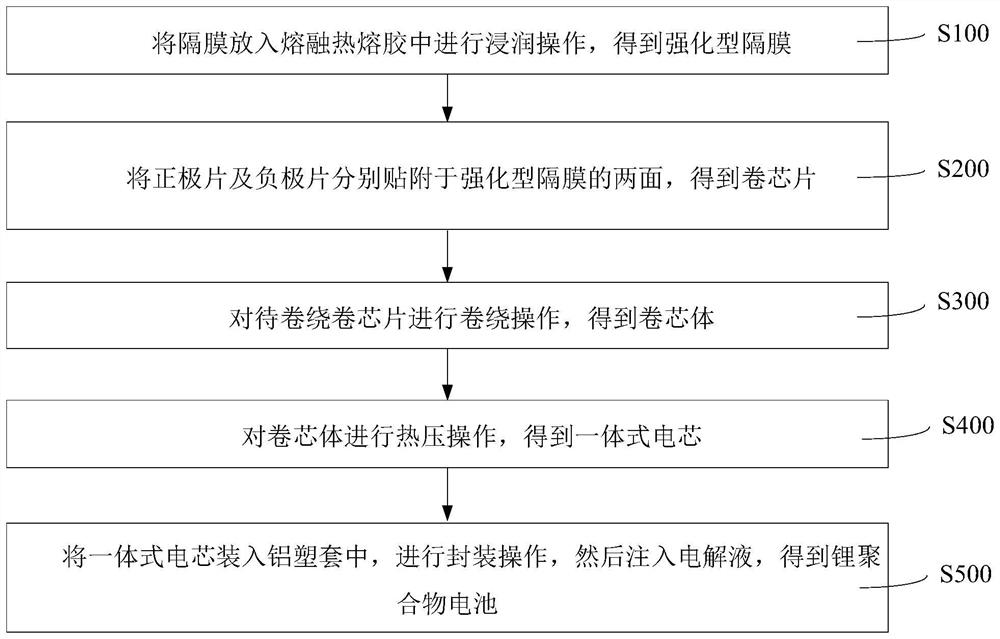

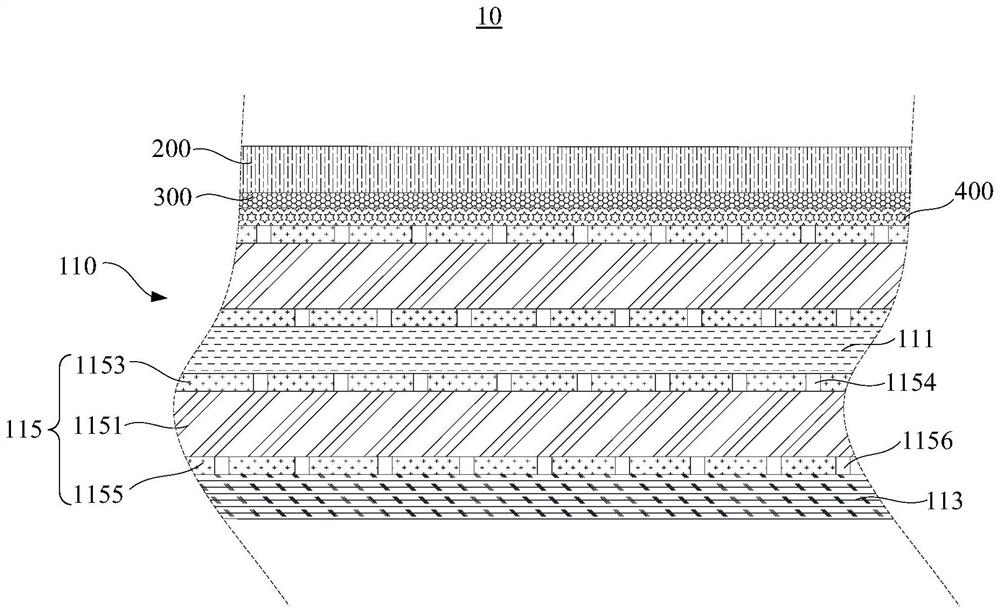

[0039] The present application provides a preparation method of a lithium polymer battery. The preparation method of the above-mentioned lithium polymer battery includes the following steps: putting the diaphragm into molten hot melt adhesive for infiltration operation to obtain a reinforced diaphragm; attaching the positive electrode sheet and the negative electrode sheet to both sides of the reinforced diaphragm respectively to obtain a roll chip; performing lug welding operation on the roll chip to obtain the roll chip to be wound; performing winding operation on the roll chip to obtain the roll core body; performing hot pressing operation on the roll core body to obtain An integrated battery cell; the integrated battery cell is put into an aluminum-plastic sleeve, injected with an electrolyte, and then packaged to obtain the lithium polymer battery.

[0040] In the preparation method of the above-mentioned lithium polymer battery, the separator is put into the molten hot m...

Embodiment 1

[0063] Put the hot melt adhesive in the molten state in the reactor, add 0.05 parts by mass of foaming agent, put the diaphragm into the molten hot melt adhesive for infiltration operation, and then take it out to obtain a reinforced diaphragm. The surface of the diaphragm is attached with a release film. While tearing off the release film, attach the prepared positive electrode sheet to one side of the reinforced separator, and attach the prepared negative electrode sheet to the side of the reinforced separator that is away from the positive electrode sheet to form a roll Winding roll chips. Then put the winding chip to be wound into the winding machine for winding operation, so that the separator, positive electrode sheet and negative electrode sheet are wound to form a single winding core; the winding core body is subjected to hot pressing operation to obtain an integrated battery core, in which the heat The pressing temperature is 100°C, and the hot pressing pressure is 0...

Embodiment 2

[0065] Put the molten hot melt adhesive in the reaction kettle, add 0.2 parts by mass of foaming agent, put the diaphragm into the molten hot melt adhesive for infiltration operation, and then take it out to obtain a reinforced diaphragm, and strengthen it The surface of the diaphragm is attached with a release film. While tearing off the release film, attach the prepared positive electrode sheet to one side of the reinforced separator, and attach the prepared negative electrode sheet to the side of the reinforced separator that is away from the positive electrode sheet to form a roll Winding roll chips. Then put the winding chip to be wound into the winding machine for winding operation, so that the separator, positive electrode sheet and negative electrode sheet are wound to form a single winding core; the winding core body is subjected to hot pressing operation to obtain an integrated battery core, in which the heat The pressing temperature is 150°C, and the hot pressing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com