Inorganic ceramic artificial board and preparation method thereof

A technology of ceramics and plates, which is applied in the field of inorganic ceramic man-made plates and its preparation, can solve the problems such as mechanical strength and other properties that are not as good as ceramic plates, and achieve the effects of improving mechanical properties, broad application prospects, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

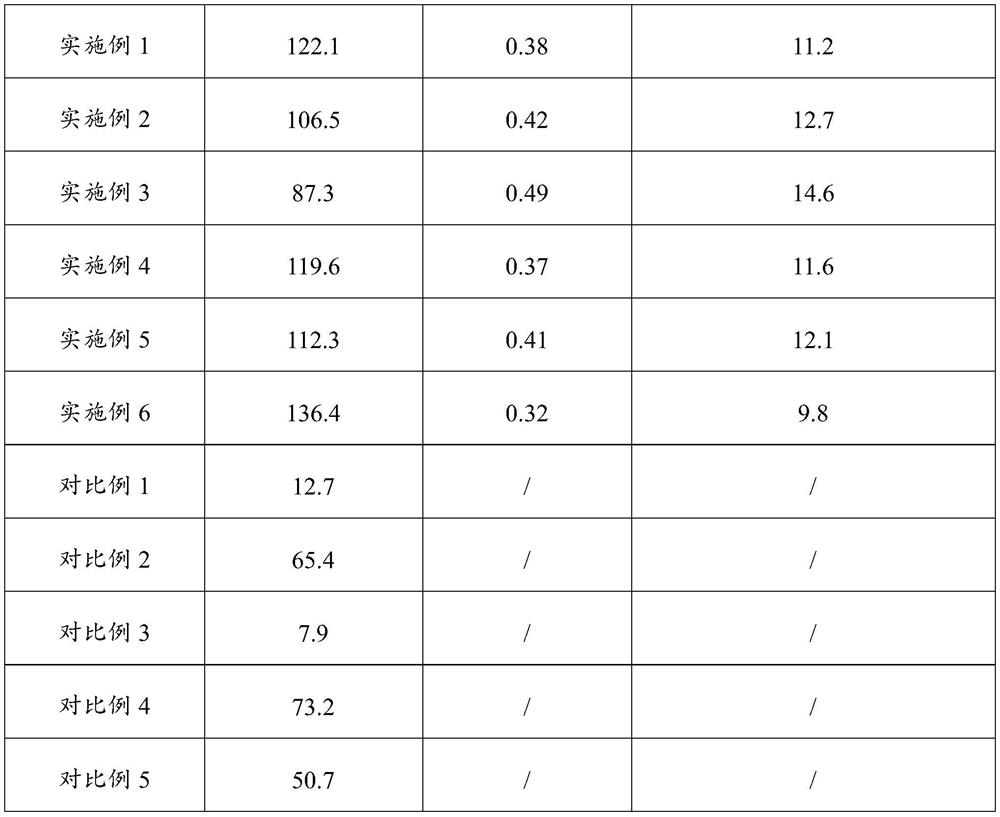

Embodiment 1

[0063] This embodiment provides a kind of inorganic ceramic man-made board, and its raw material composition is as follows:

[0064] Metakaolin 38kg, activator 4kg, water 7kg, inorganic curing agent 3kg, water reducer 0.3kg, azo pigment 5kg, silane coupling agent 0.3kg, quartz sand 76kg. Among them, the molar ratio of silicon to aluminum of metakaolin is 1:1, and the purity is 95%; the activator is 3 kg of sodium silicate with a modulus of 2.3, and 1 kg of sodium hydroxide; the inorganic curing agent is gypsum; the water reducing agent is polycarboxylic acid It is a water reducer.

[0065] The preparation method comprises the following steps:

[0066] Mix and stir the activator and water evenly in parts by mass, and cool for 12 hours to obtain a liquid activator;

[0067] Pour metakaolin and quartz sand into a mixing tank and stir to mix evenly, then add activator solution, water reducer, pigment, coupling agent and inorganic curing agent and stir to obtain a semi-dry-wet mi...

Embodiment 2

[0073] This embodiment provides a kind of inorganic ceramic man-made board, and its raw material composition is as follows:

[0074] Metakaolin 46kg, activator 8kg, water 12kg, inorganic curing agent 6kg, water reducing agent 0.5kg, azo pigment 10kg, silane coupling agent 0.8kg, quartz sand 92kg. Among them, the molar ratio of silicon to aluminum of metakaolin is 1:1, and the purity is 95%; the activator is 6 kg of sodium silicate with a modulus of 2.3, and 2 kg of sodium hydroxide; the inorganic curing agent is gypsum; the water reducing agent is polycarboxylic acid It is a water reducer.

[0075] The preparation method comprises the following steps:

[0076] Mix and stir the activator and water evenly in parts by mass, and cool for 12 hours to obtain a liquid activator;

[0077] Pour metakaolin and quartz sand into a mixing tank and stir to mix evenly, then add activator solution, water reducer, pigment, coupling agent and inorganic curing agent and stir to obtain a semi-d...

Embodiment 3

[0083] This embodiment provides a kind of inorganic ceramic man-made board, and its raw material composition is as follows:

[0084] Metakaolin 32kg, activator 2kg, water 4kg, inorganic curing agent 1kg, water reducing agent 0.1kg, quartz sand 48kg. Among them, the molar ratio of silicon to aluminum of metakaolin is 1:1, and the purity is 95%; the activator is 1.5 kg of sodium silicate with a modulus of 2.3, and 0.5 kg of sodium hydroxide; Carboxylic acid water reducer.

[0085] The preparation method comprises the following steps:

[0086] Mix and stir the activator and water evenly in parts by mass, and cool for 12 hours to obtain a liquid activator;

[0087] Pour metakaolin and quartz sand into a mixing tank, stir and mix evenly, then add activator solution, water reducer and inorganic curing agent and stir to obtain a semi-dry-wet mixture, and stir the semi-dry-wet mixture for 8 minutes;

[0088] Place the semi-dry and wet mixture mixed in the above steps in the steel m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com