Graphene natural rubber oil-resistant mixed foaming material and preparation method thereof

A technology of natural rubber and foaming materials, applied in the field of rubber products, can solve the problems of poor comprehensive performance such as wear resistance, high compression set rate, and small elongation at break, etc., to improve quality stability, durability Good grinding performance and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

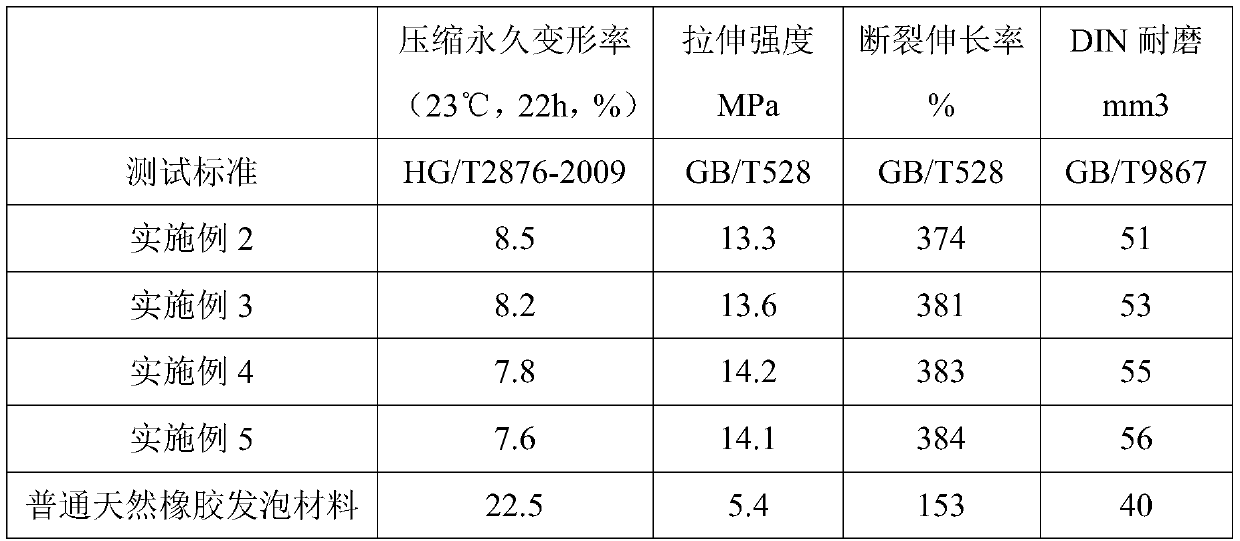

Examples

Embodiment 1

[0036]A graphene natural rubber oil-resistant mixed foaming material, made of the following raw materials in parts by weight: 36-44 parts of natural rubber, 28-33 parts of nitrile rubber, 8.5-11.5 parts of butadiene rubber, and 14 parts of polyvinyl chloride resin ~16 parts, 4~6 parts of white carbon black, 1.2~1.5 parts of silicone oil, 1.7~2.1 parts of zinc oxide, 1.4~1.8 parts of zinc stearate, 1.3~1.6 parts of stearic acid, 2.3~2.9 parts of crosslinking agent 2.5-3.5 parts of graphene, 1.9-2.5 parts of foaming agent, 1.8-2.4 parts of flow aid; the cross-linking agent is sulfur, 1,1-di-tert-butyl peroxy-3,3,5 - a mixture of trimethylcyclohexane and N,N'-p-phenylbismaleimide; the graphene is edge graphene oxide.

[0037] Preferably, the graphene natural rubber oil-resistant mixed foaming material is made of raw materials comprising the following parts by weight: 42 parts of natural rubber, 31.5 parts of nitrile rubber, 10.8 parts of butadiene rubber, 15.4 parts of polyvinyl ...

Embodiment 2

[0051] A graphene natural rubber oil-resistant mixed foaming material, made of raw materials comprising the following parts by weight: 36 parts of natural rubber, 28 parts of nitrile rubber, 8.5 parts of butadiene rubber, 14 parts of polyvinyl chloride resin, 4 parts of white carbon black 1.2 parts of silicone oil, 1.7 parts of zinc oxide, 1.4 parts of zinc stearate, 1.3 parts of stearic acid, 2.3 parts of crosslinking agent, 2.5 parts of graphene, 1.9 parts of foaming agent, 1.8 parts of flow aid; The crosslinking agent is a mixture of sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and N,N'-p-phenylbismaleimide; The graphene is edge graphene oxide.

[0052] In this example, the sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and N,N'-p-phenylbismaleimide The mass ratio of sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and N,N'-p-phenylbismaleimide in the mixture is 10: 19:6.

[0053] In this embodiment, the relative content of sulfonic ac...

Embodiment 3

[0064] A graphene natural rubber oil-resistant mixed foaming material, made of raw materials comprising the following parts by weight: 44 parts of natural rubber, 33 parts of nitrile rubber, 11.5 parts of butadiene rubber, 16 parts of polyvinyl chloride resin, 6 parts of white carbon black 1.5 parts of silicone oil, 2.1 parts of zinc oxide, 1.8 parts of zinc stearate, 1.6 parts of stearic acid, 2.9 parts of crosslinking agent, 3.5 parts of graphene, 2.5 parts of foaming agent, 2.4 parts of flow aid; The crosslinking agent is a mixture of sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and N,N'-p-phenylbismaleimide; The graphene is edge graphene oxide.

[0065] In this example, the sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and N,N'-p-phenylbismaleimide The mass ratio of sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and N,N'-p-phenylbismaleimide in the mixture is 10: 22:7.

[0066] In this embodiment, the relative content of sulfonic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com