Preparation method and application of silica sol for chemical polishing

A technology of chemical polishing and silica sol, which is applied in the direction of chemical instruments and methods, inorganic chemistry, polishing compositions containing abrasives, etc., can solve the problems of low polishing removal rate, low hardness of silica sol, poor polishing effect, etc., to achieve Cost savings and labor training costs, high polishing rate, and increased surface activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

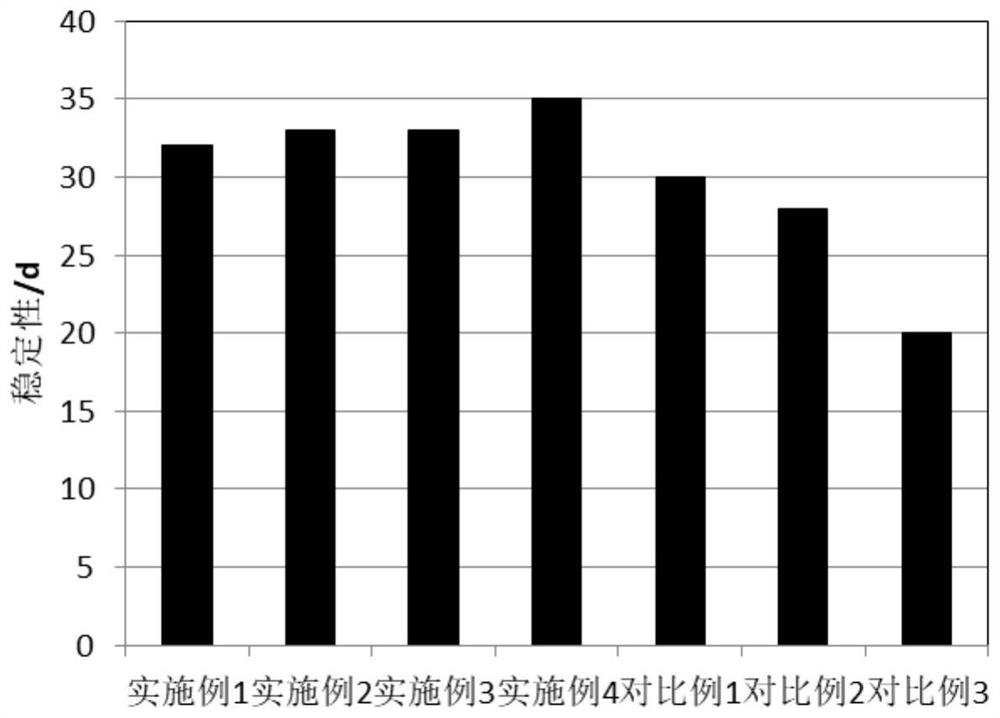

Examples

Embodiment 1

[0031] A preparation method of silica sol for chemical polishing, comprising the following steps:

[0032] (1) Put the silicon powder in a container, add water 3 times the weight of the silicon powder, add alkali with 0.5% weight of the silicon powder, heat up to 60° C. and soak for 100 minutes to obtain a pre-reacted silica sol;

[0033] (2) passing through cation and anion exchange resin columns after diluting the water glass solution to remove metal ions and miscellaneous ions to obtain an active silicic acid solution whose mass concentration is 2-5%;

[0034] (3) Add the pre-reacted silica sol to the active silicic acid solution to increase the particle size, add a modifier at the same time, continue to stir, and adjust the pH to 9-11 at the same time. The reaction time is 1 hour, and the final product silica sol is obtained after concentration.

[0035] The alkali described in step (1) is sodium hydroxide.

[0036] In step (2), the cation and anion exchange resin columns...

Embodiment 2

[0043] A preparation method of silica sol for chemical polishing, comprising the following steps:

[0044] (1) Put the silicon powder in a container, add water 5 times the weight of the silicon powder, add alkali with 1.0% weight of the silicon powder, heat up to 90° C. and soak for 120 minutes to obtain a pre-reacted silica sol;

[0045] (2) after diluting the water glass solution, pass through the cation and anion exchange resin columns to remove metal ions and heteroions to obtain an active silicic acid solution whose mass concentration is 2-5%;

[0046] (3) Add the pre-reacted silica sol to the active silicic acid solution to increase the particle size, add a modifier at the same time, continue to stir, and adjust the pH to 9-11 at the same time. The reaction time is 2 hours, and the final product silica sol is obtained after concentration.

[0047] The alkali described in step (1) is potassium hydroxide.

[0048] In step (2), the cation and anion exchange resin columns a...

Embodiment 3

[0055]A preparation method of silica sol for chemical polishing, comprising the following steps:

[0056] (1) Put the silicon powder in a container, add water 5 times the weight of the silicon powder, add alkali with 1.1% weight of the silicon powder, heat up to 110° C. and soak for 120 minutes to obtain a pre-reacted silica sol;

[0057] (2) after diluting the water glass solution, pass through the cation and anion exchange resin columns to remove metal ions and heteroions to obtain an active silicic acid solution whose mass concentration is 2-5%;

[0058] (3) Add the pre-reacted silica sol to the active silicic acid solution to increase the particle size, add a modifier at the same time, continue to stir, and adjust the pH to 9-11 at the same time. The reaction time is 3 hours, and the final product silica sol is obtained after concentration.

[0059] The alkali described in step (1) is sodium hydroxide.

[0060] In step (2), the cation and anion exchange resin columns are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com